Manual transmission VAZ 2107

- checkpoint

- VAZ

- 2107

The 5-speed manual transmission 21074 or otherwise VAZ 2107 five-speed appeared in 1982 along with the seven Zhiguli.

This transmission is considered the most advanced among the classic AvtoVAZ gearboxes and is still in production. The classic family also includes manual transmissions: 2101, 2105 and 2106.

- Application

- Description

- Problems

- Prices

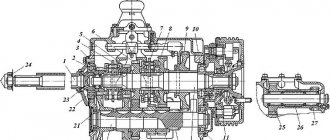

The gear shift pattern of a 5-speed gearbox itself is almost the same as a 4-speed gearbox, with the only difference being that another 5th speed has been added to it, which is activated by moving the lever all the way to the left and forward. A schematic representation of the main components of the structure looks like this:

The VAZ 2107 transmission is contained in housing No. 3, which is closed with covers. Shift lever No. 5 is located at the top.

Main details

The main systems and parts of the gearbox are located in building No. 3.

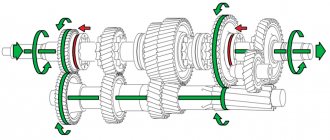

The transmission system consists of three shafts:

- primary with four gears;

- secondary No. 10 with gears;

- intermediate.

Since the schemes of these mechanisms are complex, we will dwell on them in more detail.

Primary shaft

The input shaft is one piece with gears rotating on bearing No. 3, which is located in the gearbox housing.

Secondary shaft

The secondary shaft is in some way an extension of the primary shaft. It contains gears of the 1st No. 23, 2nd No. 24 and 3rd No. 25 speeds, which move in predetermined positions, which mesh with the corresponding gears of the intermediate No. 1. The gears differ in diameter, as a result of which the amount of torque changes.

The secondary shaft rotates on bearings No. 9, No. 11 and No. 12. The first one - the roller one is placed in the primary one, the others - in the crankcase and the rear cover.

Intermediate shaft

The intermediate shaft is necessary to transmit the required torque to the secondary from the primary. Rotation occurs on ball bearings No. 2, No. 22 and No. 19. The gears and shaft are one unit. This block contains the gears of the 5th No. 18 and rear No. 20 gears. The rear one is placed on shaft No. 21 and connected to secondary splines.

Transmission lubricant is poured into the VAZ 2107 gearbox through hole No. 11, which is located on the left side of the case and is closed with a special plug. The lower part of the body is closed with a steel lid secured with nuts. The places where the cover and body connect are sealed with gaskets that prevent possible lubricant leakage. The bearings of all axes are sealed with special seals that prevent the lubricant from leaking out.

The volume of oil required to refill the VAZ 2107 gearbox is approximately 1.6 liters. Some drivers pour lubricating fluid through the place where the handle is inserted into the box. This method is much easier than the usual one, because the handle is located in an easily accessible place, which cannot be said about the oil filler neck.

Speed shifting occurs through forks driven by a lever. The key parts of the gearshift system are shown in the diagram.

It is installed in the clutch housing. Inside there is an oil seal for the input shaft. On the end wall there is a hole for draining transmission oil, which can flow out of the crankcase if the oil seal is worn. In addition, the box housing contains:

- Primary and secondary shaft.

- Gears, synchronizers.

- Intermediate shaft with shift drive elements.

There is a filler hole in the left wall of the new VAZ-2107 gearbox. It is closed with a metal plug with a conical thread. At the bottom, the box housing is closed with a stamped steel cover. The crankcase is secured with ten nuts. There is a breather in its cavity. There is a passage for oil in the rear wall of the crankcase. it enters the cavity of the lid.

REPAIR

The VAZ 2107 has -speed gearbox, which, despite the comparative simplicity of its design, can become unusable for reasons classic for manual transmissions:

DON'T WASTE MONEY ON REPAINTING! Now you can remove any scratch from the body of your car in just 5 seconds.

- wear and tear due to natural reasons: high mileage, irregular operation and depletion of the service life of components, weather conditions not meeting the desired ones, and as a result - a decrease in service life, etc.;

- non-compliance of the working fluid with standards suitable for normal operation of the transmission;

- non-original spare parts included in the box;

- damage to the gearbox housing due to mechanical impact;

Front shift mechanism

Gear shift mechanisms

Numbers 1, 2 and 16 are the speed forks: 3rd, 4th, 1st and 2nd, rear and 5th. Fork rods No. 5, No. 7 and No. 9 are controlled by lever No. 8, which is located in the car interior.

The gear shift works according to the following scheme: if lever No. 8 changes position, the hinge engages with a recess located on one of the axes, the other end of which is in rigid engagement with fork No. 3. It, in turn, fits into the recess on the forward gear at numbers 16, 23, 24, 25 or number 20 for the rear. Lever 8 moves the fork, which leads to engagement of the required secondary shaft gear with the appropriate intermediate gear. The torque transmission circuit is closed and the secondary axis rotates at a speed that corresponds to the gear ratio of the meshed gears. If you engage reverse gear, then, unlike others, the lever will be pushed down while driving.

VAZ-2101 gearbox device

All other steps are switched on in approximately the same way. To prevent the inclusion of two stages at the same time, the driver, before turning on the required speed, first disengages the gears of the engaged stage, that is, first moves the lever to “neutral”, and then connects the necessary gears. The transmission of the VAZ-2101 car consists of a manual gearbox, which transmits torque to the rear axle through a driveshaft. The gearbox itself is mechanical, 4-speed (4 forward gears and 1 reverse), three-way, with manual control (gear shifting is performed by the driver using a lever located in the car's interior). At the time of the release of the VAZ-2101, this type of gearbox was one of the highest priorities, since it ensured the least losses.

Please note => When will the benefits of a labor veteran in the Amur region for October be paid?

Intermediate shaft

It is a block with four gears. The intermediate shaft rotates in bearings located on the rear and front walls of the gearbox housing. The drive gear is in constant contact with the input shaft.

Also, a block of reverse and fifth gear gears is attached to its end. The other end of the intermediate shaft rests on the bearing.

Gearbox VAZ 2107

Despite the fact that among the entire line of VAZ cars, the seventh model is structurally one of the most affordable and easy to maintain, not everyone will be able to carry out diagnostic and repair work on their own. This is due to the fact that the car has both simple and complex components and assemblies. So, manual transmission 2107 belongs to the second type.

Box 5th mortar VAZ 2107: design features, switching diagram

The VAZ 2107 gearbox diagram (five-speed) is practically the same as in a four-speed gearbox, the only difference is the presence of another fifth speed, activated by moving the lever to the left all the way and forward. The VAZ 2107 5 mortar gearbox allows you to change the torque frequency in five different positions:

- moving forward at different speeds in accordance with gears from 1 to 5;

- moving backwards when engaging sixth (reverse) gear.

Gear shifting in a five-speed gearbox is carried out in the same way as in a classic four-speed gearbox. When squeezing the clutch, you need to move the gear shift lever to the desired position corresponding to the speed limit of the car.

Inside the box there are the following main elements:

- The input shaft of the VAZ 2107 is a shaft with four toothed gears (one of the main elements of the box). The input shaft, being one piece with the gears, rotates with them on a bearing, which is fixed in the lower part of the gearbox and sealed with an oil seal;

- The secondary shaft with ten gears, being a continuation of the primary shaft, has gears for first, second and third gears. All gears on the secondary shaft have different dimensions to ensure torque conversion. The secondary shaft rotates on bearings, just like the primary one;

- The intermediate shaft is a kind of “layer” between the secondary and primary shafts and has gears that are one with it. It is through them that torque is transmitted from one shaft to another;

The 2107 gearbox has gear ratios and technical characteristics similar to the VAZ 2105 gearbox. Parameters of the VAZ 2107 five-speed gearbox:

- main pair - 4.1/3.9 (4.3);

- 1st gear - 3.667 (3.667);

- 2nd gear -2.100 (2.100);

- 3rd gear - 1.361 (1.361);

- 4th gear - 1.00 (1.00);

- 5th gear – 0.820 (0.801);

- Reverse gear - 3.530 (3.530).

The main technical characteristics of the box include working in conjunction with a single-plate clutch, which has only one (central) pressure spring and synchronizers for each forward gear.

Perfect gear shifting

transmissions are becoming increasingly common.

.

In terms of their technical characteristics, they have long been not inferior to their mechanical counterparts, in addition, attracting the potential owner by the absence of the need to independently control the process of switching gears

, making many gestures over and over again. However, on the secondary market in the middle price segment the ratio of cars sold will still be rather, in favor of those who have a manual transmission.

While driving, these speed ranges are “erased”; practice shows that, starting from second gear, switching occurs differently. The fact is that the power of new cars can allow its owner to reach an acceleration of 70 km/h even in second gear, however, this is too ill-considered a step, since it is too costly. Most drivers switch to fifth gear when the speed exceeds 110 km/h, although it is recommended to do this already at 90 km/h. The car owner, naturally, must know about the standards, but change speed based on the capabilities of the car and. So, proper gear shifting comes down to one thing - smoothly squeezing the clutch mechanism and quickly changing gears. 21 Dec 2021 marketur 264

Share this post

- Related Posts

- Benefits for kindergarten in Krasnoyarsk region

- Benefits for electricity in Rostov-on-Don

- How to calculate a pension for a woman born in 1964

- How to register ownership of a house in gardening

Features of repair of a five-speed gearbox VAZ-2107

1. To facilitate the removal and subsequent installation of the elastic coupling, wrap it tightly with tape.

2. Having unscrewed three nuts with two 19mm wrenches and removed three bolts, remove the coupling.

Remove the elastic coupling flange, gearbox support, and speedometer drive.

3. Using a 10mm wrench, unscrew the three nuts securing the ball joint of the gearshift lever and...

4...remove the lever from the studs of the rear gearbox cover.

5. Using the “27” key, unscrew the reverse light switch and remove it.

Remove the bottom cover of the gearbox and...

Using a 13mm wrench, unscrew the nut securing the rear cover to the gearbox housing

Unscrew the remaining nuts securing the rear cover to the gearbox housing

8. Use a screwdriver to recess the shift rod for 1st and 2nd gears.

9. Remove the rear cover of the gearbox.

10. Remove the rear bearing of the secondary shaft and its inner ring.

12. Remove the speedometer drive gear with the lock – a metal ball

Removing the oil deflector washer

14. Using a 10mm wrench, unscrew the bolt securing the 3rd and 4th gear shift fork

15. Use a screwdriver to engage third gear.

16. Using a “17” wrench, unscrew the bolt securing the gear block.

17. Remove the bolt securing the gear block.

18. We take out the block of gears of the 5th gear and reverse gear.

19. Remove the spacer washer.

20. Using a “13” wrench, unscrew the two bolts securing the clamp cover and, having removed it,...

21...remove three springs and three retainer balls.

22. Remove the 5th gear gear bushing.

23. Remove the 5th gear gear assembly with the synchronizer.

24. Raising the rod, remove the 5th gear synchronizer clutch and the reverse intermediate gear

Remove the 5th gear and reverse shift rod with the fork

Remove the 5th gear synchronizer clutch hub.

We further disassemble the gearbox in the manner described above.

Assembly of the V stage, reverse gear and gear selection mechanism is carried out in the reverse order of disassembly, taking into account the following.

We fasten the axis of the reverse gear intermediate gear before installing the shafts into the gearbox housing with a torque of 78 Nm (8 kgcm).

Before installing the fifth gear and reverse fork rod into the crankcase, install a spacer bushing on it.

We press the inner ring of the bearing onto the gear block of the 5th gear and reverse gear, and the outer ring into the socket of the rear cover.

We press the rear bearing of the secondary shaft onto the shaft to facilitate installation of the rear cover. We install the reverse intermediate gear, the 5th gear driven gear and its fork at the same time.

Tighten the gear block mounting bolt to a torque of 78 Nm (8 kgcm).

Since 1992, five-speed gearboxes do not have a washer installed on the secondary shaft and the configuration of the secondary shaft and the 5th gear synchronizer clutch hub has been changed.

On the secondary shaft, the diameter for the hub was 28, became 25 mm; The width of the hub landing part has become larger and the landing diameter has been reduced from 28 to 25 mm.

The specified parts are not interchangeable with previously produced ones, therefore, when repairing a gearbox of an “old” design, we follow the following rules:

— if the washer is changed, then we install the secondary shaft and hub of the “old” design;

— if instead of the secondary shaft or hub, parts of the same name of a “new” design are installed, then we replace them as a whole, that is, when replacing the hub, we also replace the secondary shaft and vice versa. In this case, we do not install the washer.

How to change gears correctly on a VAZ 2101

This position applies when driving under normal conditions. The car starts off in first gear and then automatically shifts between 2nd, 3rd and 4th gears. The switching moment depends on the position of the accelerator pedal and the driving speed. Removed the decorative cover Removed the boot (pulling it up) The process of removing the lever. I picked up the locking sleeve with an awl and thereby took it out of the groove on the lever rod and removed the lever rod. The process of removing the old repair kit. Using two screwdrivers, I carefully opened the petals of the spacer bushing and removed it, and then the elastic and locking bushings.

Please note => How to call the position of warehouse accountant

VAZ 2107 box repair

Before starting work, you should thoroughly clean the outer surface of the gearbox and wash it with kerosene.

Important: before repairing the VAZ 2107 gearbox, it is necessary to drain the transmission oil from it. It's easier to do this before removing it from the car.

Further actions are performed in the following sequence:

- Remove the clutch fork from the gearbox.

- Remove the rubber coupling flange from the gearbox output shaft.

- Unscrew and remove the cross member securing the gearbox.

- Remove the speedometer drive.

- Remove the reverse lamp switch.

- Remove the cuff from the ball joint of the gearshift lever.

- Unscrew the nuts securing the gearshift lever housing cover to the rear wall of the crankcase.

- Remove the housing and gasket from the studs.

- Unscrew the nuts securing the gas exhaust pipe.

- Remove the mounting bracket and remove the mounting bolt.

- Unscrew the 5 nuts of the gearbox rear cover with a 13mm wrench.

- Unscrew the 10 nuts of the bottom cover with a 10mm wrench.

- Remove the cover along with the gasket.

- Unscrew another rear cover nut.

- Press in the 1st and 2nd gear rods using a screwdriver.

- Tapping the rear cover, remove it from the gearbox along with the gasket.

- Remove the plug for the reverse gear and 5th gear block (repairing the 5th gear of a VAZ 2107 often involves replacing worn gears or bearings).

- Remove 5th gear and reverse gear.

- Place the rear cover on wooden blocks and press out the 5th gear block bearing.

- Remove the sealing gasket.

- Press the oil seal out of the front gearbox cover and remove it with pliers (if it needs to be replaced).

- Remove the spring ring from the gearbox shaft.

- Unscrew the bolt securing the front bearing and remove it along with the washers.

- Unscrew the gear bolt

- Move the 5th gear fork and remove the gear block.

- Clamp the gear block in a vice.

- Remove the secondary shaft washer.

- Unscrew the cover bolts and remove the cover together with the gasket.

- Remove the springs and fixing rods from the crankcase holes.

- Remove the retaining balls using a rubber bulb (by creating low pressure in it).

- Remove the 5th gear and synchronizer from the output shaft.

- Remove the ring.

- Remove the 5th gear clutch by sliding the shift fork.

- Remove the reverse idler gear from the axle.

- Remove the reverse and 5th gear shift rod, shift fork and rod bushing.

- Unscrew the bolt securing the rod.

- Pull out the locking pin.

- Release the locking ring associated with 5th gear.

- Remove the hub, spring washer, gear and reverse bearing from the shaft.

- Remove the front intermediate shaft bearing.

- remove the intermediate shaft.

- Remove the rear bearing ring part.

- Unscrew the bolt securing the 3-4 gear fork to the rod.

- Remove the 3-4 gear rod and fork.

- Pull out the locking pin.

- Unscrew the fastenings of the 1-2 gear fork.

- Remove the rod and fork of 1-2 gears.

- Unscrew the screws securing the secondary shaft bearing plate using an impact screwdriver.

- Pull the bearing out of the crankcase.

- Remove the input shaft.

- Remove the roller bearing from the shaft.

- Pry off the retaining ring of the secondary shaft intermediate bearing and remove the bearing.

- Remove the secondary shaft.

- Unscrew the nut and remove the reverse axle.

- Remove the 3-4 gear synchronizer and the hub shaft spring washer from the shaft.

- Remove the stabilizer clutch hub and 3rd gear.

- Press the secondary shaft out of the gear.

- Remove the shaft gear bushing and remove the gear and 1st gear synchronizer.

- Remove the 1st-2nd gear clutch hub and the synchronizer clutch.

- Remove the 2nd gear and bearing race.

- Remove the Belleville washer.

- Press the secondary shaft out of the bearing race.

- Pull out the retaining ring and 4th gear spring.

- Continue repairing the VAZ 2107 gearbox (5 mortar), disassembling other gears.

- Replace all worn parts with new ones.

- Reassemble the gearbox by performing the steps in reverse order.

Disassembling the box

Troubleshooting speed box 2101

Despite the long service life of the high-speed gearbox, this unit requires periodic maintenance and care. Among the causes of device breakdowns when it is necessary to disassemble it, it should be noted - poor gear engagement. In this case, you need to inspect the cylinder and seals. Also, the car owner should check the level of the existing working fluid in the tank. In addition, synchronizers are subject to diagnostics. When they are deformed while the engine is running, changing speed modes occurs with difficulty. The best option is to replace worn parts.

It is advisable to repair the gearbox on a VAZ 2101 if the gear is knocked out. As a rule, this manifestation is due to the fact that the teeth of the gearbox gears have become unusable, the springs and bearings have worn out. Premature deformation of these mechanisms is due to the fact that trips were often made in difficult conditions.

Manifestations such as noise at the 2101 gearbox are a consequence of insufficient oil in the system or the driver uses low quality fuel. Because of this, all components related to the gearbox suffer. Failure of the synchronizer and wear of the clutch basket also contribute to the appearance of noise from the gearbox, and a characteristic crunch may be noted when changing gears.

If any of the above occurs, driving is dangerous. That is why it is worth repairing the VAZ gearbox.