Engine control unit: device, faults and diagnostics

One of the most important elements of almost all modern engines is the electronic control unit. This name is quite long, so it is shortened to Engine ECU. The unit has a complex structure, and its production is carried out by a limited number of companies. In fact, they own patents and limit the activities of other companies, but that’s another question. A competent car enthusiast should understand what an engine ECU is, what place it occupies in the structure of automotive systems, what elements are controlled by it and for what reasons it can fail. About all this - in the material Avto.pro.

Important note

Let us immediately note that ECUs generally mean all embedded systems that receive control signals from one or several vehicle systems and subsystems. It sounds quite complicated, so let's try to figure it out. For example, most vehicles use the following control systems and subsystems:

- ECM controller

. It is often called simply the engine control system controller; - ECM

. The same engine control module; - ECU

. Another electronic control unit, but this abbreviation usually denotes the basis of all electronic control systems of a car.

And again we return to the term ECU and its, so to speak, universality. There are many truly embedded control systems: the electronic engine control unit (the most common), the central control unit, the main electronic module, the central synchronization module, the integrated engine-transmission control unit, the suspension control module, the brake system control unit, and the body controller. And this is only a part of the possible options. Often all systems are combined under one term “car computer”. However, it is important to understand that:

- The electronic control system consists of many blocks and modules;

- Each block and module is specialized and cannot take on the tasks of another block and module.

Protection

To more reliably protect the engine control unit from polarity reversal of the battery fault and the generator battery, it is possible to install diodes (preferably excellent zener diodes with a stabilization voltage of 15 - 17 Volts) along the supply circuits in reverse connection.

Then reverse polarity and overvoltage will lead to failure of the fuses serving the power supply circuits of the ECU; the increased voltage or voltage of reverse polarity will not pass to the control unit, and this is the greatest danger.

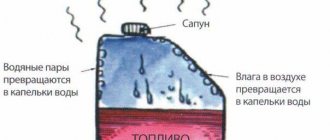

In order to protect the ECU from climatic influences, you need to monitor the quality of the sealant. After five years of operation, it is necessary to improve the seals, since the previous sealant may dry out in conditions of elevated temperatures under the hood.

Video - protection of the engine control unit of Renault Duster (Logan, Largus):

It is prohibited to block access to the unit with additional structures or place rags near it. This reduces the natural ventilation of the device, which becomes hot during vehicle operation.

More information about the ECU design

The electronic control unit, otherwise called the controller, or popularly the “brains” of the engine, is quite complex. Externally, it is a relatively small unit with a metal body, but all the most interesting things are hidden inside. The control unit includes the following elements:

- The processor part, otherwise called a microcomputer;

- Elements that generate signals, otherwise input and output shapers;

- Power supply;

- Multi-pole plug connector.

As the reader probably knows, the ECU works in tandem with many sensors. Here are some examples: throttle position sensor, mass air flow sensor, knock sensor. Almost all of these sensors are covered in separate materials in the “Useful Tips” section on Avto.pro – we recommend that you familiarize yourself with them. And we will continue analyzing the ECU.

Troubleshooting P0603

- Charge your car battery and erase the mistakes.

- Check both battery terminals, clean, restore contact.

- Check all fuses.

- Check the wire between the battery and the housing.

- Check the charging voltage with a digital multimeter (should be more than 14 volts at idle).

- Check "+" ECM/PCM.

- Check "−" on ECM/PCM.

- Check for water/corrosion inside the ECM/PCM.

- Check for corrosion in the control unit connector.

- Replace the ECM/PCM if it is faulty.

How the processor part works

The basis of the processor part of the ECU is a single-chip microcomputer (microelectronic computer). In fact, this is the very “brain” of the electronic engine control unit. By modern standards, a microcomputer is designed quite simply. The fact is that its key elements are included in a structure that fits on one crystal (chip). An important point in describing a microcomputer is its capacity. Bit capacity refers to the number of bits of information that the microprocessor will operate with. There are microcomputers 8-

,

16-

and

32-bit

. The devices themselves include:

- Central process;

- Read-only memory (abbr. ROM);

- Analog-to-digital converter (abbr. ADC);

- Random access memory (abbr. RAM);

- Input and output ports;

- Clock generator;

- Timers, otherwise called counters.

A parallel can be drawn between a modern computer and the processor part of the ECU

. In fact, the ECU combines a number of components that come separately from each other in the system unit of personal computers and laptops, but are combined by the motherboard. There are interesting features here, but we will not consider them - it is important for a car enthusiast to understand that the circuit diagrams of modern electronic computers are very similar to each other.

The central processor of the computer selects commands and data from memory and performs various operations on this data. In addition, it controls signals passing through the internal address and data bus. Read-only storage is where programs and data are stored. The information is in the form of constants. The program itself is written in the form of microcomputer machine codes. The data are calibration tables of constants involved in the calculation process. Data from tables can also be selected as control parameters. Interestingly, data in ROM is stored indefinitely

. Random access memory takes on the task of storing data that may change. For example, intermediate results of calculations or values received from sensors. RAM can store information for a limited period of time - it is erased after the power is turned off.

Causes of P0603

The most common cause of this trouble code is water intrusion, which damages the control unit. There may also be a short circuit in the ECU wiring that damages the internal parts of the controller.

You should always check/measure all connections before changing the ECM as if the short circuit is still there you may also damage your new ECM/PCM.

- Low battery voltage.

- Poor connection at battery terminals.

- Keep Alive Memory (KAM) module error in ECM/PCM.

- Water entering the ECM/PCM.

- Faulty ECM/PCM power wire.

- Faulty ECM/PCM ground wire

- ECM/PCM software error.

- Charging problems (alternator, rectifier, wiring).

How input and output signal conditioners work

As already stated, there is no point in an ECU if there are no sensors connected to it. They measure physical parameters, convert the measurement results into an electrical signal and then send it to the control unit. The signal from the sensor passes through a shaper, in which it is amplified or attenuated - this is called level matching. Input drivers also protect the ECU from overvoltage. Shapers work with the following signals:

Shapers are divided into subtypes depending on what signals they work with. This is due to the fact that different types of signals have different parameters

. For example:

- Analog signals change continuously over time. An example is the signal from the throttle position sensor. Continuously incoming signals pass through processing into the formers, and then go to the analog-to-digital converter and to the processor part of the ECU;

- Discrete signals change abruptly and are intermittent. As an example, we can take the ignition switch signal. Its changes occur abruptly, and the signal itself enters first the converter, and then directly to the processor part of the ECU;

- Frequency signals are the most interesting. They don't just change the frequency - these changes themselves carry information about real changes in the quantities that the sensor measures. Accordingly, the processing of these signals will be difficult. First, they are limited in amplitude and then fed to the timer input.

Special microcircuits, otherwise called drivers, are responsible for generating output signals. They amplify the power signals and also protect the controller outputs from short circuits

and

overloads

. Drivers are often called “smart” because if they operate abnormally, they inform the central processor that an error has occurred. Output shapers are divided into subtypes according to the power of the signal with which they work.

How to Diagnose Code P0603

This is a guide on how a professional auto mechanic can solve this problem. It may require some automotive electronics skills and some tools, but it can help you even if you don't know much about cars.

Always connect the car charger when diagnosing your vehicle. Low voltage can cause other fault codes and even damage control units.

- Visually inspect the battery terminals to see if they are loose. Check the wire between the battery and the housing. Clean the contacts if you see corrosion or poor connections. Check grounding points and clean controller connector.

- Connect the car charger to the battery and make sure it charges the battery. Let it charge for a while.

- Connect the OBD2 scanner and read the P0603 code. Erase the code and restart the ignition. Check if an error code is returned. Drive it a few times to see if the problem goes away or if P0603 keeps coming back. If the problem still occurs, continue troubleshooting.

- Measure the voltage between the battery terminals at idle (> 14 Volts) and with the engine off (> 12 Volts) using a digital multimeter. Replace any damaged fuses.

- Disconnect the ECM/PCM connector and find the pinout diagram for its connector. Measure 12 volts on all power wires and make sure the ground pins are OK. Check for short circuits.

- Open the control box and check for visible damage/water ingress.

If all power, ground, battery/alternator voltage wires are ok and you cannot detect any short circuits, it may be an internal fault in the engine control module. You can either have it repaired or replace it.

In newer cars, the ECU usually has an immobilizer built into it, and you cannot replace it without programming it. Some control units can only be programmed once. If you buy a used control unit, you cannot program it twice. However, some services have tools for flashing them, but this requires additional work. Buying a new ECU is always the easiest choice. Old parameters should always be read from the old control unit before installing a new one.

Device malfunctions

Due to the fact that the ECU is the key control element of the power unit, its malfunctions immediately affect the operation of the unit and the car enthusiast cannot fail to notice the problem. Another thing is to diagnose the device. Often the problem lies not in the control unit itself, but in the wiring and specific sensors. There are quite a few reasons why the ECU itself can fail. Here are the most common:

- Short circuit of one or more solenoids;

- Strong mechanical impacts or vibrations, the results of which are the appearance of cracks in the ECU board and at the soldering points of the contacts;

- Overheating of the electronic unit due to sudden temperature changes - from low to high (this is sometimes observed in cars operated in extreme cold);

- Moisture entering the device and causing corrosion

Purpose of the electronic control unit

The ECU uses signals sent by sensors installed on the power unit to adjust the composition and amount of fuel entering the engine. During its operation, the engine operating mode is set and the fuel mixtures are accurately dosed.

As a result of the functioning of the controller, engine operation is stable both when cold and after warming up. It is impossible to start the engine if there is a breakdown in the ECU or if its control signals are missing.

- injection system ignition coils;

- idle speed valve;

- electric injectors;

- fuel tank ventilation valve;

- electromagnetic coils - solenoids;

- turbocharging;

- intake-exhaust system;

- exhaust gas recirculation;

- cooling system.

The electronic device is an integral part of the vehicle’s on-board equipment; it is in constant information communication with the following important systems:

- Anti-lock system.

- Automatic transmission.

- Stabilizing system.

- Car security system.

- Cruise control.

- Climate control.

Self-diagnosis

You can determine some ECU malfunctions yourself. Or at least understand whether he is showing “signs of life.” This is also possible thanks to the self-diagnosis system that almost all control units have. If a car enthusiast wants to carry out independent diagnostics, he will need a special tester or a computer with a pre-installed program. It will be easy to find on the Internet. In addition, you will need an adapter. Here's what to do:

- Connect the adapter to the USB port of the computer and to the output of the electronic unit;

- Turn on the ignition (it is not necessary to start the engine itself);

- Run the previously downloaded and installed diagnostic scan on your computer;

- Watch for a message to start diagnostics to appear on the screen. If it is not there, check the connection is secure;

- Go to the DTC section (may have a different name depending on the program) - it contains the codes of all faults. The codes are encrypted, and you can decipher them in the same program or using data from the technical documentation for your car.

Unfortunately, there are times when the computer cannot be connected to the unit. In this case, the car enthusiast will need an oscilloscope, a cable and specialized software. It’s not difficult to find the necessary software, but with an oscilloscope

may have problems. Next, diagnostics will need to be continued using a tester or multimeter. The car enthusiast will have to carefully study the electrical circuit of the controller and measure the resistance. It is best to turn to specialists, but if the car enthusiast is well versed in electrical engineering and has a lot of time for diagnostics, he can identify the problem on his own.

What does P0603 mean?

P0603 is triggered when there is an internal fault in the Keep Alive Memory (KAM) module or the control unit power/ground is faulty.

The engine control unit or ECU in English is called Engine Control Unit (ECM) / Powertrain Control Unit (PCM).

When you drive a car, the engine control unit receives information from a large number of sensors. The ECU senses how you drive your car and optimizes the injection composition and timing.

RAM is used to store these settings to optimize fuel economy and other settings based on your driving.

Trouble code P0603 is a generic trouble code that applies to all vehicle makes and models since 1996.

If you disconnect the battery terminal, the power to the KAM memory will be lost and the information will be erased. The car will go back to default mode without optimization and will have to go through training again.

Every time you start the car, the ECM tries to read the memory from the CAM. If it fails to read the memory several times/attempts, it will throw trouble code P0603. If there is a P0603, the engine will run in default mode and will not optimize/learn while driving.

Conclusion

The engine ECU is perhaps the most critical element of a car's on-board electrical system. Thanks to it, the power unit has optimal performance, exhaust composition and high stability. ECU malfunctions occur frequently, but in most cases they are caused by a problem with some electrical or electromechanical element of the car. If the problem lies precisely in the ECU, then often the only way to solve it is... an expensive replacement of the unit. We advise you to contact trusted specialists for diagnostics, and only then make plans for purchasing the necessary spare parts and their further installation.

If you liked the publication, share the news on social networks and subscribe to the

channel .

Source

Purpose of the electronic control unit

The ECU uses signals sent by sensors installed on the power unit to adjust the composition and amount of fuel entering the engine. During its operation, the engine operating mode is set and the fuel mixtures are accurately dosed.

As a result of the functioning of the controller, engine operation is stable both when cold and after warming up. It is impossible to start the engine if there is a breakdown in the ECU or if its control signals are missing.

- injection system ignition coils;

- idle speed valve;

- electric injectors;

- fuel tank ventilation valve;

- electromagnetic coils - solenoids;

- turbocharging;

- intake-exhaust system;

- exhaust gas recirculation;

- cooling system.

The electronic device is an integral part of the vehicle’s on-board equipment; it is in constant information communication with the following important systems:

- Anti-lock system.

- Automatic transmission.

- Stabilizing system.

- Car security system.

- Cruise control.

- Climate control.