Causes of failure and how to check the cylinder head gasket

The consequences for the engine can be disastrous even when driving a car with this problem for a short time.

If the breakdown of the cylinder head gasket is ignored, even after a short mileage, a major overhaul becomes necessary. This breakdown can occur in both a gasoline and diesel engine, in a turbocharged or naturally aspirated unit. Gasket failure requires correct and timely diagnosis. An increase in fuel consumption, difficult engine starting and unstable operation, a decrease in internal combustion engine power, a drop in the coolant level in the expansion tank, and low compression in the cylinders can indicate a problem at an early stage.

The most common causes of breakdown or burnout of the cylinder head gasket are:

- engine overheating;

- incorrect installation when replacing the gasket;

- consequences of power tuning of internal combustion engines;

- the tightening force of the cylinder head bolts does not meet the standards;

- driving on low quality gasoline, which is accompanied by detonation;

Engine overheating is the main cause of cylinder head gasket failure. Engine overheating occurs for various reasons, ranging from a malfunction of the cooling system to phenomena such as engine detonation or glow ignition. Both metal (asbestos) gaskets and paronite gaskets in such conditions usually cannot withstand the rising temperature during overheating and burn out. After such a burnout, the strength of the gasket becomes less and it blows out.

It is noteworthy that among the indirect signs of a burnt-out cylinder head gasket, in some cases an increase in engine temperature, that is, overheating, was noted. A breakdown of the combustion chamber edging on the gasket leads to hot gases breaking into the engine cooling system and overheating the antifreeze. It turns out that overheating of the engine often damages the gasket, and then a breakdown of the gasket provokes an increase in engine temperature.

The list of consequences of overheating of the power unit also includes curvature of the cylinder head, or rather its plane. In everyday life, the definition “cylinder head led” is found. Most often, the block head suffers from overheating if the material used for its manufacture is aluminum alloy. Note that cast iron heads are more resistant to high temperatures, although in some cases cracks may occur.

Signs of a burned out cylinder head gasket

Burnout of the cylinder head gasket on passenger cars, if this happens, will cause a lot of trouble for car owners.

The main sad news is that the operation of the machine becomes unacceptable.

Be careful! Take the following signs seriously, and if they appear, then you should stop using your car and take measures for qualified repairs:

- if the temperature of the coolant rises and antifreeze (antifreeze) begins to boil;

- the engine starts to stall, traction disappears;

- The interior stops being warmed up by the heating system, as the system becomes airier and the heater motor drives cold air.

But there is still hope, albeit scanty, that the signs of a burnt-out cylinder head gasket will not be confirmed.

How to figure out how to find out the true cause of the malfunction?

Cylinder head gasket defects

No manufacturer can absolutely guarantee a long service life, since the formation of defects is influenced by many factors - engine condition, car model, driving style. Among the main defects, it is worth highlighting breakdown and burnout of the element in question. Why does the cylinder head gasket break, and what reasons can cause a burnout?

Almost all drivers do not notice a burst gasket until a serious breakdown makes itself felt. Parts of domestic cars are more susceptible to breakdown, since traditionally their quality is much lower than imported ones.

The need for repairs may be indicated by the presence of steam under the hood and noise when the engine is running, which was not there before. These signs of a broken cylinder head gasket indicate an external breakdown.

An internal breakdown is much more dangerous due to its invisibility. The problem can be detected by measuring compression in the cylinders, and drivers often perform such diagnostics when the engine is shaking.

Air bubbles in the radiator fluid and the presence of white steam in the exhaust pipe also indicate a problem. Oil may leak at the joints in the engine.

When it comes to causes, driving negligence is one of the most common. Let's look at them in more detail:

- Engine overheating will immediately make itself felt if the gasket is asbestos with the addition of metal. It cannot withstand high temperatures and swells at the first overheat. A leak forms after several heating/cooling cycles, as the strength decreases at the site of the bulge.

- Deformation of the plane of the head, which is adjacent to the block. This problem is common among aluminum heads. Cast iron immediately cracks. Replacement in this case is not necessary; repair will consist of grinding using a high-precision machine.

- Incorrect or uneven tightening of the mounting bolts will result in loss of clamping force. The breakdown occurs precisely in this zone.

- The quality of the gasket itself also plays an important role. Using a non-original gasket is not a way to save money, but a reason to replace it after several thousand kilometers.

As for burnout, the problem area is considered to be the area between the water jacket and one of the cylinders. As the burn gets worse, it spreads further. Among other possible options, it is worth highlighting the area between the cooling channel and the oil channel. If we are talking about a new engine, there is only one cause of burnout, and it is overheating, even if it is minor. A driver without experience will not pay attention to the first symptoms of a breakdown, and only worsening symptoms will force him to pay attention to the problem.

Since the car will not be sent to the service station immediately after the cylinder head gasket has burned out, but after further use, the burnout is not associated with recent overheating, and the search for causes continues in the wrong direction. Slight overheating of the head may occur if the coolant is filled in insufficiently.

Circulation in the system allows the liquid to cool, but heat removal in the required volume does not occur. The temperature of the liquid is displayed by the car's instruments, and at first glance everything is fine, but the temperature of the parts is not displayed. Consequently, the driver will not even notice how the gasket burns out due to overheating.

Other reasons relate to omissions after repair work:

- incorrect selection of gasket thickness;

- violation of the bolt tightening sequence;

- Excessive or too little tension when tightening;

- poor condition of the mating surfaces (presence of scratches or holes, remnants of an old gasket, deformation of the head).

Since we are talking about two main defects in the cylinder head gasket, the signs of their manifestation should also be considered separately. If the cylinder head gasket is blown, the symptoms will be as follows:

- Engine oil is mixed with antifreeze, and fuel enters the coolant. An alarming signal may be oily spots in the expansion tank of the cooling system.

- If the combustion chamber edging is pierced, the engine temperature rises. Next, burning gases enter the cooling system, the antifreeze heats up, and active gas formation occurs.

- The presence of antifreeze or moisture in the combustion chamber may be indicated by white smoke in the muffler. This symptom is characteristic of a gap between the combustion chamber and the cooling jacket channel.

- When the outer shell ruptures, oil leaks appear at the junction of the head and cylinder block.

- Starting the engine can be problematic because the exhaust gases from one cylinder mix with the fuel mixture of the other. After warming up, the stability of the motor does not cause any complaints.

The following changes in the operation of the machine indicate burnout:

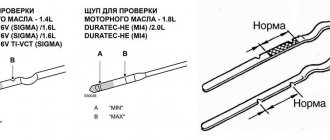

- Drops of water or a water-oil emulsion appear on the engine dipstick, therefore, the burnout is localized between the cooling and oil channels. When oil is mixed with coolant, a kind of emulsion is formed, which cannot be ignored when pulling out the oil dipstick. If little liquid has entered, delamination may occur after stopping due to the instability of the emulsion. If you loosen the oil pan plug slightly, you will see water first and then oil will seep out. There will be condensation on the dipstick and internal parts of the motor, resulting from the evaporation of some of the liquid. If drops of condensation form regularly, there is no doubt about burnout. An oily film in the expansion tank on the surface of the antifreeze will also indicate a problem.

- The instability of engine temperatures is associated with the temperature of the antifreeze. If a small amount of gas enters the cooling system, it can escape through the valve to the outside, but the antifreeze will not be knocked out. Only some of the gases will accumulate in front of the thermostat, but heat transfer to the coolant will be partially blocked. As a result, the thermostat responds too late and the motor overheats. The temperature drops sharply when the thermostat turns on, and everything starts all over again. If such temperature jumps are not accompanied by bubbles in the expansion tank, the problem may be in the thermostat and not in the gasket.

- If cold air comes from the heater, the problem is easy to recognize, but it does not appear on all cars. In some cases, escaping gases may have time to escape through the valve of the expansion tank plug. In other cases, they create an air lock that blocks the heating of the air leaving the stove. It is possible to detect the problem in the cold season, provided that the stove is actively used.

- If the coolant is knocked out, but there are no signs of leakage, the integrity of the gasket is clearly compromised, and the burnout is localized between the coolant channel and the combustion chamber. It is prohibited to open the expansion tank cap while the engine is running. The engine must be turned off and wait for the pressure in the system to decrease, otherwise the escaping antifreeze can cause severe burns.

Before starting repair work to replace the cylinder head gasket, we recommend checking it for damage using the following methods:

- Magnetic powder diagnostics is considered the fastest and easiest method. Install magnets on all sides of the cylinder head and sprinkle the cylinder head with metal shavings. It will move to the magnets, but will remain in the defect zone.

- Pressure testing without immersion in water involves using a soap solution. It must be poured onto the plane of the cylinder head cover and compressed air supplied to the circuit. The appearance of bubbles indicates microcracks.

- Applying immersion pressure involves completely submerging the head in a container of hot water. Next, compressed air is supplied using the same principle, and bubbles will indicate defects.

- Water can also be tested without immersion. Close the holes tightly and pour water into the channel. Pump air to ensure a minimum pressure of 0.7 MPa. After 2 - 3 hours, check for water. If it is not there, the gasket is defective.

How to find out if the cylinder head gasket is blown

A driver with any experience can check the cylinder head gasket for breakdown without removing it from the engine. Modern cars will notify you of a malfunction by the appearance of a Check icon on the dashboard. The check can be carried out in the simplest ways.

Using a bag, glove or balloon

If the cylinder head gasket is breached, recirculated gases can enter the water cooling system. The test is carried out using rubber products and a plastic bag. Need to:

- Open the expansion tank.

- Stretch a balloon over the neck.

- Start the engine.

If the ball begins to fill with air, this is the first sign of a breakdown of the cylinder head element. Exhaust gas can also be determined by the concentration of white, thick steam in the tank. It is enough to warm up the engine to a temperature of 25-40 degrees; the pressure will force gases to penetrate into the cooling system through a weak spot under the head.

Checking the cylinder head gasket using a rubber product

Using a bottle

This method is very similar to testing for breakdown using a ball. You will need a plastic bottle filled above half with water. Next you will need:

- Place the hose coming from the expansion tank into a container filled with liquid.

- Start the unit.

Checking the cylinder head gasket using a bottle of water.

A breakdown of the gasket will be indicated by air bubbles from the breather hose.

Signs of a broken cylinder head gasket

If the cylinder head gasket has burned out or is punctured, then the list of main symptoms of such a malfunction includes:

- gas breakthrough or leaks in the area where the head meets the cylinder block;

- the appearance of an emulsion in the engine lubrication system;

- the engine begins to smoke white smoke;

- oil and/or exhaust gases entering the engine cooling system;

If exhaust gases break through at the place where the cylinder head meets the cylinder block, then this is a clear sign of a broken cylinder head gasket. This phenomenon is also accompanied by a significant increase in noise during engine operation. A noticeable escape of exhaust gases through a broken gasket is not common, but it is quite easy to diagnose.

- The appearance of brownish-white foam on the oil dipstick, as well as a white emulsion on the oil filler cap, indicates that coolant is penetrating the engine lubrication system. Coolant can enter the oil system in two ways: through the cylinder head gasket, and also in the event of a crack in the cylinder block. Liquid from the cooling system dilutes the engine oil, which leads to a significant deterioration in its protective properties.

- If the engine constantly smokes thick white smoke (after warming up and reaching operating temperatures), then there is a high probability of coolant getting into the cylinders of the power unit. This happens due to the fact that the liquid passes into the gap in the gasket between the channel of the engine cooling jacket and the combustion chamber of the power unit. At the same time, the coolant level in the expansion tank decreases, since part of the liquid evaporates during engine operation. Note that at an early stage the engine often runs stably, the coolant drains slowly, but after some time the defect becomes more serious. In some cases, excessive coolant entering the cylinders can lead to water hammer, since the antifreeze or antifreeze in the cooling system contains about 40-50% distilled water.

We also recommend reading a separate article abouthow to diagnose engine malfunctions by the color of the exhaust gases

. From this article, using a diesel internal combustion engine as an example, you will learn about the reasons why an engine can smoke white exhaust.

- The presence of oil stains that are noticeable on the surface of the coolant after unscrewing the expansion tank cap, as well as traces of engine oil in the radiator of the cooling system, often indicate problems with the cylinder head gasket. The penetration of exhaust gases into the cooling system can be determined by the formation of bubbles that are constantly visible in the expansion tank or radiator during engine operation. Such bubbling of the coolant is a sign of a gasket leak.

It is more difficult to diagnose a breakdown or leakage of the cylinder head gasket if the defect is localized between the cylinders. If the cylinder head gasket is burnt out, symptoms in this case may not appear on the outside, and the problem itself is accompanied only by indirect signs: fuel consumption increases, the engine runs unstably and stalls, and there is a drop in power.

It is worth adding that in the event of a burnout of the head gasket between the combustion chambers, mixing of exhaust gases and the fuel-air mixture in adjacent cylinders may occur. More often, the malfunction manifests itself in the form of unstable operation of a cold engine, which normalizes after warming up. These malfunctions in the operation of the internal combustion engine can be caused by various problems.

Why does the cylinder head gasket break?

The cause of the breakdown may be natural aging of the engine, but more often it is due to violation of operating rules or gross errors during repairs.

Engine overheating

The engine head and cylinder block are made of materials with very similar thermal expansion coefficients. Therefore, massive parts tightly pulled together behave as one whole. But this is only possible with uniform heating within acceptable limits.

In practice, there may be cases where overheating is local in nature. Heat removal from some areas is more effective, others heat up more, and thermal deformations occur.

The aluminum head suffers especially; its lower plane, theoretically ideal to within hundredths of a millimeter, becomes more like an airplane propeller.

On topic: How to bleed a car’s clutch yourself

An unevenly pressed gasket cannot correct such a defect; breakthrough of gases and liquids is inevitable. Curvature appears precisely when overheating, since in normal mode and at the design temperature, uniformity is inherent in the design.

Aluminum cylinder blocks are also as lightweight as possible; their rigidity is not enough at extreme temperatures, and recently cast iron blocks are no longer produced. As a result, irreversible violations of the geometry occur, which immediately leads to failure of the gasket, which is not able to seal the joint of two surfaces of arbitrary shape.

Incorrect torque when tightening the head bolts

In order to qualitatively and evenly press the gasket material onto both planes, a strictly defined technique for tightening powerful head bolts is used.

The fastener is pulled sequentially in several steps, gradually compressing the joint. The force here is such that apparently massive parts are deformed, and this process cannot be brought to irreversible levels.

To maintain uniform tension, the bolts are made using a strictly defined technology, which requires that they begin to reach the yield threshold of the material at the moment the calculated longitudinal force is created.

The tightening is carried out first by increasing torque, and then by turning it at certain angles. The bolt rod leaves the zone of elastic deformation and begins to “flow”, that is, further turning does not cause an increase in the torque on the key. Once in this zone, it is guaranteed that the bolt will no longer loosen during engine operation and will not require post-break-in pulling.

Violation of this technology in order and torque will lead to uneven pressure, deformations, loosening of fasteners and subsequent burnout.

Poor quality material

When purchasing a gasket as a spare part, you can easily end up with a known counterfeit product or simply a cheap, low-quality product.

Replacing the cylinder head gasket

There are no difficulties in replacing the gasket yourself, but the procedure requires care and attention.

You must follow the step-by-step instructions:

- Disconnect all attachments, interfering parts and piping.

- Clean the fastening bolts from dirt and oil accumulations.

- Unscrew the bolts, starting from the middle, one turn at a time to relieve tension.

- Remove the cylinder head and get rid of the old gasket.

- Clean the seat thoroughly and install a new gasket. It must fully correspond to the guide bushings and marked centering grooves.

- Reinstall the head and begin tightening the bolts. At this stage, use a torque wrench and strictly follow the diagram provided by the manufacturer specifically for your car. The bolt torque settings must match your car exactly, otherwise the gasket will soon burn out. It is advisable to find out in advance the tightening torque for your car and check whether the new gasket meets the required parameters.

- After assembling the engine, the attachments can be returned to their places and connected.

How to check if the cylinder head gasket is blown

Almost all possible methods were indirectly discussed above. Based on this, we will summarize the methods for determining a breakdown. The following is checked:

- cooling radiator for release of exhaust gas bubbles;

- oil filler plugs for the presence of emulsion;

- spark plugs for carbon deposits;

- joint of the block and cylinder head for leaks.

Knowing how to find out if the cylinder head gasket is broken, it is necessary to carry out diagnostics when the first signs of a breakdown appear in order to eliminate the consequences. And they won’t keep you waiting long, because spoiled motor oil cannot provide protection to engine parts.

How to change the cylinder head gasket correctly

Let's start with the fact that removing the cylinder head on some engines is a complex and time-consuming procedure that requires draining fluids and dismantling individual units and components. When replacing the cylinder head gasket, you must make sure that the head has the most even plane of contact with the cylinder block.

Dirt, deep scratches and other defects are not allowed on adjacent surfaces. If the block head has been ground, then it is necessary to separately take into account the thickness of the removed layer from the adjacent surface.

It is imperative to follow the recommended sequence and force when tightening the cylinder head bolts. To obtain accurate data, the engine manufacturer and cylinder head gasket manufacturers provide a diagram according to which it is necessary to tighten the fasteners. The recommended tightening force (torque) is also indicated.

If the cylinder head stud breaks off, but the gasket does not burn out, then the broken part must be unscrewed. After this, the bolt must be replaced with a new one. To remove a broken bolt, you can use a simple method that involves welding a metal tube to the remainder of the bolt.

As mentioned above, in the process of replacing the gasket, increased attention is paid to the fastening bolts, as well as correct tightening. The head must be tightened only with the recommended torque according to a clearly defined pattern (sequence). Over-tightening or under-tightening is unacceptable.

Overtightened cylinder head bolts can cause the head of the mounting bolt to come off. Loss of pressing force will mean that the head of the block does not fit tightly enough, a loss of tightness occurs and the gasket breaks again.

As for pulling the cylinder head after replacing the gasket, it is advisable to carry out this procedure after several tens of kilometers. During this time, the driver is obliged to closely monitor the engine and its operation. An engine with a new gasket must operate stably in all modes, the exhaust must be clean, and the operating temperature of the engine must not exceed the permissible limit.

The head must be pulled if there are any leaks in the area of the joint with the cylinder block. To do this, you need to use a torque wrench and tighten with the force recommended by the car manufacturer for tightening the head on a specific engine.

Which cylinder head gasket to choose

If the engine specification specifies a metal gasket, then that is what should be used. It will be most reliable to use an original spare part, but if you experiment, then for the better.

Many manufacturers produce products of even higher quality, not being limited by the peculiarities of mass production of cars. Their brands are easy to find through online reviews.

Usually they are also factory suppliers, but the goods are supplied according to their own catalog numbers. A list of analogues is available in the catalogs of major suppliers.

Metal or paronite cylinder head gasket: which is better?

Many car enthusiasts are wondering which cylinder head gasket is better, metal or paronite. According to experts and auto mechanics, a metal cylinder head gasket can withstand greater loads compared to a reinforced paronite gasket. This is especially true for turbocharged engines and forced internal combustion engines, on which the paronite cylinder head gaskets are quickly blown out after installation.

If the engine is naturally aspirated, is in stock configuration and there are no plans for tuning it, then a metal-paronite gasket is a completely suitable option. Moreover, the undeniable advantage of such a gasket is the ability to slightly smooth out small nuances and unevenness of the adjacent surface.

It is also necessary to add that the walls between the groups of holes in the gaskets are very thin. For this reason, the service life of metal or paronite gaskets is primarily affected by correctness and accuracy during installation, and only then by the material of manufacture. The result of incorrect installation is that the gasket quickly burns out, after replacing the cylinder head gasket, the car does not start or the pistons knock. The latter case is more typical for diesel engines, when the piston can touch the edge of the gasket.

What is a cylinder head gasket, signs of its damage

The cylinder head gasket is a sealing element that serves to seal the connection between the cylinder head and the block itself. Thanks to it, the combustion chamber is separated from the cooling jacket channels through which the coolant circulates.

The main materials from which cylinder head gaskets are made are either thin sheet metal or reinforced paronite, which has additional metallized rings located at the locations of the combustion chamber openings.

It is for this reason (thin-layer material and very high loads) that situations where the cylinder block gasket is damaged or burns out are not so rare.

Cylinder head gasket VAZ

So, by what indirect signs can a car enthusiast find out that the cylinder head gasket of a VAZ 2114 has burned out? In fact, there are quite a few of them, and just one of them will not solve the problem (if the gasket damage is really to blame).

These signs are as follows:

- light or almost white exhaust smoke;

- abundant carbon deposits on candles;

- exhaust gases penetrate into the expansion tank, due to which a viscous emulsion is formed in it;

- the expansion tank, as well as the pipes, are inflated;

- the oil cap begins to become covered with a white coating;

- the stove heats poorly;

- the coolant is covered in oil stains;

- the coolant bubbles when the engine is on;

- The engine oil level rises and its color also changes.

The cylinder head burned out

If similar signs of burnout of the cylinder head gasket of a VAZ 2114 are found (and there are several of them at once), then the gasket is definitely damaged and should be replaced with a new one. If only one sign is present, then you can perform a check and accurately determine whether it is suitable for further use or not.

Why did the cylinder head gasket burn out?

The requirements for both gasket materials and their production technologies are very high and increase with the growth of engine power.

The essence of all gasket defects encountered in practice is in the sealing pattern of the joint between the block and the cylinder head. Indeed, the gasket must simultaneously provide a gas seal (cylinder cavity), water seal (cooling system channels) and oil seal (oil system channels). The proximity of these channels and cavities to each other can obviously lead to internal leaks. But external leakage is also not a gift.

A cylinder head gasket can lose its seal for many reasons. But the main ones still remain violations of operating rules, technology for car maintenance and repair. It is equally important to note that the external manifestations of a faulty cylinder head gasket are also very diverse. One might even say that one symptom rarely appears independently of another. But, taken together, they make it possible to diagnose and fairly accurately determine the cause of the malfunction.

Of course, correct diagnosis requires experience and knowledge of the engine, including the design and operating processes occurring inside it. And then, based on detected traces of oil or coolant, changes in the color of liquids or parts, carbon deposits, traces of compression, burning or erosion on the surface of parts, the truth will be established.

Defects in gaskets after long-term use of a car are most often associated with malfunctions of the cooling system that were not noticed and not corrected in time, less often with disturbances in the combustion process (detonation is a rapid process of combustion of the fuel mixture in the cylinder approaching an explosion, glow ignition). On the contrary, after an engine repair, according to statistics, in more than 80% of cases the gasket is damaged due to improper tightening of the bolts (including due to non-compliance with the tightening torque and order).

Overheating is one of the main causes of gasket damage. And not only them: when overheating, the plane of the head, and sometimes the cylinder block, is often deformed.

But first of all, the block head suffers, of course. In addition to local overheating of individual sections of the combustion chambers, which causes cracks, general heating of the head leads to an increase in the compression force of the gasket, since the aluminum alloy of the head expands more than the steel of the bolts. Once cooled, a compressed gasket may no longer provide a seal where the specific pressure (force per surface area) is too low. In fact, when overheated, a kind of “hardening” of the surface layers of the gasket occurs, as a result of which it loses its elasticity and can no longer ensure a seal between the head and the cylinder block along the entire plane.

Find the cause, i.e. It can be determined that the gasket has leaked due to engine overheating by inspecting it. Typically, in such cases, the surface of the gasket becomes hard, and in some places near the combustion chambers, charred.

Repair in this case is rarely limited to just replacing the gasket. In addition to processing the head plane, it would be a good idea to find the cause of overheating in the cooling system - perhaps there is a malfunction of the thermostat, fan, or simply a hose leak.

But let’s say the engine was very overheated, but the gasket seemed to hold up. In such situations, there are two options: either tempt fate by waiting for a leak to appear (and it most likely will), or immediately replace the gasket. The second solution will be more successful: after all, whatever one may say, a planned repair is better than an unexpected breakdown on the road.

If the gasket is not pressed properly, then it will definitely “leak”. This usually happens when the head bolts are not tightened properly. But such errors today are the exception rather than the rule: the necessary information is now available at any service station. It’s another matter when everything is tightened correctly and the gasket is not compressed. What's the matter?

The reasons usually lie in violations of basic repair technologies. For example, in repair manuals they write that the threaded part of the bolts must be lubricated with oil before tightening.

What if you don’t lubricate it? Then almost all of the tightening torque will be spent on overcoming the friction forces in the thread, and not at all on pressing the head to the block.

Maybe this is one of the reasons that on some modern engines the threaded part of the bolts is coated? These bolts do not need to be lubricated. But seriously, “solid” lubricant is much more effective and significantly improves the performance of bolts (remember that with conventional bolts only 20-25% of the torque is directly converted into tightening force).

It's even worse when the bolts are doused with too much oil. In this case, the well-known rule “you can’t spoil porridge with oil” will not work: the oil is incompressible, having filled the threaded hole, it simply will not let the bolt go further. And it’s good if the block doesn’t crack at the threaded holes.

On modern engines, bolts that operate at the yield point are often used. After one use, they should be replaced with new ones, since they can stretch unacceptably.

The fact that the gasket was not crimped properly can be easily detected when inspecting it. Often there are practically no signs of compression on it at all, and the thickness remains the same as that of a new gasket. In such cases, a leak appears within the first hours of engine operation, which indicates the true cause of the malfunction.

Prevention here is simple: you must strictly follow all the manufacturers’ recommendations regarding the torque, tightening order and replacement of bolts, as well as their lubrication before assembly.

It is known that, depending on the material and design, gaskets can “weaken” under the influence of temperature and vibration. And if, after some time of engine operation, the bolts are not re-tightened, the specific pressure at the junction of the head and the block may decrease unacceptably, after which the gasket will “leak”.

Not all engines and not all gaskets require retightening. But when such recommendations are given by the engine manufacturer, they must be followed strictly. If this is not done, a leak will appear after several thousand kilometers of the car, which will directly indicate the cause of such a malfunction.

Disturbances in the combustion process in the engine include detonation and glow ignition. Without going into their nature (this is a topic for a separate discussion), we point out that these phenomena cause a significant increase in temperature in certain areas of the combustion chamber. Excessive pressure in the cylinder, resulting from premature ignition of the fuel mixture, sharply increases the load on the cylinder head, “stretching” the bolts and thereby reducing the compressive force of the gasket. And the shock waves of detonation “knock” not only on the driver’s ears, but also on the cylinder head gasket surround.

The fact that it was a violation of the combustion process that caused the damage to the gasket can often be determined by its appearance. In such cases, it often burns out between the cylinders. Burnout along the edging is often accompanied by erosion of the surface of the block head and the edging itself near the damage. A change in the color of the gasket material near the surround may also indicate high temperature in the combustion chamber.

Mechanical problems. As you know, the cylinder head gasket is a very delicate part, easily damaged if handled carelessly. If it has obvious defects, then installing it is either dangerous or simply pointless - it will “leak” sooner or later anyway.

The same goes for trying to reuse an old gasket. Its material is already compressed and will never provide a reliable seal. Maybe it will be enough for several thousand kilometers, but this can only be considered as a temporary way out of the situation. Sometimes gasket burnout occurs due to foreign materials getting between it and the sealing surface. This may well happen if the planes of the head and block are not cleared of the remnants of the old gasket before installing a new one.

By the way, the same thing will happen if the planes turn out to be deformed - in places of “dips” the specific pressure will be unacceptably low, and eventually the seal will be broken. Therefore, before installing the gasket, checking the planes of the head and block is mandatory.

It is clear that the deformed plane must be processed, i.e. align. In some workshops, the heads are milled, in others they are ground, and in others they are ground on a plate with abrasive paste. Which way is better?

Let's figure it out together. If the surface is too rough, then leakage of working fluids and gases is possible. On the contrary, if the surface is excessively smooth, then the gasket may slip between the sealed parts and ultimately lose the seal. Therefore, when treating the surfaces of the head and block, not all products are good. It is desirable to ensure a certain optimal roughness, which mainly depends on the materials of the parts being sealed. Of course, these are general recommendations. But they can be used when other data, for example from the engine manufacturer, is not available.