Just a few decades ago, the vast majority of cars ran exclusively on carburetor engines. Nowadays, there are no new cars with a carburetor, since they have been completely replaced by injection systems.

The history of the injector began with aviation, where in 1916 Soviet designers Mikulin and Stechkin created the first aircraft engine equipped with a fuel injection system. But mass production started only 20 years later, literally before the start of the war. Moreover, the production of injectors was carried out in Europe by Bosch.

In vehicles, new fuel supply systems began to be used only in the 50s of the last century. Initially, neither the automakers themselves nor consumers were interested in injectors. After a couple of decades, the question arose regarding the environmental friendliness of engines, plus technology has reached a level that allows us to engage in the full production of injection systems.

Nowadays, no one will argue with the fact that injectors dominate the market, while carburetors are gradually becoming history.

What is this

The first step is to understand exactly what injectors are on modern cars. Automotive injection systems are modern internal combustion engines that are equipped with a special injection system for fuel injection. Comes from the word injection, that is, injection or injection.

All modern cars are equipped only with an injector, which has become a worthy alternative to already morally and technically outdated carburetor engines. With their help, the required level of productivity, efficiency and environmental friendliness is achieved.

When choosing a new car, buyers are interested in what an injection car is and why an injector is needed in the engine design. This is a special system for supplying the required amount of air and fuel itself inside the combustion chamber, which differs significantly from a carburetor, where the supply is carried out by gravity.

Here a mixture of fuel and oxygen (air) is formed, which is injected into the working cylinders using injectors. Moreover, the system itself determines in what proportions these components need to be mixed, based on the readings of sensors and controllers. By atomization, rather than gravity, it is possible to significantly save fuel, increase combustion efficiency, reduce the volume of exhaust gases produced, and also increase the power of the power plant.

In order to understand what an injection car means, it is worth comparing it with carburetor analogues, studying the types of available injection car systems, and also understanding their operating principle and the device itself.

Antifreeze temperature sensor

This device allows the electronic control unit to understand that the engine has warmed up to operating temperature. When starting a cold engine, the amount of air in the fuel mixture must be reduced; for this, the idle air regulator is used. With this, the motor operates as efficiently as possible and quickly returns to a stable mode. The principle of operation of 2nd generation HBO on an injector is the same as on a carburetor. But with the help of a signal from the temperature sensor, you can start the engine on gasoline and, after warming up, automatically switch to gas fuel. The temperature sensor is located in the engine block or in the thermostat housing.

Injector vs carburetor

The key difference between these two popular systems can be found in the principle of operation of more modern injection engines. They are equipped with a fundamentally different fuel supply scheme. Therefore, according to the principle of its operation, an injection engine is exactly different from a carburetor conventional competitor.

Without going into details, the injection type of engine is most different from an outdated carburetor in terms of the design of the fuel supply system itself and in relation to the power supply of the power plant.

In the case of carburetor internal combustion engines, mixing gasoline with oxygen (air) occurs in a special separate device, which is located on the outside. This is the carburetor itself. Once the mixture is formed, it begins to be sucked into the cylinders. Moreover, this happens by so-called gravity.

If we talk about how injection engines work, then the system has special supply nozzles. They dose the amount of injected fuel, which occurs under a certain pressure, and then this amount of fuel is mixed with a certain portion of air.

The efficiency of a car injector exceeds the carburetor by an average of 15%. That is, all other things being equal, a power plant with an injection system will be 15% more powerful than a similar carburetor engine.

Another significant argument in favor of the injector is the issue of fuel economy. Regardless of the selected operating mode of the power plant, the injection system consumes less fuel.

Device

A modern injector contains several subsystems:

- A fuel pump that takes gasoline from the tank and supplies it to the injector ramp input under a strictly defined pressure;

- Gasoline injectors consisting of solenoid valves and nozzles;

- Electronic engine control unit (system) ECM;

- A set of sensors that provide the ECM with information about the engine operating mode, pressure, temperature and air flow, the phase in which the engine parts are located at each moment, the position of the accelerator pedal and many other parameters;

- Emission reduction systems, including a catalytic converter of exhaust gases, oxygen sensors, a valve for feeding part of the exhaust back into the cylinders (recirculation or EGR);

- Ignition spark timing control with knock sensor.

All components are located on and around the engine, with the exception of the fuel pump, which is usually submerged in gasoline inside the tank.

Kinds

When choosing a car with an injection fuel supply system, you should pay close attention to what type is used.

There are several subcategories:

- single point systems;

- distribution;

- straight.

Each presented injector differs in where the injection is located, as well as where and how many nozzles are located.

- Single-point systems, also often called mono-injection, are the earliest development. Its distinctive feature is the presence of only one nozzle, which is located inside the intake manifold. That is, one nozzle works for the benefit of all cylinders that are provided on the power unit. This system has many shortcomings, which is why they began to abandon it. And then the mono-injection ceased to exist altogether.

- Having sorted out all the previous mistakes, after the mono-injection, a distributed injection system appeared. It also uses a manifold, but there is a separate injector above each inlet valve of the cylinder.

- Direct injection is considered the newest and most advanced development. Their operating principle is different from all others presented. The injectors are placed in such a way that the fuel is supplied directly, that is, directly into the cylinder itself. The supply goes inside the combustion chamber, and not through the manifold. Cylinder heads were used to accommodate the injectors. In many ways, this system resembles the supply and formation of the fuel mixture implemented in diesel engines.

In addition to this classification, systems are also distinguished depending on the type of injection provided.

In total, there are 3 injection options using distributed type injectors:

- Simultaneous. Here, all the injectors in such a system simultaneously inject the air-fuel mixture.

- Pair-parallel. A distinctive feature is the paired opening of the working nozzles. That is, one opens immediately before the injection itself, and the second before one of the engine strokes, which is called exhaust.

- Phased. The system differs in that the nozzle opens immediately before the intake.

- Straight. It is carried out directly into the working cylinder itself.

Injection cars are gradually developing and improving. Engineers manage to extract the maximum from the potential of these systems.

Location, classification and marking of injectors

Design and principle of operation of a turbocharger

After analyzing the question of how the injector works, let’s look superficially at the entire injection system. The injection system injects fuel into the intake manifold and engine cylinder through a nozzle that can open and close many times in a second. The system is divided into two types. The classification depends on the location of the nozzle mounting, the way it works and the quantity:

- Mono-injection, otherwise known as central fuel injection Throttle body injection (TBI), works through a single nozzle that supplies fuel to the engine cylinders. The jet supply is not synchronized with the opening time of the engine intake valve. Single point injection is simple and contains little control electronics. The entire TBI system is located inside the intake manifold. The technology is not popular today and is almost not used in car production, as it does not meet current requirements.

- Distributive fuel injection Multiport Fuel Injection (MFI) is in demand today because it is much more advanced. Its essence is that each injector supplies fuel individually to each cylinder. The structure is attached to the outside of the intake manifold. The signals are synchronized with the engine ignition sequence. This type of injection is more complex in design, however, it is 7–10% more powerful and more economical than its predecessors.

Comparison of carburetor and injector

There are several classifications of distributor injection:

- simultaneous - the operation of all injectors is synchronous, that is, injection goes to all cylinders at once;

- pair-parallel - when one opens before the inlet, and the other before the outlet;

- phased or two-stage mode - the injector opens only before the intake. Makes it possible to increase engine torque at low speeds when pressing the accelerator pedal sharply. The injection takes place in two stages.

- direct (injection on the intake stroke) GDI (Gasoline Direct Injection) - the jet goes directly into the combustion chamber. Motors with such injection also require higher quality fuel, which contains a small amount of sulfur and other chemical elements. The GDI engine is capable of functioning properly in the combustion mode of an ultra-lean air-fuel mixture. The lower air content makes the composition less flammable. The fuel inside the cylinder arrives as a cloud, staying next to the spark plugs. The mixture is similar to the stoichiometric composition, which is highly flammable.

Injection nozzles have different methods of jet delivery:

- Electrohydraulic. It works through the difference in diesel pressure on the piston and injector. When the valve is de-energized, the nozzle needle is pressed against the seat by the liquid. And if the valve opens, then the throttle also opens, after which the fuel line is filled with diesel. During this, the pressure on the piston decreases, but nothing happens on the needle, which raises it at the moment of injection.

Injector device

- Electromagnetic. An electrical discharge controlled by the ECU is supplied to the valve winding. As a result, an electromagnetic field arises along with the squeezing of a spring. The field attracts the needle and releases the nozzle to supply the jet. The spring returns to its previous position after the electromagnetic field dissipates, sending the needle into place.

- Piezoelectric. The most advanced type, used in diesel units. Its speed of action is four times higher than previous types; in addition, the amount of injected fuel is adjusted to the maximum. The actions of the injector are based on the principle of hydraulics; work is carried out due to pressure differences. First, the needle is on the seat, then the current stretches the piezoelectric element, which begins to act on the pusher, which opens the valve to allow fuel to move into the line. Then the pressure drops and the needle rises, injecting upward.

Advantages and disadvantages

Objectively, in the world of modern cars there is hardly a choice between an injection and a carburetor engine. The advantages are definitely on the side of the injector.

But even under such conditions, it will not be superfluous to know what strengths and weaknesses the injection power unit is characterized by.

Its main advantages include the following:

- The engine automatically changes its operating mode. It directly depends on the current conditions. This is what gives the injector a huge head start over the carburetor. The driver does not need to do anything to make the engine work differently. He will analyze what is happening and change his work to achieve optimal performance.

- Manual settings. They simply don't exist. And this is another weighty argument in favor of the injector. Motorists do not need to climb under the hood, configure, twist or change anything. The electronics do everything on their own.

- Economical. One of the factors in the transition from carburetors to injectors was the issue of appropriate use of resources. Injectors have proven in practice that they require less fuel with more power and speed. All other things being equal, the injector consumes on average 15-20% less fuel than its once competitor in the form of a carburetor system.

- Environmentally friendly. It was precisely because of the need to preserve the environment that engineers began active production of injection systems. Without an injector, achieving compliance with current extremely stringent environmental standards would be impossible.

- Easiest engine starting. This is achieved due to the presence of automatic determination of optimal operation. As a result, in any weather and temperature, the injectors start without any problems.

But don't rush to conclusions. In addition to the obvious advantages, injection systems also have certain disadvantages.

The main disadvantages include:

- Complex design. The injection power unit is indeed much more complex than the same carburetor engine. But at present this is no longer a serious problem. Car service workers easily cope with all tasks related to injectors. And car owners themselves have learned to solve a number of issues on their own.

- Cost. Design features entailed increased costs for component production and assembly. This caused an increase in the cost of the engine itself.

- The problem of repairing elements of the fuel supply system. Some components cannot be repaired at all, while others are very difficult to repair. Therefore, it is often easier to immediately change a part than to try to bring it back to life. And these are additional financial costs.

- Fuel requirements. If the carburetor could digest almost everything, it is important for the injector to fill the tank with fairly good fuel with certain characteristics and composition. They are determined by the automaker itself. Refueling at cheap and dubious gas stations often causes many breakdowns and malfunctions.

- Repair and service. The injector requires skillful hands and a professional approach. Experts do not recommend trying to repair and maintain these systems yourself, since any mistake can lead to serious negative consequences. To properly service some elements, you need special tools and professional equipment. Although minor repairs are still available to do yourself. You can change the same consumables yourself.

- Dependencies on electricity. If the voltage in the on-board network is lost, the battery will be discharged and the engine will stop working. Therefore, in the case of injectors, increased demands are placed on the quality of the batteries used. It is also extremely important to monitor and maintain the generator's performance.

Actuators

For the normal functioning of the injection system, actuators are used. The operating principle of the Audi mechanical injector is slightly different from the electronic one. The essence of the processes is approximately the same.

The system uses the following actuators:

- Electric fuel pump.

- Idle speed regulator.

- Fuel injectors.

- Throttle assembly.

- Ignition module.

With the help of all these devices, the internal combustion engine is controlled. It is with their help that you can maintain idle speed at a normal level. The principle of operation of the injector in this mode is the same as in any other.

Typical faults

The complex and multi-component design is both an advantage and a disadvantage of the injection system. Some elements may break over time and if used incorrectly, their performance is impaired, which leads to the need for repair work.

The injector is designed to burn fuel as efficiently as possible. This was made possible thanks to electronic control, which determines the optimal composition of the mixture consisting of fuel and oxygen.

There are several of the most common malfunctions that occur in the operation of the injector on modern cars.

- Damage or malfunction of the sensors. Regardless of which sensor is damaged, the overall balance in the operation of the entire fuel injection system is disrupted. This situation leads to the appearance of floating speed while driving and at idle speed. Also, the engine does not start or the engine stalls. All this is due to the fact that air and fuel are mixed in incorrect proportions. This can often be noticed by the changed color of the exhaust. Sometimes a sensor failure causes the engine to go into emergency operation mode. As a result, the speed cannot be gained, and the corresponding lamp lights up on the dashboard.

- Filters or nozzles are dirty. Another common situation that occurs mainly through the fault of the car owner himself. A similar malfunction is relevant for injection machines that are filled with low-quality fuel. Impurities and various debris in the fuel clog the filter, and in the future the injectors themselves may become dirty. If they become clogged, the shape of the spray pattern is disrupted. This leads to a local increase in temperature, detonation and valve burnout. To prevent this situation, the filter must be periodically replaced. Additionally, it is worth changing the filter mesh on the fuel pump when the mileage exceeds 70 thousand kilometers, and also wash the fuel tank once every 3-4 years.

- Fuel injectors pouring. This happens because the injectors do not close after the supply of pulses from the electronic control unit stops. As a result, some of the fuel penetrates into the combustion chamber, into the engine lubrication system, seeping through the piston rings. This leads to dire consequences for the entire engine. After all, fuel mixes with oil, and lubrication characteristics are significantly reduced. If fuel ends up in the exhaust system, the catalyst designed to clean the exhaust from harmful impurities breaks down.

- Fuel pump failure. The pressure in it may drop below the standards established by the automaker. The reasons for the breakdown are different, but mostly it is pollution. This reduces the performance of the injectors themselves.

The most important procedure that car owners of injection cars often carry out with their own hands is cleaning the injectors. They are cleaned by removing them or directly on the power plant.

Engine flushing involves the use of special flushing compounds. They are poured into the engine and pumped through the system. In this case, the fuel line should be disconnected from the ramp, and a compressor should be installed in place of the fuel pump. It is with its help that a special flush intended for injectors is pumped throughout the system.

Another option involves removing the nozzles and using an ultrasonic bath on a stand. But this is only available in specialized car services. It is almost impossible to implement such washing in a garage.

The essence of an ultrasonic bath is that a special device uses wave vibrations to influence accumulated deposits and destroy them.

https://www.youtube.com/watch?v=XhSyHJkh4xg

The principle of operation of the injector and its design

I think it will be best if we consider the principle of operation of the injector on a distributed injection system, since it is this system that is installed on most cars and is considered one of the most successful and widespread.

For convenience, I propose to divide the fuel supply system into two main components - electronic and mechanical. The role of the mechanical system is quite simple - ensuring a continuous and dosed supply of fuel to the cylinders. But the system is controlled and monitored electronically.

Mechanical part

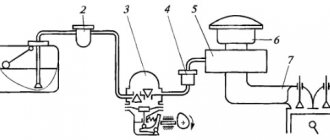

The mechanical component of the injection system includes the following components:

- fuel pump (electric);

- fuel tank;

- gasoline purification filter;

- fuel rail;

- high pressure fuel lines;

- nozzles;

- throttle assembly;

- air filter.

This list of components is not exhaustive. Depending on the design features of the engine and control system, other elements may be included in the mechanical part. The above list is a list of must-have items for any engine.

https://www.youtube.com/watch?v=XhSyHJkh4xg

Principle of operation

Now let's look at why all these components are needed and what work each of them does. I think everyone already knows that a fuel tank is a container for gasoline. The electric fuel pump, which is located in the tank, ensures a continuous supply of fuel under pressure.

After which the fuel enters the filter, where it is cleaned of impurities and other debris. High pressure fuel lines allow gasoline to move freely through the fuel supply system.

The pressure regulator does not allow the critical pressure level to be reached throughout the entire system. Through the regulator, the fuel enters the fuel frame, which supplies it to the injectors. The injectors are located in the intake manifold.

A few years ago, injectors were triggered by fuel pressure and their design was completely mechanical. Here the principle of operation is quite simple - gasoline puts pressure on the injector spring and opens it, and through it it is injected into the cylinders.

Nowadays, most cars have electromagnetic injectors. The main component, which is a regular armature and winding. The fuel supply channel opens by receiving a signal from the electronic control system.

On the reverse side, air is forced into the system through an air filter. The throttle assembly with a damper is located in the pipe through which air flows. When the driver presses the gas pedal, he acts on the throttle. But the driver only controls the air that is supplied to the cylinder; the fuel is regulated by an electronic control system.

Electronic part

The memory unit and controller are the main components in the electronic control system, which in turn serves as the basis of the electronic part of the injection system. The control unit controls the fuel supply system thanks to a number of sensors that are included in the injector design.

The main sensors that provide the electronic control unit with information about the operation of the fuel system are:

- Lambda probe.

The task of this sensor is to determine the remaining air in the exhaust gases. Based on the data received, the control unit regulates the air supply to the fuel mixture. - Mass air flow sensor.

The job of this sensor is to determine the volume of air that passes through the throttle valve. Typically this sensor is installed inside the air filter housing. - Throttle position sensor.

Giving a signal about the position of the gas pedal is the main purpose of this sensor. - Power plant temperature sensor.

Depending on the engine temperature reported by this sensor, the control unit regulates the fuel mixture. - Crankshaft position sensor.

This sensor is responsible for selecting the cylinder into which fuel must be supplied and the timing of the spark. - Knock sensor.

It is located in the cylinder block and is designed to detect and eliminate detonations. - Speed sensor.

Creates impulses, thanks to which the speed of the vehicle is calculated. The fuel mixture is adjusted based on the readings from it. - Phase sensor.

It determines the angular position of the camshaft.

Useful tips

If you have a car with an injection engine, then the air-fuel mixture distribution system used here requires compliance with certain rules and recommendations.

This will allow you to maintain the operation of the power plant, maintain its integrity, avoid typical malfunctions and prevent expensive repairs.

- It is recommended to change the fuel filter on the engine. This procedure is carried out at least once every 15 thousand kilometers.

- Be sure to periodically clean the injectors. If you do not have the experience and skills to clean yourself, it is better to entrust this procedure to specialists.

- Cleaning of injectors is carried out at intervals of about 30-40 thousand kilometers.

- Also, for reliable and trouble-free operation of the injector, a large role is played by the fuel used. The higher the quality of the fuel, the fewer problems will arise in the operation of the injection system.

- For prevention, cleaners are often used to remove contaminants in the fuel system. They are added directly to the fuel itself. But such additives are important to use on new cars, as well as after deep cleaning. Additives are preventative, and it is important to remember this. There is no need for such additives when the injectors are already dirty. They need to be cleaned first. And to further prevent severe contamination, it is allowed to periodically pour additives into the tank.

- Never wait until your car begins to show symptoms of dirty injectors. Experienced motorists note that it is better to carry out this procedure in advance. Under the operating conditions that are relevant for most regions of Russia, the injectors should be washed before every second scheduled maintenance.

- If you use flushing fluids to clean the injectors, you should do this before changing the engine oil.

Replacing the fuel filter

Caring for the injector is the direct responsibility of every car owner. Proper operation, timely prevention and cleaning will help maintain engine performance for a long time.

Injectors are truly the best option for internal combustion engines nowadays. Despite the existing disadvantages, the advantages objectively surpass them. The main thing here is to rationally use the opportunities that the injection system provides, as well as to properly manage the engine resource.

Throttle position sensor

Installed on the throttle body, the sensor can be analog or non-contact. The first ones work on the principle of a variable resistor - when the damper axis rotates, the slider on the winding moves. In this case, the resistance of the element changes, the level of the signal supplied to the electronic control unit decreases or increases. There are non-contact type devices, they work in the same way as encoders. They are highly reliable, but are not interchangeable with analog devices.

The device allows you to evaluate the position of the damper in order to provide information about this to the control unit. The latter, based on this value, will supply exactly as much gasoline to the fuel rail as is necessary for normal mixture formation.

What is the difference between an injection engine and a carburetor engine?

Rice.

No. 4. Injection and carburetor engines. The following differences can be distinguished in the operation and design of the injector and carburetor:

- In an injection engine, a mixture of gases and fuel is supplied to a special chamber ; in a carburetor engine, the formation of the air-fuel mixture occurs in the carburetor itself;

- The mixture in an injection engine is forced by injectors into the cylinders and into the intake manifold. In a carburetor, this process occurs on its own;

- In an injection engine, the injectors supply a strictly metered amount of fuel ;

- The injection system provides 15% more engine power than a carburetor;

- The injector is more economical and environmentally friendly than a carburetor.

Direct injection

Direct injection, a type of distributor injection system, is the last word in gasoline engine power systems. The main feature of direct injection is the supply of fuel directly into the combustion chamber.

GDI, FSI, D4 are abbreviations used by Mitsubishi, Volkswagen and Toyota, respectively, to designate direct injection engines. The power system of such internal combustion engines is more similar to diesel engines than to the Otto cycle internal combustion engines familiar to all. Device: