More than four cylindersEdit

V-shaped five-cylinder engineEdit

With the advent of four-stroke engines in Gran Prix competition in 2002, manufacturers turned their attention to developing machines that would accommodate all sorts of weight and size restrictions.

Honda has concluded that a V-twin five-cylinder engine is the ideal design to meet these constraints. This engine, with three cylinders in the front and two in the rear, with a transverse crankshaft in the frame, is similar to the old V-twin three-cylinder two-stroke engine and extremely compact. This is not the first five-cylinder motorcycle engine (though they are very popular in the automotive industry). Back in 1965, Honda (for the first time) created an in-line five-cylinder two-stroke engine capable of reaching a speed of 20,000 rpm.

Inline six-cylinder engine

How does an inline engine work?

What does FSI engine mean? Features, repair, maintenance

Apart from the fact that each engine has a different number of cylinders, a 6-row and 4-row engine operate almost identically. The principle of operation is based on the basic characteristics of any internal combustion engine.

All cylinders in such a unit are arranged in one row. The crankshaft, which drives the pistons using the force of fuel combustion, is the same for all cylinders. The same applies to the block head - it is the same for everyone.

The main classification of in-line engines is balanced and unbalanced. Actually, balance is required due to the very complex crankshaft and depends on the number of cylinders used. The more there are, the more balance is needed. Thus, only designs with a small number of cylinders can be unbalanced in-line engines, otherwise very strong vibration appears during operation, which simply destroys the crankshaft. Simply put, even the cheapest 6-cylinder engines are much better balanced than expensive 4-cylinder engines. Thus, to improve balance, 4-row engines sometimes also require special balancing shafts, which are often called “smoothing” shafts.

Also, differences in classes arise due to the size and installation method. The “four” can easily be installed in any position under the hood, and the large 6-cylinder engine will not fit across, even if dozens of good engineers work on it - the cost of such an installation is unimportant, since there is simply not enough space for transverse installation.

Operating principle

How does the internal combustion engine work? Apart from the fact that each engine has a different number of cylinders, an inline engine with six or four cylinders operates the same. The principle is based on the traditional characteristics of any internal combustion engine.

All cylinders in the block are arranged in one row. The crankshaft, driven by pistons due to the energy of fuel combustion, is unique for all parts of the cylinder-piston group. The same applies to the cylinder head. She is the only one for all cylinders. Of all existing in-line engines, balanced and unbalanced designs can be distinguished. We will consider both options below.

Some examples of X-shaped engines

- used the prototype X-8 engine in the 1920s, which eventually led to a line of side-valve engines.

- Daimler-Benz DB 604 engine, developed for the B bomber. Development was frozen.

- An engine developed under the direction of V. Dobrynin for a strategic bomber.

- It was one of the engine options on the fighter prototype, but preference was given to the modification with.

- Rolls-Royce Exe engine, prototype air-cooled engine with valve timing.

- reports that it experimented with X-32 engines in the 1960s for its power plants in cars, but stopped development due to the complexity and unreliability of the design.

- It is planned to install a 12N360 engine in the X-12 version with a power of 1500 hp on the Russian tank.

Motul oil for diesel engines and gasoline engines

Disadvantages and advantages of modern in-line engines

Model range of Moskvich cars

Actually, except for a few points, the pros and cons of in-line engines are the same as those of conventional internal combustion engines.

Four-cylinder units, which are the most common, are considered the most reliable and simplest. They are relatively lightweight, do not require special repair costs and take up little space. The main disadvantage, which was already described above in the article, is imbalance. But, modern manufacturers have learned to cope with this, supplementing the design with balancing elements. Thus, the inline four is the best engine for a modern passenger car up to the middle class.

As for the six-cylinder engines, they are balanced almost perfectly, coping with the main disadvantage of the “fours”. But for balance you have to sacrifice an equally important size. Therefore, despite the best technical indicators, “sixes” are less common in ordinary cars - the crankshaft is very long, the manufacturing cost is too high, the dimensions are too large.

V engine

Today no one can imagine their life without cars, and therefore without engines. The most famous type of internal combustion engine is the V-shaped engine. It got its name from the characteristic arrangement of the cylinders, which have different levels of inclination in relation to each other. The angle range was from 10 degrees to 120. The type of motor under consideration works on the same principle as any internal combustion engine, the differences are only in the position of the cylinders.

Motor problems PSA DT17Ford AJD-V6276DT

The most unpleasant and widespread “sore” of this engine is the wear and rotation of the connecting rod bearings. Accordingly, the connecting rod journals also wear out. When one of the bearings rotates, oil starvation begins, which quite quickly leads to jamming of the connecting rod due to overheating due to dry friction.

The 2.7-liter engine is notorious for SUV owners with crankshaft failures. On a 3-liter engine, the crankshaft also breaks, but less often. Probably due to the fact that the 3-liter version has been produced for 6 years less.

Causes of oil starvation

There are several reasons for oil starvation of 2.7 / 3.0 HDI engines.

- The bearings rotate due to oil starvation, the reasons for which are always different. On 2.7- and 3.0-liter turbodiesels, oil starvation occurs due to wear of the oil pump. Yes, he is not very reliable here. In addition, the warning light indicating low engine oil pressure does not light up on these engines until the pressure drops to 0.5 bar. Owners of cars with PSA DT17 / Ford AJD-V6 / 276DT engines even “tune” the oil pressure sensor so that it can give an alarm signal when the oil pressure drops to 1 bar.

- There is also a problem with oil, which, according to tolerances, must be poured into the PSA DT17 / Ford AJD-V6 / 276DT and PSA DT20 / Ford AJD-V6 / 306DT engines. Through experience, owners of cars with this engine came to the conclusion that it is necessary to use thicker oil, which forms a more durable protective film. According to the manufacturer’s recommendation, this engine should be operated with oil classified ACEA A5/B5, but this engine operates most reliably with oil classified A3/B4. Oil of this category is less environmentally friendly, but at the same time forms a more durable protective film. The high-temperature viscosity at high shear rates is higher for this oil: more than 3.5 mPas versus 3.5-2.9 mPas for ACEA A5/B5 class oil.

There are no original repair liners, as well as pistons and connecting rods for the PSA DT17/Ford AJD-V6/276DT engine. If the liners rotate and the motor jams, the manufacturer suggests replacing the short block.

In general, the oil temperature in PSA DT17 / Ford AJD-V6 / 276DT and PSA DT20 / 306DT engines easily reaches 140 degrees Celsius. And if the piston group of this engine and the oil consumption in general do not bother, then overheated oil can fail it precisely at the lubrication points of the connecting rod bearings, where the protective film is destroyed. Particularly enterprising owners of heavy Land Rover SUVs equipped with this engine deviate from the manufacturer’s standards and fill the engine with truck oil with a viscosity of 10w40. By the way, according to the oldest data, the use of such oil in 2.7- and 3.0-liter turbodiesels was initially recommended.

Three-cylinder enginesEdit

Inline three-cylinder engineEdit

Four-stroke three-cylinder in-line engine with alternating flashes at 120 degrees

Four-stroke three-cylinder in-line engine with alternating flashes through 360/180 degrees

The two-stroke, three-cylinder engine was a firm favorite in the 70s, with many examples of this among motorcycles from Suzuki and Kawasaki. Both of these manufacturers even decided to create 750cc two-stroke engines. cm; GT 750 water-cooled from Suzuki and KH 750 from Kawasaki.

The crankpins of the crankshaft were positioned at an angle of 120 degrees to each other, and the first order forces were fairly well balanced, but due to the complex effect of the "swing couple" (rather, the "swing triplets"), they became famous for high levels of high-frequency vibration, especially if the unit was not well insulated from the frame with rubber pads.

Triumph has remained faithful to the three-cylinder engine; many of the company's models feature an inline three-cylinder transverse engine. However, according to most manufacturers, the three-cylinder engine has a slight advantage over the inline four-cylinder, and represents an excellent compromise between the low-revving two-cylinder engine and the blazing power of the four-cylinder engine.

Horizontal in-line three-cylinder engineEdit

BMW came up with an interesting variation on the above theme in the form of its K 75, the cylinders of which are arranged horizontally in a row, and the crankshaft is longitudinal along the motorcycle frame; it was essentially a development of their horizontal four-cylinder engine that had appeared earlier. Despite the fact that at first glance the engine is somewhat unusual (the cylinder head of this engine is located on one side, and the crank chamber is on the other), it is quite narrow and compact, and also has a low center of gravity and is well suited for a cardan drive design.

Three-cylinder V-shaped two-stroke engineEdit

Two-stroke V-shaped three-cylinder engine

For the first time, such an engine appeared as a power plant for a 500 cc Grand Prix motorcycle. The odd cylinder arrangement was chosen to avoid the problem of increased width inherent in two-stroke in-line three-cylinder engines; Even if the length of the crankshaft is reduced to the minimum possible size, with separated crank chambers the engine still remains large due to the wide cylinders with purge channels. By moving the central cylinder, partial overlap is allowed and the overall width is thus reduced. After successful performance in competitions, Honda released a road version - NS 400R.

Brief characteristics of engines

The most common and at the same time the simplest engine layout is rightly considered an in-line cylinder arrangement. The bulk of internal combustion engines, which have a relatively small volume, are designed this way. They are compact, light in weight, so they can be located in the engine compartment without any problems.

But in-line internal combustion engines also have their disadvantages. As the number of cylinders increases, the total length of the engine increases noticeably. The more cylinders are in a row, the stronger the vibrations that occur during operation. Plus, such models require heavier crankshafts. By placing the engine longitudinally, the risk of severe injuries in accidents and collisions increases, since this makes it much easier for the engine to dent the engine shield and end up in the cabin.

One thing you need to know about V-shaped internal combustion engines is that their minimum number of cylinders is 6. There are 3 cylinders installed in each row. Outwardly, it resembles the letter V from the Latin alphabet, hence the corresponding name. With this arrangement, the number of cylinders can reach 12.

The main advantage is the ability to place a voluminous and powerful power unit in a small engine compartment. In terms of safety, they are also superior to their regular competitors. But speaking about why a V-shaped car engine is better than a classic in-line engine, one cannot fail to note its disadvantages. Such motors are structurally more complex, which is why V-shapes are more expensive. In this format, it is simply unprofitable for automakers to create engines with small volume and power. There is also a fairly high center of gravity, which creates additional difficulties when creating sports cars.

The V-shaped internal combustion engine differs in that the camber of the block here is 60 or 90 degrees, although there are some exceptions. But if the same camber on a V engine is increased to 180 degrees, then a standard boxer unit or just a boxer will appear in front of you. It is marked with the letter B. This name is due to the fact that the cylinders are located opposite each other. As they work, they make movements that seem to wave their arms, like boxers. The effect of the fight between the pistons led to the appearance of the name Boxer.

If we talk about balance, then 6-cylinder boxer engines are in no way inferior to in-line sixes. A plus in favor of the boxer is the low center of gravity, which none of the competitors can boast of. This is an excellent quality when creating sports car models.

But 6-cylinder boxer engines are quite rare. The main emphasis is on 4-cylinder versions. Moreover, even diesel boxer engines have already appeared, which can rightly be called a breakthrough in the automotive industry.

About internal combustion engines and its types

An internal combustion engine can be with external formation of a fuel mixture (gasoline) or with internal mixture formation - diesel. All of them are four-stroke, and this should be noted as one of the properties that such an engine has. The first engine had a power of slightly more than one horsepower, which turned out to be clearly insufficient for its practical use. It was single-cylinder, and the decision naturally suggested itself to increase the number of cylinders to increase power.

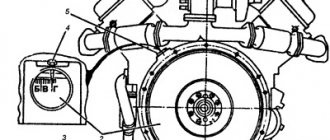

And as soon as the number of cylinders becomes more than one, the question arises about their location. Regardless of whether it is a gasoline or diesel engine, the following options are possible:

- in-line, all cylinders are located one after another on the same line;

- V-shaped, in which the cylinders are at an acute angle (usually sixty or ninety degrees) relative to each other;

- Opposite, it can be considered a special case of V-shaped. In it the cylinders are at an angle of 180°. This type of engine is most often used in motorcycle designs;

- W-shaped, it can be considered as a combination of an opposed and a V-shaped, installed on top of the opposed, and working on the same crankshaft;

- star-shaped, this is a peculiar combination of several V-shaped engines, in which the cylinders are located at an angle among themselves along the entire circumference and work on one crankshaft. Mainly used in aircraft construction.

Some of these engine build options can be seen in the figure below:

1-row; 2 – V-shaped; 3 – opposite; 4 – combined V-shaped and in-line engine; 5 – W-shaped; 6 – combined in a W-shaped arrangement.

W engine

W-shape.

There are two layout options - three rows of cylinders with a large camber angle (e) and a combination of two VR-shaped schemes (e). Currently, W8 and W12 are produced. The pursuit of power led to the birth of engines built according to the W scheme. These are, in fact, two VR engines, the angle between which is 72 degrees, or three in-line ones. The main disadvantage of such engines is that there are twice as many connecting rods on the crankshaft as on the V-shaped one, and four times! more than in a row. The connecting rods are made thin, and since these parts are among the most loaded in the engine, as a result they begin to bend at high speeds. Such motors are not created for mass use. They can only be found on sports cars.

Single cylinder enginesEdit

Typical single cylinder two stroke engine

Typical four-stroke single-cylinder engine

However, it has many disadvantages in terms of engine performance. Since the mixture in a single-cylinder, four-stroke engine ignites once for every 720 degrees of crankshaft rotation, large flywheels are required to keep the engine spinning until its next power stroke.

To avoid excessive weight gain, flywheels should be large in diameter and thin. The piston has to be lightened as much as possible, a long connecting rod is also needed, and the result is an engine called a long-stroke engine. The characteristics of such an engine are good up to a point: it is economical, has a good power curve and torque characteristics are such that it can provide dynamic acceleration from low engine speeds with relative ease. To take advantage of the excellent power characteristics, the gearbox ratios can be “stretched”, making the car less stressful to drive. Indeed, the effect of engine vibration is to a certain extent subjective and, as a rule, fairly high levels of low-frequency vibrations are preferable to less intense but more annoying "rattling".

However, if you try to make such an engine operate at high speeds, its shortcomings become obvious. Having massive flywheels means a lot of stored energy or inertia, and acceleration, by today's standards, will be limited to a slow build-up of speed. The small cylinder diameter and large piston stroke mean high speeds of linear movement of the piston, and therefore a high level of wear on these components. When trying to reduce the piston stroke, the smoothing effect of large flywheels is lost and unbalanced forces increase. This has a bad effect on the comfort of the motorcycle - the flexible single-cylinder engine turns it into a “drill moving along the road.”

Another problem with large displacement engines is difficulty starting, even when using an electric starter. But since most large-displacement single-cylinder engines are used for off-road competition and are not equipped with electric start, each time the crankshaft has to be set to a position where it is just short of TDC on the compression stroke, then given a hefty kick to force it rotate. In addition, there is a kickback problem that occurs when the crankshaft is not installed correctly or when the kick starter is not pressed hard enough. In this case, the effort for the piston to pass the compression stroke is not enough, and it rebounds sharply due to the effects of compression. This causes the kick starter lever to jump back and throw you over the handlebars or break your leg. Some single-cylinder engines are equipped with a decompressor designed to ease starting and reduce recoil. Honda has developed a system in which, when the kick starter is depressed, a small cam acts on the exhaust valve to open it slightly at TDC on the compression stroke. This reduces the force required to crank the engine. The second cam begins to operate when kickback occurs, also opening the exhaust valve slightly and reducing kickback force.

Design features of 2.7 3.0 HDI engines

All engines of the lion family are V-shaped. However, the camber angle of the block varies: 60 degrees for the “sixes” and 90 degrees for the “eights”. At the same time, the cylinder diameter and piston stroke of the 2.7-liter V6 and 3.6-liter V8 are the same: 81 and 88 mm, the compression ratio is the same: 17.3:1. The 3-liter engine is made on the basis of the 2.7-liter, the cylinder diameter and piston stroke are different: 84 and 90 mm. Compression ratio: 16:4. The compact 2.7/3.0 HDI engine block is cast from compacted graphite cast iron.

All engines of the Lion family have aluminum cylinder heads, with two camshafts and four valves per cylinder. Fuel system – Common Rail from Siemens with piezo injectors.

The 2.7- and 3.6-liter engines are equipped with two parallel turbochargers of the same size, each of which is driven by exhaust gases from its own half of the block. Turbochargers have a variable geometry guide vane. The charged air is cooled in the intercooler (intercooler).

The timing mechanism is driven by a belt and two chains. In this case, the belt drive, which operates the crankshaft and exhaust camshafts, is located on the front wall of the engine. The intake camshafts are driven by short chains from the exhaust camshafts - this drive is located on the rear wall of the cylinder head. There is also a belt drive for the fuel pump. The timing chains that drive the intake camshafts can stretch over time. It is recommended to change them every 170,000 - 200,000 km.

The intake camshafts are driven from the exhaust camshafts by separate chains. On the left rear of the block in the casing there is a belt drive for the injection pump.

The timing belt drive is located at the front end of the 2.7 and 3.0 HDI / TDV6 engines.

The exception is the 2.7-liter engine in the Land Rover configuration (engine code - 276DT). One large turbocharger is installed here. There are also other differences necessary for successful operation in off-road conditions: the radiator cooling fan is driven by the engine, and not by an electric motor; increased capacity oil pan (oil volume increased from 5.25-5.75 liters to 6.8 liters) with a large number of partitions; multi-layer seals that better protect against dirt, water and sand. The mounts for the transmission bell are also different for the Land Rover version of the engine.

The 3-liter diesel PSA DT20 / Ford AJD-V6 / 306DT switched to a fuel system from Bosch, and in all versions it is “inflated” by two different-sized turbochargers. The large turbine (main) is installed on the left side of the engine block and is equipped with electrically adjustable blades directing the flow of exhaust gases. The additional turbine is smaller, mounted on the right side of the engine, does not have an adjustable guide vane, and does not operate until the engine reaches 2500 rpm. To “activate” it, a special valve opens the exhaust flow to the turbine impeller.

The future of in-line engines

As in the nineteenth century, our designers are faced with what they call “the limits of design.” Although, the most common is still a six-cylinder engine.

Thus, inline sixes are still the main solution for a huge number of vehicles. They are used on public transport, cars, agricultural machinery, and small boats for sailing on rivers. Moreover, many large automakers continue to install conventional “sixes” in their advanced models. For example, BMW continues to present to the public every year new modifications of its six-cylinder flagship engine. Porsche also actively uses various modifications.

With all this, it is believed that in-line engines have already reached their maximum and in order to increase their power further, it will be necessary to endlessly increase the length of the crankshaft, which, in turn, will lead to a decrease in its strength and the service life of the entire unit.

At some point, it was decided that eight-cylinder engines could be considered the most efficient and powerful in-line engines. The crankshaft is relatively small, and eight cylinders provide sufficient power for the size of the entire design. The next round of evolution of internal combustion engines was the emergence of V-shaped and boxer engines, which are currently quite quickly capturing the automotive market.

Why are inline 6-cylinder engines more reliable than all others?

Over the more than 100-year history of the development of the automotive industry, engines have evolved no less than the cars themselves and have evolved from low-power 1-cylinder units to heavy-duty multi-cylinder units with different cylinder arrangements.

Modern passenger cars are equipped with in-line, V-shaped and even W-shaped engines of various sizes, and the number of cylinders in them can reach 16, for example, the engines of the Bugatti Veyron and Bugatti Chiron.

However, if you look into history, you can repeatedly see that the most reliable engines, capable of overcoming 500,000 or more kilometers without problems, have always been in-line 6-cylinder engines.

A clear proof of this are the legendary engines of the Nissan RB25 series, Toyota 2JZ series, Mercedes-Benz M104 series and BMW M50 series.

So what is the advantage of inline 6-cylinder engines and why are they so reliable?

Firstly, unlike V-shaped and especially W-shaped engines, the design of in-line engines, including 6-cylinder ones, is simpler, and the simpler the mechanism, the more reliable and durable it is.

Secondly, in-line 6-cylinder engines are much cheaper to repair and maintain than V-twin engines of similar volume, power and number of cylinders.

Thirdly, in-line 6-cylinder engines are more balanced than V-shaped engines with the same number of cylinders, due to which the load on engine parts is less and their service life is correspondingly longer.

Fourthly, unlike in-line engines with fewer cylinders, in-line 6-cylinder engines have quite a lot of power, and therefore do not need boosting, which in turn allows them to save their service life.

Fifthly, in-line 6-cylinder engines are more economical than V-twin engines with the same displacement and number of cylinders.

Unfortunately, recently, for a number of reasons, more and more automakers are gradually abandoning the production of in-line 6-cylinder engines and equipping their cars with them.

This is primarily due to the high demand for cheap front-wheel drive cars with a transverse engine, which are technically impossible and do not need to be equipped with in-line 6-cylinder engines.

And, of course, environmentalists and their strict standards for harmful emissions into the atmosphere played an important role in all this. After all, it was environmentalists who forced most automakers to abandon the production of in-line 6-cylinder engines in favor of more environmentally friendly and powerful V-shaped analogues due to turbocharging.

In conclusion, I note that currently, mainly BMW and Mercedes-Benz equip their passenger cars with in-line 6-cylinder engines.

Fortunately, these two German automakers have no plans to abandon production of inline 6-cylinder engines just yet. Did you like the post? Share!

A special problem with the 276DT engine for Land Rover

Another, but much rarer, problem with the 276DT engine (2.7-liter engine for Land Rover) is freezing of the crankcase ventilation system breather. In this case, the pressure in the crankcase increases, which most often leads to the squeezing out of the crankshaft front oil seal and very rapid oil leakage, leading to oil starvation.

Also, a violation of the crankcase ventilation system on the 276DT engine is highly likely to cause another problem: the oil used to lubricate the turbine bearings stops flowing into the sump. It either goes into the “hot” part of the turbine, where it burns to form soot. Or the oil begins to go into the “cold” part of the turbine and seep into the intake system. There is an intercooler in its path, where the oil will accumulate. At one point, when a high engine speed occurs, the oil accumulated in the intercooler will literally flow into the combustion chambers. But it will not burn there, but will lead to water hammer.

RESULT

To summarize what has been said, it can be noted that the PSA DT17 / Ford AJD-V6 / 276DT and PSA DT20 / Ford AJD-V6 / 306DT engines have many serious problems that lead to their death. There is an opinion that rotation of the connecting rod bearings occurs due to a manufacturing defect. Let us immediately note that the 3.6-liter V8 does not suffer from these ailments: nothing threatens its crankshaft and liners.

In the event of a breakdown, it is more profitable to replace 2.7- and 3.0-liter turbodiesels with contract ones. Owners of Citroen and Peugeot cars with stuck 2.7 HDI and 3.0 HDI engines often contact Evromotor.by. Recently they replaced a 2.7-liter engine on a Citroen C6 with a mileage of about 230,000 km.

The 2.7-liter DT17 turbodiesel rattled under the hood of the Citroen C6 at a mileage of 230,000 km.

The company Evromotor.by selected and sold a contract motor to the client. The knocking motor was removed and the contract one was installed at the Evromotor.by company's own service station.

Before installing the contract DT17 motor, you must check the condition of the connecting rod bearings.

The main activity of the Evromotor.by company is the sale of contract engines imported from Europe. The Evromotor.by company can select and send any required engine to the address specified by the client in Belarus and the CIS. At the same time, Evromotor.by necessarily and responsibly complies with the terms of the warranty for the engine it sells.

If necessary, the client can order the removal of the faulty motor and installation of the contract motor at the service station of the Evromotor.by company. The replacement time for most engines is 2 days. Large engines, which have to be removed not through the engine compartment, but by lifting the body, are replaced in 3-4 days. Before installation at the Evromotor.by service station, the contract motor is completely inspected: the valve covers and pan are removed, and the condition of the cylinder-piston group is assessed with an endoscope. All in order to provide a 60-day guarantee on the installed contract engine.

APPROXIMATE COST OF ENGINE REMOVAL AND INSTALLATION:

| Motor type and age | Motor replacement cost* |

| 4 cylinders, until 2000 | 400 rubles |

| V6, before 2000 | 600 rubles |

| 4 cylinders, after 2000 | 600 rubles |

| V6, after 2000 | 600 – 800 rubles |

| V10, after 2000 | from 700 rubles |

| The cost of replacing the engine includes work on replacing the timing belt, rollers and other parts at the request of the client. It is also possible to transfer parts from the old motor to the one being installed. Also, if necessary, glow plugs are replaced on diesel engines. |

Evgeniy Dudarevaautospot.by

In-line and V-shaped sixes: pros and cons

6-cylinder engines are associated with some of the greatest cars of all time, so how are V-twin engines so different from their inline brethren?

6-cylinder engines were installed in some models that over time became truly legendary, including the Jaguar E-Type, Toyota Supra and BMW M3, which have inline engines under the hood, as well as the Honda NSX, GT-R R35 and Lancia Stratos with engines having a V-shaped layout. Unfortunately, the golden time of in-line sixes has come to an end, since nowadays manufacturers are increasingly using V6-type engines, both in regular models and in their charged versions. So what are the advantages and disadvantages of each scheme, and why does the V6 dominate now?

Advantages of straight sixes

First of all, like any in-line engine, such sixes are quite simple and reliable. The cylinder block is easier to manufacture, and unlike V-shaped engines, there is no need for a second set of cylinder head and camshafts. Instead of using four short camshafts, the inline six can make do with two long shafts.

The simplicity of such engines is also important during repairs, since on an in-line engine you can easily get to any spark plug, wires and other elements during routine maintenance, which makes any in-line six a good mechanic’s friend.

But the biggest advantage is engine balancing. In the usual operating pattern of such motors, the cylinders move in pairs with their “reflection in the mirror” on the other side of the motor. 1 and 6 work first, then 2 and 5, and the stroke ends with 3 and 4. When pistons 1 and 6 are at top dead center, the other pistons are evenly positioned at an angle of 120 and 240 degrees, respectively, relative to the working cycle, due to which the reciprocating the forward movements themselves balance the motor. Thanks to this, they develop smooth speeds, which is what engines like the S50 and RB26 are famous for.

Disadvantages of straight sixes

Unfortunately, there are many reasons why the straight six is now extinct. The placement of such a motor has always raised questions, since due to the additional cylinders it is not possible to install such a motor lengthwise under every hood. If you install it transversely, then there is no room left for the transmission and drives that are needed when used on front-wheel drive models. And since manufacturers are trying to make the most universal motors for use on many models, they simply do not need long “rows”.

In addition, a long motor and its components suffer from reduced rigidity compared to more compact models. Long camshafts and crankshafts flex slightly during rotation, and the cylinder block is not as rigid as that of the same V6. The size of the inline-six also has a negative impact on the car's center of gravity, as it sits slightly higher than more compact models.

V6 benefits

Available in 60- or 90-degree variants, the V6 can still be found in a huge number of charged models, and thanks to the installation of turbos, such engines easily develop 500 horsepower, like the MY17 GT-R or the technologically advanced NSX. V6s have also been used on other platforms, including the Mondeo ST200, so versatility is also a huge plus for these engines.

Due to its more compact parameters, such a motor can be installed in a much larger number of models from the manufacturer’s line, which reduces the cost of testing other engine options.

And the free space saved by the engine size can be used to install various types of superchargers. Front-wheel drive models can also use a V6 engine, which could lead to some really cool models like the MG ZS180 with a Rover KV6 engine under the hood or the Mazda MX-6, which had a 2.5-liter V6 in its second generation. Thus, the V6 allows companies to easily create powerful versions of boring 4-cylinder models without major changes to body dimensions or engine compartment layout.

Disadvantages of V6

Such engines may have the same number of cylinders as their in-line counterpart, but the V6 is not at all as well balanced. Essentially built from two inline 3-cylinder engines, any V6 requires special balancer shafts to balance the engine while it's running. Without such balancing shafts, the crankshaft would be subject to enormous vibrations created by such a motor during reciprocating movements.

Engine balancing deteriorates as the volume of such a motor increases (long stroke of the piston) and the size of the cylinder increases (as the mass of the piston increases). Counterweights in this case also add complexity to the engine structure and production process, increasing its cost. For example, a DOHC V6 must have 4 camshafts and 24 valves, and additional balancing shafts located in each cylinder head will only add to the complexity of maintenance and provide a headache for anyone who decides to get into it.

Although many car enthusiasts have complained about the lack of modern inline sixes, things may soon change dramatically. More recently, Mercedes-Benz introduced a new engine with a similar layout that will use a 48V battery to power attachments and assist the transmission. And even with such a revival of inline sixes, I advise you to remember that BMW made a name for itself with 4-cylinder engines, including on the M3 and 2002 models.

In the absence of straight-sixes, V6s have completely taken their place in the market, and it will take time for that to change. But with such a variety of models using V6s, it's hard to doubt the potential of such engines, which can be unlocked with minor modifications.

What engine format do you prefer? Do you want to see the return of inline 6-cylinder engines under the hood of modern sports cars? Share your thoughts on this in the comments!

Subscribe to our Telegram channel

About the design of a V-shaped engine

You can understand what a modern V-shaped engine is by looking at the photo below.

After the power growth reserves inherent in increasing the cylinder diameter were exhausted, their number began to increase. Then they began to make the engine using several cylinders. The easiest way was to place them in a row one after another. This is how the in-line engine appeared, both gasoline and diesel.

It would seem that everything is fine, increase the number of cylinders and increase the power delivered by the engine. But at the same time its dimensions increase, and if we consider that the main application was designed for the design of a car and motorcycle, then a large engine did not fit there. During all such work, it was found that an in-line four- or six-cylinder power unit is optimal for the car. Such engines are also used today as they are the simplest to produce.

Engines

The question of why V-twin engines and in-line two-cylinder engines are different is an important one and requires some consideration.

Virtually all motorcycle manufacturers have their own two-cylinder engines. Taking one type of V-Twin engine, you will notice that they all differ in the arrangement of the cylinders, which ranges from 42 to 90 degrees. For example, Harley-Davidson adheres to traditions and uses engines with 45 degrees between the cylinders. At the same time, Ducati two-cylinder engines are often called L-Twin due to the arrangement of the cylinders at an angle of 90 degrees. In addition, there are many companies that have used V-Twins in a wide variety of shapes. To understand the difference between them, consider the principle of operation of the engines.

Let's start with the V-Twin. One cycle in four-stroke engines is completed in two revolutions of the crankshaft. The first cycle (rotate 180 degrees) - injection, piston position at the top (top dead center) and open intake valve. Further, due to the rotation of the crankshaft, the piston moves down, sucking in the fuel mixture. When the piston reaches bottom dead center (end of stroke), the intake valve closes and the piston moves up until the fuel mixture is compressed to a fixed degree. At the same time, the spark plugs fire, the fuel mixture explodes and automatically moves the piston back down. At the same time, the exhaust valve opens, exhaust gases leave the cylinder, and the piston rises.

Now let's look at in-line two-cylinder engines. There are two most common designs: • 180 degree ignition angle, one piston goes down, the other up • 360 degree ignition angle, both pistons move parallel up and down, but alternately ignite for each crankshaft revolution

It's also worth noting that Triumph uses a 270-degree engine in the Thunderbird these days. It essentially replicates the properties of a V-twin engine with 90 degrees between cylinders because the 90* V-Twin fires every 270 degrees of crankshaft rotation.

Each engine design has its own advantages. The compact overall dimensions of twin-cylinder in-line engines are more suitable for chassis design; engineers have the ability to move the engine forward or backward, thereby finding the optimal center of gravity and mass distribution of the motorcycle as a whole.

For the most part, V-twin engines are placed longitudinally in the motorcycle chassis, since the transverse arrangement creates a risk of damage to the cooling fins and cylinders. This makes it more difficult for engineers to find optimal weight distribution parameters, but at the same time the bike is thinner between the rider's knees. There is a misconception about the power, torque and vibration of V-twins and inline-sixes. In general, engine configuration has virtually no effect on power and performance. Much depends on the settings of the engine and transmission.

The main problem these days is vibrations. All manufacturers are interested in rider comfort and vibration becomes a big problem. Harley-Davidson uses various rubber “mounts” and dampers that dampen engine vibrations. When it comes to two-cylinder in-line engines these days, their designs are optimally balanced, so the vibrations aren't as bad. For comparison, consider a vintage Triumph Bonneville from the 1960s and a modern Bonneville T100 (both inline-twins with 360-degree ignition). According to experts, a modern motorcycle vibrates very little compared to its ancestor.

At the same time, the design of Ducati engines virtually eliminates their own vibrations. Due to the 90° angle of the cylinders, the movement of the opposing piston is always counteracted by the vibration of the cylinder in which the fuel detonates.

In general, it can be noted that there is no recipe for the best engine. They are all good, a lot depends on the transmission, exhaust and biker preferences.