Coarse and fine filters

The fuel purchased at gas stations is not clean enough for the efficient operation of automotive equipment. It contains various tiny particles of water and mechanical impurities. When driving, products that pollute the fuel also appear in the system itself, the results of the activity of all systems.

The ingress of solid particles and water into the engine negatively affects its functioning and the durability of parts. Therefore, fuel in cars goes through 2–4 stages of purification. First, so-called coarse cleaning is performed using special filters that trap large particles of contaminants.

For better fuel cleaning, it is also useful to install a fine fuel filter, which removes small contaminants that are invisible to the eye.

Types of filter elements

To choose the right filter or filter element for a car, bus, tractor or other vehicle, you need to understand what types of filters there are, what characteristics and features they have.

Firstly, all filters are divided into groups according to filtration fineness (the ability to trap particles of contaminants contained in fuel):

- Coarse filters - ways to retain particles with a size of 100 microns (0.1 mm);

- Normal cleaning - retains particles with a size of 10 microns;

- Fine cleaning - retains particles with a size of 5 microns;

- Particularly fine cleaning - retains particles as small as 1 micron.

However, in practice, filters are often divided into two groups based on the fineness of filtration: coarse purification - they retain particles with a size of approximately 50 microns, and fine purification - they retain particles with a size of 2-3 microns.

At the same time, filtration fineness, according to standards, is of two types - nominal and absolute. The nominal filtration fineness indicates the size of particles retained by the filter element by 95%, absolute - by 98% or more. Manufacturers use both parameters, which you should definitely pay attention to when purchasing.

Secondly, all filters are divided into two types according to the method of retaining polluting particles:

- Surface adsorption filters;

- Filters of volumetric adsorption type.

Surface filters consist of porous sheet materials of small thickness; contaminant particles are larger in size than the pores and are retained (stuck) on the surface of these materials. Surface adsorption filters include filters based on paper, synthetic nonwoven materials, thin felt, etc.

Volumetric filters consist of a relatively thick layer of porous material; polluting particles are retained both on the surface and inside the entire volume of this material. Volumetric adsorption filters include coil (filament) filters, as well as filters made of various pressed materials - fine wood flour, ceramics, etc.

Finally, thirdly, filters are divided into two types according to design:

- Non-separable - the filter element is placed in the housing, and this entire structure is replaced as an assembly. Most often, such filters are used on passenger cars;

- Collapsible (with a replaceable filter element) - the filter element is placed in a collapsible housing and can be replaced if necessary. Most often, filters of this design are used on trucks, tractors, buses, special equipment, etc.

In what follows, we will talk about replaceable filter elements, but everything that has been said is also true for non-separable filters.

Installation of fine and coarse fuel filters

Two types of filter elements are often installed on modern cars:

The coarse filter has a metal body and mesh-shaped insides, which allows it to trap particles with a length of more than 0.1 mm. That is, rough fuel purification involves the elimination of the largest contaminants.

Predominantly injection cars are equipped with a fine filter, since their performance depends entirely on the quality of fuel purification. The mechanism is a plastic case with cardboard inserts inserted into it. Special paper traps the smallest particles in the fuel flow, which contributes to high-quality fuel purification.

That is, the mesh and paper liners are designed to trap particles of dirt and impurities, preventing them from penetrating into the engine cylinders.

Some manufacturers install combined filter models (coarse and fine cleaning are carried out by one device - a seperator)

Why do you need to change the fine filter?

Any car that uses various working fluids is equipped with special elements that serve to cleanse the fluids from harmful impurities. The fuel system uses a coarse and fine filter to clean the fuel. During the operation of the car, it becomes clogged and does not perform its functions efficiently. Therefore, it has to be changed periodically.

Gasoline contains abrasive particles that negatively affect the operation of the internal combustion engine. There are special meshes on the gas tank, carburetor and fuel pump for cleaning fuel, but they are not enough for high-quality purification of gasoline. They can only trap large particles.

Fine filters are designed to capture small particles. They can trap elements as small as 15 microns.

If you do not change the filter element in time, this can lead to the following problems when operating the car:

- The engine runs jerkily, first at high speeds, and then when switching to low speeds.

- The car loses power. A contaminated element does not perform its functions, as a result, the fuel injection nozzles become clogged and the fuel system becomes clogged. Thus, an insufficient amount of gasoline enters the engine, which leads to a decrease in its power.

- Premature wear of lambda probes, spark plugs and accelerators. If cleaning is poor, the fuel does not burn out completely; some of it settles on the cylinder walls, spark plugs and pistons. As a result, the fuel mixture is saturated with heavy metals and foreign particles, and then enters the exhaust gas system through accelerators and lambda probes, which significantly reduces the service life of parts.

- Fuel consumption increases. A clogged fuel filter does not directly affect fuel consumption, but it does cause a decrease in vehicle power. As a result, to accelerate the car to the desired speed, you have to put more pressure on the gas, which requires more fuel consumption.

- The car won't start. If you neglect to change the filter element, as required by the manufacturer, the engine may not start.

Filters differ in design and are divided into non-separable and collapsible products. Non-separable ones refer to disposable parts.

The collapsible one consists of a ceramic element and a mesh that can be cleaned, washed and used several times. The cost of a dismountable filter is slightly higher than a disposable one.

Features of fuel filters for diesel engines

Water in diesel fuel is a long-known problem and has several causes. Free water is separated from the fuel, usually using filter separators.

Low quality fuel filters often do not retain water well and it simply passes through them. Then the water, along with the fuel, enters the injection system. As a result, the combustion process of the mixture is disrupted and corrosion occurs, since even a small amount of water quickly leads to damage to the sensitive injection system.

Another important requirement for a diesel fuel filter is that it must remain operational at very low temperatures. Cold causes wax to crystallize in diesel fuel, which can clog a regular filter.

Quality fuel filters prevent this by returning warmed fuel to the filter. A special element built into many filters monitors the fuel temperature and ensures an optimal mixture of heated fuel and fuel from the tank.

But what can happen to filters without an element that controls the temperature: since the fuel does not heat up without circulation, it becomes viscous, and besides, paraffin crystals appear in it. They get into the filter and clog it. Gradually, fuel stops flowing into the injection system, causing the engine to lose power and stall.

Filter clogging indicators

Key indicators that the filter is clogged:

- When driving uphill you feel a strong jerk;

- A sharp drop in engine power;

- The engine often stalls;

- Fuel consumption has increased;

- The car jerks when driving.

Particularly economical drivers try to cheat and wash the filter with water and then install it back. This will not make the process easier since the dirt is absorbed into the fibers of the mesh and cannot be washed off so easily. But after such cleaning, the filter loses its throughput, which is even worse for the machine.

You should only change the filter outdoors; fuel fumes are hazardous to health and can lead to fire; it is recommended to have a fire extinguisher ready before work. Do not smoke or light a fire near the machine. We recommend disconnecting the battery to avoid sparks. It is also recommended to monitor the pressure level in the system.

Filtration stages and types of devices

It is important to note that the system that makes the fuel in the car cleaner is divided into 2 stages:

- rough cleaning, removing all large particles of dirt;

- fine cleaning that removes small particles of dirt and dust from the fuel.

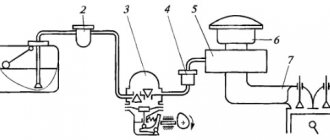

Not all drivers know where the fine fuel filter is located, as well as the coarse filtration device. Screening out foreign particles can be carried out in the fuel tank before the flammable substance enters the fuel system of the car, or the device can be located in the engine compartment under the bottom of the car. And the element for purifying small particles is located between the pump and the carburetor.

Based on their design properties, filters are divided into:

- Collapsible - mesh elements made of brass or ceramic located in collapsible structures clean gasoline quite efficiently. Among the advantages of such devices is the ability to disassemble and wash them. After this you can use it again.

- Non-removable - such cleaners are usually installed in front of the fuel pump. They are inexpensive and, due to their spiral design, last longer and provide high-quality fuel filtration.

- With a transparent body - they do an excellent job of filtration, allow the driver to assess the degree of contamination and change the element in a timely manner.

It is important to understand that the fuel systems of different cars may have their own characteristics. When selecting a part, it is worth taking this into account.

Sometimes the fuel system may contain not two, but as many as four stages of purification.

Design and types

In the overall design of the car, the fuel filter can be located:

- in the fuel tank;

- under the bottom of the car;

- in the engine compartment.

Design of coarse and fine fuel filters

Modern fuel purification systems have from 2 to 4 stages. First, the fuel goes through a coarse fuel filter, which removes large fractions visible to the naked eye. Next, it enters the fine fuel filter, where microparticles that pose the greatest danger due to their abrasive properties are removed.

Purpose and design of the fuel filter

Fuel purification usually occurs in several stages:

- First of all, large particles of impurities are retained (rough cleaning). This function is performed by the protective mesh of the fuel pump installed in the tank.

- The final purification of gasoline from contaminants is carried out by a fine filter installed in the fuel line between the tank and the vehicle’s power unit.

The design of fuel filters may vary. Fundamentally, it consists of a housing with an inlet and outlet fitting, inside of which there is a filter element (for example, 10-micron filter paper).

Pre-filter fuel - what is it for?

- Pre-filter fuel - what is it for?

- 1. Types and categories of coarse fuel filters.

- 2. Indicators of clogging of the coarse fuel filter.

- 3. Replacement of the coarse fuel filter.

The fuel filter in a car is one of the vitally important elements of the fuel system. These devices are able to filter all small particles of dust, dirt and rust, thus preventing them from entering and reaching the fuel system line. If there is no filter and there is a small flow area in the fuel line itself, then particles of rust and dust will quickly clog the entire system, as a result of which the supply of fuel to the internal combustion engine will be prevented.

- 1. Types and categories of coarse fuel filters.

- 2. Indicators of clogging of the coarse fuel filter.

- 3. Replacement of the coarse fuel filter.

It is important to note that the filter system is divided into two filtration stages. The first and main stage of fuel purification will be coarse cleaning, which is capable of removing all large particles of dirt from the fuel. The second stage of fuel purification consists of fine cleaning, which is a filter that is installed between the internal combustion engine and the fuel tank, through which small particles of dust and dirt are removed.

Types and categories of coarse fuel filters.

In addition, filters are divided into two more categories. So, there are main filters , which are located directly in the fuel line, and submersible filters, which are located directly in the tank, paired with a pump. Thus, the fuel filter, which is a coarse filter, is a mesh and at the same time a reflector. Thus, it is through this device that all large impurities are removed from the fuel. The device of the filter element itself is located in a glass, which is attached to it by means of a small ring and a pair of bolts.

The gap between the body and the glass is closed using a paronite gasket. There is a special calming agent at the bottom of the glass. Thus, the filter is able to clean itself before the fuel enters the fuel part of the system. In addition, a special valve is used in the fuel filter, which is designed to reduce injection and is capable of regulating the operating pressure in the entire fuel system. All this is installed as an addition to the direct fuel injection system. All excess fuel can be safely and without obstacles removed and returned directly to the fuel tank. The diesel system functionally uses the filter in the same way, although it always has a completely different design.

If the procedure for replacing the fuel filter is carried out independently, then first you should determine the location of this filter. In most designs, it is located under the bottom of the car, in the engine compartment or directly in the fuel tank.

The fuel filter device can be replaced without much difficulty yourself. However, if a motorist doubts his abilities, he should turn to professionals or ask for basic advice from specialists. However, many manufacturers and experts claim that the fuel filter should be replaced at least every 25,000 km. However, these are only conditional figures, since everything will depend on the fuel used and the mode in which the vehicle is operated.

Indicators of clogging of the coarse fuel filter.

There are several main signs by which you can determine that the fuel filter is clogged:

— engine power drops sharply;

— the engine stalls quite often;

— the engine shakes a lot when driving uphill;

— when driving directly, the car jerks;

Some thrifty motorists quite often cheat by washing the filter with water, as a result of which they return it back to its place.

However, you should know that this will not make the process easier, since the dirt is firmly eaten and absorbed into the fibers of the mesh, as a result of which it is impossible to wash it with plain water.

But in addition, there is also a negative impact, since the filter will lose its capacity, which will only have the worst effect on the operation of the vehicle. That is why this kind of element needs confidence, reliability and quality during operation. Therefore, you should not save on it, but it is better to purchase genuine spare parts from the original manufacturers.

It is important to note that it is recommended to replace the filter only in the open air, since all fumes from the fuel can cause not only harm to the health of the motorist, but also lead to a fire.

In addition, you should never use fire or smoke near the vehicle. To avoid sparks, disconnect the battery.

Replacing the fuel coarse filter.

Due to the fact that all filters have different designs, there will not be one single unifying algorithm for carrying out work to replace the device.

For the sake of example, you should choose the most common fuel filter, which is installed on most injectors. To begin with, even before replacement, you should reduce the pressure in the system.

In order to do this, you need to remove the fuel pump fuse, which is located near the variable gearbox knob. This procedure will turn off the pump, after which you can turn on the engine. After 2 minutes of operation, it will stall, which will be a sign that the pressure in the fuel system has dropped. Now you should move to the right wheel, near which the filter itself will be located (near the fuel tank). By pressing the latches you need to unfasten the pump and remove the old filter.

It is important to be careful when installing a new filter, as its arrow should go in the direction of fuel flow. The fuel fuse should be returned to its rightful place. Due to the fact that a certain pressure imbalance has arisen in the fuel system, it will be quite difficult to start the car the first time, therefore, you will need to wait a certain period of time for the pressure to stabilize. It is important to note that many old carburetor cars did not have a built-in filter, as a result of which the motorist had to install it himself.

The standard case is when this is done through a cut in the suction line near the fuel pump itself. It is also worth taking into account that some modern cars do not have a filter at all. This is as common as a car not having a pump. However, this was done on purpose. Therefore, there is no particular need to add this device to the system, since the mesh wears out at approximately the same time as the pump.

Another option requires a complete replacement, which is quite expensive and difficult, since the pump device is often located in the most unfavorable and inaccessible place. Thus, the filter device can be very diverse: remote; cartridge, which is located directly in the fuel pump. All easily removable tips are connecting elements of the fuel line. To completely remove them, you should use pliers.

Replacing the coarse water filter

The time will come when the filter will become unusable. You need to change it to a working one.

Sequence of process steps:

- The water in the room is turned off. The taps throughout the room open. This is necessary so that possible residual water is “bleeded out” and the pressure in the pipe decreases. After this, the taps must be closed again.

- The old water purification filter is slowly unscrewed with a standard wrench so that no “kinks” form. If clamps were installed with the previous design, they are now removed.

- Be sure to completely remove the seal and install a “fresh” one.

- The new design is attached to the prepared place and screwed using a wrench. It is very important to ensure that the gasket remains in place, otherwise leakage cannot be avoided.

Purpose and principle of operation of the fuel filter

The fuel filter is one of the important elements of the fuel supply system. In order to ensure system reliability and efficiency, maintain high performance, minimal fuel consumption and stable exhaust emissions, fuel filters must not only match the engine type, but also be large enough in capacity to collect the maximum amount of particulate matter.

The standard type of fuel filtration is two-stage purification. Initially, the fuel goes through a coarse filter - its task is to retain large mechanical impurities. After preliminary cleaning, gasoline/diesel enters the fine filter, where final cleaning occurs.

Given the high requirements for diesel fuel purity, the filtration scheme differs for gasoline and diesel engines. In particular, for gasoline engines, the optimal indicator is the filtration of particles no larger than 10 microns in size, while the diesel power system requires the elimination of even very small contaminants, as well as water and paraffins, which very quickly clog the filter, impairing its throughput.

Liquid phase fuel filters

The gas is pre-cleaned using a mesh tip, which is provided on the intake tube of the multivalve. Next, the fuel is cleaned either in the solenoid valve or in the gearbox (if its design allows for the installation of a filter). In each case, the HBO filter performs the same function, but their operating conditions are different.

The gas valve operates under conditions that are practically no different from atmospheric conditions. The gearbox operates at the same temperatures as the engine, as it is connected to its cooling system. This necessitates the use of filter materials that can withstand elevated temperatures.

Important: When using non-original filters, extreme caution should be exercised, as they do not always meet the requirements for the operation of gas equipment of a certain type. If they do not comply, the equipment may cause significant damage: gearbox failure with subsequent failure of the injectors.

The filter design consists of a frame made of metal or plastic and a filter element made of cardboard. These parts are securely and hermetically glued to each other. However, the location where different materials are connected during operation under conditions of temperature changes limits the service life of the device. Gas valve filters operate under constant conditions in which there are no temperature fluctuations, so they are much more durable.

In more advanced designs of liquid phase filters, there is no adhesive connection. Special locks are provided to connect the parts.

The design of the gas valve includes a magnet, thanks to which small metal inclusions are captured.

General information

Filter systems are designed to retain small particles, thereby ensuring the primary purification of the incoming liquid from the water intake source. A coarse water filter for wells in autonomous water supply lines retains clay, grains of sand, and silt. With a central water supply, this kind of contamination does not penetrate into it, but in the process of transporting liquid through old water pipes, rust particles get into it. Moreover, the chemical composition does not change.

It is possible to maintain the normal operation of the filter only if it is periodically cleaned or new mesh equipment is installed. Cleaning devices without self-cleaning involves dismantling the mesh and washing it. Before unscrewing the mud trap, you need to close the access of water to the filter device.

When the mesh is cleaned, ensuring that there is no deformation on it, the device is assembled in the reverse order. Moreover, you need to pay attention to the condition of the silicone seals; if there are leaks in the connection area, they simply change.

Mesh filter devices have a simple design Source teplocity.com

Attention! Cartridge designs do not require cleaning; if they become clogged with dirt, the cartridge is simply replaced.

A coarse water filter is placed in front of the meter, washing machine and dishwasher; this helps reduce the likelihood of equipment failure due to incoming low-quality liquid and thereby extends the operating time of the devices.

So, among the main functions of filtering equipment it should be noted:

- protection of the pipeline from abrasive damage;

- retention of dirt particles dangerous to people;

- getting rid of unpleasant tastes and odors due to contaminated particles in water;

- protection of equipment from premature wear;

- prevention of pipeline clogging.

This equipment has different levels of cleaning, sizes, designs, but operates on the same principle - it allows water to pass through, creating a barrier to the passage of polluting particles.

A mud trap must be placed in front of the water meter Source moikolodets.ru

FUEL PURITY REQUIREMENTS

The presence of fuel purification filters and their ability to purify fuel depends on the fuel system used on the car.

Gasoline carburetor fuel systems are less susceptible to the harmful effects of contamination in fuel. Fuel mixing in such a system is carried out in the carburetor. Although it has small-sized passage holes in the jets, they are not so small that they could become clogged with small contaminant particles. Therefore, for such a system it is enough to have a mesh as a coarse filter and a fine filter element made of corrugated paper, which is installed in front of the carburetor.

Injection vehicles are more susceptible to fuel contamination. These fuel systems use injectors to spray fuel into the intake manifold. The design of these nozzles includes plunger pairs with high surface precision. If dirt particles get on these surfaces, they will damage them and the nozzle will fail. In addition, the holes in the injector through which fuel is supplied are small and easily clogged.

The most popular clean fuels are diesel engines and gasoline injection engines, which use direct injection of gasoline into the cylinders. In these systems, fuel is supplied directly to the cylinders by injectors. But it is supplied under pressure, which is provided by a high-pressure fuel pump, and plunger pairs are used.

FINE FILTER DESIGNS

There are several designs of fuel filters, but they are similar. They depend on the power system used. Thus, on gasoline carburetor cars, the fine filter consists of a transparent plastic housing in which a filter element is placed - corrugated paper folded in a certain way. A cover with two fittings is attached to the top of the sealed body. A pipe coming from the tank is connected to one, and a pipe leading to the carburetor is connected to the second. To avoid confusing the fittings during installation, there is a mark on the cover indicating the direction of fuel movement. This filter is capable of capturing dirt particles of 15-20 microns in size, which is sufficient for such a system.

This FTO is located in the engine compartment behind the engine, on the exit side of the fuel pipe.

In injection cars, since fuel moves through the pipes under pressure created by the fuel pump located in the tank, the fine cleaning element has a metal body, with fittings coming out of its ends to connect it to the fuel system pipelines. Inside there is a filter element, also made of corrugated paper. But this filter element is capable of capturing particles 5-10 microns in size.

This filter is located near the tank. It can be installed directly at the outlet of the fuel line from the tank, and can be accessed from inside the car. It is also possible to install the filter a little further, on the bottom of the car. Access to such a FTO is made from below the car.

For diesel engines, the fine filter can have two designs - collapsible and non-removable.

Collapsible diesel FTO with filter-sump

A collapsible filter includes a metal or aluminum housing, onto which a cover with fittings is screwed on top. A replaceable filter element is located inside the housing.

The non-separable one also consists of a body and a cover, but the connection between them is permanent.

Non-separable filter

These elements are installed in diesel engines in the engine compartment, not far from the high-pressure fuel pump.

REPLACEMENT FREQUENCY

The fine fuel element is replaced after 30 thousand km. However, the frequency of replacement is also affected by the fuel itself. If it contains a large number of foreign impurities, then replacement is carried out more often.

Checking the degree of filter contamination to determine whether it needs to be replaced is performed differently on cars with different systems. If this filter is transparent on a carburetor car and you can visually assess its condition, then on an injection car you cannot assess the degree of contamination. At a service station, the filter is checked by measuring the pressure created by the pump. If the pressure is below normal, the FTO is replaced.

The transparent housing allows you to assess the contamination of the filter

With diesel engines you can’t check the degree at all. All that remains is to look at the mileage of the car and the behavior of the car itself. If there are jerks when driving, first at high speeds, and then at low speeds, they often indicate contamination of the fine filter.

Fine filters, except for the diesel dismountable ones, are not washed in any way; these elements are considered consumables and if they are severely clogged, they are simply replaced. In a collapsible FTO, the filter element is replaced.

REPLACING FTO ON A CARBURETTOR CAR

Next, we’ll look at how to replace a fine filter on a car with different power systems.

Carburetor system of the VAZ-2108 car. Replacement is not that difficult since there is no pressure in the system. All you need to have on hand is a screwdriver and a new filter.

To replace it, find the old FTO under the hood, use a screwdriver to unscrew the clamps securing it, and disconnect the pipelines from it. Next, we find out from the mark how gasoline should flow, connect the pipelines to the new filter and tighten it with clamps. Then we start the engine and check whether fuel is leaking at the connection points.

Replacing the fine filter VAZ 2107

Before you start replacing, it is worth saying that these filters are disposable and cannot be cleaned . After using them, it is recommended to recycle these elements and install new elements in their place that have a relatively low price, which does not put a big dent in the car owner’s pocket.

The need to replace the fuel filter arises after the vehicle has been driven, on average, after 30 thousand kilometers. This indicator depends on the quality of the filter and gasoline that is used to fill the car each time. However, there are many other external signs by which many drivers immediately determine that the filter element is faulty:

- There are interruptions in engine operation . This is especially noticeable in idle mode, when the engine shakes and vibrates, and the speed is in different ranges that do not correspond to the norm (800-1000 rpm).

- Deterioration of dynamic characteristics. In the language of many drivers, this problem sounds like this: “the engine does not pull.” That is, the motor does not develop the required power, or there are failures in its operation.

- There are difficulties starting the engine. If the engine becomes more and more difficult to start each time, then the problem may not only be in the fine filter. However, this is the first thing people pay attention to if a malfunction occurs.

- A sharp increase in fuel consumption. Clogging of the filter channels leads to an increase in pressure in the fuel system, which is accompanied by strong spraying of the injectors, which do not supply the amount of fuel that should be in the combustion chamber. Therefore, if your car begins to consume much more fuel, then the problem is most likely in the fuel filter.

Now you need to buy the fine filter you need. When choosing a new element, pay attention only to foreign manufacturers, since domestic filters have a higher wear rate, which increases the frequency of their replacement, and therefore is uneconomical.

Replacing the filter on a carburetor car is quite simple. In this case, it is located under the hood of the car, so you need to open it and unscrew the clamps whose hoses are attached to the filter tubes. After this, the old filter needs to be unscrewed and another one installed in its place.

In injection cars everything is much more complicated. The fact is that such a filter is installed under the bottom of the car, near the fuel pump, so replacing it cannot be done without using an inspection hole or overpass. Let's consider the replacement process using the example of a VAZ 2170 Lada Priora car.

Before replacing, it is recommended not to start the engine for 4 hours. During this time, the pressure accumulated in the fuel system will decrease, although you can start working right away, but be prepared for a small stream of fuel to pour on you. Now prepare a small container, preferably a basin or trough, and place it under the fuel filter.

Now, on one side of the filter, press the spring-shaped retainer and pull the tube going to the filter from the fitting. On the other hand, you need to press on the plastic plates, after which the tube will easily disengage with the filter. Now you need to unscrew the nut of the clamp that holds the filter under the bottom of the car. Open the clamp and remove the filter. Check the condition of the tube seals on the vehicle's power system and replace if necessary.

Install the new filter in reverse and secure the tubes to the fittings. Pay special attention during installation. There should be an arrow on the element body indicating the direction of fuel movement. The fuel filter must be installed in strict accordance with the arrow. After this, start the engine and make sure there are no fuel leaks.

Fuel filters: types, features and replacement periods

Euro-5, you say? The quality of Russian fuel may have improved in recent years, but car dealers still recommend changing fuel filters more often than in Europe. After all, water, impurities or dirt getting into the expensive fuel equipment of a modern engine can be fatal. Let's talk about fuel filters - the main protectors of the car's fuel system.

The average annual mileage of a car in Russia is 17,500 km. With a consumption of 10 l/100 km, 1,750 liters of gasoline or diesel fuel pass through the vehicle’s fuel system in 12 months. But many people have much longer mileage! And all the fuel consumed by the engine must be carefully filtered - for this purpose, not one, but several fuel filters are usually installed in the car.

Types of fuel filters

The dirtiest (literally) work is performed by the coarse fuel filter , also known as a mesh filter or fuel pump filter. It is usually installed on the pump itself, preventing it from pumping large particles of dirt and rust into the fuel line. The more the mesh becomes clogged, the more difficult it is for the gas pump to pump fuel - very often it burns out due to a dirty coarse filter. Therefore, you need to update the filter mesh regularly, and when installing a new pump, this procedure is completely mandatory to maintain the factory warranty.

The main cleaning of gasoline from dirt is performed by a fine fuel filter , also known as a high pressure filter. In the classic version, it is a separate metal barrel with a filter element inside, installed in the fuel line: either under the bottom of the car or in the engine compartment. The fine gasoline filter traps particles as small as 10 microns.

On modern cars, a fine filter is increasingly installed directly in the gas tank, integrating it into the fuel module - such a filter, like the gas pump, is called submersible . The modular design is convenient for automakers: there is no need to make a break in the fuel line and seal the pipes with a separate filter - all elements are located inside the tank. But replacing such a filter is time-consuming and complicated, requiring complete disassembly of the fuel module, and sometimes removing the gas tank.

Diesel fuel filters differ from gasoline filters in design, since the requirements of diesel engines for fuel filtration are stricter. The pressure created by the fuel injection pump and diesel injectors is noticeably higher, which requires smaller clearances in the fuel system elements. This means that the minimum particle size retained by the filter should be smaller. In addition, diesel filters separate water from fuel - it is collected in a settling tank at the bottom of the filter, equipped with a sensor. Periodically, the collected water must be drained manually by unscrewing the fitting, so diesel filters are not made submersible - they are always installed separately, in an easily accessible place. Also, diesel filters are usually equipped with a manual fuel pump, and sometimes with heating

Finally, low-pressure carburetor filters are often used as additional fuel filters on both diesel and gasoline cars. They are cheap and quick to change, and thanks to the transparent plastic body they allow you to easily monitor the condition of the fuel, the presence of air in the system and the contamination of the filter element. Sometimes carburetor filters are used in another role - for example, as intake tract oil catchers.

Where is the fuel filter located?

The location of the fuel filter can be seen on car fuel system diagrams (for example, in our parts selector) or calculated on site by examining the fuel line. The diesel filter in a passenger car is always under the hood; You can also find a fine gasoline filter there, although more often it is installed under the bottom. If you checked the fuel line from the injectors to the gas tank and did not find the fuel filter, then it is of the submersible type and is located directly in the tank.

How often to change the fuel filter

The service life of the fuel filter depends on its type. Diesel filters are changed frequently - sometimes with every oil change (that is, every 10,000 km) or every other one. Recommended interval for replacing the gasoline filter: 30,000–40,000 km. Car manufacturers require submersible filters to be changed less frequently than those installed outside the tank, but this is only due to the complexity of the operation - the dirt holding capacity of submersible filters is no greater than that of remote filters.

Signs of a clogged fuel filter

A dirty fuel filter significantly impairs engine performance. The lack of traction first appears in peak modes - at high speed, during sudden acceleration, under intense load. If you do not promptly replace the filter, the power deficit will manifest itself during everyday driving. Also, a clogged fuel filter makes it difficult to start the engine and reduces the life of the fuel pump, the load on which increases many times over. Due to the lack of traction and improper operation of the engine, fuel consumption also increases.

Replacing the fuel filter

Threaded connections are one of the reasons for more frequent routine replacement of remote fuel filters. If the filter located under the car is not changed for several years, it will be difficult to unscrew it - the threads of the fittings become tightly soured, and the external fasteners rust. It is better to change the filter more often so that dismantling it does not cause problems.

It is recommended to change any type of fuel filter with a minimum amount of fuel remaining in the tank - this way there will be less fuel leakage. Before replacing the filter, it is better to remove the tank filler cap to relieve residual pressure. When changing a separate (remote) filter, it makes sense to relieve pressure in the fuel line itself - to do this, you need to pull out the fuel pump fuse and start the engine, exhausting the gasoline remaining in the filter and fuel line. Some filters have arrows indicating the direction of fuel flow (towards the engine) - make sure that the filter is installed the right way.

Replacing submersible filters (fine and coarse filters) is usually done through the inspection hatch in the car body, but may also require dismantling the gas tank. It is better to disassemble and reassemble the fuel module in accordance with the factory instructions - any forgotten or incorrectly installed rubber seal (of which there are many in the module) will lead to problems with starting the engine. In this case, all rubber seals must be replaced with new ones - order them in advance.

An example of replacing submersible filters with removing the tank on a Toyota Rav4:

Replacing the fuel filter

Depending on the make and model of the car, the work of replacing the filter differs slightly. The first step is to buy a suitable fuel filter (FF).

When purchasing, you should consider the following points:

- Filtration level. That is, after the fuel passes through the filter, it should no longer contain mechanical impurities. Otherwise, this may lead to damage to parts of the cylinder-piston and valve groups.

- Area of the filter element.

- The presence of a rubber seal covering the entrance to the filter itself. It can be made without a rubber seal, but changing it later will be problematic.

Fine filters are classified according to engine type into:

- Carburetor. Tolerance level of purification level from 15 to 20 microns (micrometers, 20 meters divided by 1 million). Particles smaller than 15-20 microns (a micrometer is called a “micron”) will pass through the fuel delivery system and into the internal combustion engine, but will not cause them harm.

- Injection. Injection engines are more delicate engines, so the permissible level of cleaning degree is within 5-10 microns. The injection system will clog faster if the filter allows particles larger than 10 microns to pass through.

- Diesel. Fuel filters for diesel engines are capable of capturing particles 5 microns in size and removing moisture, which is very important for a diesel engine.

To select the correct fuel filter, tell the store the make and model of the car.

You can replace a fine filter in a few minutes. On different cars, the TP is located in different places. If you have easy access to it, then replace it without any problems.

Reviews of the Fuel Free fuel saver have been published.

Procedure for replacing fuel filters:

- With the engine running, remove the fuel pump fuse and wait until the engine stalls. This action relieves pressure in the fuel system and fuel will not spill out when the filter is removed.

- Disconnect the “-” terminal from the battery so that there is no fire when a spark is formed.

- Loosen the fuel inlet/outlet clamps, or it could be wing nuts.

- Remove the old filter.

- Install a new one after first checking the direction of fuel movement. As a rule, an arrow of liquid movement is drawn on the filter housing.

- Connect ground.

- Reinstall the fuel pump fuse.

- Start it. After replacing the filter, it may not start immediately. Then take a ride and feel the difference in the operation of the internal combustion engine.