Causes of engine detonation

It is immediately worth noting that the described process is conventionally divided into critical and acceptable. In the latter case, we mean an infrequent phenomenon that reveals itself irregularly. Most often, such detonation is heard at low speeds and lasts a short period of time. This is typical for engines of small (1.4-1.6 l) volume and relatively high power: for example, 105 hp. s., 1.5 l with a torque of 135 Nm.

However, where does detonation come from in conventional power plants? There are several reasons.

Incorrect engine operation

Detonation can also occur on a fully functional engine: for example, during a long climb in the wrong gear while simultaneously pressing the accelerator pedal. In such conditions, the crankshaft simply cannot gain the required speed and accelerate the car.

Ignition

Some car owners set the ignition timing early so that the engine responds faster when pressing the gas. This is how it works, but in this case the mixture ignites prematurely and the engine detonates, counteracting the upward movement of the piston. In addition, carbon begins to form and accumulate in the working chamber, as a result of which it decreases in volume and overheats. Sometimes deposits smolder, making the process of ignition of the mixture uncontrollable.

Glow ignition and its effect on detonation

Detonation of the power plant can be caused by improper replacement of spark plugs when these parts are installed with the wrong heat rating. We are talking about a phenomenon similar to detonation, but not one. Glow ignition is just a consequence of early ignition of the mixture, as a result of which the engine can run for some time even when the ignition is turned off.

Tampering with the ECU

Often, car owners try by any means possible to make their child more economical. To do this, the ECU is reflashed, chipped, and other manipulations are carried out with the electronics of the unit. As a result, the mixture becomes leaner, and a little less fuel is actually consumed. But detonation is inevitable, leading to a reduction in engine service life.

Incorrect octane number of gasoline

Compared to a diesel engine, in a gasoline power plant the mixture is ignited not by compression, but by an electric spark. With a high octane number, the fuel can be compressed more strongly without causing detonation. Accordingly: using fuel with a low parameter (different from the requirements of the car manufacturer) will inevitably lead to this unpleasant phenomenon. It is also worth considering that the label on the gas station pump does not always correspond to the contents of its tanks. That is, if you want to refuel with high-quality fuel, select the appropriate station. And as practice shows, this can be done experimentally.

Design Features

The peculiarity of the power unit can also cause detonation. The process of its formation is influenced by:

- combustion chamber configuration;

- piston crown type;

- engine compression ratio;

- presence (absence) of turbocharging.

Turbocharged engines running on gasoline have the highest compression ratio, and therefore the risk of detonation. Here, low quality fuel with an abnormal octane rating is not only inappropriate, but also dangerous.

Sensor malfunctions (for injection engines)

A feature of injection engines is the presence of elements capable of monitoring the performance of the system at any time. Below are the sensors whose failure leads to detonation:

- Throttle position sensor (TPS). Its malfunction is accompanied by power failures and jerks during movement, acceleration, as well as a “floating” idle. In this case, detonation will make itself felt especially clearly when the driving style is associated with constantly “drowning” the gas pedal to the floor. It is worth noting: the indicator on the Check Engine instrument panel most often does not light up in such a situation.

- Coolant temperature sensor (CTS). If it is faulty, the motor will begin to overheat and the ECU will not “know” about it. That is, detonation will only appear in critical temperature conditions.

- Knock sensor (DS). Its failure is a rather rare occurrence: most often the wires connecting to it are damaged. But if it is the DD that is faulty, the Check light will not light up. To verify that the knock sensor is faulty, start and stop the engine. Then remove any terminal from the battery and reconnect after a few seconds. Start the engine: if detonation appears but disappears before the next start, the reason is in the sensor. He may also be “to blame” if the power plant continues to operate with the ignition off.

Main causes of detonation

Among the various causes of detonation, experts note incorrectly set ignition timing on gasoline engines (fuel injection timing on diesel internal combustion engines), failures in the mixture formation process, decreased efficiency of the cooling system, as well as a number of other possible reasons.

Engine detonation is conventionally divided into permissible and critical. Permissible detonation should be understood as a short-term (sometimes unnoticeable) phenomenon. Critical detonation can occur constantly, only with increasing loads on the engine, at idle, and also during operation of the internal combustion engine in various modes.

The list of main causes of detonation includes:

- violation of engine operating conditions;

- using gasoline with an octane number different from the recommended one;

- design features of the power unit;

Engine Operation

Detonation can be heard on a fully functional engine when the unit is operated under load. The mixture in the cylinders usually detonates on a long climb when moving at a speed that does not correspond to the selected gear.

In other words, engine knock is clearly noticeable when the driver tries to go uphill at a low speed without downshifting and presses on the gas. The crankshaft speed at this moment is low, the engine “does not pull”, that is, it does not gain power and does not accelerate the car. In this case, a ringing metallic detonation knock, similar to the knock of piston pins, is added to the general sound of the engine. This sound is the result of a blast wave hitting the walls of the combustion chamber at high frequency.

It should also be noted that the tendency to detonation of the fuel-air mixture directly depends on the proper operation of the ignition and cooling systems. The mixture may detonate in the cylinders if the following factors are present:

- early ignition;

- engine overheating;

- abundant carbon deposits in the combustion chamber;

- severe coking of the engine, as a result of which the compression ratio increased;

Ignition is often set early to improve engine response to the gas pedal, especially at low speeds. Pre-ignition causes the mixture to ignite before the piston reaches TDC. Since the piston is still moving to top dead center, early ignition of the mixture means resistance to its movement. An additional negative phenomenon with such ignition is overheating.

The accumulation of carbon deposits in the combustion chamber leads to a decrease in the volume of the chamber itself and an increase in the compression ratio. The second most important factor influencing detonation is a significant increase in temperature in the combustion chamber in the presence of deposits. In some cases, carbon deposits can literally smolder, causing the mixture in the cylinders to ignite uncontrollably. It turns out that detonation, under certain conditions, provokes the appearance of glow ignition, which is also an abnormal spontaneous ignition of the mixture.

We also recommend reading the article about what glow ignition is. From this article you will learn about the causes of this malfunction, as well as the consequences of a short circuit on the motor and its service life.

Additionally, it is necessary to take into account the fact that engine detonation can occur as a result of installing spark plugs with an inappropriate heat rating for this type of engine. Separately, detonation can be affected by making various changes to the fuel equipment, as well as chipping the ECU and other manipulations that affect mixture formation in order to save fuel. Conventionally called “economical firmware” by tuners, it means that a number of adjustments are made to the engine control unit, affecting fuel maps. The result is a lean mixture in different operating modes of the internal combustion engine, and the dynamic characteristics of the car are reduced.

When the engine ECU is operating at the factory settings, the mixture is designed for “soft” ignition, due to which the temperature inside the combustion chamber remains within the specified limits. Under heavy loads in the engine after flashing, detonation often occurs on a mixture that is too lean. A lean mixture leads to overheating of parts. This overheating during subsequent fuel injection can cause spontaneous ignition of the fuel charge.

Octane number of gasoline

One of the most common causes of engine detonation is the use of low octane gasoline, which is not recommended for this type of internal combustion engine. Let us add that this parameter is not so important for a diesel engine, since the main characteristic of diesel fuel is the cetane number.

The fact is that diesel fuel is initially more resistant to detonation. In a diesel engine, ignition occurs as a result of compression and heating from such compression of the fuel mixture. For this reason, diesel engines are designed to have a higher compression ratio.

Gasoline has noticeably lower resistance to detonation compared to diesel fuel. The octane number is a characteristic that reflects the knock resistance of gasoline. In a gasoline engine, the compression ratio is lower; the fuel-air mixture ignites from a spark. The higher the octane number, the more compression of the mixture is allowed without the risk of detonation.

It turns out that refueling a car with 92-octane gasoline, the engine of which has a high compression ratio and the use of fuel with an octane rating of only 95 and higher is allowed, will lead to detonation when the engine is running under load.

It must be separately taken into account that detonation can occur even if fuel is filled with the required octane number. In this situation, the issue may be due to low fuel quality, since gas stations often use various methods to artificially increase the octane number. Among these, the addition of liquid gas (propane, methane) to gasoline is especially noteworthy. These gases are volatile, that is, they evaporate after a short period of time. As a result, the fuel tank quickly ends up filled with low-octane gasoline, although the initially filled fuel corresponded to that recommended for this type of internal combustion engine.

ICE design features

Detonation can occur in an engine due to a number of design features of the power unit. The list of main solutions includes the following:

- compression ratio of a specific internal combustion engine;

- the shape of the combustion chamber itself and the piston crown;

- features of placement of spark plugs;

- turbocharging;

Highly accelerated gasoline atmospheric and turbo engines have a higher compression ratio compared to their standard atmospheric counterparts, as a result of which they demonstrate an increased susceptibility to detonation. Such internal combustion engines require operation exclusively on high-quality gasoline with a high octane number.

Design solutions to prevent detonation

To combat detonation, engineers at different times used certain design solutions. Such solutions are aimed at the most efficient and rapid combustion of the fuel charge in the flame front, complete combustion from a spark, and slowing down oxidation processes, which result in uncontrolled ignition.

It must be added that in order to counteract detonation, engine speed can be increased, resulting in a shorter time for oxidative reactions to occur and a reduced likelihood of self-ignition of the fuel-air mixture.

Another engineering solution is turbulization. Due to the design features, the mixture flows in the combustion chamber receive a certain rotation, and the flame front from the spark spreads faster. Reducing the distance the flame front travels also helps resist detonation. To shorten the distance, the cylinder can be made with a smaller diameter, and it is also possible to install another spark plug.

Separately, it is worth noting the prechamber-torch ignition, which at one time was designed to effectively combat detonation. Motors with a pre-chamber are structurally designed to have two chambers: a pre-chamber and a main chamber. The principle of operation is that an enriched mixture is created in the small chamber, and a lean mixture is found in the main chamber. After ignition of the mixture in the prechamber, the flame front ignites the mixture in the main chamber, eliminating the possibility of detonation.

On modern engines, electronics actively resist detonation. The advent of microprocessor-based engine control units (ECUs) made it possible to automatically change the ignition timing (IAF) based on readings from sensors, as well as dynamically make adjustments to the composition of the combustible mixture.

Engine detonation when ignition is turned off

A fairly common occurrence during the operation of gasoline and diesel internal combustion engines is that engine detonation appears after the ignition is turned off. In this case, the engine jerks as the crankshaft has time to make a few more revolutions.

Such engine detonation after turning off the ignition can be caused by two phenomena:

- dieseling;

- glow ignition;

In the first case, which is typical for gasoline units, short-term or long-term operation of the engine occurs as a result of an increase in the compression ratio or the use of fuel that does not match the knock resistance, which leads to spontaneous ignition of the fuel-air mixture. In the second case, the fuel in the cylinders may spontaneously ignite after the ignition is turned off due to contact with hot surfaces or a smoldering layer of carbon deposits in the combustion chamber.

Causes of engine detonation

As practice shows, detonation most often occurs on old carburetor engines, although in some cases this process can also occur on modern injection engines equipped with an electronic control unit. Reasons why detonation may occur include:

- Excessively lean air-fuel mixture . Its composition can ignite even before a spark enters the combustion chamber. At the same time, high temperatures provoke the occurrence of oxidative processes, which are the cause of the explosion, that is, detonation.

- Ignition earlier . With an increased ignition angle, the processes of ignition of the air-fuel mixture begin even before the piston hits the so-called top dead center.

- Using the wrong fuel . If gasoline with a lower octane number than prescribed by the manufacturer was poured into the car tank, then there is a high probability of a detonation process. This is explained by the fact that low-octane gasoline is more chemically active and enters into chemical reactions faster. A similar situation will occur if, instead of high-quality gasoline, some kind of surrogate like condensate is poured into the tank.

- High compression ratio in the cylinders . In other words, coking or other contamination in the engine cylinders, which gradually accumulates on the pistons. And the more carbon deposits there are in the engine, the higher the likelihood of detonation occurring in it.

- Faulty engine cooling system . The fact is that if the engine overheats, the pressure in the combustion chamber can increase, and this, in turn, can cause fuel detonation under appropriate conditions.

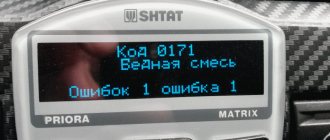

The knock sensor is like a microphone

These are common reasons that are typical for both carburetor and injection engines. However, there may be another reason for an injection engine - failure of the knock sensor. It supplies the corresponding information to the ECU about the occurrence of this phenomenon and the control unit automatically changes the ignition angle in order to get rid of it. If the sensor fails, the ECU will not do this. At the same time, the Check Engine light on the dashboard will be activated, and the scanner will display an engine knock error (diagnostic codes P0325, P0326, P0327, P0328).

Currently, there are many different options for flashing the ECU in order to reduce fuel consumption. However, their use is not the best solution, since there are often cases when such flashing led to dire consequences, in particular, incorrect operation of the knock sensor, that is, the engine control unit simply turned it off. Accordingly, if detonation does occur, the sensor does not report it and the electronics do nothing to eliminate it. Also, in rare cases, damage to the wiring from the sensor to the ECU may occur. In this case, the signal also does not reach the control unit and a similar situation occurs. However, all these errors can be easily diagnosed using an error scanner.

There are also a number of objective factors that influence the occurrence of detonation in individual engines. In particular:

- Engine compression ratio. Its importance is determined by the design features of the internal combustion engine, so if the engine has a high compression ratio, then theoretically it is more prone to detonation.

- Shape of the combustion chamber and piston crown. This is also a design feature of the engine, and some modern small but powerful engines are also prone to detonation (however, their electronics control this process and detonation in them is rare).

- Forced engines. They usually have a high fuel combustion temperature and high pressure, and accordingly, they are also prone to detonation.

- Turbocharged engines. Similar to the previous point.

As for detonation on diesel engines, the cause of its occurrence may be the fuel injection advance angle, low quality diesel fuel, or problems with the engine cooling system.

The operating conditions of the machine can also cause detonation. In particular, the engine is more susceptible to this phenomenon provided that the car is driving in a high gear, but at low speed and engine speed. In this case, a high degree of compression occurs, which can provoke detonation.

Some car owners also strive to reduce fuel consumption, and to do this they reflash the ECU of their cars. However, after this, a situation may arise where a poor air-fuel mixture reduces the dynamics of the car, while the load on its engine increases, and at increased loads there is a risk of fuel detonation.

What reasons are confused with detonation?

There is a concept called “glow ignition”. Many inexperienced car enthusiasts confuse it with detonation, since with glow ignition the internal combustion engine continues to operate even when the ignition is turned off. In fact, in this case, the air-fuel mixture is ignited by heated engine elements and this has nothing to do with detonation.

Another phenomenon that is mistakenly believed to be the cause of engine knocking when the ignition is turned off is called dieseling. This behavior is characterized by short-term engine operation after turning off the ignition at an increased compression ratio or using fuel that is inappropriate for detonation resistance. And this leads to spontaneous ignition of the air-fuel mixture. That is, ignition occurs as in diesel engines, under high pressure.

Detonation when starting the engine

Detonation when starting the engine occurs when lean air-fuel mixtures enter one or more cylinders. The reason for the depletion of the mixture is the clogging of special sprayers - nozzles.

When blockages appear, the calculated value of the volume of fuel supplied is violated. To determine the cause of the blockage, it is necessary to check the coarse filter, as well as the filters of each injector.

A cold engine, after warming up, often restores its operation, and engine detonation stops.

VAZ engine detonation

Without exception, all VAZ cars, from model 2101 to modern versions, are equipped with gasoline power plants, which are a higher priority for all automobile manufacturers.

The normal functioning of any gasoline engine is ensured by a number of factors - maintaining the correct proportion of the air-fuel mixture, the quality of gasoline, the appropriate ignition timing, and the condition of the CPG. If at least one of these factors does not correspond, a negative effect such as detonation may occur.

Where does the knocking in the engine come from: how to find out

Specialists diagnose problem nodes by the nature of the knock, its tone and area of localization. A stethoscope is widely used for diagnosis. You can also make your own device for listening to engine knocks. To solve the problem, you will need a steel rod to which you need to solder a metal can. The bottom of such a container will effectively act as a membrane. To determine the cause of the knocking, the end of the rod is applied to various parts of the diagnosed internal combustion engine, while the can is pressed tightly against the ear.

The tone of the sound is an indirect sign, since on different engines the knock may appear louder or muffled. For example, the conventional knock of the crankshaft main bearings on a 1.4-liter Korean car may well be louder and easier to hear compared to the knock of connecting rods on a 3.0-liter German car. Often, the individual design features of each engine can cause a knock that has a different sound color, but the breakdown may be the same.

If we talk about diagnostics based on the nature of engine knocking, then it is worth highlighting a constant knocking, periodic knocking with one frequency or another, as well as occasional knocking. In the latter case, it is worth understanding the impacts that occur unevenly.

Engine knocking is usually associated with engine speed, that is, with the frequency at which the crankshaft rotates. The faster the engine spins, the higher the knocking frequency. The indicated frequency may or may not coincide with the crankshaft speed. It is also worth noting that the sound can become more or less intense (differ in strength) depending on the operating mode of the internal combustion engine.

For example, with an increase in the speed and load on the engine, there is a natural increase in the loads on the moving parts of the crank mechanism and the timing belt. In this case, the worn elements will knock more strongly than when the engine is idling.

At this stage, when diagnosing, it is important to determine whether the knocking increases with increasing speed. This often requires experience, since it is necessary to listen for knocking against the background of the general increasing noise of the operating unit.

In parallel with this, it is necessary to separately take into account the fact that the oil pressure in the engine lubrication system also increases with increasing speed. In some cases, the engine oil itself acts as a “damper”, and the knocking itself may become less intense even with increased load on the engine. For this reason, an important parameter is the temperature of the internal combustion engine. The engine may knock heavily when hot because the oil is diluted. At the same time, the knocking may hardly appear when cold. The opposite situation also happens when the engine knocks distinctly when cold, but after reaching operating temperature the noise disappears or is minimized.

What is detonation?

For the working process to occur in internal combustion engines, 2 conditions are required:

- creation and supply of a combustible fuel-air mixture to the cylinders;

- its subsequent arson.

On diesel engines, the mixture ignites independently due to the high temperature that occurs in the combustion chamber at the end of the compression stroke. In a gasoline engine it needs to be ignited. Spark plugs are used for this purpose. How does the ignition process occur under normal conditions?

After applying high voltage, a spark is formed between the electrodes of the spark plug, which ignites the combustible mixture. If you watch the combustion process in slow motion, you will see that the flame torch sequentially passes the entire volume of the combustion chamber from the spark plug to the most distant walls at a speed of about 50 meters per second.

However, in some cases the combustion process occurs differently. After the flame front begins to spread, due to the high temperature, spontaneous ignition of the mixture in the compressed volume occurs. A pressure wave arises, further accelerating the ignition process, as a result of which the combustion process accelerates to supersonic speeds (from 1 to 2 kilometers per second).

It sounds like an explosion, hence the metallic sounds caused by the shock wave. Moreover, the latter causes mechanical damage to parts (pistons, rings, valves).

Reasons causing detonation:

- high compression ratio in the cylinders;

- unsuitable grade of gasoline or its low quality (insufficient octane number);

- ignition timing is too large;

- driving at low engine speeds;

- increase in load;

- increased engine heating;

- high ambient temperature.

Detonation manifests itself only in motion, from which we can conclude: when the ignition is turned off, it is not engine detonation that occurs, but something else.

This is the name given to the working process in the cylinders of a gasoline engine, which proceeds similarly to the diesel cycle. As mentioned above, detonation occurs when the engine is running under load. This means that it cannot be even at idle. Why doesn't the engine stall with the ignition off?

One of the reasons for this phenomenon is excessive heating of the engine with a high compression ratio in the cylinders. After turning off the ignition, the crankshaft rotates by inertia for a few more seconds until it comes to a complete stop, and the time of each stroke increases. Since the ignition is turned off, there are no new flashes at first.

At some point, the high temperature of the air mixture over an increased period of time leads to such heating of the mixture that it spontaneously, in the absence of a spark, ignites. That is, ignition took place like a diesel engine. The crankshaft received a torque impulse and began to rotate.

However, with an increase in rotation speed, the duration of the compression stroke has decreased, and the mixture does not have time to heat up to the ignition temperature. The flashes stop and the engine stops. But here the compression time increases again, the heated mixture begins to ignite again, and this can continue for some time.

Most often, the engine still stops on its own. If this does not happen, it must be silenced forcibly. To do this, simply engage the gear and release the clutch pedal. With increased load, the motor will finally stall.

Dieseling is generally a harmless process. It does not cause any harm to the engine, although it happens quite rarely. Moreover, this phenomenon indicates that the engine compression is excellent, which means there is no wear on the parts of the connecting rod and piston group.

Why does detonation occur in engine cylinders?

Experts identify several main reasons why fuel detonates in the engine.

- First of all, it is worth immediately highlighting the use of low-octane gasoline in units with a high compression ratio. Simply put, the octane number of gasoline (AI-92, 95 or 98) actually indicates its resistance to detonation, and not its quality, as many people mistakenly believe.

The use of fuel with an inappropriate octane number for a particular engine naturally leads to the fact that the fuel-air charge detonates under strong compression. Let us also add that simple engines that do not have an ECM and a knock sensor are at greater risk.

- Engine coking. It is important to understand that modern engines not only in foreign cars, but also in domestic cars are very different from their analogues from the times of the USSR. In a nutshell, if the engines on the Moskvich 2141 model had a compression ratio of about 7 units and worked normally on any fuel, today the units have from 9 to 11 or more units.

In this case, a decrease in the physical volume of the combustion chamber as a result of the formation of a carbon layer will lead to the fact that the fuel charge in the cylinder will be compressed more strongly, and detonation will appear. If we add to this the low quality of fuel at domestic gas stations, then the risks increase even more.

- Violation of the mixture formation process. In this case, a too “rich” mixture, in which there is a lot of fuel in relation to the amount of air, may begin to detonate.

Note that such detonation can be short-term and often goes unnoticed by the driver, however, it is impossible to say that there is no harm to the engine.

- Ignition timing (IDA). In simple words, the ignition angle determines at what point the spark will be supplied to the combustion chamber. If we consider that normally fuel does not explode, but burns, then it becomes clear that the combustion process also takes some time.

In this case, it is important to ensure that the maximum gas pressure on the piston, which is formed as a result of the combustion of a portion of fuel, occurs precisely at the moment of the working stroke of the piston. This is the only way to effectively transfer the energy of the expanding gases through the piston to the crankshaft.

To do this, the spark can be applied a little earlier than the moment the piston reaches top dead center (TDC). During this time, the fuel will have time to ignite, and the expansion of gases and an increase in pressure on the piston will occur just at the moment when the piston has already reached TDC and then goes down.

Currently reading

How to maintain and charge a maintenance-free type of battery for...

ZIL 130 engine: a legend of the Soviet automobile industry

At the same time, you need to understand that incorrect adjustment of the ignition moment (shift of the ignition moment closer to TDC), when the mixture ignites almost when the piston has already risen to the top dead center, often becomes the cause of detonation. Again, we traditionally add to this the low quality of fuel.

- Design features of the combustion chamber. It happens that some engines are initially prone to detonation. In some cases, the reason is the design of the combustion chamber itself, the implementation of its cooling, etc.

Another culprit may be pistons that have an unsatisfactory thermal balance (for example, the piston bottom is thickened closer to the center, which noticeably worsens the quality of excess heat removal). One way or another, the risk of detonation on such engines is much higher.

- Engine overheating. If you pay attention to the previous point, it becomes clear that an increase in temperature in the combustion chamber is the cause of detonation. It is quite obvious that a decrease in the efficiency of the cooling system can lead to the engine overheating.

We also recommend reading the article about what an engine knock sensor is. From this article you will learn about the purpose, structure and operating principles of this element.

Under such conditions, detonation is quite likely to occur, and detonation itself also additionally leads to local and general overheating. For this reason, engine detonation as a result of a faulty cooling system is especially dangerous, since the power unit can not only be severely damaged, but also cannot be repaired in the future.

How to fight

Every driver should understand that the main cause of detonation is fuel, or rather, low-quality fuel. Therefore, when this problem occurs, the first thing you need to do is check the gasoline. If necessary, refuel your car from trusted suppliers. Know that the cheaper the fuel, the greater the chance that it is absolutely of poor quality. Sometimes it is better to overpay a symbolic amount so as not to face a problem tomorrow.

You also need to adjust the ignition if necessary. If nothing changes with early ignition, try adjusting it again, put it in neutral. It can also occur under light loads, but during prolonged use. In this case, a layer of carbon deposits forms on the cylinder walls, which increases compression and reduces heat dissipation. To prevent this from happening, it is advisable to carry out diagnostics: give the engine a load at least once a month (accelerate the car to high speed for several minutes). It is advisable to do this outside the city.

You should also check the spark plugs. But here you need to remember that the spark plugs for your car were recommended by the car manufacturer, so here you need to listen to their opinion. Otherwise, you will soon have to return to car repairs again.

Sometimes detonation may be accompanied by a green or black stream of smoke from the exhaust pipe. This indicates that the pistons are being destroyed or have already collapsed and parts of aluminum are being released through this pipe. In this case, adjustment will not help. Here you need to start replacing the entire piston group.

So you've checked every possibility and still can't figure out where the legs come from? Sometimes it happens that the cause may be engine overheating. You need to check the coolant and find out the status of the thermostat. In the event that everything is in order here, the best advice would be to go to the nearest service station.

I would like to think that in this article everyone learned something new and useful for themselves. In order to never encounter such a problem, take care of your horse, do not refuel it at unverified gas stations and sometimes do diagnostics of all its systems and components. Good luck!

Detonation or spontaneous combustion of the mixture

Due to inexperience, these two phenomena can be confused.

Self-ignition of the mixture occurs as a result of severe overheating of the engine. At the same time, at the end of the compression stroke, the temperature of the fuel mixture becomes higher than normal, and it flares up uncontrollably.

Also, if the engine is heavily coked, then hot carbon deposits on its walls as a result of contact with the fuel mixture can ignite it.

To separate these two phenomena, you need to turn off the engine by turning off the ignition. If the engine does not stall immediately, then most likely a phenomenon called detonation is occurring inside it.

Signs and consequences of engine detonation

All parts that make up the motor design are designed only for a certain temperature and pressure. But they are not designed for increased shock loads, which always accompany detonation. A characteristic ringing (knock) is heard outside the engine, and the following happens inside: centers of destruction form on the parts. Such defects do not decrease over time, but quite the opposite. Cut, torn edges of the pistons are the result of detonation, which appeared regularly.

The side surface and top edges are affected first

Its result may also be a breakdown of the cylinder head gasket. Note that the phenomenon of detonation itself is accompanied by a change in the exhaust: the composition changes, the color darkens, the temperature drops. However, all this is difficult to notice - detonation can appear and disappear. We can only rely on sensitive hearing and the Check Engine light.

Even the appearance of sustained detonation does not always trigger the indicator. For example, if the throttle sensor fails, the following results: the ECU “thinks” that everything is fine, but the engine “sputters” at a lean mixture and, of course, it will “ring.”

Methods for eliminating detonation

The most common causes of detonation in the engine and the very concept of this phenomenon are described above, and now we should talk about what methods exist for eliminating this problem in a car. Increasing the speed can help reduce the likelihood of explosive fuel combustion because it reduces the time it takes to burn. Enormous pressure is reduced and the fuel is not subject to increased temperature.

For example, we can cite the case if a driver is driving along a straight section of road from a mountain. When the car begins to climb the mountain, its speed decreases and you can hear engine detonation. Therefore, in order to accelerate the car, the driver switches to a lower gear and by accelerating the car, this phenomenon is eliminated.

The risk of occurrence of the described malfunction is reduced by increasing humidity. The water contained in the air reduces the combustion temperature of the fuel. The most common tricks that drivers use to get maximum engine performance without knocking are:

- Use of the highest quality gasoline;

- Braking to advance the ignition;

- Reducing the combustion temperature of fuel.

This can be achieved using an intercooler or water injection. The cooler receives air and sends it to air coolers, which reduce the temperature. The described problem is far from new in the field of vehicle operation, and car manufacturers have tried their best to reduce or completely eliminate the occurrence of detonation for a long time.

Intercooler automobile

This is a rather complicated process that includes a large number of different factors. In order to understand engine operation, one must gain an understanding of the occurrence of detonation and study the stages that contribute to it.

You need to constantly pay attention to all non-standard sounds and noises in the engine, because they can help determine the occurrence of detonation and must be eliminated as soon as possible. Although this phenomenon is very dangerous for a car engine, it is not difficult to control; the main thing is to understand the cause of the malfunction

comments powered by HyperComments

Eliminating engine detonation

The occurrence of detonation in an injection engine is influenced by the following parameters:

- Ignition timing.

- Leaning of the fuel mixture.

Many car owners are interested in how to eliminate engine detonation with their own hands. In order to get rid of explosive combustion of flammable mixtures, craftsmen often use the following techniques:

- Operating the engine in higher gears. When operating at high speed, fuel combustion time is reduced against the background of maximum pressure. Accelerating the car reduces the likelihood of detonation.

- Replacing spark plugs.

- Increase in air humidity. More humid air significantly reduces the temperature in the combustion chamber.

- Using an intercooler air cooler to reduce the temperature of the air before it is forced into the cylinders.

- Replacing gasoline with fuel having a higher octane number.

- Moving the distributor to change the ignition timing towards a decrease for stable operation of the carburetor engine at idle speed.

- Engine braking to advance ignition timing.

The method of adjusting the position of the distributor is used for a short time to get to the nearest gas station and change the fuel to higher octane gasoline. After this, the distributor must be installed in its previous position to ensure the optimal advance angle.

There are cases when car owners deliberately adjust the ignition timing upward, leaning the fuel mixture. As a result, the dynamic characteristics of the car increase and the torque increases. When carrying out this operation, the likelihood of engine detonation increases significantly.

Eliminating or reducing engine knock is a difficult task. To identify the real cause of explosions inside the engine, it is necessary to carefully study the operating principle of the power unit and understand what contributes to their occurrence.

The root causes of the precedent

Having understood the peculiarities of the concept of “detonation” and its practical destructive effect on the functionality of the engine, it is worth moving on to the search for factors that provoke such a phenomenon. There are many factors as a result of which detonation can occur in an engine, although most of them are considered indirect and lead to negative consequences in a complex manner. The causes of engine detonation are identical for all types of power units, often as follows:

- Refueling with low octane fuel or poor quality fuel.

- Coking of the engine with combustion components.

- Operation of spark plugs that do not meet the requirements of the vehicle manufacturer.

- Failures in the process of mixture formation.

- Overheating of the power unit.

- Malfunction of the engine cooling system.

- Incorrect operation of the injectors or fuel pump.

Each of these factors can become the primary source of detonation, provoking the appearance of additional problems in the combustion of the fuel mixture, which will lead to incorrect functioning of the engine

When detonation occurs, it is important to understand what is happening in the engine, to determine the exact source of the malfunction at the start of its progression, when eliminating the problem is simple and inexpensive. A knock in the engine can be caused not only by its detonation, but also by other problems not related to this precedent

If the causes of detonation of an injection engine can be determined using a special sensor installed on the car from the factory, then timely detection of the problem on carburetor car models depends directly on the attentiveness of the owner and his ability to “hear” the car. Let's take a closer look at the most popular causes of incorrect combustion of the fuel mixture, knowledge of which will help prevent many problems with the performance of the machine and its specific working components.

Low octane rating of fuel

Often, the car owner’s desire to somehow save on car maintenance results in the method of refueling vehicles at points of dubious origin. This saving method allows you to refuel with inexpensive fuel, the quality of which does not meet international standards. As a result, the consumer fills the car with a lean mixture or liquid with a reduced octane rating, which directly affects the functionality of the engine, causing engine detonation and more. In the vehicle's passport, the manufacturer indicates the technological features of the fuel that should be used when operating the vehicle. Fueling a car with a mixture with an octane number several orders of magnitude lower than the manufacturer recommends provokes a rise in the operating temperature of the unit under load, as well as an increase in pressure in the internal combustion engine. The cause of the malfunction in this situation is premature ignition, which causes the fuel to burn longer. This process occurs due to reduced compression of the cylinders, and provokes a subsequent detonation factor, which consists in the formation of carbon deposits on the surfaces of the internal combustion engine elements.

Carbon formation on the internal surfaces of the cylinder

Accumulations on the internal walls of internal combustion engine components are provoked mainly by prolonged use of low-quality fuel and the lack of systematic engine maintenance in accordance with the regulations. The appearance of deposits in the form of soot on the cylinder walls entails a decrease in their working volume, which provokes, accordingly, an increase in the compression of the fuel mixture with its subsequent uncontrolled flammability. As a result, the prospects for detonation in the engine increase significantly.

Incorrectly selected spark plugs

The purchase of inexpensive spark plugs that do not meet the criteria specified by the manufacturer may cause unauthorized ignition of the fuel mixture in the internal combustion engine. Spark plugs, by their purpose, act as a controller for the ignition moment of the fuel in the combustion chamber. Defective spark plugs or those that do not meet the automaker’s requirements can provoke a decrease in cylinder displacement with a subsequent increase in mixture compression and an increase in engine temperatures. All these phenomena in complex combination provoke incorrect ignition of the fuel mixture and detonation processes. When engine detonation is predominantly observed after turning off the ignition, the driver needs to check the spark plugs for functionality and replace them if they do not meet the parameters specified in the vehicle operating regulations.

Carbon deposits and design features of internal combustion engines

An implicit reason for engine detonation is the shape of the combustion chamber, which is very different from the “ideal” hemispherical one. Depending on the design operating mode of the internal combustion engine, the shape of its chamber can affect the ease of starting, efficiency (completeness of combustion of the mixture), noise, vibration level, and thermal operating conditions. A specific symptom is glow ignition, which occurs due to poor evacuation of combustion products. The accumulated soot becomes hot, early igniting fresh portions of fuel in the “corners” of the chamber, or provoking engine vibrations after the ignition is turned off.

Carbon deposits on valves

Eliminating such shortcomings is the job of the factory, but sometimes a similar “jamb” occurs after a major overhaul, when when grinding the cylinder head (to increase the compression ratio), a thin layer of metal remains at the edges of the combustion chamber (not chamfered), which later becomes red-hot, performing the role of soot.