The 1.2-liter engine under the S-TEC logo in Daewoo cars traces its origins to the 3-cylinder Japanese engine for the Suzuki Alto. Based on it, the Koreans created 4-cylinder engines with a volume of 1.0 and 1.2 liters. These are extremely simple engines with a single camshaft in the cylinder head, a cast iron cylinder block, and a timing belt drive. There are no hydraulic compensators; the valves are adjusted according to the “Japanese” scheme. Also, an EGR system was added to these engines.

The 1.2-liter 8-valve engine was installed on the Chevrolet Aveo and clone models under the Daewoo brand.

On our YouTube channel you can watch a disassembly of the 1.2-liter B12S1 engine, taken from the European Chevrolet Kalos - a twin of the Aveo model. (Kalós means “beautiful” in Greek).

The resource of the 4-cylinder B12S1 engine is quite decent, but its cylinder head may fail prematurely. We’ll tell you about this and everything else now.

You can select and buy an engine for Chevrolet in our catalog of contract engines.

Crankshaft and camshaft position sensors

The crankshaft and camshaft position sensors of the B12S1 engine serve well and for a long time, but errors may occur on them, and the engine idles unstably after starting. In this case, removing the sensors and wiping off any magnetized metal powder can help. Of course, powder or even shavings on the sensors is a serious sign of wear, which we will discuss below.

List of car models in which b12s1 is installed

General Motors originally designed the b12s1 engine for its subsidiary Chevrolet. It was installed on cars:

The cheapest modifications of the above car models were equipped with this power plant. A little later, General Motors introduced its engines into another subsidiary - Daewoo. The engine began to be installed on Daewoo Matiz cars.

High reliability and dynamic parameters attracted the interest of other automakers and the world saw cars with b12s1 under the hood:

Chinese manufacturers took the design features of the motor as a basis. The technical solutions found by General Motors are still used today. The b12s1 engine sits securely in the niche of small cars.

Throttle valve

The throttle valve of the B12S1 engine is connected to the accelerator pedal by a cable; it does not have a separate idle speed control. Therefore, at idle, the opening of the damper is controlled by a built-in servo drive.

Often the teeth on the gears break off in this servo drive. Depending on how many teeth are broken, the engine either idles rough, stalls after starting, or won't start or run unless the accelerator pedal is pressed.

This mechanism can be repaired by selecting suitable gears.

You can select and buy a throttle valve for a Chevrolet engine in our catalog of contract spare parts.

Engine 1.2 for Aveo T250, T255

Among motorists, it is no secret, but always news, that such a phenomenon as the merger of several automobile companies under one concern.

So, for example, the situation is with a number of car manufacturers such as: Kia/Hyundai, Daewoo/Chevrolet/Opel, Ford/Mazda, etc. In most cases, the result of a merger is a common base (internal combustion engine, gearbox) for cars of one concern. This is exactly the situation with the Chevrolet Aveo B12S1 engine , which, being developed by General Motors specialists, can be successfully used in Daewoo cars. The B12S1 engine has the following characteristics: 8 valves, displacement 1.2 liters, gasoline, operating mode 4 strokes. Over its short history, this power unit has managed to establish itself as reliable, durable and unpretentious for operation in domestic conditions. Also one of the most important and positive qualities is the ease of maintenance of the Chevrolet Aveo engine .

But, despite all the positive reviews available about the operation of the B12S1 internal combustion engine, it cannot be 100% insured against natural wear and tear or engine accidents. In the event of a cessation of normal operation or a complete stop of the Chevrolet Aveo engine, it is necessary to correctly assess and calculate the cost of the upcoming work. This requires certain minimum knowledge and experience in working with power units, since restoration work with spare parts can cost several times more than purchasing a contract Chevrolet B12S1 engine

The most common failures of B12S1 engines

As mentioned above, the main reasons for stopping the performance of power units include: wear and accidents. Wear correctly refers to those irreversible processes that occur when mechanical parts operate at elevated temperatures and pressures, as well as the natural process of corrosion. Moving elements are most often susceptible to wear, as well as the frame itself and the elements on which the moving parts rest. An internal combustion engine accident should mean its complete stop. As a rule, accidents are caused by untimely and poor-quality engine maintenance, as well as improper operation. The most common accidents with a used Chevrolet Aveo engine are a violation of the lubrication regime, overload, or a malfunction of the speed controller. All emergency cases, without exception, can be prevented by timely maintenance.

Catalog numbers

- 96659598

- 96666210

- 96659597

- 96666195

- 96643127

- 96666194

- 96643126

- 96666205

- 96643137

- 96666204

- 96666203

- 96643135

- 96666202

- 96643134

- 96666201

- 96643133

- 96666200

- 96643132

- 96666199

- 96643131

- 96666198

- 96643130

- 96666211

In our KorMotor store you can not only purchase spare parts, but also order their installation and delivery to the regions or throughout the city of St. Petersburg. Installation of small engines for Chevrolet Aveo, Chevrolet Spark, Daewoo Matiz takes place in the shortest possible time (1 working day).

Ignition coil

The service life of the ignition coil on the B12S1 engine is about 70,000 km. It fails due to increased loads caused by wear of high-voltage wires or spark plugs. In this case, misfires and corresponding errors appear. A worn coil should be replaced along with the wires and spark plugs.

You can select and buy an ignition coil for a Chevrolet engine in our catalog of contract spare parts.

Crankcase ventilation system

In severe frosts, condensation may freeze in the crankcase ventilation system of the B12S1 engine. To prevent this and subsequent extrusion of the dipstick and seals, it is recommended to plug the tube from the VKG valve to the inlet pipeline. It is necessary to plug both the tube and its opening in the pipe.

In this case, frosty air is not sucked into the tube, and gases enter the intake along the main path into the throttle space. This improvement should be carried out in the winter.

Crankcase ventilation valve

If the crankcase ventilation valve is heavily worn and jammed in the slightly open position, it can become a source of air leakage into the throttle body. Depending on whether the air leaks in small portions or flows in a continuous stream, the engine will maintain an unstable idle speed or will maintain a high idle speed. This is due to the fact that the control unit will adjust the fuel mixture and supply gas based on the vacuum in the intake manifold. The opposite situation is also possible: the VCG valve may jam in the closed position, then gases from the crankcase will not be sucked into the intake. High crankcase gas pressure will push out the dipstick and seals. Therefore, the patency of this valve needs to be monitored, and it is better to preventively change this cheap part.

EGR valve

The EGR valve was literally attached to the B12S1 engine, as evidenced by the “balcony” on which it is mounted. In addition, the EGR valve takes exhaust gases, relatively speaking, from the 4th cylinder.

On this 8-valve engine, the valve is easily suppressed by installing an exhaust gasket. In most cases, this valve does not cause any problems.

But on almost all B12S1 engines it was necessary to remove the EGR valve and its bracket to replace two gaskets. In particular, one “figure-of-eight” gas supply channel gasket requires attention. It was installed incorrectly at the factory - offset, and partially blocked the path of exhaust gases. Naturally, over time, the gases burned through it and slowly leaked out. The owners learned about this by the puffing or clicking of gases. This gasket was replaced under warranty, although many owners encountered this little problem after the warranty expired.

The exhaust gas supply pipe stretched from the EGR valve to the intake manifold in the area of the 1st cylinder may crack, after which air leaks will appear. Because of this, the idle speed will be unstable or high.

You can select and buy an EGR valve for a Chevrolet engine in our catalog of contract spare parts.

Maintenance schedule

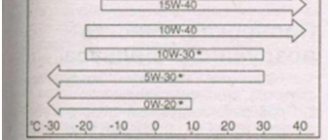

The recommended oil change frequency indicated in the manual is 10 thousand kilometers. According to the manufacturer's instructions, preference should be given to 5w-30 or 5w-40. Thanks to the thoughtful design and good fit of parts, the engine rarely has high oil consumption. After break-in, the engine rarely needs to be topped up with lubricant.

It is recommended to accompany each oil change for b12s1 with the installation of a new filter. The question of which oil to use should be taken as seriously as possible. Poor quality lubrication can cause the camshaft to jam. After this, the cylinder head will require replacement.

Bottom view of the b12s1 engine with the timing cover removed

The b12s1 motor needs valve adjustment, since hydraulic compensators are used only on the F14D3. The rocker arms should be inspected periodically. Replacing timing elements may be required after a mileage of about 40 thousand kilometers. If valve clearance is not given due attention, fuel consumption will increase and the technical characteristics of the vehicle will deteriorate.

A feature of the b12s1 power unit is an imperfect crankcase gas exhaust system. It often becomes clogged with oil, so it requires frequent cleaning. The lubricant begins to be squeezed out through the seals, as a result of which it is necessary to pour it more often during operation of the machine.

The air filter must be changed in accordance with the technical regulations for servicing the iron horse. Candles on b12s1 last twice as long as the manual indicates.

This is interesting: The principle of operation of internal combustion engines

Injectors

The fuel injectors of the B12S1 engine may become clogged, as indicated by jerking during acceleration, and then unstable idling. These injectors are easy to clean.

You can select and buy injectors for the Chevrolet engine in our catalog of contract spare parts.

Adjustment of valves

The B12S1 engine does not have hydraulic compensators and needs to check the thermal valve clearances every 15,000 km. The gaps are adjusted as simply as possible - using a wrench and a screwdriver. The nominal clearances of the intake and exhaust valves on a cold engine are 0.15 and 0.2 mm ±0.02.

In most cases, the exhaust valve clearances need adjustment. If the clearances are too far from the nominal value, the engine will shake at idle and shoot into the exhaust system.

Replacement and adjustment of timing belt tension Aveo Chevrolet with B12S1 engine

1. Remove the generator drive belt.

2. Unscrew the four fastening bolts and remove the top cover 3 (Fig. 1) of the gas distribution mechanism drive

Rice. 2. Checking the timing belt tension

Rice. 3. Places for attaching the lower cover of the gas distribution mechanism drive

3. Check the belt tension. A correctly tensioned belt should rotate along the axis by 90° from a finger force of 15-20 N (1.5-2 kgf) applied in the middle to the front branch of the belt (the right branch of the belt is shown in Fig. 2) between the crankshaft and camshaft pulleys.