Why does the engine temperature drop while driving?

But the problem has not gone away, and everything here has even become warmer, but the problem remains. Further interesting, no matter where I went, everyone said the same thing - thermostat!

At speed, the engine temperature drops. Note that a decrease in the temperature of the internal combustion engine while driving can also occur naturally and not be a consequence of any malfunction.

This usually manifests itself in the cold season, that is, during frosts. On many cars, when driving on the highway, the engine temperature drops, since the engine temperature drops when the Chevrolet Lacetti is driving and the front part of the engine compartment is open to blowing by oncoming air. This mode can be considered the most economical, that is, the minimum amount of fuel burns in the cylinders.

For ease of understanding, the lower the speed and the less fuel burned in the cylinders, the less heat the engine has.

Do not forget that in winter the driver constantly uses the stove in the cabin, which additionally takes away heat. This phenomenon is typical for entry-level and middle-class cars, which are often equipped with low-volume internal combustion engines and do not have additional hood insulation.

What is the operating temperature of the Lacetti 1.6?

It is also worth noting that many diesel engines do not heat up well at idle and can cool down noticeably while driving. It is especially noticeable on small cars and models equipped with medium-sized engines.

The situation is also typical for diesel engines, which not only do not warm up well at idle, but also cool down quickly when driving with insufficient intensity. The car heater has a special radiator, which is included in the general operating circuit of the cooling system. When the driver turns on the interior heating, antifreeze passes through it, giving off some of the heat.

Engine temperature drops when driving

The amount that will be given depends on the set temperature of the heater and its operating mode. The higher these indicators are, the more the interior of the car will heat up. If the engine operates at low speeds, and is also used in winter, there may simply not be enough heat to fully warm up the coolant.

Is it possible to slow down the drop in engine temperature when driving a Chevrolet Lacetti engine in cold weather? In the past, different materials were used to create engine insulation. These are the different felt fabrics available in circulation. But such decisions did not keep the heat for long. Modern thermal insulating car blankets are now used. Their composition prevents ignition, which has a positive effect on the safety of vehicle operation.

Also, numerous engine warm-ups will not be required.

This will save time and fuel. When the weather conditions are too harsh, such techniques will be able to retain heat in a short period of time. It is possible to use special covers for the radiator.

Its lower part, together with the pipe, must be thermally insulated in order to maintain a stable temperature of the running engine.

Actions to prepare the cooling system for winter The winter period of operation is difficult for all vehicle owners. Preparatory work will help you be fully prepared. Discussion closed by moderator Lexona The thermostat is located at the coolant outlet from the head, the coolant temperature is maximum here.

When the engine takes a long time to warm up

In winter, with the onset of frost, car owners have one experience replaced by another, and the latter is much more troublesome than the usual overheating of the engine. When it’s -20 -30 °C in the morning and the engine takes a long time to warm up, you can’t help but remember the beautiful, warm days. Well, it’s okay that the engine warms up a little, the main thing is that the fingers straighten! But the heat is still far away, and problems with the engine are already happening. In winter, there are three reasons why a diesel engine heats up slowly:

- The thermostat is made;

- An air lock has appeared in the coolant system;

- The motor is not insulated enough.

Checking the thermostat

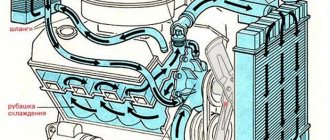

Designed to be sensitive to changes in temperature, regardless of changes in pressure in the coolant system, the service thermostat will limit the circulation of antifreeze to a small circuit through the cooling jacket of the block and cylinder head. As the temperature difference between the environment and the engine increases, the thermostat smoothly opens the coolant supply from the main radiator to the engine. This is exactly what happens in the opposite case. Thanks to this, the temperature limits of engine operation are maintained and limited, and the vehicle interior is heated.

Hydrodynamic and boundary lubrication: what are the differences?

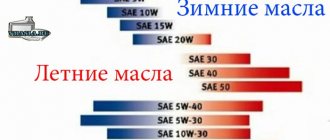

The hydrodynamic process occurs as follows: the oil fluid is pumped through a pump and, passing through a heat exchanger, reaches the crankshaft through the filtration system. These actions are performed under pressure, and if the engine operating temperature is normal, the lubricant travels all the way in a fraction of a second. At the beginning of rotation, a so-called oil wedge is created. It is formed due to the fact that lubricating fluid under strong pressure enters the gap between the crankshaft journals and the bearings.

Auto information panel

If the engine is started in the cold season, exactly the same processes occur in it. But due to its high viscosity, the oil cannot pass through the filter. As a result, the lubricating fluid passes through the bypass valve, causing the product to be partially unfiltered. However, this situation does not affect the normal operation of the engine. The design features of the motor ensure the passage of oxol to its parts, even if the filter blocks the flow of liquid. As the temperature rises, the viscosity decreases and the lubricant again begins to pass through the filter system without affecting the bypass valve.

A process called “boundary lubrication” involves constantly renewing the oil. In this case, a liquid containing anti-wear additives is used. This way, all engine parts that the oxol passes through without pressure are lubricated.

The lubricant is renewed by spraying through nozzles or by splashing. New generation engines have special cooling nozzles, which reduces the piston temperature. Boundary lubrication allows you to constantly remove used oil from parts of the mechanism and bring it a new portion.

Basic faults

If the sensor is working correctly, the needle moves smoothly, but if there is a problem, the movements will be sharp and jerky. With such work, not only can it be impossible to correctly assess the temperature position, but it can also cause damage to the engine and the entire system. Breakdowns can be different and happen in several places at once, but most often motorists encounter the following reasons:

- Thermostat failure.

- Malfunctions in the operation of the coolant temperature sensor.

- Malfunction of the indicator itself and the sensor needle.

- Short circuit in the electrical board.

These causes are arranged according to frequency of occurrence, so we advise you to make the same diagnosis. If it is possible to turn to a specialist for help, this will significantly reduce the time it takes to find and eliminate the cause.

Thermostat failure

The problem with the thermostat is the most common, and all because of the poor protection of this part. The fact is that it can break even on a new car. Some people talk about randomness, and others about the conditions of use. One way or another, it is worth understanding how this system works and how to check its serviceability.

Often such breakdowns occur at low temperatures, but can and will also occur in the opposite conditions (heat waves). When the car starts and the engine warms up, the sensor needle immediately jumps to the correct value, and then the thermostat opens. The coolant begins its movement through all components through the pipes, however, if the thermostat is broken, it shorts out and blocks further passage for the liquid. There are cases of complete closure of the thermostat valve, and there are cases of partial closure, but in both cases, prolonged operation of the engine will lead to overheating and the engine temperature sensor will jump.

To independently diagnose, you should check the thermal state of the supply pipes. In cases where the thermostat is stuck, the lower pipe will be colder than the top. This will prevent the coolant from making a large circle and the engine from starting to operate normally.

Coolant temperature sensor

The next most common breakdown is the coolant temperature sensor. Sometimes it may happen that a contact in it comes loose and data will not flow or will come with breaks in the circuit. Because of this, the needle will twitch, because for it the indicators jump sharply from the working value to zero. There is also a possibility that the sensor itself is broken and it simply cannot record data properly.

When each sensor is detected, you need to make sure that it is intact, as well as that the contacts are properly connected. To fix it, two people will be needed: one moves the contact, and the other monitors the arrow readings. If the arrow reacts to actions and starts jumping, then the problem is with this sensor.

Arrow and temperature sensor

In cases where the thermostat and the thermal sensor connection contact are in order, it is worth paying attention to the sensor indicator itself, there may be malfunctions in the integrity of these parts. In order to identify a breakdown, you need to have certain knowledge about the resistance and structure of this electrical mechanism

Because perhaps it is the poor condition of the sensor that makes the needle jump like crazy.

This knowledge can be studied independently on the Internet or in specialized books, where all operations and indicators are carefully described. But the best outcome, of course, would be to contact a specialist who already knows about all the intricacies of the sensor design.

Electrical board of instrument panel

If everything works well, but the temperature sensor still jumps, then all that remains is to disassemble the instrument panel and check the electrical board. If the soldering is broken or done poorly, it will lead to problems like this. If you plan to fix this problem yourself, we recommend taking a soldering iron with a thin rod and low power so as not to damage the board and adjacent parts.

It is also worth paying special attention to the output mass and resistors. And if you can’t do this kind of work yourself, then contact a specialist who will do it quickly and without errors.

Causes of engine overheating

Overheating can be caused by many reasons, all of them are related to a malfunction of the cooling system, or the quality of the coolant, as well as contamination of the cooling system jacket, which impairs the fluid throughput

It is important to use high-quality spare parts, otherwise the reasons below will happen suddenly. Let's consider each of the reasons

Low coolant level

The most common problem is a lack of coolant in the system. Coolant, in the form of antifreeze or antifreeze, constantly circulates through the system, removing heat from heated engine parts. If the coolant level is insufficient, the heat will not be removed sufficiently, which means an increase in temperature will be inevitable.

_

If it is not possible to add coolant, then turn on the heater to reduce the likelihood of overheating. As a last resort, add regular or distilled water, after which the cooling system must be flushed and then filled with fresh antifreeze. At temperatures above 90 degrees, you should immediately stop the car, turn off the ignition, and allow the engine to cool.

Electric cooling fan failed

The electric fan forces cool air onto the radiator, which is especially necessary when driving at low speeds when there is insufficient air flow. The fan can be installed either in front or behind the radiator. If the temperature arrow starts to rise, stop the car and check the fan for serviceability. Reasons for fan failure:

- electric motor failed

- connector oxidized

- fan relay burnt out

- The internal combustion engine temperature sensor has failed.

To check the fan, remove the connectors from it and connect the wires directly to the battery, which will allow you to determine the cause of the failure.

Thermostat malfunction

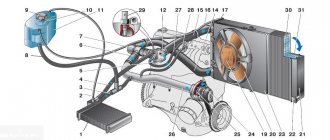

The thermostat is one of the main elements of the cooling system. The cooling system has two circuits: small and large. A small circuit means that fluid circulates only through the engine. In a large circuit, fluid circulates throughout the system. The thermostat helps you quickly reach and maintain operating temperature. Thanks to the sensitive element, which opens the valve at 90 degrees, the liquid enters a large circle, and vice versa. The thermostat is considered faulty in two cases:

- operating temperature of the coolant is not reached

- the power unit tends to overheat.

The thermostat can be located directly in the cylinder block, in a separate housing, or as one unit with a temperature sensor and pump.

Broken cooling fan belt

On vehicles with a longitudinally mounted engine, the fan can be driven by a drive belt from the crankshaft pulley. In this case, the fan works forcibly. The service life of the drive belt is from 30 to 120 thousand km. Typically, several units are driven by one belt. When a belt breaks, the internal combustion engine immediately tends to overheat, especially when the speed decreases. If you have a domestic car with a belt-driven fan, it is recommended to install an additional electric fan to avoid unpleasant incidents.

Dirty radiator

Once every 80-100 thousand kilometers it is necessary to flush the radiator along with the entire cooling system. The radiator becomes clogged for the following reasons:

- untimely replacement of antifreeze

- use of low-quality liquid

- application in water system

- application of cooling system sealant.

To wash the radiator, you should use special compounds that are added to old antifreeze; the engine runs on this “mixture” for 10-15 minutes, after which you need to remove water from the system. It is advisable to remove the radiator and wash it with water under pressure, inside and out.

The temperature needle drops. Why?

The most common problems are when the temperature of the unit increases uncontrollably, reaching critical values. The cause of overheating is a jammed thermostat, which does not allow the coolant to pass through the radiator. The heated antifreeze continues to circulate in a small circle until it boils.

The opposite situation often occurs when the engine temperature gauge drops while driving. Why? The point, again, is the quality of operation of the mentioned valve. If the thermostat cannot close all the way, allowing the fluid to continuously circulate in a large circle, the engine will not warm up to its operating temperature.

Sometimes the thermostat gets stuck after the engine has warmed up. When this happens, the driver may notice that the engine temperature drops while driving, although it should be maintained at a consistently even, operating level.

Sometimes the temperature regime changes abruptly, sometimes increases, sometimes decreases sharply. This means that the valve periodically jams, and the driver will notice a situation where the temperature arrow periodically drops.

Thermostat malfunctions

The thermostat is a consumable item, which means it cannot be repaired. You can carry out the replacement yourself or contact a car service center with this question. In the first case, only the cost of the device itself will be included in the costs. When contacting specialists, about 400 rubles will be added to this amount for the work of a car mechanic. The part is changed because there is nothing to repair in it. The most common malfunction is the failure of a solid-state temperature-sensitive element.

Before changing the thermostat or checking its performance, you need to know what malfunctions are typical for it. There are three signs that indicate a breakdown:

- The valve is stuck open. In this case, the coolant always circulates in a large circle, even when starting a cold engine. It takes much longer for the engine to warm up to operating temperature. In the summer, such a breakdown does not bring any inconvenience to the car owner, but with the onset of cold weather the engine may not warm up at all. The stove will not work as expected and fuel consumption will increase.

- The valve is stuck in the closed position. If the device cannot open, then the coolant circulates only in a small circle. The engine will constantly overheat, and there will be a risk of complete failure. Long-term operation of the vehicle with such a malfunction is prohibited. To prevent overheating, you can turn on the heater fan at maximum blowing speed and constantly monitor the engine temperature gauge.

- The valve opens earlier than it should. When the valve opens at a temperature of 70-75 degrees, the engine does not have time to warm up to operating temperature and spends more time and fuel on this.

The latter problem occurs rarely - mainly on devices that are not suitable for use on this car or are made in a homemade way.

Causes of malfunctions and ways to identify them

The most common problems:

- the appearance of corrosion on the moving elements of the device is rare, mainly when tap water is used instead of antifreeze;

- foreign objects entering the housing, contamination or scale formation;

- low quality antifreeze;

- Coolant pump malfunction.

There are several ways to test the thermostat. The following describes a method for testing the device without the need to dismantle it:

- Start the engine. Since in a working thermostat the valve should be closed, the lower radiator hose should be cold a few minutes after startup. If the hose is warm, this indicates that the valve is not tightly closed or completely open. The engine will take longer to warm up and consume more fuel.

- If the pipe begins to heat up after reaching operating temperature, then the thermostat is working. Or it is stuck with the valve closed - the engine will overheat and an urgent replacement will be needed.

All actions should be carried out with caution. During operation of the SOD, the pipes and the engine become very hot; accidental touching them can cause a serious burn.

When the small circle is operating, the radiator is not activated, the upper hot and lower cold pipes indicate problems, provided that the engine is warmed up. If the described manipulations do not give complete confidence in the operation of the unit, you can carry out a more thorough check, but this will require removing the thermostat from the car. This testing method looks like this:

- Place the device in a metal container filled with water and place it on the stove.

- Wait until the water is hot enough. At a temperature of about 60 degrees the valve will begin to open slightly. It will open completely at a temperature close to boiling – 90-95 degrees.

- Remove the device from the container and watch how the valve begins to close as it cools. Eventually it should close, blocking the channel completely.

If during the inspection, malfunctions in the operation of the valve were identified - it does not open, does not open completely, does not close tightly - it should be replaced.

Selecting and purchasing a thermostat for Kalina

Here I will not discuss what is better to buy and which thermostat to choose. Given the disgusting quality of most spare parts in stores, I do not consider it necessary to waste time on dubious tests and comparisons of parts from different manufacturers. I’ll just say one thing: I chose a factory-made thermoelement, that is, the element itself, and not the thermostat assembled with the housing.

If you do not have any problems with the body of this part, the thread for the sensor and thermoelement are in place, then you should not overpay 500 rubles on top. Feel free to buy an element that costs about 500 rubles for Kalina - the price of the factory one. When replacing it, there are much fewer problems with it; you only need a hexagon and a pair of heads with a knob for unscrewing the clamp screws.

As for the result of the work done, as expected, now there are no problems with the cooling system. The engine began to heat up much faster, and the operating temperature remains stable at 90 °C, and the on-board computer shows exactly these numbers.

As for the operation of the heater, it goes without saying that the higher the coolant temperature, the hotter it will be inside the car. Now it has become even warmer in my Kalina, which is what was required from this repair.

During the operation of the car, its owner has to deal with various malfunctions. As a rule, breakdowns that are somehow related to the operation of the power unit are of particular concern.

Even for beginners, it is not news that the car’s engine must warm up to its normal operating temperature, which is 90 degrees. This temperature regime is optimal.

5) Dirty radiator

If your car has driven more than 80 thousand km, then most likely the cooling radiator is very dirty, which can also cause the engine to overheat.

In order to avoid this, it is necessary to flush the radiator every year. It is advisable that, along with cleaning the radiator, the coolant itself is changed. Despite the fact that the manufacturer itself recommends changing antifreeze every 3 years, we, for our part, strongly recommend changing this coolant every year.

In conclusion, dear readers, we would like to once again remind all car enthusiasts that in addition to regularly checking the entire cooling system (especially before a long trip), it is necessary to periodically conduct a complete diagnostic of the operation of all the most important systems of the car. Don't forget to regularly check the oil level in your car engine. Remember that by maintaining the engine oil level at optimal values, you reduce the load on the engine itself and thereby prevent unnecessary overheating (heating) of the engine in advance.

The lower the load on the engine, the longer the service life of the vehicle's power unit. Good luck to you friends!

An internal combustion engine is a kind of furnace in which, during the combustion of working mixtures, the temperature in the cylinders reaches 2000 °C and higher. At such temperatures, the metal begins to lose its strength characteristics, which can lead to problems associated with the operation of the engine, or, in general, send it to the cemetery. To avoid such consequences, cars are equipped with a cooling system that limits the temperature limits of the engine, thereby ensuring the correct conditions for its operation. A car engine is a metal mechanism, which, unfortunately, is not perfect. And various types of failures in its operation are still present. The most famous are when the engine gets very hot, or, conversely, takes a long time to warm up. What causes this?

Why does the engine not warm up to operating temperature?

If the car engine does not warm up to 90 degrees during operation, it is necessary to urgently check its cooling system; most often the problem is related to it. The following faults can be identified that can lead to this kind of problem:

- Thermostat is not working properly. In a car engine, the thermostat is responsible for switching the direction of coolant flow. When the engine just starts, the coolant in it moves in a small circle, warming the engine up to operating temperature. When the engine temperature reaches approximately 90 degrees, the thermostat switches the direction of coolant flow to a large circle. If the thermostat gets stuck and does not fulfill its direct duty of switching the direction of coolant flow, this can lead to both overheating and overcooling of the engine. Accordingly, you need to check the thermostat, and if it is faulty, you will need to replace it with a new one;

- Air is sucked in through the pipes. If the pipes are not tightened properly, additional air from the atmosphere may enter the system. Most often, if there is a similar problem, you can see traces of coolant on the pipes, which partially flows through them. In such a situation, you need to tighten the clamps better and check the pipes for cracks and tightness;

- Error in the operation of the coolant temperature sensor. If the sensor provides incorrect information, the driver may be misled by the information displayed on the instrument panel. The scale will indicate that the engine is not warming up enough, although in fact this may not be the case. To avoid the possibility of this type of problem, you need to check the coolant temperature sensor and replace it if there are deviations from optimal results.

Above are the three most common reasons why the engine does not warm up to operating temperature (or the driver believes that the engine is not warm enough). In 95% of cases, the problem is related to the thermostat, which is recommended to be changed every 3 years or every 50 thousand kilometers.

(405 votes, average: 4.55 out of 5)

2) Electric cooling fan failed

If your car has an electric cooling fan and it fails (no rotation when the engine is hot), this can also lead to overheating of the car (engine).

The point here is this: the electric cooling fan transfers cold air from the street to the engine, which passes through the cooling radiator. The fan cools the engine while your car is moving at low speed, thereby helping the engine cool.

If while driving the car you see that the engine temperature has begun to rise and move towards the red danger zone, then please stop the car, then open the hood and check whether the cooling fan is working.(?) If the fan does not spin, then you It is necessary to find out on the spot the cause of the malfunction, which may be the following:

— Poor contact feeding the fan

In order to check the contact of the cooling fan, it is necessary to remove the wiring harness that powers the fan. Using two wires, power the fan directly from the battery. If the cause of the fan malfunction is the wiring harness, the cooling fan will work.

If your car does not have a radiator sensor, then this test method may not be suitable for you. Then, to detect a malfunction, you need to remove the electrical connector from the fan, and then you can close the contacts of the connector of the fan itself. If it is working properly, the fan will work.

— The fan switch sensor is faulty

Many, and especially modern cars, have a temperature sensor that turns on the cooling fan. This happens after the coolant temperature has reached its certain temperature.

I have contact

As electricians say, there can only be two faults: there is no contact where needed, or there is contact where it is not needed. This rule also applies in the situation under consideration. The arrow will jump if the joints are oxidized or weakened. Moreover, most often this happens when additional consumers are connected: low beam, headlights, etc.

As mentioned above, the first thing to do when diagnosing DTOZH is to check the contact in the connector. Returning to the previous section, the following should be added: if the sensor malfunctions, the readings fluctuate within the same range, and if they change chaotically, the wiring may be damaged. How important the negative contact is - the mass - will be confirmed by one case described by a forum participant.

The gauge needle sometimes jumped to 130°C. After stopping the engine, it showed the correct result - 90°. The voltage at the battery terminals when the engine was not running was about 12.5 V, and after starting it rose to 13.7.

After a year and a half of unsuccessfully searching for the cause, replacing the battery, alternator and two temperature sensors, I came across one grandpa who installed an additional ground wire from the engine to the body, and the problem was solved.

Principle of operation

Coolant enters the radiator through the thermostat. This is a large circle of fluid circulation. The thermostat usually opens at a temperature of 100 degrees Celsius. If the temperature has not reached this limit, then the liquid moves in a small circle. A thermostat malfunction is manifested by improper opening of the valves.

When the thermostat is closed, the engine overheats, and a constantly open one leads to low temperatures, since the liquid will only flow in a large circle.

Due to irregular changes of antifreeze or antifreeze, use of running water or mixing of coolants, various deposits in the form of scale may accumulate in the system. In this case, the thermostat will inevitably jam in one of its positions.

The engine temperature arrow does not rise, the engine temperature fluctuates, the engine cools down while driving

The time it takes for the engine to warm up to operating temperature may vary for each serviceable unit. This happens due to the fact that heating and its intensity depend on a number of conditions. The warm-up speed can be affected by the degree of engine boost, its type (gasoline/diesel), the general condition of the cooling system, the quality of the antifreeze or antifreeze poured in, the outside temperature, the degree of load while driving, the intensity of the heater in the cabin, and so on.

Let us add that many experts agree that different types of motor oils and their viscosity can also affect the overall heating of the engine, although only slightly. The operating temperature of the oil in a conventional engine is around 100-150 degrees, not exceeding the maximum threshold of about 200 degrees (all indicators are averaged). In parallel with this, the maximum oil temperature in the engine is determined by the flash point of the oil, its coking, etc.

It may seem that the temperature range will be the same for different oils, but this is not the case. Special additive packages that reduce friction losses and the base itself (synthetic, semi-synthetic) affect the degree of oil heating. In other words, low-viscosity oils cool rubbing couples better, but the lubricant itself heats up more. It turns out that with different engine oils, the temperature in the crankcase of the same internal combustion engine can differ by 5-7 degrees. If we take into account these features, then we can assume that with “liquid” synthetics, the engine will not only be easier to start in winter, but will also warm up faster.

So, let's return to the cooling system. A cold engine and a non-working heater in most cases are the consequences of thermostat malfunctions. If you notice that the power unit takes a very long time to heat up, the engine does not warm up to operating temperature, and the engine temperature gauge needle drops while driving, then you should start checking with this device.

The thermostat allows heated coolant to enter the radiator. This circulation through the radiator is called a large circle. The thermostat opens strictly at a certain temperature on different internal combustion engines (on average about 90 degrees Celsius), that is, up to the specified value, the liquid circulates only in a small circle. Problems begin when the thermostat stops opening or closing in a timely manner. If it does not open, then the engine overheats. If the thermostat is open all the time, the antifreeze will constantly circulate only in a large circle, and the engine will not warm up to operating temperature.

The thermostat jamming, both open and closed, occurs due to the accumulation of scale and other deposits in the cooling system. The reason is irregular changes of antifreeze or antifreeze every 3 or 4 years, mixing coolants with each other, using running water in the cooling system, ignoring the need to flush the system.

We also recommend reading the article on how to flush the cooling system yourself at home. From this article you will learn about various methods and means for flushing the engine cooling system with your own hands.

To check the thermostat, start the cold engine and let the unit idle for 5-10 minutes. Then you should feel with your hand the upper and lower hoses going to the radiator. If the thermostat is in good condition, then the pipes should not be heated. In other words, the coolant does not enter the large cooling system circuit until the liquid warms up to a temperature that is the opening temperature of the thermostat on a particular engine. In practice, this looks like this: the temperature arrow on the dashboard should rise, warm or even hot air should come out of the air deflectors, but the radiator pipes remain cold. Once the pointer reaches operating temperature, the thermostat should open. After this, the hot liquid will flow through the pipes in a large circle into the radiator, heating the indicated elements. It turns out that if the radiator and pipes immediately warm up after starting a cold engine, then the thermostat does not close the large circle, that is, its malfunction is obvious.

It is more difficult to determine a breakdown when the device opens or closes, but not completely. In such a situation, there may be partial overheating or insufficient heating of the motor. There are also cases when the thermostat does not jam constantly, but only periodically. In any case, the element must be removed, defective, repaired or completely replaced. On different engines, the location of the thermostat may differ. On some motors, access to the element can be very difficult. Usually the device is located in the place where the upper radiator hose approaches the engine. Less common are designs where the installation location is the area where the lower hose is supplied.

Performance test

To check the thermal sensor, it will have to be removed from the car. To do this, follow these steps:

- Allow the engine to cool to 40-50 °C to avoid burning your hands during operation. Partially or completely drain the antifreeze from the cooling system.

- Disconnect the battery from the on-board power supply by removing the negative cable.

- Disconnect the block with wires from the thermoelement.

- Unscrew the part using a wrench of the appropriate size.

If the device is installed at the top point of the system, then it is not necessary to empty it entirely; it is enough to drain a third of the liquid into the container. All antifreeze must be drained when the thermocouple is located at the bottom of the radiator.

To carry out the tests you will need:

- a multimeter or other device capable of measuring circuit resistance;

- a small container for water (you can use a regular glass);

- thermometer with a scale up to 100 °C.

A thermometer is essential if you want to make accurate resistance measurements by referring to the reference chart for your vehicle. When there is no table, the serviceability of the part is checked without a thermometer according to its operating principle: the hotter the water in the glass, the lower the resistance at the contacts should be.

If the multimeter shows a certain resistance, then immerse the thermocouple in a glass of cold water and record the readings. Then add hot water and watch the resistance change, it should decrease. If there are no changes, purchase and install a new temperature sensor.

If the tests were successful and the device changes resistance when heating the water, then it is worth checking the connecting wires and cleaning the contacts. Little things like this often cause major problems.

Causes of malfunction

Arrow stuck on dashboard

It’s probably no secret to anyone that the arrows hanging on the dashboard are inextricably linked with the electrical circuits in the car. To troubleshoot the problem, the car enthusiast will need some knowledge of auto electrics, as well as design knowledge of the VAZ-2114.

As practice shows, most motorists, when such a breakdown occurs, turn to a car service center, but this problem can be eliminated on their own. But, first of all, it is necessary to find the immediate cause of the effect.

What are the options?

So, let's look at the possible options for the engine temperature indicator arrow to hang on the dashboard:

- The magnetic motor of the pointer drive is broken.

- Breaks and disturbances in the operation of the electrical circuits of the dashboard.

- Short circuit in the circuit board of the device itself.

- Freeze related to temperature sensor.

- Problems with the ECU.

Elimination methods

Once the root causes have been identified, you can move directly to methods to resolve the problem.

So, now that the motorist is fully armed, you can proceed directly to the diagnostic and repair process.

The magnetic motor of the arrow drive is broken

The process of repairing and disassembling the dashboard

The most common problem with the arrow hanging or not responding on the instrument panel is a breakdown of the drive motor. To diagnose this device, you need to use a multimeter to close the winding contacts to an electrical circuit or resistance.

To troubleshoot the problem, of course, it is recommended to contact an auto electrician, who will do everything quickly and efficiently, but if the car enthusiast has the necessary skills and abilities in repairing such equipment, then he will be able to independently replace the motor and solder the necessary contacts.

We recommend: Why and how does oil get into antifreeze?

Breaks and disturbances in the operation of the electrical circuits of the dashboard

Wiring related fault determination

Another common reason for a stuck sensor is a break in the electrical circuit from the coolant sensor to the dashboard. It is quite simple to identify this; you need to remove the ground wire from the sensor and connect it to any other “minus” so that the electrical circuit is closed.

If the wire is not broken, then the arrow will begin to move; if not, then according to the electrical diagram it is necessary to find the wire in which the break occurred and eliminate the fault. As practice shows, motorists do not change the wire, but simply connect and insulate the contacts at the break point.

Short circuit in the board of the device itself

Detection of short circuits on the instrument board

But, in this case, an indirect sign is that nearby signs also fail. So, the tachometer and other indicators may not show. Here, troubleshooting is to replace the instrument panel assembly.

Freeze due to temperature sensor

Temperature sensor location

A frozen temperature arrow on the instrument panel will be associated with a faulty temperature sensor. So, its diagnosis can be carried out by analogy with a wiring break, or checked using a tester. If, as a result of diagnostic operations, it turns out that the coolant sensor is faulty, it must be replaced.

Problems with the computer

The process of identifying ECU errors and eliminating them

In this case, using the appropriate cable, you need to connect to the “brains” of the car and see if there are any errors. If there are too many of them, then you need to reset them.

Of course, if this procedure does not help, then it is recommended to reset the software. It is recommended to trust this procedure to professionals who will not only fix the problem, but also set the motor to optimal operating mode.

Other reasons

A malfunctioning thermostat may not be the only reason why the engine does not reach operating temperature.

If the pipes were not tightened well during the previous repair, the car owner is faced with air leaks. Coolant begins to leak. If this is the problem, then you should tighten the clamps for a tighter fit of the tubes and add fluid to the required level in the expansion tank.

In this case, the car owner will see a low temperature on the dashboard, which is insufficient for operation. In fact, the engine will overheat and may even boil.

During the winter season, engine performance is also affected by the use of other systems. So, using a cabin heater can lead to the engine not heating up well, since the stove takes some of the heat onto itself. In this case, you will see how the arrow of the engine temperature indicator drops.

A faulty temperature sensor can cause the engine to feel like it takes a long time to warm up or may not heat up at all. In this case, the engine works properly. The sensor transmits temperature status data to the dashboard. If it does not work correctly, then the readings will be incorrect. Replacing this part will bring all indicators back to normal.

The problem with the sensor is quite serious on modern cars equipped with electronics. Here again you will have to deal with supplying an over-enriched mixture and replacing many other parts.

How to check the coolant temperature sensor?

There are two ways to check the functionality of the DTOZh: by dismantling it or directly on the car. Let's take a closer look at them.

Checking the removed sensor

First, the coolant temperature sensor must be removed. To do this, you only need a wrench of the appropriate size. Then for diagnosis you will need water, a boiler or electric kettle, an electronic multimeter that can measure resistance and a thermometer.

We pour water into the container we are using and place the sensor and thermometer in it and heat it up. After this, we measure the resistance at intervals of every 5 °C. The output will be a table with data that needs to be compared with those indicated in the technical documentation of your car. You can also find a similar table on the Internet.

This method, of course, is not without errors, but they are not critical and depend entirely on the diagnostic conditions, as well as on the characteristics of the sensor itself.

You can check the performance of the DTOZH without a thermometer. To do this, the sensor is immersed in boiling water, and then its resistance is measured using a multimeter. If the part is in good condition, then the resistance value will be as close as possible to what is indicated in the table. Small discrepancies in this case are acceptable.

VAZ-2114 engine temperature arrow goes off scale: photos and videos

Many motorists have encountered the fact that the temperature indicator arrow on the instrument panel of a VAZ-2114 went up, beyond the red zone. This malfunction can be due to many factors. But, this problem is related to the electrical part of the car.

Why the temperature arrow goes off scale - the main reasons!

The normal operating temperature of the engine on the instrument panel is 90 degrees. The arrow indicates the red zone of engine overheating. Learn more about the situation when the instrument panel does not show the engine temperature.

You can find out why the malfunction occurred in your garage, and you don’t have to go to a car service center. But to fix the problem, you may need outside help from professionals.

So, let's look at the main reasons why the temperature arrow on the VAZ-2114 dashboard goes up:

- Dashboard diagram.

- Temperature sensor.

- Wiring harness.

- ECU.

Solution methods

The arrow is off the charts!

When the reasons are identified, you can proceed directly to eliminating them and consider the issue in more detail. So, to begin with, it is worth noting that the motorist will need some knowledge of the design features of the car, as well as knowledge of the electrical part.

Dashboard diagram

Dashboard board

The next step is to find the motor that powers the arrow. There may be two malfunctions here. Which ones exactly:

- Due to a short circuit, the motor winding burned out.

- The wire that is soldered from the motor to the dashboard board has come unsoldered or has come off.

To eliminate this cause, it is necessary to inspect the place and determine the presence of breaks. For complete reliability, it is necessary to ring the contact wires of the motor that close the winding.

Another stage of diagnostics will be the connector that connects to the board. It is necessary to find the contact that is responsible for the temperature indicator and also ring it using a multimeter. If a connection break is detected, it must be repaired.

Attention! If a motorist does not have experience in repairing such components, it is strongly recommended to contact professional auto electricians so as not to cause even more trouble when doing the repairs yourself. They will do everything quickly and efficiently

temperature sensor

The temperature sensor is checked with a multimeter

If the problem was not hidden in the dashboard, then you need to contact the temperature sensor directly. It is this that serves as an indicator of the engine temperature and transmits data through the computer to the needle. Failure of the product can cause a freezing effect and the needle on the dashboard going off scale.

Wiring harness

Disconnecting the wiring harness from the instrument panel for inspection

If the first two reasons are eliminated, but the problem remains, then you should look for the problem in the wiring harness that goes from the engine to the dashboard. Of course, not all motorists are able to cope with this type of diagnosis, due to ignorance of wire pinout. Therefore, in this case, it is also worth contacting professional auto electricians to find out the causes and repair. Although, the reason here is quite simple and understandable - a wire break or burnout.

ECU

List of ECU errors

It is not often that the problem of the needle leaving its normal position can be caused by an electronic control unit. It is he who sets all the parameters and signals on the dashboard.

To troubleshoot the problem, you need to connect to it and check for errors related to the temperature sensor and cooling system. Thus, a simple reset of errors can lead to normal operation of the device.

There are not many reasons why the VAZ-2114 engine temperature needle goes off scale, but all of them are quite difficult to diagnose, and some can only be eliminated in a car service center. Therefore, if the motorist has not carried out repair operations of this nature, it is necessary to contact a car service center, where they will help and repair everything.