M9R Engine Characteristics

Let's look at the main technical characteristics of the 2.0 M9R engine:

- environmental class – Euro-4 and Euro-5;

- torque (N*m) – 240-400;

- cast iron cylinder block;

- permissible oil consumption (grams per 1000 km) – 500;

- lubricant change frequency (km) – 15,000 and 7,500 when operating in difficult conditions;

- engine oil volume (l) – 7.4;

- fuel used - diesel;

- number of cylinders – 4;

- piston stroke (mm) – 90;

- valves per cylinder – 4;

- approximate resource (km) – more than 350,000;

- power supply (injection) – Common Rail system manufactured by Bosch;

- exact volume (cubic cm) – 1995;

- compression ratio – 15.6;

- operating temperature (degrees) – 90;

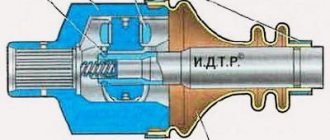

- The timing belt is driven by a chain;

- cylinder diameter (mm) – 84;

- years of production – from 2005 to the present.

power (hp) – 90-180;

Fuel consumption

The diesel consumption rate of the M9R engine directly depends on the model of the car on which it was used. The following shows the fuel consumption of the M9R engine with a power of one hundred and fifty horsepower for certain car models:

The all-wheel drive Nissan X-Trail with a six-speed automatic transmission consumes 8.1 liters per hundred kilometers in the combined cycle. The consumption rate in urban mode is 10.5, and outside the city 6.7;

Nissan X-Trail of the second generation (T31) with 6-speed manual transmission and all-wheel drive:

- city – 8.7 l/100 km;

- highway – 6.2 l/100 km;

- mixed - 7.1 l/100 km.

Technical features of the M9R

Japanese and French designers participated in the development of the M9R diesel engine. This led to the creation of a sixteen-valve two-liter engine equipped with a chain drive gas distribution mechanism. The diameter of the intake valves is 27.7 mm, and the exhaust valves are 26 mm. Their operation is allowed without adjustment, since hydraulic compensators are installed. The cylinder block is made of cast iron. The power unit uses piezo injectors with battery injection of the fuel mixture. On internal combustion engines with the Euro-5 environmental class, a particulate filter was used (not used in Euro-4) and an EGR valve.

The turbine has variable geometry. Boost indicators for all modifications of the M9R engine:

- 130CV (130 hp): with boost pressure (P) up to 2.5 bar and torque (M) 320 N*m;

- 150CV (150 hp): P up to 2.6 bar, M = 320-380 N*m;

- 160CV (160 hp): P up to 2.7 bar, M = 380 N*m;

- 175CV (175-177 hp): P up to 2.8 bar, M = 360-380 N*m;

- 180CV (178 hp): P up to 3.0 bar, M = 400 N*m.

Design Features

The M9R turbocharged diesel engine received the following design features from French and Japanese developers:

- the block, intake manifold and cylinder head are made of aluminum alloy;

- the turbine has variable geometry to eliminate the effect of turbo lag at low speeds;

- recirculation of exhaust CO gases in the EGR valve is double-flow;

- braking energy is recovered at the moment the engine starts and stops;

- the pistons were modernized due to graphite coating of the skirt;

- DOHC V16 gas distribution diagram (twin-shaft, four-valve);

- A special feature of the timing chain drive is the hydraulic tensioner.

M9R cylinder block

Brake Energy Regeneration

This made it possible to increase the cylinder volumes to 2.0 liters and provide 320 - 360 Nm of torque. The diesel engine complies with Euro-4 environmental standards and has a compression ratio of 16 units. Rotation from the crankshaft is transmitted by a chain only to the intake camshaft, and from it by a gear transmission to the exhaust camshaft. The cylinders are made of steel liners inside a silumin block, installed using the wet method.

Timing chain drive M9R

All high-pressure fuel lines connect the injectors with the high-pressure fuel pump and high-pressure fuel pump. There are twin-turbocharged versions with 400 Nm of torque and 180 hp. With. power.

M9R crankshaft

Traditionally, for 75% of French engines, it is very difficult to carry out major repairs on your own in a garage environment. The crankshaft must be additionally fixed, and the position of the camshafts is held with a special template. Almost all attachments have to be removed, even during maintenance.

Service

The quality of operation and maintenance of the M9R engine directly affects its service life. The range of motor maintenance measures includes:

- cleaning the EGR valve from carbon deposits once a year;

- When the mileage reaches 300,000 km, the condition of the connecting rod bearings is checked. If the condition is unsatisfactory, they are replaced;

- It is recommended to replace the timing chain after 300,000 km. This is due to the formation of a strong stretch;

- The oil in the M9R engine is changed every fifteen thousand kilometers. In harsh climatic conditions or heavy engine loads, the oil change period is halved - 7,500 km.

- The motor is equipped with hydraulic compensators, so valve adjustment is not required.

Advantages and disadvantages

In general, the internal combustion engine device is designed for dynamic operation of the power drive at any speed and ensuring a long service life. For example, a silent chain lasts much longer than a reinforced, but still rubber timing belt. On the other hand, Chinese chains last 30–40 thousand km, and standard chains last about 150,000 km.

Camshaft clamps included in the set

To lock the crankshaft, you will have to remove part of the attachment (for example, an air conditioning pump) in order to insert a metal pin. It is impossible to remove the valve cover without removing all the injectors. In other words, the attachment is arranged extremely poorly.

At the moment the timing chain breaks, the piston bends the valves, the thermal clearances of which are regulated by hydraulic compensators, so the internal combustion engine is demanding on the quality of consumables - chain and oil.

On the one hand, major repairs can be easily done in the garage, thanks to the step-by-step instructions contained in the manual. On the other hand, DIY repairs are impossible without special tools, for example, a template for mounting camshafts.

Traditionally, the problem unit for a diesel engine is the EGR valve and particulate filter. Despite the high technology of the power unit, problems with starting in severe frosts have been identified.

Disadvantages and weaknesses of the M9R

During operation of the M9R engine, the following problems and disadvantages may appear:

- Stretching of the timing chain can be observed with a mileage of up to 150,000 km. The disadvantage is characterized by an increase in noise in the engine compartment. The replacement process requires significant investment and special skills.

- Piezo injectors are the weak point of the M9R power units. They are very picky about the quality of diesel fuel. The malfunction is manifested by engine shaking. Bosch fuel system injectors are officially beyond repair, which is accompanied by the need to purchase new spare parts.

- The EGR valve and DPF filter are problematic. After these elements become clogged, floating speeds are observed. Cleaning the valve is difficult, but possible. In turn, the DPF filter must only be replaced. Its cost is very high, so an emulator is used instead.

- Reduced oil pump performance due to clogging. In the absence of proper control, this deficiency can lead to rotation of the crankshaft liners. This occurs due to the decrease in pressure created by the oil pump.

Reliability, weaknesses, maintainability

Reliability

The M9R's reputation as an ideal diesel engine has been strengthened. It is noted that the engine is very reliable and, with timely and correct maintenance, easily covers more than 500 thousand km. As an example, three confirmations of what has been said are given.

Artem: “...M9R is one of the most reliable in the 2.0 class. Timing belt 300,000 km, injectors 330,000 km, total mileage without turning the bearings 390,000 km. Change the oil more often and that’s it.”

Sergey: “...I confirm the previous commentator, the chain was removed at 320,000 km, the condition is such that it will cover the same amount, and easily.”

Sergey: “...I have a 2009 Nissan Primastar. I’ve done 976 thousand, and if I hadn’t crushed the pallet, I think I would have done more.”

Some car enthusiasts disable the USR, but, in order to save money (or ignorance), do not reflash the ECU. The engine immediately responds to such “freedom” by causing significant problems. Fans of chip tuning can expect similar troubles, especially when it is performed by unqualified craftsmen.

The conclusion is simple: the internal combustion engine is reliable when used correctly. Various “improvements” reduce reliability and often cause serious breakdowns.

Weak spots

The motor, for all its reliability, is not without weaknesses. The most significant are the unfinished piezo injectors, oil pump and exhaust gas cleaning system. If the internal combustion engine is poorly maintained, problems arise with the timing chain.

Piezo injectors are sensitive to fuel quality. At the slightest discrepancy with the standards, they immediately fail. Not repairable, require replacement with new ones.

The oil pump is also highly demanding on oil quality. Attempts to replace the oil with a cheaper one lead to a decrease in the performance of the unit, which in turn causes the crankshaft liners to rotate.

The low quality of our diesel fuel leads to clogging of the EGR valve and DPF filter. The result is floating engine speed. If the EGR valve is difficult, but still can be cleaned, then the DPF filter must be changed.

According to the manufacturer, the timing chain has an unlimited service life, but in our conditions it cannot withstand more than 150 thousand kilometers. Servicemen and many car owners advise reducing this period to 120 thousand km.

Timing chain

Car service workers note the difficulty of replacing this part. Hence the high cost of the process.

Maintainability

The engine is repairable. A cast iron cylinder block indicates the possibility of carrying out major repairs of any complexity.

There are no problems purchasing parts to restore the unit’s functionality – they are available in any specialized or online store.

It should be borne in mind that they are not always cheap (a distinctive feature of French spare parts). In addition, additional costs are caused by the need to replace not only a failed unit (part), but also a number of associated ones. For example, when repairing (replacing) a torsional vibration damper pulley, the auxiliary drive belt must be changed. And vice versa - when changing the PVA belt, the DShKK also must be replaced.

Overhauling the M9R is quite expensive. Sometimes an easier way out of this situation will be to purchase a contract engine. Its cost is in the range of 80-120 thousand rubles.

The motor, jointly developed by Renault and Nissan M9R engineers, has proven itself to be a reliable, practical and economical unit. But demanding on the quality of technical fluids, especially fuel and oil. If all the manufacturer's requirements are met, the engine significantly exceeds its intended mileage.

Tuning

Tuning the M9R engine does not require large investments and labor costs. You can make a noticeable increase in power using chip tuning. The new firmware increases power to one hundred and ninety horsepower on engines with an initial power of 130, 150 and 160 hp. The maximum torque value will increase to 400 N*m.

For engines with a starting power of 185 and 190 hp, the firmware allows you to achieve about 210 horsepower with a torque of 440 N*m.

What cars was the M9R installed on?

The 2.0 M9R diesel power unit is used in Nissan and Renault vehicles. For Nissan models, the following internal combustion engine codes were used:

- 740, 832 – Qashqai;

- 760, 830 – X-Trail.

In turn, Renault models were equipped with engines with the following codes:

- 740, 760, 845 – Laguna;

- 760, 762, 763 – Vel Satis;

- 610, 700, 722 – Megane;

- 740, 760, 812, 815, 858 – Espace;

- 610, 615 – Scenic;

- 830, 855, 865 – Koleos.