Adjusting the gas gas system on a carburetor engine is required so that the car can be started and when gas is supplied there is no deviation in its concentration in the combustible mixture. There are more modern gas equipment for cars, but 1st and 2nd generation units are popular among car owners. These modifications have a gas reducer. It lowers the gas pressure by evaporating it and supplying it to the engine in vapor form. Adjustment of the gas reducer is necessary so that the mixture has the correct concentration of fuel. There are 2 types of this unit - electronic and vacuum, each of which must be configured correctly.

How to set up an electronic gearbox

On such a gearbox there are a couple of main adjustments - the pressure of the 2nd stage (professionals refer to it as “sensitivity”) and the volume of gas that passes through the idle airlock. It is recommended to adjust both of these criteria. In a variant of this type of unit, gas adjustment on a car with a carburetor is done with your own hands, following the following sequence of steps:

- The engine is started on gasoline and warmed up until the temperature reaches the operating level. The engine idle speed is kept at 950-1000 rpm. Next I produce fuel. In the starting position of the adjustments, the dispenser is set to the peak value (maximum gas supply). When this element has a pair of sections, the first is transferred to the peak value, and the other to the lowest.

- The idle screw is tightened completely, and then turned back 5 turns, while the “sensitivity” control is set to the middle position.

- Setting the idle speed - start the car on gas and, using a choke, set the speed to 1700-2000 rpm. Now, gradually, in several stages, the choke is removed, while at the same time, turning the idle speed control, they look for the peak value of engine rotation. These steps are repeated until the choke is completely in its original position, and the motor begins to function stably.

- Set the idle speed screw to the highest speed, gradually tightening the “sensitivity” screw. If any changes in rotation occur, adjust the idle speed control to the peak value. So, the “sensitivity” will be tightened almost all the way, and the engine will idle at the highest speed - 1100-1200 rpm.

- By tightening the idle speed control, the rotation is gradually reduced so that it is slightly lower than the nominal value. Then, unscrewing, set the value to 950-1000 rpm.

- Debugging the sensitivity of the evaporator gearbox - the “sensitivity” regulator is gradually unscrewed until it begins to affect the rotation of the engine at idle. Then it is twisted ¾-1¼ turns. They try to squeeze the accelerator hard - the engine must respond to pressing the gas.

- Final calibration - press the accelerator, tighten the “sensitivity” regulator ¼ turn. When there is a feeling of “failure” in the growth of rotations, stop doing this. Then unscrew this regulator ½ turn. This procedure is performed by “starting off” on a weak “gas”, and not by “hearing”. If necessary, the adjustment is repeated.

Attention! After you have set up your LPG, you need to evaluate it by checking the car in motion.

This is because the position of the adjustment screw may need to be calibrated.

Review of Lovato gearbox models

Lovato is the oldest company specializing in the production of LPG. This is a family-owned Italian company that has adopted the principle of “lean production”, when every detail is made with a minimum of losses, with the highest quality and eliminates the appearance of defects. That is why the price of a Lovato LPG reducer may be lower than its analogues, but higher in terms of quality characteristics. The diagnostic cable connectors to the Lovato gas equipment are universal; repair kits for the Lovato gas reducer can be purchased in any city.

The range of gearboxes of this company is represented by the following products for engines with injectors and carburetors, for different temperature conditions.

Modern gearboxes for propane gas equipment

Modern gearboxes for propane gas equipment from Lovato have practically no analogues in terms of compactness and reliability. The devices are among the most popular:

- Lpg/gpl reducer Lovato rgj-2L. installed on cars with 4 cylinders, for propane systems. They are connected to gas cylinder kits of the fourth generation, and even to systems of the 5th generation. It has the best characteristics in its class in terms of stable gas fuel pressure levels. This is one type of single-stage device. The 4th generation Lovato LPG reducer is equipped with an electromagnetic valve and a device for purifying the gas mixture at a low temperature. Built-in temperature sensor RGJ 421053. Very compact in size. Replacing the repair kit is not difficult.

- Lovato Easy Fast RGJ uhp is made specifically for powerful 6-8 cylinder cars. The designers took care to use it in cold winter conditions. The emphasis in the design of the Lovato Easy fast RGJ hp device is on power characteristics and good heat transfer. Equipped with a solenoid valve and a large gas filter. The dimensions are also quite massive. There is no need to modify anything; it copes with its functions independently.

- Lovato RGJ-rgj-2l DD works great in winter, with poor gas quality, designed for engines up to 100 kW. The automotive gearbox has a single-stage design and has a double membrane (Lovato’s own development) for systems with sequential injection of a propane-butane mixture. Has a solenoid valve and an enlarged filter.

On a note! There is no need to drain condensate from the 4th generation Lovato gearbox. The design does not provide for a drain; all condensate, as planned by the developers, goes into the combustion chamber for processing.

For methane gas equipment

Lovato products for methane gas treatment are manufactured strictly in accordance with European standards and Russian Technical Regulations:

- RMJ gearbox with a two-stage circuit for connection to engines with sequential methane injection. Between the first and second pressure reduction barriers there is an electronic valve as well as an inlet filter. The methane pressure is equalized by engine decompression.

- Lovato RMJ-3.2S - for methane gas and sequential injection engines. It has an electric shut-off valve with a filter, as well as a pressure gauge showing how much methane is left in the cylinder. Automatically equalizes gas pressure.

On a note! Gas pressure equalization devices from Lovato ensure smooth engine operation due to high precision settings and enhanced quality control at every stage of product assembly.

Lovato 2nd generation electronic gearboxes

Lovato gearboxes of the 2nd generation are in particular demand among Russian car owners. These are reliable devices that can last up to 2-3 years without overhaul. Overhauling the Lovato gas reducer is usually required due to low-quality fuel. Using the Lovato gearbox repair kit and a pair of keys, you can do this yourself:

- The 2nd generation LPG gearbox Lovato RGV090 is considered a classic propane two-stage gearbox for carburetor engines. The main mechanisms are an electric starter and a gear screw for adjustment. The gas fuel pressure is regulated by vacuum. A time-tested, reliable device for the first and second generations of HBO.

- The 2nd generation Lovato gas reducer RGE220 is designed for connection to carburetor and injection vehicles. Consists of a solenoid valve and an adjusting screw. The highest quality ensures smooth running of the car on gas.

- The Lovato RGV140 vacuum reducer is chosen for 190 hp vehicles. With. with carburetors. The vacuum membrane does not allow gas to pass through during an unplanned engine stop, as a reaction to a change in pressure in the intake manifold.

- Lovato RGE090 with a cast aluminum body works with carbureted and fuel-injected engines up to 122 hp. The gas mixture output is blocked during an emergency engine stop using a fuel type switch with the corresponding function (purchased separately).

How to calibrate a vacuum reducer

If the installed gas-cylinder equipment has a vacuum reducer-evaporator, then you need to determine what type of element it is. There are 2 types - with a combined regulator (idle speed and “sensitivity”) and a separate one. In the case of the latter type of design, its calibration coincides with the debugging required by the electronic element. In the version of the integrated regulator, it is calibrated as follows:

- start the engine and set the choke to 1700-2000 rpm;

- gradually reduce the suction and turn the idle speed control, finding the peak value of engine rotation;

- repeat the manipulation until the choke is in the starting position and the motor begins to function stably at idle;

- the idle speed regulator sets the peak value - 1000-1100 rpm;

- tighten the idle screw, reducing the torque until it is less than the nominal value;

- unscrew the idle speed control and set it to 950-1000 rpm.

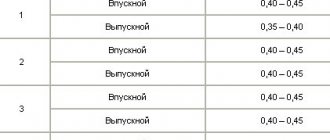

Upon completion of this setup, a check is carried out. It is recommended to measure emissions, which normally correspond to 0.35% -0.45% in terms of carbon dioxide. This method is one of the best in establishing the correctness of the manual calibration of gas equipment. The correct setting is determined in the same way in the case of professional adjustment of the evaporator reducer. If a lambda probe emulator is installed in your car, then you can view the combustion indicator of the mixture on it, which will display the correctness of the settings.

How to debug the dispenser

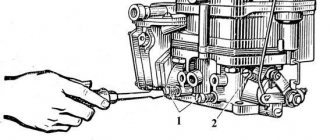

This is the final stage of manual calibration of gas equipment on your car. On a functioning engine, set approximately 3000-35000 rpm, but the choke cannot be used. It is better to debug the gas equipment dispenser not alone, since at this stage it is prohibited to use the suction, it is better to take someone to help you.

Tighten the dispenser screw until the stent reaches a threshold for changing motor rotations. To do this, turn the dosing regulator to the sides stronger and weaker - this helps to check that the threshold is detected accurately. After these actions, the screw is released ½-¾ from the calculated threshold. Then the idle speed is debugged and the LPG calibration is completed. If carbon dioxide in the exhaust gases exceeds the norm, adjust the regulators to increase the volume of the air part on the carburetor engine and the idle speed on the gearbox.

Attention! If the presence of carbon dioxide in the “exhaust” is increased, then the carburetor screw is calibrated, and in case of the opposite situation, gear adjustment is used.

Why is calibration required?

Debugging of gas equipment on cars is mandatory, since otherwise, if you don’t “tighten” the evaporator gearbox, it will be impossible to start the car. This is due to the fact that there is no electronic control unit (ECU) that would have the necessary firmware for a car of a certain make and model. In such equipment, the main task is to set the desired program and check the correctness of its operation. But such gas equipment is mostly installed on injection engines with complex injection technology.

If you do not perform such adjustments on gas equipment of the 1st and 2nd generations, then the incorrect concentration of the gas-air mixture composition may also be supplied to the engine. Because of this, excessive consumption of fuel is observed or the next portion of it burns out at the outlet. Gradually, due to incorrect engine operation, the valves burn out. It should be taken into account that it is impossible to obtain the same fuel consumption in gas and gasoline modes. The consumption of the first will always be 15-20% higher relative to the second, and deviations from this value indicate an incorrect composition of the gas-air mixture.

Adjusting the gas equipment of early generations is mandatory; without it, the engine may not start or the composition of the air-gas mixture will be incorrect. This adjustment is made after installing the equipment on the car, and then every season. It is not difficult to do, but at the last stage - when setting up the dispenser, it is recommended to take someone to help you, since you cannot use the suction.

What is gas equipment

HBO is gas-cylinder equipment. It is a gas installation that powers the engine instead of conventional fuel. Gas can be of two types - propane or methane. In practice, they differ little (except for the state of aggregation), but in terms of price and storage they still have slight differences.

LPG for a passenger car

There are several types of HBO:

- First;

- Second;

- Third;

- Fourth;

- Fifth generation.

The higher the generation, the more advanced the system (more sensors and electronics are used, everything is calculated more accurately and the operating efficiency is higher). But the generation of HBO is selected depending on the type of engine and it is not always possible to use the 5th generation installation on an old engine.