Reading time:

In the ZZ series of the Toyota manufacturer, the 2ZZ GE engine was developed by Yamaha Design Bureau employees. The main difference from the 1ZZ with the same cylinder capacity of 1.8 liters, developed in the USA (Buffalo, West Virginia), is a different ratio of piston stroke to cylinder diameter.

In 1ZZ the ratio is 91.5 mm/79 mm, which means the internal combustion engine is long-stroke, designed for medium speeds. In 2ZZ this ratio is slightly more than one - 85 mm/82 mm, that is, the engine is almost “square”, which is more convenient for high speeds.

Unlike the previous 3S family, the ZZ series engine uses an aluminum cast block. The cylinders are made of aluminum liners, the engine design corresponds to an “in-line four” with two overhead camshafts - DOHC 16 V. Yamaha developers managed to increase the power of the basic version of the 2ZZ GE through the use of technical solutions:

- compression ratio 11.5 - only for AI-95/98 gasoline;

- VVTL-I system - double profile of both intake and exhaust camshafts (valve lift 7.6 mm with a phase of 228 degrees and 11.2 mm with a phase of 292 degrees at the intake, 7.6 mm with a phase of 228 degrees and 10 mm with a phase of 176 degrees at release, respectively);

- equipped with two gearboxes – tiptronic and six-speed manual transmission;

- system for increasing the volume of air supply - only after 2004 due to additional holes above the intake valves;

- DIS-4 ignition system – individual coil for each spark plug;

- MPFI injection system - the intake manifold is equipped with a pressure sensor instead of an air meter.

VVTL-i system

MPFI system

The VVT-i variable valve timing system was used in Toyota engines until this time. The VVTL-i mechanism allows you to further increase valve lift at high speeds from 6200 rpm, but only after the engine has warmed up to 60 degrees. An electronic limiter cuts off spark and fuel supply at 8200 rpm for the Toyota Celica and 8500 for the Lotus.

At maximum speed there is a peak in the power of the vehicle's power drive. However, in this case, oil starvation and destruction of the oil pump are possible. In the first 2ZZ engines, valve lift remained unreliable, that is, it actually did not exist. After 2002, management modified the design by simply increasing the length of the lift bolt.

An important feature of the 2ZZ is the fact that the motor bends the valves at the moment they collide with the pistons when the timing chain is pulled out or broken. Full technical specifications of the 2ZZ GE are collected in the table below:

| Manufacturer | Shimoyama Plant |

| Engine brand | 2ZZ GE |

| Years of production | 1999 – … |

| Volume | 1796 cm3 (1.8 l) |

| Power | 140 kW (190 hp) |

| Torque moment | 180 Nm (at 6800 rpm) |

| Weight | 112 kg |

| Compression ratio | 11,5 |

| Nutrition | injector |

| Motor type | in-line petrol |

| Ignition | DIS-4 |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 4 |

| Cylinder head material | aluminum alloy |

| Intake manifold | duralumin |

| An exhaust manifold | cast iron |

| Camshaft | 2 pieces with 8 jaws each |

| Cylinder block material | aluminum with inclusion of aluminosilicate |

| Cylinder diameter | 82 mm |

| Pistons | aluminum, steel coated skirt |

| Crankshaft | 6 counterweights |

| Piston stroke | 85 mm |

| Fuel | AI-95/98 |

| Environmental standards | Euro 4 |

| Fuel consumption | highway – 6.6 l/100 km mixed cycle 8.4 l/100 km city – 10.5 l/100 km |

| Oil consumption | maximum 0.6 l/1000 km |

| What kind of oil to pour into the engine by viscosity | 5W30 |

| Which engine oil is best by manufacturer | Liqui Moly, Idemitsu, Mobil, Motul |

| Oil for 2ZZ GE by composition | synthetic in winter, semi-synthetic in summer |

| Engine oil volume | 4.4 l |

| Operating temperature | 95° |

| ICE resource | declared 200,000 km actual 500,000 km |

| Adjustment of valves | washers |

| Cooling system | forced, antifreeze |

| Coolant volume | 8.2 l |

| water pump | GWT-124A |

| Spark plugs for 2ZZ GE | IFR6A11 from NGK or SK20R11 from Denso |

| Spark plug gap | 1.1 mm |

| Valve train chain | 13506-88600 |

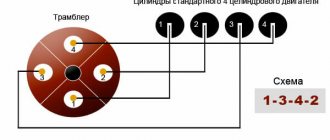

| Cylinder operating order | 1-3-4-2 |

| Air filter | Bosch 0986AF2375, blue Print ADT32227, Ashika 20-02-239, Alco MD-9146 |

| Oil filter |

Source: https://auto-gl.ru/tehnicheskie-harakteristiki-2zz-ge-1-8-l-190-ls/

Toyota 2ZZ-GE engine characteristics

| Production | Shimoyama Plant |

| Engine make | Toyota 2ZZ |

| Years of manufacture | 1999-present day |

| Cylinder block material | aluminum |

| Supply system | injector |

| Type | in-line |

| Number of cylinders | 4 |

| Valves per cylinder | 4 |

| Piston stroke, mm | 85 |

| Cylinder diameter, mm | 82 |

| Compression ratio | 11.5 |

| Engine capacity, cc | 1796 |

| Engine power, hp/rpm | 164/7600 182/7600 192/7800 221/7800 243/7800 260/8000 |

| Torque, Nm/rpm | 169/4400 176/6800 180/6800 215/5500 230/5500 236/6000 |

| Fuel | 95 |

| Environmental standards | Euro 4 |

| Engine weight, kg | 112 |

| Fuel consumption, l/100 km (for Celica T230) - city - highway - mixed. | 10.5 6.6 8.4 |

| Oil consumption, g/1000 km | up to 1000 |

| Engine oil | 5W-30 10W-30 |

| How much oil is in the engine | 4.4 |

| Oil change carried out, km | 10000 (better 5000) |

| Engine operating temperature, degrees. | ~95 |

| Engine life, thousand km - according to the plant - in practice | n.d. ~200 |

| Tuning - potential - without loss of resource | 300+ n.a. |

| The engine was installed | Toyota CorollaToyota Celica Toyota Matrix Toyota MR2 Lotus Elise Lotus Exige Lotus 2-Eleven Pontiac Vibe |

Maintenance schedule 2ZZ GE 1.8 l/190 l. With.

The “disposable” naturally aspirated in-line all-aluminum engine 2ZZ GE requires the following maintenance regulations:

- The timing chain will last about 150,000 km;

- It is recommended to adjust valve clearances every 30,000 miles;

- The manufacturer provides for cleaning the ventilation inside the crankcase every 2 years;

- the factory recommends changing the oil and filter after 7500 km;

- the fuel filter needs to be updated after 30,000 miles;

- according to the manufacturer's regulations, the air filter is changed annually;

- from the factory, the additives inside the antifreeze lose their properties after 40,000 km;

- in the DIS-4 ignition system, the service life of engine spark plugs is 20,000 mileage;

- the walls in the intake manifold begin to burn out after 60,000 km.

Service 2ZZ GE

Frequent oil changes are due to the presence of the VVTL-i system and a complex lubrication scheme for the cylinder walls.

Malfunctions and repairs of the 2ZZ-GE engine

In 1999, Yamaha engineers developed a sports version of the ZZ engine - 2ZZ-GE with a high compression ratio of 11.5, for 95 or 98 gasoline. It received a new composite cylinder block, under the crankshaft with a reduced stroke and a larger cylinder diameter (compared to 1ZZ), an improved variable valve timing system VVTL-i, which is the usual VVTi from 1ZZ-FE, but after 6200 rpm the valve lift increases to 11.2/10.0 mm and the engine produces its 190 hp. at 7600 rpm. For some markets, power is reduced to 164-180 hp. In addition to the main engine, there were also compressor versions based on the Eaton M45 supercharger with a pressure of 0.25 bar and a power of 220 hp, as well as based on the Eaton M62 compressor, a pressure of 0.3 bar and a power of 225 hp. Subsequently, the Eton M62 1.8 liter 2ZZ was inflated to 240 and 260 hp. Compressor motors were only available for Lotus and the compressor Corolla.

Malfunctions and their causes

1. High oil consumption. This problem awaits all 2ZZ owners after 150 thousand km, the oil burn indicates an approaching capital crisis, you can delay the moment by doing decarbonization, but after a while everything will return and the time will come to choose either a major overhaul or the purchase of a contract engine. 2. Noisy operation, engine knocking. The problem, as on the 1ZZ, is in the timing chain, the issue is solved by replacing it. 3. Floating speed, the problem is in the banal throttle block and idle air valve, clean and check.

Among other things, the VVTL-i system is very capricious and in order for everything to work like clockwork, once every 50 thousand km, you need to replace the lift bolts, otherwise there is a possibility of system failure and, as a result, loss of power after 6000 rpm. In terms of service life, the 2ZZ-GE engine is the same disposable as the 1ZZ, lives, on average, about 200 thousand km, after which it is changed to a contract 2ZZ or something else, 3S-GTE for example)).

Features of Toyota engines for hot cars

+79139857900 March 16, 2011 at 14:00 2011-03-16 2011-03-16 admin

“If we made girls, they would never break down either” - this is the charismatic slogan that people came up with for Toyota. In Novosibirsk, cars of this brand are still the most popular due to their reliability and relatively low maintenance costs. Toyota engines are especially famous for their reliability. Let's take a closer look at the most interesting power units of the Japanese brand.

A true little monster, the legendary 4A-GE(20V) has become an icon for many. Extremely reliable, and one of the most powerful naturally aspirated small engines today.

Output of 165 hp.

in combination with a manual transmission makes small cars such as Corolla Levin, Sprinter Trueno, Corolla FX incredibly fast for "sporty" production cars.

The previous generation 4A-GE 16V engine was installed on the famous Hachiroku (from Japanese 86), Toyota Levin in the A86 body. Since the first generation of Toyota Levin cars was rear-wheel drive, the A86, due to its compactness and good 4A-GE performance at that time, became incredibly popular among drift enthusiasts.

Tuners love the Hachiroka so much that each copy of this car is worth its weight in gold - probably finding an A86 in stock now will be a big problem. However, the second generation (A91, A 92 body) was already front-wheel drive.

The Japanese loved the Cuny for its light weight, good handling, and most importantly, the car had a new 4A-GE, which, thanks to the VVT system and an increased number of valves (5 per cylinder), already developed 165 hp.

There are several modifications of 4A-GE: Silvertop, BlackTop, as well as a version 4A-GZE with a supercharger. BlackTop is 5 hp more powerful, and 4A-GZE is the coveted 170 hp. develops already at 6400 rpm, but this version with a supercharger is quite rare. All versions of 4A-GE are very reliable under proper operating conditions. The main thing is to use only 95 gasoline and change the oil every 7,000 kilometers.

Toyota 2ZZ-GE engine tuning

Chip tuning. Atmo

Atmospheric tuning 2ZZ is not the most popular way, it is believed that the engine is pushed to the maximum, but this is not so)) What are we going to do? Porting of the cylinder head, combination of head channels, manifold, channel cutting, lightweight valves, lightweight TRD ShPG with a high compression ratio of 13, MWR St.3 shafts, 440cc injectors, DD performance manifold for the intake, 90mm damper, 4-2-1 direct-flow exhaust, setting up Apexi Power FC. This will produce about 250 pure naturally aspirated horses.

Turbine for 2ZZ-GE/2ZZ-GTE

Due to the prevalence of the motor, there are time-tested driving solutions on the market. To assemble a proper turbo, we will need Darton liners, Wiseco pistons with an 8.8 compression ratio, standard connecting rods, lightweight Monkey Wrench Racing valves and springs, an enlarged oil pan, a Walbro 255 lph pump, 700cc injectors, a turbo kit with an intercooler based on a Garrett GT28, an exhaust pipe 63mm, Apexi Power FC setting. The output will be 300+ hp. To get 400 hp, we replace the factory connecting rods with Crower ones, 800cc injectors, and a 76mm exhaust pipe.

Main disadvantages and advantages of the unit

The advantage for many drivers was the high engine speed threshold. But this also made the unit not very torquey at low speeds - you have to rev the engine hard to achieve good dynamics. And this despite the fact that the unit uses the Turbo system.

The main disadvantages are summarized as follows:

- too high sensitivity to low-quality fuel and oil;

- lack of possibility of major repairs due to the characteristics of the piston group;

- It is not uncommon for the VVTL-I system, which controls the valves, to break down;

- increased oil consumption, sticking of piston rings are problems with almost every unit in this series.

Many owners of cars with this engine have tuned some systems in order to achieve higher power levels and reduce the rev threshold to achieve rated performance. But this also leads to increased wear of engine parts.

The scope of use of the unit is as follows:

| Model | Power | A country |

| Toyota Celica SS-II | 187 hp | Japan |

| Toyota Celica GT-S | 180 hp | USA |

| Toyota Celica 190/T-Sport | 189 hp | Great Britain |

| Toyota Corolla Sportivo | 189 hp | Australia |

| Toyota Corolla TS | 189 hp | Europe |

| Toyota Corolla Compressor | 222 hp | Europe |

| Toyota Corolla XRS | 164 hp | USA |

| Toyota Corolla Fielder Z Aero Tourer | 187 hp | Japan |

| Toyota Corolla Runx Z Aero Tourer | 187 hp | Japan |

| Toyota Corolla RunX RSi | 141 kW | South Africa |

| Toyota Matrix XRS | 164-180 hp | USA |

| Toyota WiLL VS 1.8 | 190 hp | Japan |

| Pontiac Vibe GT | 164-180 hp | USA |

| Lotus Elise | 190 hp | North America, UK |

| Lotus Exige | 190 hp | USA, UK |

| Lotus 2-Eleven | 252 hp | USA, UK |

Design Features

The 2ZZ GE engine was designed taking into account the following requirements:

- suitability for front-wheel drive cars;

- level of the world's best analogues in terms of cylinder volumes;

- Dimensions like 1ZZ;

- boost “in terms of revolutions” for normal throttle response at the bottom.

As a result, version 2ZZ received the following design features:

- aluminum block made of composite material - aluminum with aluminosilicate fibers;

- duralumin cylinder head with two camshafts for 16 valves;

- increasing the cylinder diameter to the limit (there is only a 5.5 mm jumper between them);

- composite sleeve with high thermal conductivity (even steel overheats in such operating conditions);

- cylinder volumes are 1.8 liters due to an increase in their diameter, but a decrease in the piston stroke;

- modernization of the intake tract and exhaust manifold;

- VVTL-I system with variable phases and valve opening height;

- gas distribution according to the DOHC 16V scheme;

- improved oil supply circuit;

- attachments compactly placed on the body.

It is believed that a major overhaul of the cylinder block is impossible due to the small size of the jumpers - there is nowhere to bore for a larger diameter liner.

Advantages and disadvantages

The main design problem of the 2ZZ GE engine remains the ultra-small size of the jumper between the cylinders:

- During the cooling of an aluminum cast block, the formation of shells and cavities is possible with a probability of more than 75%.

- aluminosilicate inclusions have a different cooling rate, microcracks form near them;

- during the hardening process, a porous structure is possible, again due to foreign inclusions of MMS aluminosilicate.

Cylinder liners 2ZZ GE

Such an internal combustion engine device is initially prone to liner scuffing. The hone mesh (a special coating on the inner wall of the liner) wrinkles, unlike a similar coating on a steel or aluminum liner. The manufacturer declared the cartridge case life to be sufficient, but did not ensure this in practice.

All of the above is true for the piston, since this part is manufactured using a similar technology. The hardness of the piston skirt is increased by applying phosphorus-containing and iron-containing coatings.

https://youtube.com/watch?v=u92DTbU_wHs

The locking pin is the weak point of the VVTL-i system, since this part constantly collides with the rod, leading to mutual wear of the consumables. Often the bolt that secures the rocker arm axis is cut off and the lubrication of the unit is disrupted.

The advantages of the 2ZZ GE design are:

- maintaining dimensions relative to previous modifications of the series;

- reduction of heat loss due to a partition in the exhaust tract for rapid heating of the catalytic converter;

- large-sized resonator in the intake manifold;

- improved design of the oil pan, which eliminates the lubrication system from clogging;

- service life 500 thousand km.

Layout of 2ZZ GE under the hood

Technical features

The Toyota 2ZZ-GE engine is built on the basis of an aluminum cylinder block , cast iron liners and fused into the block. A light-alloy internal combustion engine is lighter than its counterparts with the same volume. The cylinder diameter is 82 mm , and the piston stroke is 3 mm longer. Therefore, the 2ZZ-GE engine can only be called long-stroke when compared with the 1ZZ internal combustion engine.

Traction at low speeds is worse, but remaining high piston speed worsens oil removal and increases demands on the rings. When creating a compact engine, the developers reduced the diameter and length of the crankshaft journals. As a result, the load increased and the resource of the internal combustion engine decreased .

Smaller T-shaped piston skirts run hotter and start knocking sooner. a major overhaul of the 2ZZ engine, although there are options for “re-lining” with non-original spare parts. The liners, despite their size suitable for repair, have the same problems.

In general, the 1.8 engine is considered “disposable”, and this is a typical picture for the series.

In some cases, the chain can stretch even before the resource of the 2ZZ-GE internal combustion engine is exhausted. When replacing an old part with a new one, it doesn’t hurt to update other drive elements, but the camshaft sprocket responsible for the intake is assembled with the variable-phase system drive, so it is often left behind. As a result , replacing the timing chain gives a temporary effect .

Disadvantages and weaknesses of 4ZZ

The gasoline 1.8 2ZZ-GE, like other engines in the series, demonstrates a total problem - excessive oil consumption due to waste.

The reason is in the design features of the internal combustion engine itself, so there is no risk of incorrect operation. The engine is designed in such a way that the oil scraper rings can become stuck during the warranty period. The attempt to overhaul the engine and replace the rings with new modifications did not solve the problem. Only the 2005 update improved the situation slightly.

The upgraded pistons were coated with an anti-friction coating , which the pioneers did not have. The lubrication volume of the 2zz-GE engine has also increased, which is noticeable on the oil dipstick with moved marks. The first pistons had four drainage grooves (small), the latest versions were already equipped with eight large ones.

In addition to excessive oil consumption, another problem made itself known at the very beginning. We are talking about a knocking sound in the engine caused by crankshaft play in the longitudinal direction. The VVT drive making a cracking noise is not such a typical negative (in comparison with other series). Although when replacing the timing chain, it makes sense to install a new VVT-I. The weak point is the chain itself, which sometimes stretches even before the resource is exhausted.

All these troubles reveal a significant shortcoming of the concern regarding the ZZ series engines.

Review of faults and methods for repairing them

Initially, the 2ZZ GE engine, when the timing chain breaks, bends the valves with the pistons due to their collision. However, there are other problems that are characteristic of it:

| The revolutions are floating | 1) valve failure XX 2) throttle failure | 1) replacing the idle air control 2) cleaning the damper |

| Knocks and noises | valve train chain | tension or replacement |

| Maslozhor | production of oil scraper rings | replacing rings |

Engines from 1999 to 2002 have a short lift bolt, and the VVTL-i system does not work at high speeds. The problem is solved by installing a long bolt.

List of car models in which it was installed

The 2ZZ GE engine was developed for front-wheel drive Toyota cars:

- Celica 190 and T-Sport - for the UK, 198 hp. With.;

- Celica GT-S – for the USA, 180 hp. With.;

- Celica SS-II – for Japan, 187 hp. With.;

- Corolla RunX RSi – for South Africa, 199 hp. s., 187 Nm;

- Corolla RunX Z Aero Tourer – for Japan, 187 hp. With.;

- Corolla Fielder Z Aero Tourer – for Japan, 187 hp. With.;

- Corolla XRS – for the USA, 170 hp. With.;

- Corolla Compressor – for Europe, turbo version 225 hp. With.;

- Corolla TS – for Europe, 189 hp. With.;

- Corolla Sportivo – for Australia, 189 hp. s., 180 Nm;

- Matrix XRS – for the USA, 18 l. With.;

- WiLL VS – for the USA, 190 l. With.

Toyota Corilla XRS

The engine characteristics are also suitable for cars from third-party manufacturers:

- Lotus 2 Eleven – for the UK and USA, turbo, 252 hp. With.;

- Lotus Exige - for the USA and Great Britain, turbo, 243 hp. With.;

- Lotus Elise - for the UK and North America, 190 liters. With.;

- Pontiac Vibe GT – for the USA, 180 hp. With.

Lotus 2 Eleven

Toyota MR-S is already MT › Logbook › [Tuning] Swap 2zz-ge

The easiest to swap in MRSK is the 2zz-ge engine.

The thing is that the blocks of the 1zz and 2zz engines are identical. But even despite this, there are still no real descriptions of swaps carried out in Russia. For those who are really concerned about these issues, the following information will be useful. All information was taken from the American site spyderchat.com, my translation. These are the tips of someone 22XY:

The right engine mount must be rebuilt or you can install it from the rear sight.

The oil dipstick needs to be replaced from the old engine. On a 2zz engine you need to cut the tube for the dipstick and weld it from 1zz or just hang it on the brackets.

The fuel rail remains from 1zz.

The throttle cable should come from the other side. Simply attach the connection of one of the bolts to the fire wall and there should be no play. You must then use the colletcore mounts so that the throttle cable runs like it does on the rear sight.

We also use brackets for attaching the mounted ones from 2zz or remake them from 1zz. It's best to use 2zz in stock. It will be easier to install and will look more like stock, even if no one sees it.

We use the idle block (I don’t know what exactly is meant, the original is idler pulley) with 1zz, we put it in the place where the same crap was previously on 2zz.

We use a bypass belt one size smaller.

If you had a plastic cover on top of the 2zz (which covers the ignition coils), you can install it.

It goes on to say that you can use a table in Excel from a certain blitzo to correctly assemble a new braid. The author redid it a little, because there are differences in the brains of '00 and '02.

The exhaust manifold must be cut from the side and remade 2-3 cm higher. There is some other information about the collector, but it’s unreadable, there are a lot of errors, you won’t understand what the author wanted to say. I think it will be easy to deal with the collector.

Source