Cold running

At the cold running stage, a number of technologies are used to obtain good running-in of parts.

Low-viscosity oils are used, for example industrial I-20A or I-ZOA, a mixture of industrial oil I-20 and motor oil MG-10-B2. Add additives to the oil (colloidal sulfur 0.9-1.1%, molybdenum disulfide, organometallic additives based on copper glycerate OMP-2 - up to 15% by volume of oil, etc.); they use special break-in oil OM-2, add additive DK-8, etc. to the oil. This reduces the break-in time by 1.5-2 times, and reduces the removal of metal from the surfaces of parts.

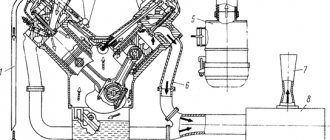

Engines are run in and tested depending on their power on electric brake stands KI-5542 (37 kW), KI-5541 and KI-5543 (55 kW), KI-5540 (90 kW), KI-5274 (160 kW), KI-5527 (for starting motors). These stands allow you to crank the crankshaft of engines at a variable frequency during cold running, and during hot running, return electricity to the electrical network.

The cold running mode is established by the technical requirements for engines of each brand. For example, D-240 engines are run in engine oil for 30 minutes - 10 minutes at each of three stages with a crankshaft speed of 500-600, 700-800 and 900-950 min-1; The D-160 engine is run in for 55 minutes, of which 15 minutes at a shaft speed of 400-450 min-1 and 40 minutes at a speed of 900 min-1. Cold running of starting and carburetor engines is carried out for 20 minutes.

During the cold running-in process, the heating of the rubbing surfaces is checked by touch, knocks inside the engine are listened to, the tightness of connections is determined, and the oil pressure and temperature are monitored. If malfunctions are detected, the run-in is stopped and the malfunctions are eliminated. If necessary, the engine is sent for re-repair.

Why is the engine broken in?

Running in the engine after a major overhaul is necessary to ensure uniform grinding of the rubbing surfaces. Despite the fact that modern materials and processing methods make it possible to obtain surfaces without scuffing, rubbing parts have some roughness. For the most part, this applies to the cylinder-piston group. Thus, a repaired cylinder block and new pistons have deviations in size and surface defects.

Running in allows:

- adjust the mating of parts and reduce wear;

- minimize deformations;

- stabilize oil consumption;

- check the result of the overhaul.

During operation of the internal combustion engine, a large amount of heat is generated. Thus, the piston bottom heats up to 300℃ from interaction with the combustible mixture. The part is cooled through compression rings. In contact with the cylinder walls, the piston rings release heat, which goes away along with the lubricant.

During long-term operation, the piston rings rub against the cylinder walls. After the overhaul, the “connection” disappears. This is why you cannot reinstall used rings: they were “sharpened” to fit other dimensions of the cylinder and are not suitable for further work.

Failure to run-in leads to poor heat transfer from the piston to the cylinder. In turn, this causes overheating of the piston, detonation, deformation of the piston rings, or burning of the entire part.

To reduce break-in time, spare parts manufacturers have developed new profiles of compression rings: beveled, rounded, ribbed with tin filling, etc. Two-stage cylinder honing also affects the running-in regime, since the surface is run-in at a micro level.

How to properly break in an engine?

The engine is the main component of the car, which requires increased attention. During running-in, the operation of the piston group, injection system, ignition units, etc. is checked. To properly prepare a new motor for future loads, you need to follow the recommendations:

- The break-in period for a modern engine is 1000-1500 km. During this period, you should not load the system above 3500 rpm.

- Minimize idling and completely eliminate over-gas on the spot. High idle speeds are more harmful than the same speeds under load.

- Try to run the engine on country roads. At 3000 rpm, the maximum compression of the compression rings against the cylinder walls occurs. If you feel that the car is behaving calmly, you can smoothly increase the speed to 4500 rpm for 5-10 seconds.

- A complete running-in of all engine components takes about 7-10 thousand km. This figure is for those who strive to squeeze maximum speed out of the car, race on tracks and set records on the track.

As you can see, the procedure for running a car is a complex process that simultaneously affects a number of components. The technical condition of the car and its reliability on the road depend on its correct implementation. If you follow the recommendations correctly, you can carry out the entire procedure correctly and have complete confidence in the car in the future.

Source

First launch after major overhaul

The first start of the internal combustion engine is carried out according to the following scheme:

- Fill in engine oil. It will take 10 minutes for the lubricant to fill the system. The oil filter is left dry to avoid air lock.

- Connect the fuel pump or supply fuel manually.

- Open the throttle manually if there is no automatic drive.

- Start the starter.

- Spin the motor up to 2000 rpm.

- Leave to idle for 15 minutes until engine rotation becomes stable at operating temperature.

- Turn off the unit and wait for it to cool completely.

During startup, the pressure in the lubrication system is monitored. The indicator signal for 4 s indicates incorrect engine assembly. We urgently need to turn off the engine! If the pressure quickly stabilizes, the internal combustion engine is warmed up to operating temperature.

There should be no leaks upon visual inspection. In the first 3 minutes, the engine may knock: the hydraulic compensators are being pumped or the cups are running in. In the future, the sound should become uniform, without vibration. The appearance of a burning smell and slight smoke for the first start is normal - the assembly lubricants are burning through.

If the internal combustion engine is operating stably, start running-in. In order to properly run in the engine after a major overhaul, you need to understand the nuances of the test.

Transmission break-in stages

The transmission is the second most important unit in a car. Its structure is very complex, it has many moving and rubbing elements, so you should be meticulous in running the box.

Careful running-in of the transmission will extend its uninterrupted service life and postpone costly repairs for a considerable period.

Automatic transmission

An automatic transmission is an extremely complex mechanism that requires careful handling and careful running. It’s better to wait a little, drive off wisely, than then shell out for expensive repairs, which, of course, will happen after the warranty expires.

Recommendation for running in an automatic transmission:

- before driving, the automatic transmission should be warmed up to operating temperature so that the transmission fluid reaches the desired consistency; in winter this can take up to 10 minutes;

- It is strictly forbidden to use the kickdown mode;

- make sure that the neutral mode does not turn on while driving, which can happen due to a decrease in the pressure of the transmission fluid when it heats up, causing pressure on the planetary unit;

- avoid wheel slipping;

- It is strongly recommended to test the automatic transmission outside the city to avoid rough driving conditions;

- avoid transporting heavy objects or large numbers of passengers;

- Avoid overheating of the automatic transmission in every possible way during the first 500 kilometers due to the fact that the upper layers of the friction discs, hydraulic transformer and other parts of the planetary assembly are being rolled in;

- if the automatic transmission is serviceable, i.e. provides for the replacement of transmission fluid, it would not be superfluous to replace the working fluid to remove possible chips or other foreign components from it.

Manual transmission

A manual transmission is considered more unpretentious in operation and has a longer service life. But even it is recommended to run it in carefully over the first few thousand kilometers.

Tips for properly breaking in a manual transmission:

- it is necessary to start moving and pick up speed smoothly, changing steps in a timely manner;

- It is necessary to engage the gears in the manual transmission smoothly with the clutch pedal fully depressed, avoiding sudden movements or applying significant force;

- during the first thousand kilometers, it is recommended not to travel at speeds exceeding 80-90 km/h and in higher gears (4,5,6);

- it is necessary to change the stages one by one and in a timely manner; when running in, it is strictly not recommended to jump over speeds (for example, from 4th to 2nd, from 3rd to 5th);

- during running-in, it is necessary to use a smooth ride mode, if possible avoid long climbs or travel on roads with poor surfaces;

- After finishing the break-in of the manual transmission, it would not be superfluous to completely replace the working fluid in it to remove metal shavings or other foreign substances that could have formed during the grinding of manual transmission components.

A new car requires careful handling and proper operation, especially during the first thousand kilometers, during which grinding in of various parts and components occurs.

The break-in procedure is simple, but its correct implementation will extend the life of the main components and help avoid numerous breakdowns. The main principles of break-in are daily monitoring of working fluids and avoiding loads on the internal combustion engine and transmission, for which you should follow the simple recommendations described above.

Types of engine running-in

There are several types of engine break-in.

Cold stands

It is produced on special equipment and workshops using a cardan shaft that connects an autonomous electric motor and the shaft of the vehicle’s propulsion system. An electric motor drives the engine of the machine. The master sets the intensity of rotation using an encoder, and the process itself is controlled by a computer, setting the rate of rotation according to the data received.

However, not every workshop has a stand, so you have to resort to other methods.

Running in the engine on the stand

Cold without a stand

You can run it “in a simple way”. Oil is poured into the engine, the radiator needs antifreeze or antifreeze. After filling with technical fluid, the car is simply moved around the site for about 2 hours, without turning on the engine.

When lapping, the engine temperature plays an important role. At stations, temperature control is carried out using oil and hot water.

Hot running

This break-in method can also be used at home. You will need to start the car engine and bring the speed up to its idle level. The motor should run for no more than three minutes. Then you should take a break and wait until the engine cools down. You need to repeat the procedure several times.

The engine must be started and left running for 50 minutes. You should start at 1200 rpm and slowly increase the value to the middle of the permissible value. If the engine overheats, it should be turned off and cooled.

When performing a hot run-in, it is worth checking the oil and the condition of other technical fluids, making sure the connections are tight and checking the compression.

Run-in in natural conditions

The engine is simply operated in a gentle mode - no excessive loads, sudden starts or braking.

The initial mileage of 3,000 kilometers is considered the most important - it is at this time that the engine is most exposed to adverse factors.

Auto dashboard

Grinding must be done carefully. When the car travels the first thousand kilometers, the filter and engine oil should be replaced. It is better not to use various additives and other additives. Prefer pure oil.

To run in a post-overhaul engine correctly, you should follow a few simple rules:

- do not abuse too high or low speeds when driving;

- do not drive at a fixed speed and with the same number of revolutions - it is better to vary these indicators;

- do not use engine braking - the running-in mode is not suitable for this;

- It is prohibited to tow trailers or transport cargo in the luggage compartment;

- Do not accelerate or brake suddenly.

Before starting the engine for the first time after repair, it is necessary to prepare the vehicle for the break-in procedure. Otherwise, the power unit may not receive proper grinding, which will shorten its service life.

Engine compartment of the car

First, you need to fully charge the battery. The initial start-up is of paramount importance - the crankshaft speed is too tight, the load on the battery is high. Do not allow the battery to fail during the first start-up.

Secondly, the oil filter and the oil itself must be replaced. It is important not to wet the filter element with the oil mixture before installation, otherwise an air lock may form.

The ideal process for breaking in a new car

When the car has moved, it is then that it is necessary to monitor the engine speed. During the first run-in, the number of revolutions should be no more than 2500 rpm. The first test run-in process has five stages.

Second stage: for the next 100 km, the speedometer speed is allowed to be somewhere around 60/70 km/h.

Third stage: for the next 100 kilometers you need to drive at a speed of approximately 70-80 km/h, without overloading the engine with high speeds.

The fourth stage: again you need to drive 100 kilometers, but at a speed of 90 km/h.

Fifth stage: acceleration over 90 km/h is allowed, it is advisable to look at the temperature of the car engine and stop after a short distance and let the engine cool.

As a result, for a perfect break-in of a new car you will need to drive 1500-5000 kilometers. And, of course, pay a considerable amount for fuel, but it's really worth it.

Run-in on the stand

Cold running on a stand is carried out in a professional auto repair shop after a major engine overhaul. It means that parts of the engine make movements, while the engine itself does not start. The procedure is suitable for gasoline and diesel units.

- The engine is placed on a special running stand.

- The crankshaft is connected to an external electric motor.

- Fill in oil and coolant.

- The electric motor is started so that the crankshaft rotates.

The rotation speed of the electric motor can be changed, which allows you to start running in at low speeds. The process is controlled by a computer program. Sensors are connected to the main nodes, which transmit data to the computer. In accordance with the indicators, the electric motor speed is reduced or increased.

Control helps maintain optimal engine temperature and prevents it from overheating. Therefore, the running-in was called “cold”.

How long to run an engine after a major overhaul?

How long it takes to run-in after an engine overhaul depends on the test method. An incorrectly carried out test leads to jamming of the motor on the first day. To avoid breakdowns, you need to act carefully and follow the prescribed inspection regime.

On average, the grinding-in of internal combustion engine parts lasts 3000 - 8000 km. You can determine the readiness of the engine by its responsiveness and torque: after pressing the gas pedal, the car cheerfully takes off and confidently accelerates at full speed.

Is it necessary to break in a new car or not?

A question that cannot be answered unequivocally. Manufacturers of modern cars believe that when running in it is enough to follow two recommendations:

- Do not drive at high speeds and do not allow the engine to reach high speeds.

- Do not brake sharply, do not transport heavy loads, do not use trailers, or tow other vehicles.

Recommendations are prescribed for the initial section of the journey from 1 to 2 thousand kilometers.

Moreover, these restrictions, according to the manufacturers, are not related to the operation of the engine, but to the need to work on tires and brake pads, and transmission parts. New technologies and high precision engine manufacturing, in their opinion, make it possible to operate the car without additional running-in. Many automobile companies roll in engines when cold, using servos; the duration of such running in varies from 10 minutes to an hour for different models.

Towing

Break-in of a new car, as well as a car after repair, can be done by towing. The coupling to the towing vehicle must be rigid and carried out in third gear. The spark plugs are removed from the car being run in and the gears are turned off. Towing lasts for an hour. During this time, forces are transmitted through the wheels to other parts of the car, which leads to their gradual grinding in.

Experienced drivers say that after a major overhaul, the engine should burn a tank of fuel at idle speed. Towing is not an ideal break-in option because it is difficult to control how hot the engine is.

Break-in laws.

There is a certain “set” of rules that will help you run in a new car more efficiently. These rules must be followed so that everything goes smoothly, the grinding in is successful, and you do not lose sight of the hidden fault.

1. The car tank must be filled with high-quality fuel. 2. Tire pressure should be as specified in the recommendations. 3. Do not keep the car idling for a long time. 4. Oil, brake fluid and coolant must be filled to the correct level. 5. Make sure there are no leaks. 6. The first thousand kilometers should be driven without reaching a speed of 80 km/h. 7. Carefully study the operating instructions in the section on gears. During break-in, follow the switching diagram according to these instructions. 8. During the break-in period, do not exceed engine speed. Maximum – 3000 rpm. 9. Do not overload the car with cargo. 10. Sharp braking and sudden acceleration are excluded. 11. Run-in is carried out on free roads outside the countryside. Preferably with an even surface.

Recommendations for proper engine break-in

Many car enthusiasts are concerned about the question of how to properly break in an engine after a major overhaul. There are some features that drivers often ignore.

For the first 3 thousand km, the speed should not exceed 50 km/h. During this time, the motor will undergo initial grinding. Everything will finally return to normal once the mileage reaches 10,000 km. It is hardly possible to drive for such a long time at a speed of 50 km/h, but it is not recommended to exceed the speed of 100 km/h and subject the car to excessive loads.

After this, the machine will be ready for full operation, even with heavy loads. After 5,000 km, you should change the oil and fill it with the one recommended by the car manufacturer.

How to properly break in an engine

There are 3 engine break-in stages, each of which includes 500 kilometers, and the final fourth, the length of which is the difference between the break-in duration declared by the manufacturer and the mileage of the first three stages.

Run-in step by step:

- Stage one . The most important, requiring maximum attention and care from the driver. It is better to carry out it on a country road with good coverage, without large differences in elevation, at low speed. For the first fifty kilometers, the car must be driven in third gear at a speed not exceeding 50 km/h, then gradually increase the speed to 70 km/h and switch to fourth gear. Further progress at the first stage is an increase in speed by 10 km/h every 100-150 km. At this point, the preliminary part of the run-in can be considered completed.

- At the second stage, the engine is run in 5th gear on a flat road with a maximum speed of 120 km/h and a set of revolutions to 3000 per minute. To overcome sudden long climbs, you should smoothly switch to fourth or third gear.

- At the third stage, driving uphill should not be done in 5th gear, but the speed can be increased to 3.5 thousand. The maximum speed periodically when driving on a flat straight road in 5th gear increases to 140 km/h.

- The fourth stage turns out to be long in length, but involuntary in relation to speed and number of revolutions. In 5th gear, you can already overcome small climbs, but the speed should not exceed 100 km/h, and on flat areas, drive the car for a long time in 5th gear with a speed reduced to 80 km/h, if road conditions require it. The engine can be accelerated to 4 thousand revolutions when changing gears and starting at a traffic light.

The break-in mode does not include idling; every driver should remember and know this. Idle speed is permissible during break-in only when the engine warms up for no more than 2-3 minutes. An oil film on engine parts does not form at low engine speeds, so there is a risk of dry friction, leading to premature wear of rubbing parts and a decrease in engine life.

During the running-in stages, engine braking is not possible; this can lead to irreparable consequences.

Hot running

Instead of cold rolling, hot rolling is sometimes used. The car is parked with the engine turned on and running continuously. Hot running is also used on a stand, when the engine is removed, connected to the stand and allowed to idle for 3 minutes. After this it should cool down. This is repeated 3-4 times, after which it is turned on for 40 minutes.

The surface of the engine being run in should not heat up by more than 80 °C. Cooling of the engine is the main requirement of the procedure. As a result of overheating, parts may become deformed, which, instead of running in parts, will lead to failure of the entire system.

What is engine break-in

In common parlance, break-in refers to the permissible operating conditions for the first few thousand kilometers, which the car manufacturer most often indicates in the technical manual. There is an opinion that modern cars do not need to break in the engine, but it is wrong. Even with the improvement of technologies for the production of car components, it will not be possible to assemble an engine perfectly every time.

Here we come to the definition of the concept of “break-in”. By it, drivers understand the process of grinding car parts into each other. Most often, running-in is considered in terms of the engine, but on a new car it is also necessary for the suspension, brakes and other components. During the operation of the car for the first few thousand kilometers, the parts in it break in, that is, they rub against each other. Microscopic irregularities as a result of friction are eliminated, thereby creating a tight fit between the machine parts, and the efficiency of its motor approaches the maximum possible values.

What not to do

To avoid engine wear after repair, during break-in it is recommended:

- do not load the engine, choose routes without difficult road conditions: traffic jams, off-road conditions;

- keep the crankshaft speed no higher than 50 - 70% of the nominal, drive calmly;

- do not run the engine at idle speed, since grinding occurs under load, when the exhaust gases exert a uniform pressure of 15 - 20 atm;

- do not drive in one mode - the internal combustion engine must operate at different frequencies for uniform grinding of parts.

What is the engine life after a major overhaul?

Quiet driving extends the life of any engine. The more the internal combustion engine spins, the faster it wears out. Therefore, the engine life after a major overhaul largely depends on the driver. If, of course, the master installed good spare parts and did his job conscientiously.

Proper running-in “hardens” the engine and allows it to “get” its clearances. The unit gradually adapts to the loads, which increases its service life. Theoretically, a repaired engine, with proper operation, will be able to go as far as it did before the overhaul. But don’t forget about timely maintenance and filling with high-quality fuels and lubricants.

Changing the oil after engine overhaul

Engine break-in oil is poured after overhaul before the first start. To save money before the first replacement, it is optimal to fill in semi-synthetics that meet the tolerance.

There is an opinion that after the first starts the lubricant becomes contaminated with chips from machining and wear products, so the oil must be changed after 1000 - 2000 km. In practice, a good motor lubricant can last 4000 - 7000 km. To know for sure, check the level and quality of the lubricant once a week.

When changing the oil, be sure to install a new filter.

The rate of oil contamination is also affected by the quality of the overhaul. Mechanical processing of parts using modern equipment, performed by a skilled craftsman while observing clearances and tolerances, does not result in strong grinding. Cleaning and purging the motor after repair gets rid of the main dirt that clogs the lubricant.