Device

The injector involves forced injection. This requires a special device and a number of sensors. The VAZ 2114 power system consists of the following elements:

- Air preparation;

- Gasoline preparation;

- Injection of the fuel-air mixture.

These three components, in turn, contain a number of elements. To prepare the gaseous component, you need to purify it.

Preparation of the gaseous component

Air supply:

- Air purifier;

- Receiver;

- Throttle assembly;

- Mass air flow sensor.

Fuel preparation

Supply to injectors:

- Electric fuel pump;

- Fine filter;

- Gasoline pressure regulator;

- Speed sensor.

The VAZ 2114 injector is quite simple in design compared to foreign cars.

The principle of operation of the VAZ 2114 injector power system

Supply of fuel-air mixture

Gasoline injection consists of:

- ECU (electronic control unit);

- Fuel rail;

- nozzles;

- Crankshaft position sensor;

- Phasing sensor.

In addition to the listed elements, the 2114 power supply system also contains other parts. For example, hoses, tubes, devices for maintaining normal pressure in the tank, condensate drain, valves.

How to change the engine on a VAZ 2114

The VAZ 2114 engine changed throughout the entire production period of this car. The first models of the VAZ 2114 or “Samara-2” (as it began to be called by analogy with its predecessor) rolled off the production line with an engine from the VAZ 2109. It was an eight-valve injection engine with a relatively small volume - only one and a half liters. This engine did not differ in terms of developed power, which was 78 horsepower.

Since 2007, VAZ 21114 engines began to be installed on cars, with an increased volume of 1.596 liters and a maximum power of 80-84 hp. With. This engine complied with the Euro-3 environmental standard.

And since 2010, a model with a 16-valve engine has been produced. It's also a four-cylinder engine, but instead of two valves per cylinder there are four. The 16-valve engine has more power - 98 horsepower, faster acceleration, but is more susceptible to breakdowns than the eight-valve engine.

Thus, under the hood of the VAZ 2114 there are key mechanisms, the main one of which is the engine. Its operation is based on a distributed fuel injection system, which is regulated by an electronic control unit.

Source

Operating principle

The operation of the 2114 power supply system is to supply the prepared combustible mixture to the combustion chambers. This requires precise dosing.

The memory of the controller (ECU) contains a complex program that calculates how much fuel is needed and when it is needed.

The fuel pump is turned on by a control signal from the ECU. The moment of mixture injection is determined by the crankshaft position sensor. The portion (weight) of gasoline depends on the mass of gas. The throttle valve was opened and the position sensor signaled this. The gas mass is also known from the signal from the mass air flow sensor. Based on this data, the ECU regulates the fuel supply. As is known, the composition of a normal fuel-air mixture has a ratio of 1/15, i.e. 1 part gasoline to 15 gas with a normal oxygen content. An increase in gas content leads to depletion, and a decrease leads to an enrichment of the mixture. The opening of the injectors is controlled by a signal from the ECU. At his command, the solenoid valve is activated, and fuel is supplied to the cylinders.

Zhiguli models with an electric throttle drive have so-called lambda probes. These are sensors for oxygen content in exhaust gases. All this is necessary to prevent sudden opening of the damper in order to protect the atmosphere.

A whole complex of devices combined into one fuel system is responsible for supplying fuel to the VAZ 2114 engine. This article is dedicated to it, by studying which you will learn what the power supply system of the VAZ 2114 injector consists of, what is the principle of its operation, and what preventive measures must be taken in order for the system to work out its resource to the fullest.

The fuel supply system is the main artery of the car

Motor maintenance

When the design and main technical characteristics inherent in the VAZ 2114 engine have been reviewed, it is necessary to consider maintenance and provide answers to questions that motorists are increasingly asking.

Maintenance

If you believe the plant, the manufacturer, the VAZ 2114 engine must be serviced every 12-15 thousand kilometers. It depends on what marking the motor is installed on the vehicle. Maintenance scheme for all engines installed on the “fourteenth” model:

- At the first maintenance, the oil, oil filter and air filter element are replaced, as well as the functionality of all systems is checked.

- The second maintenance is done after 12,000 km. In this case, it is necessary to change the oil and oil filter element.

- Third maintenance – 25,000 km, replacing not only the oil, but also the air filter, and ongoing repair of faults.

- After 45,000 km, it is necessary to replace the timing belt and roller so that the VAZ 2114 engine does not have to be overhauled.

Subsequent maintenance is carried out in accordance with 2 and 3 maintenance.

Frequently asked questions and their answers

The process of repairing a VAZ 2114 engine.

Many car enthusiasts on forums ask the same questions. Let's try to classify all of them, and also give answers according to factory standards and recommendations.

What kind of oil should be poured into the VAZ 2114 engine?

If you rely on the manufacturer’s data, then different oil is poured into the VAZ 2114 engine, depending on the type. So, what kind of oil should you put in the VAZ 2114? If you take it for an 8 valve engine, then ideally it would be suitable with the 10W-40 marking. If it is a 16 valve engine - 5W-30. In any case, the oil for the VAZ 2114 should be semi-synthetic.

What is the operating temperature of the engine?

Based on the manufacturer's data, the operating temperature of the motor for engines installed on models 2113-2115 is 87-103 degrees Celsius. After 105 degrees the electric fan turns on.

Where is the engine number on the VAZ 2114?

The engine number is quite easy to find. It is located on the gearbox side, near the thermostat. The engine number always has a pad on the cylinder block, which is located in a visible place.

What is the resource of ICE 2114?

The service life of the VAZ 2114 engine is 150 thousand km for an eight-valve power unit and 180,000 km for a 16-valve power unit. To extend the service life, you need to know what oil to pour into the engine, as well as service it on time. Although driving style and careful operation of the car play an important role.

Do valves bend on VAZ 2114 engines?

Of course, like in any other engine, the VAZ 2114 has a valve mechanism that bends. This often happens due to overheating, when the head bends. The valves can also bend if the timing belt breaks.

What to do if the engine does not develop power and the speed drops?

In this case, it is worth carrying out a comprehensive diagnosis of the power unit. The issue may lie either in the inoperability of one of the sensors or in the mechanics. You can find the fault on your own or with the help of professionals at a car service center.

Engine malfunctions and repairs

Disassembled VAZ 2114 engine.

The fault diagram of the 2114 motor and its modifications is quite typical. Typically, the most common ones are floating speed, tripping, pump failure, as well as others that car owners are familiar with in detail. Where certain faults are located can be determined by carrying out diagnostic work.

After 150,000 km, the engine will need a bulkhead (overhaul). Every car enthusiast can repair his engine on his own, but many do not take risks and turn to a car service center.

For the VAZ 2114, repairs are carried out by analogy with the 2108 engine, since they are quite similar. In order to replace the timing belt, you will have to fix the camshafts. The set of replacement operations includes changing the timing belt, a roller or two, as well as adjusting the valves.

To replace the water pump, you will have to fix the camshafts, just like to change the timing belt. Because the belt also passes through the pump, and therefore the process is quite complicated.

Engine tuning

Tuning version of the VAZ 2114 engine.

Tuning the VAZ 2114 engine is carried out typically for the entire series of power units installed on 2113-2115. As you know, there are two options for modifying the engine: mechanical and chip tuning. The modification scheme is quite simple, the mechanics are done first, and then the electronics. But many car enthusiasts only carry out chip tuning to reduce consumption, since the price of fuel is too high.

Chip tuning of the VAZ 2114 is carried out using special equipment and is aimed at increasing power or reducing fuel consumption. This type of work should be entrusted to professionals, since only they have the necessary skills and knowledge.

As for mechanical modifications, the scheme is standard. In case of complete modification of the motor, it must be completely disassembled. It is necessary to gain full access to the interior of the power unit. Next, the process of boring-honing and installation of new spare parts with light weight is carried out.

Installed turbine on a VAZ 2114 engine

After assembly, it is recommended to install a tuning version of the cooling and exhaust system, since combustion will occur with the release of more heat than before. Standard oil will not be suitable for the VAZ 2114 engine after tuning, so it is recommended that the modification process be done by professionals.

WHAT GASOLINE TO POUR IN THE VAZ-2114?

This topic has become overgrown with various conjectures and speculations, but we will try to put everything in its place.

The technical data sheet of the fourteenth indicates that the car engine requires AI-95 gasoline, and there is no reason not to trust the manufacturer’s recommendations.

Another thing is that many car owners, over their long driving experience, have accumulated rational doubts about the existence of any serious differences between 95 and 92 gasoline. Adding fuel to the fire was the recent statement by the chief engineer of the Moscow oil refinery, A. A. Abrosimov, that we do not make 95-grade gasoline in our country, and everything that is sold under its guise is either 92-grade or unknown fuel brought from somewhere.

As evidenced by reviews from VAZ 2114 owners who use exclusively 92-octane gasoline, there were no problems with the car during its service life due to fuel, and they see no point in using a more expensive analogue. However, the final decision about what to pour into the fourteenth is yours.

COMPONENTS OF THE FUEL SYSTEM

The VAZ 2114 fuel system consists of the following main elements:

- Gas tank;

- Fuel pump;

- Gasoline filtration devices;

- Pipeline system;

- Fuel rail;

- Injectors;

- Waste disposal unit.

Fuel system diagram

Let's analyze each component separately.

GAS TANK

The VAZ 2114 gas tank is a container made of two equal metal parts. A neck is removed from the tank into which gasoline is poured. The neck is connected to the tank via a rubber pipe and clamps.

FUEL PUMP

The fuel pump is located directly in the tank. It has a fuel level sensor, which transmits information about the current amount of gasoline to the ECU. The gasoline pump is connected to a line through which gasoline is transported to the fuel rail. The fuel pump itself consists of several parts - coarse filters, wiring and an electric motor, which pumps fuel. As evidenced by reviews from owners of fourteenth cars, fuel pumps from the German company BOSCH have proven themselves to be the best.

FILTRATION DEVICE

The VAZ 2114 fuel injection system very much depends on the quality of the filter devices used. A bad filter will significantly reduce both the efficiency and the longevity of the entire system.

On the fourteenth, non-separable filters with a working element made of paper are installed. Such filters clog quite quickly, and they need to be changed at least once every 10-15 thousand kilometers.

FUEL RAIL

The fuel rail is located on the intake manifold housing. Its design consists of two parts, separated by a spring-loaded diaphragm. The first is the fuel one, in which the required level of gasoline pressure is set, the second is the air one, air is pumped into it, due to which the diaphragm compresses the fuel chamber and changes the pressure level in it.

Ramp

PIPING AND HOSES SYSTEM

To circulate gasoline from the gas tank to the injectors, the fourteenth uses steel fuel lines located on the bottom of the car. The VAZ 2114 fuel supply system also provides for a return pipeline through which excess gasoline from the injectors is returned back to the gas tank.

The principle of operation of the main elements of the fuel unit

Fuel system VAZ 2114

Container for storing flammable materials

It is made of steel, consists of two firmly welded parts, the neck through which the fuel enters is connected to the tank with a rubber pipe and secured with clamps.

Gasoline pump

This tool with an electric mechanism is located in a tank with a fuel mixture level indicator. Its actions are coordinated by the engine control box, through a special pump relay, which supplies fuel through the line to the injectors. At idle or when the engine is completely turned off, the pressure is maintained due to the action of a one-way lock, which is located near the unit itself.

The VAZ 2114 power system has a fuel pressure regulator and injectors. The voltage is supplied to them from the battery through the main relay. Thus, the amount of driving fluid is indicated by the duration of the pulses, which are generated by the engine control unit and transmitted to the injectors.

Ramp

Located on the intake manifold, it includes a fuel control element and a pressure valve with a spring-loaded diaphragm. It, in turn, divides the regulator body into 2 parts: the fuel part regulates the pressure of the combustible mixture, the air part, due to the rarefaction of the air, raises the membrane and produces constant fuel pressure readings in the rail.

When the engine starts, the vacuum behind the damper decreases, the diaphragm closes the power system valve, so the pressure increases. When the vacuum is maximum, then the fuel pressure decreases. The regulator is not dismountable, so if it fails, it is replaced with another one.

Fuel mixture control sensor

The pump module has a float, which is located in the tank cavity. When the position of the float changes, the resistance of the unit changes proportionally. According to a certain signal, the fuel quantity indicator on the dashboard displays the presence of fuel in the system.

Why does the sensor often fail?

Due to:

- fragility of the case;

- frequent temperature changes;

- condensation formation in the tank;

- when using a low-quality combustible mixture;

- oxidation of contacts when sealing is broken.

That is why it is so important to carry out preventive maintenance on time, clean the unit, change contacts in order to prevent its destruction. Changing a device is not that easy. Many markings are original and unique, which means that the services of professionals will be required, which are also not cheap.

Hoses and pipelines

Such irreplaceable products guarantee uninterrupted circulation of flammable liquid from the container to the main line and nozzles, and if there is excess, they transfer the residual liquid back to the tank. The pipelines are located on the bottom of the vehicle, they need to be carefully checked, cleaned, inspected for integrity, various deformations identified and promptly eliminated in order to avoid fuel leakage, as well as poor transmission to the injectors.

Another function of the pipelines is the transfer of fuel vapor from the tank to the activated carbon section, where waste is collected when the engine is turned off. After it is started, the electromagnetic device is triggered and the vapors escape into the engine, where they are destroyed.

Highway

The design of the VAZ 2114 fuel system includes a main line that guarantees the supply of fuel to all injectors. Today, the fuel pressure regulator is placed in the tank and is not located on the line; there is also a service valve, which performs the function of eliminating air after a technical inspection of the vehicle.

The fuel injection system of the VAZ 2114 includes an uninterrupted mode for collecting fuel vapors, and the gravitational unit located in the device helps prevent fuel from leaking when the vehicle is in an emergency position.

When the engine's air consumption is high, the system is purged more intensively. The filter element is made of durable paper material, after which the air moves through the mass air flow sensor and moves into the intake hose, which leads to the throttle assembly.

Thus, the operation of the fuel fluid supply mode of an engine with a fuel injection system on a VAZ 2114 car occurs.

PREVENTION OF THE FUEL SYSTEM VAZ-2114

Prevention, as a rule, comes down to regular cleaning and, if necessary, replacing the fuel pump filter and the main fuel system filter.

Also once every 25-30 thousand km. It is necessary to clean the injectors, which is performed exclusively at a service station. There are two methods for cleaning injectors, neither of which require removing them:

- Ultrasonic cleaning;

- Cleaning with a special washing liquid.

The most effective and expensive is ultrasonic cleaning, which makes it possible to bring back to life even heavily worn nozzles.

It's no secret that the fuel line of a car is one of its main components. Any malfunctions in it will immediately lead to interruptions in the operation of the motor and other serious problems. Today we will talk about how the VAZ 2114 fuel system works, what main components it includes and how to extend their service life.

VAZ 2114 power supply system

Main components and how they work

The entire scheme of the VAZ 2114 fuel system is built on the injection principle, implying complete electronic control over the system’s operation process - starting with fuel supply and ending with the formation of a working mixture and combustion. Because of this, its constituent components are very different from devices characteristic of the carburetor principle.

So, it includes:

- fuel tank;

- pump (gasoline pump);

- pipelines for supplying gasoline;

- fuel filters;

- fuel rail;

- tank filler cap;

- nozzles;

- recycling block.

VAZ 2114 fuel system diagram

They perform the following functions.

Tank - provides storage of fuel reserves.

Pump - located inside the gas tank and serves to pump fuel to the ramp. Thanks to the sensor connected to it, it detects and transmits data on the level of remaining gasoline to the electronic unit.

According to reviews from 2114 owners, the best pump for this car is a fuel pump from Bosch, which is characterized by a long service life and great reliability.

Pipeline system - serves to move fuel to the engine and drain the remaining excess into the tank. It includes a system of metal tubes and flexible hoses, among which are the VAZ 2114 fuel hose, return hose, hose for connecting the adsorber and others.

Filters - serve to purify gasoline from possible impurities and sediments. The service life of the injectors, as well as the quality of the resulting fuel mixture, directly depends on their operation. That is why they should be replaced at least every 10,000 km.

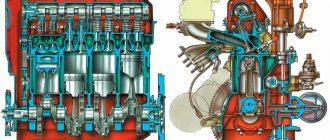

Injector device

The main task of the injection engine power system is to ensure the supply of the optimal amount of gasoline to the engine under different operating conditions. Gasoline is supplied to the engine using injectors that are installed in the intake manifold.

Injector power system design:

1. Electric fuel pump – installed in a module located in the fuel tank. The module also includes additional elements such as a fuel filter, a gasoline level sensor and a swirler.

The electric fuel pump is designed to pump gasoline from the fuel tank into the fuel supply line. The electric fuel pump is controlled using a controller via a relay.

2. Fuel filter - designed to clean fuel from dirt and impurities that can lead to uneven engine operation, unstable injector operation, and contamination of injectors. In injection systems, high demands are placed on fuel quality.

3. Fuel lines - serve to supply fuel from the fuel pump to the ramp and back from the ramp to the fuel tank. Accordingly, there are forward and return fuel lines.

4. Injector ramp with fuel injectors – the ramp design ensures uniform distribution of fuel among the injectors. The fuel rail contains injectors, a fuel pressure regulator and a pressure control fitting in the injector fuel system.

5. Fuel pressure regulator - designed to maintain an optimal pressure differential, which ensures that the amount of fuel injection depends only on the injection duration. The regulator supplies excess fuel back to the tank.

How does the fuel injection engine power system work?

For stable engine operation, it is necessary to ensure a balanced flow of the air-fuel mixture into the combustion chamber. The air-fuel mixture is prepared in the intake manifold by mixing gasoline with air. The controller, using a control pulse, opens the injector valve and, by changing the pulse duration, regulates the composition of the air-fuel mixture. The fuel pressure regulator maintains the fuel pressure differential constant, accordingly, the amount of fuel that is supplied is proportional to the time during which the injectors are open. The controller maintains the optimal air-fuel mixture ratio by changing the pulse duration. If the pulse duration increases, the mixture becomes richer; if it decreases, the mixture becomes leaner.

Many motorists, especially beginners who have just purchased a VAZ-2114, have wondered how the 8-valve injection engine that is installed on this car works. This article will discuss the design of the motor, its main characteristics, as well as dismantling and repair features. This information will be very useful for beginners and those who do not know how the main power unit works.

Video about the VAZ-2114 engine

What gasoline to use

This question is one of the most pressing for domestic car enthusiasts, because, on the one hand, gasoline prices are constantly rising, and you want to save money. But, on the other hand, the quality of fuel at most gas stations leaves much to be desired, and you don’t want to fill your car with anything.

That is why you should adhere to the basic principle - the 14th gasoline in the passport indicates exactly 95th gasoline, which means that this is what you need to fill it with.

Gasoline for VAZ 2114

As for bad fuel, if possible, you should choose from the nearest gas stations those that have the highest quality gasoline (based on the behavior of the car after refueling), and then refuel only at these stations.

True, you can also notice that many owners of the 2114 fill it exclusively with 92-grade gasoline and, according to them, do not see much of a difference in the operation of the car and in the rate of wear of the components of the gasoline system. Whether to follow these tips or use exclusively suitable fuel is up to everyone to decide for themselves.

System care

The power supply system of the VAZ 2114 is quite reliable, but at the same time it is a fragile design. When operating it, it is important to ensure that all components are securely connected to each other, that the fuel line pipes are not bent, and that the hoses are not leaking.

In addition, periodically (at least once a year) the fuel sensor located in the tank and connected to the pump should be removed and cleaned.

This is due to the fact that he:

- It is distinguished by great fragility.

- Subject to temperature changes.

- Affected by condensation.

- It actively oxidizes when there is any leak in the system.

As for the rest of the fuel path, caring for it consists of using high-quality fuel, periodic cleaning, timely replacement of filters, as well as washing the injectors, which must be done at least every 30,000 km.

This operation can be performed at almost any car service center, and it can be carried out in two different ways:

- washing with a special cleaner;

- ultrasonic cleaning.

Neither method requires dismantling the injectors or disassembling the fuel system, which is very convenient. At the same time, ultrasonic cleaning is a more radical solution - it can “bring back to life” even injectors that cannot be cleaned with a special liquid.

In conclusion, it is worth noting once again the obvious fact - it is better to carry out timely cleaning and minor repairs of fuel system elements than to subsequently carry out their expensive replacement.