Signs of oil starvation

Lack of lubrication most often destroys the engine gradually. The insidiousness of oil starvation is that it is practically asymptomatic. The hazard warning lights do not turn on, and the engine's performance at first does not raise any complaints. Sometimes even experts cannot determine that its components lack lubrication. However, oil starvation can be suspected based on several signs, most often subjective. The main ones:

- Periodic blinking of the emergency oil pressure lamp. The most obvious symptom, which reliably indicates that some units are operating, as they say, “dry.”

- Extreme heating of the engine in the absence of other visible reasons.

- The operation of the engine is accompanied by extraneous sounds, most often in the area of the gas distribution mechanism.

- The oil is dark in color or has foreign particles in it.

- Large wear of camshaft parts, which can be detected during maintenance, for example, valve adjustment.

Do not think that low lubrication efficiency is typical only for a used engine with a high mileage. In some cases, relatively new power units also suffer from it. The fact is that oil starvation is not always associated with failure of the lubrication system elements.

Turbine oil starvation

Turbine operation under oil starvation conditions is unacceptable ! Even short-term. The fact is that its shaft rotates at enormous speed, greater than the engine itself. Therefore, for the turbine shaft, the problems described above are even more relevant. If at one point its shaft rotates without lubrication, it will jam very quickly and the turbine will simply fail. In particular, the turbocharger bushings and shaft fail.

Damaged turbocharger surfaces

However, the bearings are the first to suffer . When they fail one after another, mutual friction of the turbine and compressor rotors occurs, as well as wear of the sealing rings. In the worst case, the turbine shaft may break.

The normal operating temperature of the bearings is +60°…+90°С. Therefore, heat transfer is very important, and its disruption due to the effect of oil starvation leads to significant heating of the turbine shaft. And given that heat also comes from the turbine wheel, the shaft temperature can reach +400°C. Due to this temperature, the process of coking of the remaining oil on the shaft occurs. The holes supplying oil to the bearings and the middle turbine housing are also clogged with coke. And this contributes to even greater oil starvation.

That is, due to the operation of the turbine in a dry state, the bearings quickly wear out, and foreign metal deposits appear on the shaft. The clearances in the bearings increase, resulting in shaft play. Also, due to the gaps in the bearings, a process occurs when the compressor and turbine impellers first select a gap between the housings, and then simply rub and wear out against them. The consequence of this is an imbalance that increases over time. And this is essentially the “beginning of the end” of the turbocharger. Usually, in this case, the turbine makes additional “unhealthy sounds” - a loud whistle, grinding, howling.

Result of turbine wear

Turbochargers have three types of oil starvation:

- Fast (or sharp). A sudden appearance of oil starvation can be caused by several reasons - a break or bend in the oil supply tube, a malfunction of the oil pump, or oil leakage from the system. Here we can also note the so-called “dry start”. It can happen if the compressor is installed incorrectly after repair or after purchasing a new unit. In particular, in this case, an air plug may form in the middle spring housing, which the oil cannot push through, which is a natural cause of oil starvation.

- Smooth (or slow). In this mode, the turbine constantly operates with a slight lack of oil volume. There can be many reasons for this - low performance of the oil pump, coking of the oil line, slight bending of the tubes, use of oil with inappropriate viscosity. Slow starvation is a slow failure of the turbine. Therefore, always monitor the normal operation of the listed components.

- Periodic (or cyclical). This is usually caused by improper operation of the engine. In particular, its sudden stop after a large and prolonged load. The fact is that at high speeds the turbine and other elements become very hot, and their cooling is provided by oil. And if the engine is turned off, the movement of oil will stop. The consequence of this is the heating of the lubricant remaining in the system and its coking. Because of this, the oil channels become clogged, and their cross-sectional area, and therefore productivity, decreases. Thus, the owner himself slowly “kills” the engine. To prevent this from happening, after significant loads on the engine, it is necessary to let it run for several minutes so that it cools the turbine.

It is also important for the turbine that the oil is clean and of the appropriate consistency (not thick).

Causes

The appearance of signs of oil starvation is most often explained not by the consequences of a malfunction, but by a lack of maintenance. Even failure to comply with the timing of its implementation can significantly reduce the effectiveness of lubrication. Based on this, the following main causes of oil starvation can be identified:

- No pressure or very low pressure.

- Untimely oil change.

- Low quality lubricants.

- Oil level is lower than recommended by the manufacturer.

Each of the listed reasons is a topic for a separate discussion, so it is necessary to consider them in more detail.

Causes of oil starvation

There are several reasons why this phenomenon occurs. Among them:

- Untimely addition of oil .

This is the most common reason. Often, car owners simply forget to regularly check the engine oil level using the dipstick designed for this purpose. After all, any engine, even the most modern one, gradually “eats up” oil. Therefore, the level must be monitored regularly. For each vehicle, the frequency of appropriate inspection is determined by its manufacturer. However, on average, this procedure needs to be performed approximately once a month or even more often. It is worth remembering that overfilling the engine oil also negatively affects the operation of the power unit. - Untimely oil change . Over time, during operation, the oil thickens, becomes dirty and loses its technological properties. The consequence of this is clogging of the oil passages in the engine, as well as the oil filter. Because of this, the engine components do not receive enough lubrication, that is, oil starvation occurs.

- Poor quality oil . If you bought a fake, then there is a high probability that the service life of the lubricant will end prematurely, and accordingly, the oil will lose its properties. In particular, it thickens, becomes dirty and blackens. A situation may also arise when it initially does not have the necessary properties. To avoid this situation, try to make purchases in trusted stores that have the appropriate licenses.

- Non-compliance with the car manufacturer's requirements . In particular, we are talking about a situation where a car owner or a car service worker fills the engine with oil of the wrong viscosity and tolerance. Therefore, when choosing a lubricant, it is imperative to take into account their labeling, as well as other requirements of the car manufacturer.

- Reduced oil pump performance . This can happen for various reasons. For example, clogging of its impeller, failure of bearings, aging of the unit, and so on. In any case, check its functionality.

As you can see, in most cases the main cause of oil starvation is ordinary human negligence and untimely or insufficient vehicle maintenance.

In turn, this can lead to very sad consequences and expensive repairs.

Low system pressure

Typical for used engines that have been in operation for a long time. Low pressure can be associated both with natural wear of parts and components of the lubrication system, and with contamination of its channels. This malfunction can completely disable the engine in a short time, although it is easily diagnosed. Low pressure is indicated by a warning lamp on the instrument panel. If it flashes or lights up, it means that the engine parts are poorly lubricated and measures must be taken to determine the cause.

Violation of oil change intervals

Most manufacturers recommend maintenance every 10-15 thousand km. In fact, sometimes you have to change the oil more often. Much depends on the terms of service. Modern oils have a complex chemical composition. They contain a large number of different additives that extend engine life. During operation, they gradually deteriorate or simply burn out under the influence of high temperatures.

As a result, the oil loses its lubricating properties. Wear on the moving parts of the power unit increases, which leads to an increase in temperature. This accelerates the aging process of the oil. The quality of the lubricant depends not only on high temperature. Sometimes it worsens because the engine does not have time to warm up. This happens on short trips in winter. In this case, a large amount of condensate forms in the lubrication system, which, of course, affects the quality of the oil.

Failure to comply with replacement deadlines also negatively affects the filter. Long-term use leads to contamination. The filter capacity decreases, the pressure in the system drops. The result is oil starvation of the engine.

What you can do yourself

The problem of low oil pressure greatly complicates the relationship between lubricant consumption and level drop and the overall pressure in the system. In this case, a number of malfunctions can be eliminated independently.

If leaks are detected, the problem is quite easy to localize and solve. For example, oil leakage from under the oil filter can be eliminated by tightening or replacing it. The problem with the oil pressure sensor, through which lubricant flows, is solved in a similar way. The sensor is tightened or simply replaced with a new one.

As for seal leaks, in this case you will need time, tools and skills. In this case, you can replace the front or rear crankshaft oil seal with your own hands in your garage with an inspection hole.

Oil leaks from under the valve cover or in the pan area can be eliminated by tightening fasteners, replacing rubber gaskets, and using special engine sealants. Violation of the geometry of the connecting planes or damage to the valve cover/pan will indicate the need to replace such parts.

If the coolant gets into the engine oil, then you can remove the cylinder head yourself and replace the head gasket, while following all the recommendations regarding the removal and subsequent re-covering of the cylinder head. An additional check of the mating planes will indicate whether the cylinder head needs to be ground. If cracks are found in the cylinder block or head, repairs are also possible.

As for the oil pump, if this element wears out, it is better to immediately replace it with a new one. It is also not recommended to clean the oil receiver, that is, the part is completely changed.

In the case where the problem in the lubrication system is not so obvious, and you have to repair the car yourself, then at the very beginning you should measure the oil pressure in the engine.

To solve the problem, as well as taking into account an accurate understanding of where the oil pressure in the engine is measured and how it is done, additional equipment must be prepared in advance. Note that there is a ready-made device for measuring engine oil pressure available for free sale.

To measure, a ready-made or home-made device is connected instead of an oil pressure sensor, after which the pressure readings on the pressure gauge are assessed

Please note that ordinary hoses cannot be used for self-production. The fact is that oil quickly corrodes rubber, after which the detached parts can get into the oil system.

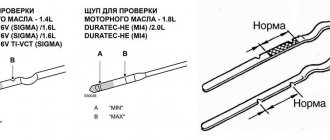

Low level

Any car engine can operate normally only if it contains a certain amount of lubricant. The oil volume is individual for each engine and is indicated in the operating documents. Control is carried out using a special probe, which is required in every car. Ideally, you should check the oil level every day. However, some car enthusiasts, relying on the newness of the car, do this very rarely.

Therefore, sometimes the level drops below the min mark. In this case, the crankshaft is the first to experience oil starvation. Its design involves constant rotation in a lubricating fluid. When the engine is running, some of the oil is in the system channels, which, given the already low level, leaves the crankshaft almost without lubrication. It is typical that in this case the emergency pressure lamp does not light up. Therefore, the car owner may not realize that the oil level is low for a long time. As a rule, the matter ends with a major overhaul.

Consequences of engine oil starvation

The consequences of engine oil starvation directly depend on how long it lasts and how critical the situation is:

- Minor oil starvation. If you notice that the oil level on the dipstick is below the minimum value, but no obvious symptoms of oil starvation have appeared, you are in luck. Some, and even below the minimum oil level, problems do not arise with the engine for some time. In such a situation, it is urgent to fill in new oil;

- The first stage of oil starvation. A clear symptom of stage 1 oil starvation is the car twitching while driving and changing gears. Also, during the first stage of oil starvation, blue smoke begins to come out of the exhaust pipe. If blue smoke is visible, this indicates that the engine piston rings are stuck and will require decoking. Blue smoke in this situation occurs due to the fact that the oil film gets onto the spark plugs and into the combustion chamber;

The second stage of oil starvation. The occurrence of rings is quite easy to eliminate, but if you do not pay attention to the symptoms of oil starvation in time, or if the engine wears out very quickly, problems will arise with the camshaft. Due to lack of lubrication, the camshaft will stop cooling, but will continue to rotate. As you know, when rotating, the metal heats up and expands. Having expanded to the limit, the camshaft will jam, after which it will tear out the entire bed of the block head;- The third stage of oil starvation. If there is virtually no oil in the engine, there will be a problem not only with the camshaft, but also with the crankshaft, as well as with the engine pistons. If they jam, they will most likely tear out part of the engine block, which will require expensive repairs or a complete replacement of the motor.

As you can see, the consequences of oil starvation are very serious, and the driver must monitor the oil level in the engine. All modern cars are equipped with a warning light that warns of low engine oil levels. Under no circumstances should it be ignored, otherwise the serious problems described above will arise with the motor.

( 412 votes, average: 4.54 out of 5)

DIY rubber ink

How to restore a sunken car

Related Posts

Using low-quality oil

The manufacturer must indicate the type and brand of recommended lubricant in the vehicle manual. Possible analogues are also most often mentioned. However, car owners, out of ignorance, and more often out of a desire to save money, do not always follow these recommendations. As a result, the filled oil not only does not contain the additives necessary for this engine, but also does not have the appropriate viscosity. Temperature stability is of great importance for the engine. This refers to the ability of the oil to maintain its viscosity when the engine heats up and cools down.

Cheap lubricants do not have such stability and at high temperatures they become completely liquid. This significantly reduces the pressure in the system, which means it increases the risk of oil starvation.

True, sometimes the driver himself does not know that he is pouring low-quality oil. There are a lot of counterfeits on the market for the most common and popular brands. Naturally, in this case, the canisters are filled with the cheapest oil, which has neither protective nor sufficient lubricating qualities. Using it will quickly lead to a major overhaul. Therefore, it is necessary to purchase oil only from trusted retail outlets.

What could be the consequences?

Prolonged operation of the power unit in oil starvation mode leads to heating and rapid wear of its parts, and sometimes entire components. In especially severe cases, the engine may not even be recoverable. However, most often the consequences of oil starvation can be as follows:

- Melting of the liners or their fusing to the crankshaft journals.

- Wear of camshaft parts.

- Pistons jamming in engine cylinders. This damage can lead to irreparable consequences. Often a detached connecting rod pierces the cylinder block.

- Knock and whistle when the engine is running.

In some cases, so many parts must be replaced that their cost, together with labor, is comparable to the price of a new engine.

Consequences of low oil level

The consequences of oil starvation can be the most unpleasant for the car owner. At the same time, you need to remember that the longer the car is driven with a small amount of oil in the engine, the more serious they will be. After all, an emergency situation can occur very quickly, literally in a matter of minutes. Let's list the announced consequences:

What are the dangers of oil starvation?

- Failure of oil scraper rings . A sign of this phenomenon will be the car jerking while driving, as well as blue smoke from the exhaust pipe. This happens because oil enters the engine cylinders.

- Damage to the upper camshaft . Due to the fact that it rotates without lubrication, and its angular velocity is quite high, the shaft expands in diameter and can simply jam.

- Damage to the crankshaft . The situation is similar to the previous point. Shock loads at high temperatures lead to bending of the shaft, as well as eccentricity of the journals. The worst thing is that this cannot always be corrected by grinding to the repair size.

- Engine pistons jamming . This is one of the most terrible phenomena in this vein, since there is a high probability that a large piece of the engine block will be torn out. And eliminating the consequences of such an accident is extremely difficult, if not impossible. It is much easier to buy a new engine.

- The half rings may become welded to the surface of the crankshaft . The consequence of this is the rotation of the liners with damage to the seats in both the cylinder block and the lower covers of the main bearings. Also, if the connecting rod bearings rotate, scuffing will occur on the crankshaft journal and significant wear on the holes in the lower part of the connecting rod.

- Damage to the geometry of the camshaft bed , as well as their supporting surfaces, is possible. In most cases, their repair is impossible.

- Deformation of the liners , both connecting rod and main bearings, with fusion of the upper sliding layer (usually made of babbitt).

- Destruction of honing from cylinder mirrors.

Result of water hammer - The so-called “fist of friendship” . This refers to the situation when a failed connecting rod breaks through the crankcase wall. This is the reason for the complete failure of the cylinder block and its irreparability.

As you can see, such a seemingly trifle as an untimely oil change can lead to significant problems with the engine and expensive repairs.