Category: KAMAZ

- Description of the boxes used

- Principle of operation

- Start

- Gear shift diagram

- Box KamAZ 15

- Box KamAZ 16 and ZF

- Management Tips

- Hill climb control

- Descent Control

- Driving on an icy road

- Is it possible to drive a KamAZ without urea?

At first glance, driving a KamAZ is similar to driving a car. The principle of operation is the same as on classic transport, however, some features cause complications for the uninitiated user.

You get a complete understanding of how to properly drive and drive a KamAZ by understanding the specifics of gear shifting. The fact is that for every heavy car you need to find an approach to the issue of manipulating the gearbox, and KamAZ is no exception. In order to achieve the required speed limit when transporting cargo, the KamAZ transmission is often operated in a low gear. The acquired skills, knowledge and experience in working with the gearbox are the key to the success of further operation of the vehicle.

KamAZ-6520, dump truck:

Description of the boxes used

The gear shift pattern directly depends on the type of transmission installed on the KamAZ vehicle. Most of the machines used use a box with five forward speeds and one reverse; this is a model with index 14. The mechanism is relevant if there is no need to tow a trailer, or the cargo being transported weighs less than 10 tons.

KamAZ-14 gearbox:

Equipment used for transporting large loads, or participating in road trains, uses a transmission marked 15. In this case, you need to know how to drive a KamAZ dump truck, since the gearbox includes a gearbox. This is the same 14 transmission with five forward and one reverse gears. The divider, if necessary, includes lower speed ranges, as a result, the car has twice as many gears.

KamAZ-ZF gearbox:

The gearbox used is index 16, with eight mechanical speeds. A four-stage gearbox and a low gear are provided. ZF gearboxes are also installed, which are equipped with nine gears and an auxiliary reduction stage.

Regardless of the transmission model, the gearbox is of a mechanical type, control is carried out using the clutch pedal. The switching takes place in stages, taking into account the lower and higher modes. The lever on the rocker handle is responsible for switching modes. When creating, it was taken into account that KamAZ is a heavy vehicle, which when loaded requires a reduction in force. Conversely, if you drive with an empty body, this will not lead to overheating and fuel consumption.

Operation of KamAZ 65115 vehicles

The service brake system serves to reduce the speed of the vehicle and stop it completely; the drive is controlled by a pedal.

Engage the parking brake system when the vehicle is parked by placing the handle of the parking and emergency brake control valve (see Fig. Cabin) in a vertical fixed position. At the same time, the brake mechanisms of the rear wheels of the car and trailer are activated.

To disengage the parking brake system, place the handle in a horizontal fixed position. When engaging the parking brake system, move the handle all the way down, otherwise you will “burn out” the brake system on the trailer.

The spare brake system is designed to stop the vehicle in the event of failure of the service brake system. Operate the emergency brake system by gradually moving the parking brake handle. When the handle is moved up a third of its full stroke, only the trailer braking system operates. By using this method of braking on a slippery road, you can avoid “folding” the road train, since the road train is “stretched” in this case. As you move the handle further up, the vehicle's braking system is activated and the braking intensity increases: the closer to the vertical, the stronger the braking.

Activate the auxiliary brake system by pressing the auxiliary brake system button (see Fig. Cabin). Use the auxiliary brake system in all cases to reduce speed and always when driving on long descents to avoid overheating of the brakes. If necessary, to reduce the engine crankshaft speed, slow down the road train with the service brake system.

When the auxiliary brake system is engaged, do not disengage the clutch or change gears.

Mechanical release of the parking brake system.

If there is no air in the parking brake system receivers, the spring energy accumulators of the brake chambers of the rear bogie are activated, and the vehicle is braked. If it is impossible to fill the receivers with compressed air, the car can be released mechanically. To do this, remove the covers from the energy accumulators of the brake chambers of the rear and intermediate axles and turn out the mechanical release screws until they stop (approximately 30 turns) (see Fig. Mechanical release of the parking brake system.). After troubleshooting the pneumatic drive of the brake system, screw in the screws.

Attention! If there is not enough air pressure in the pneumatic drive of the brake system, then after the mechanical release of the parking brake system, the car does not have any braking systems. Therefore, make sure that the car does not move spontaneously after releasing the brake.

Principle of operation

KamAZ vehicles are usually equipped with manual transmissions. The mechanism is controlled in the classic way, by pressing the clutch pedal and moving the rocker to the required position. A special feature of the transmission is low (H) and high (B) operating modes. This ability minimizes the load on the power unit. It is typical that for this purpose a divider is used, which acts as a gearbox that increases transmission ratios. On some cars, when changing from a higher gear to a lower gear, they do not use the rocker. For these purposes, a special switch and clutch pedal are used. The gear switches automatically, the upper position of the lever is typical for a loaded vehicle, the lower position is used when moving an empty vehicle. The features of driving a car are indicated in the instructions for the gearbox that comes with the product. You can also read about How to adjust the clutch on a KamAZ.

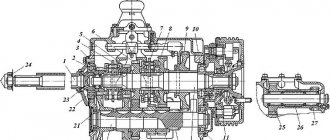

Design and principle of operation

Let's consider the location and design of the KamAZ vehicle gearbox. KamAZ trucks are equipped with manual transmissions. They have 5 speeds. The gearbox is switched by pressing the clutch pedals and moving the gearshift lever to the desired position. Since the car is heavy, it is necessary to transfer the gearbox from one gear to another in several stages.

The principle of operation of the KamAZ gearbox is as follows: with a diesel engine it works either in high mode B or in low mode H. They were created to reduce the load on the engine of a heavy vehicle when it is full, and at the same time not force it to work too actively without load.

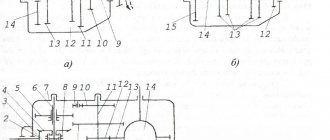

The design of a KamAZ gearbox with a divider is simple, but it differs depending on the model of the gearbox. Let's look at the KamAZ gearbox diagram, which is found on diesel vehicles. When driving on a flat road, you need to change gears without a clutch. The design of the KamAZ transfer case can be represented by the following formula: 1B - 2B - 3B - 4H - 4B - 5H - 5B.

Switching speeds is carried out as follows:

- First, switch the gearbox operating mode from high to low using a lever.

- Then release the clutch.

- The lever is set to the desired gear, without jumping over them, but turning everything on in order.

There are gearboxes with automatic mode switching.

How does the divider work on KamAZ?

The gearbox divider or multiplier is an additionally installed overdrive, which converts a 5-speed gearbox into a 10-speed gearbox.

The principle of its operation is as follows. The multiplier reduces the ranges between the main gears, tightening the number of gear ratios of the box and expanding them by 20-25 percent.

This modification allows you to improve such vehicle characteristics as:

- fuel efficiency;

- acceleration speed;

- traction force;

- controllability.

The mechanism is located in front of the gearbox, or slightly to the right of it, since the main unit does not experience heavy loads and does not require structural modifications. This allows you to repair and adjust the divider yourself if a malfunction occurs.

Location and order of gear shifting on KamAZ

Most cars from the Kama plant are equipped with manual gearboxes with 5 steps (with or without a divider). Gear shifting is carried out by moving the gearbox rocker with the clutch pedal pressed. But gears on trucks should not be engaged directly, but in stages. Theoretically, this reduces the load on the engine when driving with a full load, and when working with an empty body, it saves fuel.

The usual operating modes of the KamAZ gearbox are increased “B” or decreased “H”. In cars equipped with a gearbox with a multiplier, switching from mode “B” to mode “H” is carried out by lowering a special single divider lever.

It is important to know how to engage a higher gear when driving a KamAZ with a full load: experienced drivers recommend engaging the first 4 gears in the heavy secondary “H” mode, and then transferring the 4th speed to the “B” mode, switching to the 5th lower gear, and then go to “B”. The shift order may vary depending on the specific gearbox model.

Start

To know how to properly drive a KamAZ dump truck, you need to understand the gear shift pattern. As in the standard version, manipulations take place using the clutch pedal.

Switching stages:

- 1st gear, high mode (B);

- 2nd gear, high mode (B);

- 3rd gear, high mode (B);

- Transition to the 2nd low (H) stage and switch to 4th gear;

- Transition to the primary stage (B), the gear remains in 4th;

- Shift to a lower gear (H), engage 5th gear;

- Return to the higher gear (B), stay in 5th gear.

KamAZ:

The main feature of starting to move on a KamAZ is a smooth start and acceleration using lower gears. In the case when the dump truck is heavily loaded, or the traffic is in difficult conditions, it is advisable to switch the first 4 gears in low mode (H), then switch to 4th high gear, then lower 5th gear (H) and then to 5th -th increased (B). Manipulations are carried out when the required crankshaft speed is reached. Directly at the start in 1st gear, the shaft speed reaches 7000 min-1, the transition to 2nd gear is made when the speed reaches 3000 min-1. The correctly selected mode saves fuel and minimally wears out the power plant.

Gearbox in KamAZ 5490

KamAZ models of the 5490 series are famous for their reliability, simplicity and unpretentiousness. It’s not for nothing that people call this car a “Kamazomersedes”. And the whole point is not only in the above qualities, but also in the convenience of KamAZ. This machine could not have gained such enormous popularity if it had not had such a huge “sweep” among the customer base - KamAZ trucks of this series can have both automatic and manual gearboxes. Namely, there is a gearbox installed here from an upgradeable one - the driver has the opportunity to additionally install an intarder (a transmission retarder for trucks, also developed).

How many stages are there in the gearbox?

One of the main features of the gearbox on this KamAZ is the presence of a huge number of steps. Thus, on the first version of the automatic transmission, a maximum of 12 gears are available, and there is also automatic control (manual transmission “ZF 12AS21300 TD”). The gears have the following gear ratios:

| 1 | 2 | 3 | 4 | 5 | 6 | 3x |

| 15.86 | 9.57 | 5.87 | 3.47 | 2.1 | 1.29 | 14.68 |

| 12.33 | 7.44 | 4.57 | 2.7 | 1.63 | 1 | 11.41 |

The second version of the manual transmission is 16-speed (manual transmission “ZF 16S2220 TD”). However, the driver will have to manually change between gears. The gears have the following gear ratios:

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 16.41 | 11.28 | 7.76 | 5.43 | 3.59 | 2.47 | 1.7 | 1.19 |

| 13.8 | 9.49 | 6.53 | 4.57 | 3.02 | 2.08 | 1.4 | 1 |

On which side is the gearbox located and where?

Another important question is where and on which side is the checkpoint located on KamAZ 5490? Since we live in Russia, we have right-hand drive and, accordingly, cars are made for Russian roads with such traffic. This means that the gearbox on a relatively new KamAZ is located on the driver’s right hand next to his seat.

What is the maximum speed the car can reach?

Definitely every driver (especially truckers) will be interested in information about the maximum speed to which they can accelerate the KamAZ 5490. It is worth noting that this is a fairly fast machine, the maximum speed of which is at least 110 kilometers per hour, which is quite fast for trucks .

Box KamAZ 15

This transmission is installed on KamAZ-55111, KamAZ-43118 and other models. To accelerate the car to the required speed, the following scheme is used: 1B-2B-3B-4N-4B-5N-5B. This scheme allows the box to operate normally, provided that the rules for operating the mechanism are followed:

- Using a special switch lever, change the operating mode of the box from high to low and vice versa;

- Press the clutch pedal;

- We change gears in order using the rocker.

KamAZ switching diagram:

What is the structure of the checkpoint

Basically, two types of gearboxes are installed on KamAZ: 5-speed (model 14) and 10-speed (model 15). The first type is installed on single Kamaz vehicles, and the second type box is more suitable for use in road trains. In addition, the 10-speed consists of a regular 5-speed. Plus, equipped with a reducer-divider. The structure of the divider gearbox allows (of course, in combination with a 5-speed gearbox) to control ten forward gears and two reverse gears.

Advantages of boxes equipped with a divider:

Mechanical gearbox

- Switching frequency decreases.

- Increasing vehicle traction.

- Easier control.

For Kamaz vehicles with heavy load capacity, the previous boxes were modernized. And a new model of gearbox 152 was released. How is it different?

- Synchronizers have been strengthened.

- New gear mounts were used.

- 4 degrees were introduced into the system to thin the teeth. This allows you to avoid “knocking out” fourth and fifth gears.

- The splines are reinforced.

- Improved divider control circuit.

- The spline mount has been removed.

- The height of the teeth has been increased.

In the new model, the divider is controlled by a pneumatic system. Only a professional and a service station employee can service such a system. Since this procedure requires certain skills and knowledge.

Box KamAZ 16 and ZF

This type of transmission is used on KamAZ-65115 vehicles, as well as all-wheel drive KamAZ-43150 KamAZ-4310 and others. The peculiarity of the mechanism is the automatic switching of high and low modes. This means that when shifting from gear 4 to gear 5, the upshift mode is automatically activated. Conversely, shifting from gear 5 to gear 4 automatically activates the reduced mode. The switch is indicated by an indicator on the instrument panel.

Switching diagram ZF 9S109:

Some models of ZF gearboxes, for example, 9S109, with auxiliary gear “C”. The mode is designed for movement and maneuver in difficult conditions (snow, ice, mud).

Gearbox in KamAZ 5490

KamAZ models of the 5490 series are famous for their reliability, simplicity and unpretentiousness. It’s not for nothing that people call this car a “Kamazomersedes”. And the whole point is not only in the above qualities, but also in the convenience of KamAZ. This machine could not have gained such enormous popularity if it had not had such a huge “sweep” among the customer base - KamAZ trucks of this series can have both automatic and manual gearboxes. Namely, there is a gearbox installed here from an upgradeable one - the driver has the opportunity to additionally install an intarder (a transmission retarder for trucks, also developed). How many stages are there in the gearbox? One of the main features of the gearbox on this KamAZ is the presence of a huge number of steps. Thus, on the first version of the automatic transmission, a maximum of 12 gears are available, and there is also automatic control (manual transmission “ZF 12AS21300 TD”). The gears have the following gear ratios:

| 1 | 2 | 3 | 4 | 5 | 6 | 3x |

| 15.86 | 9.57 | 5.87 | 3.47 | 2.1 | 1.29 | 14.68 |

| 12.33 | 7.44 | 4.57 | 2.7 | 1.63 | 1 | 11.41 |

The second version of the manual transmission is 16-speed (manual transmission “ZF 16S2220 TD”). However, the driver will have to manually change between gears. The gears have the following gear ratios:

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 16.41 | 11.28 | 7.76 | 5.43 | 3.59 | 2.47 | 1.7 | 1.19 |

| 13.8 | 9.49 | 6.53 | 4.57 | 3.02 | 2.08 | 1.4 | 1 |

On which side is the gearbox located and where?

Another important question is where and on which side is the checkpoint located on KamAZ 5490? Since we live in Russia, we have right-hand drive and, accordingly, cars are made for Russian roads with such traffic. This means that the gearbox on a relatively new KamAZ is located on the driver’s right hand next to his seat.

What is the maximum speed the car can reach?

Definitely every driver (especially truckers) will be interested in information about the maximum speed to which they can accelerate the KamAZ 5490. It is worth noting that this is a fairly fast machine, the maximum speed of which is at least 110 kilometers per hour, which is quite fast for trucks .

Hill climb control

Driving up a slope is accompanied by the gearbox switching to a lower mode (H). This makes the transmission work harder and overcome obstacles more easily.

- When lifting heavy equipment, shifting from first to second gear is carried out using the double clutch method;

- To ensure the operation of the power plant, depress the gas pedal to prevent an interruption in the fuel supply;

- The crankshaft speed readings do not fall below 2000 min-1, otherwise the power plant will overheat and stop working.

Descent Control

When driving a KamAZ vehicle on a descent, please note that under no circumstances should you turn off the engine. Drivers use this method to save fuel. However, acting in this way, the amplifier stops working, which blocks the steering. This phenomenon will lead to an emergency situation, the consequences of which are unpredictable.

Problems also arise with brakes, since heavy equipment is equipped with an auxiliary system. Activating the latter eliminates the ability to use the clutch pedal and switch from one mode to another.

Driving on an icy road

A special feature of driving on icy routes is the use of chains on the wheels of the car. The measures will increase the coefficient of road adhesion.

Take into account:

- Keep your distance, leave room for maneuver;

- When braking, use the brake assist system;

- Remember, emergency braking on a KamAZ truck leads to blocking of the trailer wheels.

It is not advisable to use emergency braking, as this will lead to skidding and uncontrolled movement. When skidding, keep your foot on the clutch pedal and turn the steering wheel in the direction of the skid, this will level the car.

Rules for shifting gearboxes in different conditions

Knowing how to start and how to continue moving is not enough for the correct operation of the KAMAZ transmission. To avoid problems with the unit when using the gearbox, you must follow the rules. Errors made during operation can lead to serious malfunctions.

On the rise

How to change gears on a KamAZ when driving uphill

Driving a domestic truck when lifting must be done at increased speed. To switch from first to second speed, the driver needs to depress the clutch twice. Consider the fact that you must simultaneously press the gas pedal and the fuel pedal. These actions are important as they help stabilize the overall performance of the crankshaft. To avoid problems with the operation of the unit, you do not need to reduce the engine speed to less than two thousand when climbing. This will cause the car engine to turn off. Also, such driving increases the operating temperature of the power unit, and this can cause its breakdown.

When driving a car using this principle, you can achieve maximum directional stability. Thanks to the principle of dividing the transmission circuit into two modes, easier engine operation is achieved. Moreover, regardless of whether the car is loaded or not.

On the descent

If you are driving downhill, you do not need to turn off the engine. When the engine is turned off, the steering wheel will lock. And this will lead to an emergency on the road. When driving downhill, do not turn off the auxiliary braking, and also depress the clutch pedal all the way. Newer versions of trucks use improved transmissions, which has allowed engineers to reduce the load on the main gearbox parts. Therefore, when driving in critical conditions and on descents, the car’s engine will not wear out.

KamAZ vehicles use a double-boost braking system. That is, in addition to braking by the power unit, there is an additional engine stopping system. If you are driving downhill with active auxiliary braking, then you cannot disengage the clutch and change gears.

Schemes of the main and transfer cases on KamAZ

Icy areas

Driving a truck on icy areas should be done with the greatest reserve of speed and travel. When braking, use the active brake assist system. If emergency braking occurs, the driver must stop the trailer wheels. If you do not take this point into account, you will end up in a skid. It is recommended to slow down with the power unit only in exceptional cases. Because this leads to accelerated engine wear, but the braking distance is significantly reduced. When braking, do not allow the wheels to slip. To avoid this, you need to turn off the reduced speed in time, this will lead to a drop in crankshaft speed.

Skid

When skidding, follow the main rule - do not squeeze the clutch, otherwise this will worsen the situation. During the production of cars, engineers introduced a scheme due to which the car can drive with the greatest power reserve. Thanks to this, you can achieve course stabilization while driving on any road. If a skid occurs while driving, the steering wheel of the car must be turned in its direction. That is, if the car skids to the left, then the steering wheel also turns to the left.

If the truck begins to slip, then you need to stop moving as quickly as possible and immediately disable the differential axle. You can see the switch to turn it off on the dashboard. When the differential axle is disengaged, a corresponding indicator will appear on the instrument panel. After this, the start of movement is carried out at increased speed, from second gear. When you drive through a hard-to-reach section of the road, do not forget to engage the differential (video shot and published by Vladimir Nikonov).

Loading …

Is it possible to drive a KamAZ without urea?

Trucks that comply with Euro 4-6 standards use a method to neutralize the impact of exhaust gases on nature. To do this, urea is poured into a special tank, which is subsequently injected into the exhaust system.

In our country, the use of such material borders on difficulties:

- Low quality urea;

- Freezing of the product at a temperature of -11°C;

- Smell of ammonia from the exhaust, burns upon contact with skin;

- Lots of fakes, price.

KamAZ, fluid for the SCR system (urea):

It is not advisable to constantly operate a car without urea, as this will lead to failure of the pump pumping the material. You can disable the neutralization system at the software level, or by contacting an electrician, who will make hydrolysis in the catalyst impossible.

Construction of the KAMAZ 6520 platform

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

The platform on the KAMAZ 6520 dump truck is all-metal, welded, has a protective visor, an opening tailgate and automatic tailgate locks, it is heated by exhaust gases to prevent the cargo from freezing in the cold season. The dump truck equipment consists of a platform, a lifting and lowering mechanism and a subframe. The volume of the Kamaz platform is 12 cubic meters, and its tilting angle is 50 degrees. The subframe is a welded structure consisting of a pair of side members, a cross-shaped reinforcement and cross members. The mechanisms for raising and lowering the KAMAZ platform consist of:

- A power take-off equipped with an oil pump is designed to take power from the gearbox;

- Gear type high pressure oil pump. It provides an oil supply of 85 l/min with a rotation speed of 1920 rpm;

- Hydraulic cylinder (one-way telescopic);

- The control unit, which serves to control the pressure of the working fluid inside the hydraulic system of the tipping mechanism, it consists of an electro-pneumatic valve and a control valve;

- The platform lift limiting valve is used to stop the platform lifting when it reaches the maximum angle;

- The oil tank is stamped in two halves; it is equipped with filters located in the filler neck and in the drain line;

- The stabilizer serves to hold the platform during unloading to avoid lateral movements

Read also: How to make a car entrance at your dacha