Engine oil and engine temperature

Lubricating fluid is an important component for the operation of any engine. The document defining the classification and designation of oils used in internal combustion engines is the interstate standard GOST 17479-85, as amended in 1999. The requirements of this document are interrelated with the international standards SAE, API and ACEA, which determine the parameters of oils depending on the season and ambient temperature. The SAE standard defines the viscosity-temperature characteristics of a lubricant. The API standard specifies the use of lubricant, depending on the type of engine, its production date and technical parameters (for example, with or without turbocharging). The ACEA standard was developed by European manufacturers. It is similar to the API standard, but has more stringent indicators.

Based on these documents, motor oil can be gasoline, diesel and universal. The oil solution is made from mineral oil with the addition of various components and additives. Depending on the additives, the oil fluid in the engine unit is divided into: mineral, synthetic and semi-synthetic.

According to its structure, the oil solution is divided into three types:

- Winter. A special feature is its more liquid state, which makes it easier to start the car. During the warm season, the oil solution is not suitable for use, since during operation its viscosity will become less than the standard. The functions of protecting and lubricating units will be reduced to a minimum. Has alphanumeric markings.

- Summer. Used at ambient temperatures above zero degrees. This liquid has a high viscosity and fluidity. Use in winter is not recommended, as the high viscosity will make starting the vehicle difficult. Has digital markings.

- All-season. The most popular type of fluid among all drivers. Can be used at any time of the year at any ambient temperature. Has double marking.

The choice of oil has a direct impact on engine temperature. The operating temperature of the power plant ranges from 70 to 90 degrees in winter. As the temperature rises to zero, you can start driving when the engine warms up to 50-70 degrees. In summer, components and assemblies do not need to be warmed up. You can start moving in natural conditions. At the recommended temperature conditions, the engine starts and runs reliably, and the cylinders are filled to the maximum extent. Some types of starters have a normal operating mode at temperatures from 100 to 110 degrees. Basically, this is a wound air-cooled unit, for example a two-stroke engine.

Flash point and pour point

Flashing is a condition in which flammability appears on the lubricant. This state can be achieved by applying a gas flame to the lubricant. Under the influence of heat, oil vapors become concentrated (they are responsible for ignition). Flash and ignition temperature conditions may vary depending on the method in which the test is performed and the apparatus. The temperature state of flash and ignition indicate the degree of purification of the lubricant product, as well as the type and are indicators of volatile properties.

How does the engine lubrication system work?

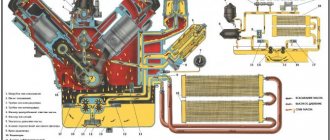

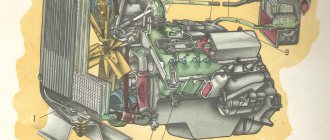

The task of the lubrication system is to store, transport, clean and supply oil to the rubbing parts of the engine in order to reduce friction of mating parts, ensure a smooth start of the engine and prevent it from overheating. The task is accomplished by a complex of components and assemblies, which includes:

- Engine crankcase (sump) with drain neck.

- Oil pump.

- Oil filter.

- Radiator for cooling oil fluid.

- Pressure reducing valve.

- Pressure meter.

- Temperature sensor.

- Pipelines.

oil

Oils made on mineral and semi-synthetic bases do not behave as resistant to overheating as synthetics. Thus, in mineral-based oil at a temperature of 100 degrees, avalanche-like, irreversible oxidation processes occur. Its service life is reduced by 10% in just half an hour, and all kinds of high-temperature deposits form in the lubrication system. Therefore, when running an engine filled with mineral oil for a long time and overheating, it is better to replace it at the first opportunity. Please note that depending on the condition of the engine and, in particular, on the cleanliness of its lubrication system, the service life of fresh oil may drop by more than 25–30%. If the car's cooling system does not provide a stable engine temperature, it is better not to use mineral oil.

It is difficult to say how oil made on a semi-synthetic base will behave. The reason is that it is unknown what the oil manufacturer means by semi-synthetic! This can be either a mixture of mineral and synthetic oils (the proportion is a company secret), or a mineral base oil that has undergone deep purification, for example hydrocracking. Depending on this, the oil’s resistance to overheating will either approach fully synthetic or mineral products. Therefore, it is extremely difficult to draw any conclusions, but we can assume that in 30 minutes of operation at a temperature of 100 degrees, semi-synthetic oil will lose 5% of its service life.

So, let's summarize: operating motor oil at a temperature of 100 degrees Celsius for 30 minutes will affect its service life as follows.

1. Fully synthetic oil - will not affect.

2. Semi-synthetic oil - the resource must be reduced by 5%.

3. Mineral oil - resource must be reduced by 10%

Functionality of lubricating fluids

In order for the power unit to function stably, it is necessary to select the correct lubricant solution. Its selection is made according to parameters, the main of which are:

- Viscosity. The main indicator of any oil. It means the ability of an oil fluid to maintain the proper level of fluidity while covering parts inside the engine. The degree of viscosity depends on the engine temperature and its own. As the temperature rises, the viscosity level drops.

- Viscosity index. A value that determines the level of viscosity of a lubricant solution depending on its temperature. Increasing the viscosity index increases the temperature range in which it can operate. The indicator is different for each type of oil.

- Flash temperature reading. A value that determines the level of low-boiling fractions in the oil liquid. In high-quality oils, flash occurs at temperatures of +230 degrees and above. If the oil solution is of poor quality, then low-viscosity components will quickly burn out and evaporate, and its consumption will increase.

- Boiling temperature reading. An indicator at which an oil fluid loses its viscosity and lubricating properties. Its boiling will lead to contact between the rubbing parts of the power plant and its failure.

- Ignition temperature reading. The amount of critical heating of the oil fluid. Its combustion begins when its temperature reaches +260 degrees. Ignition threatens to cause the engine to explode and cause injury to passengers.

- Volatility. The oil solution begins to evaporate at a temperature of +250 degrees. Determination of volatility is carried out using the NOC method. At the specified temperature, one liter of oil must be boiled for one hour. If after an hour there are 900 grams of liquid left, then the volatility level is 10%. According to international standards, this norm should not exceed 15%.

- Freeze temperature reading. A value that determines the level of loss of fluidity of an oil fluid. When the pour point is reached, the viscosity of the lubricant increases sharply or a process of increasing viscosity occurs with the solidification of paraffin, as a result of which the lubricant hardens.

- Alkaline TVN value. A number that determines the alkaline characteristics of the oil obtained as a result of the addition of detergent and degrading additives. This is an indicator of the ability of an oil fluid to neutralize harmful impurities and acids resulting from the operation of the power plant. A decrease in the alkaline index indicates a decrease in the number of active additives, which can lead to corrosion of the internal parts of the power plant.

- Acid number TAN. An indicator that determines the presence of oxidation elements in the lubricant. An increase in acid number indicates the presence of a large number of oxidation products. The acid number is determined when selecting oil for analysis. Typically, an increased acid value is associated with prolonged operation or high operating temperature of the power plant.

Engine oil viscosity

The viscosity value of the liquid 0W20, 0W30, 5W30, 5W40, 10W40 or other lubricant is considered one of the main parameters. Lubricating fluid is used to reduce the amount of friction between the surfaces of mechanisms and components of a car’s power unit. Low lubricating properties and characteristics of the substance can lead to jamming, as well as accelerated wear and breakdown of the power unit as a whole.

Oils with a high or low flash point must have the following qualities:

- eliminating the possibility of friction between components and elements of the motor;

- unhindered passage of the substance through all lines of the lubrication system.

Oil manufacturers use special additives designed to improve temperature and viscosity parameters. Thanks to additives, motor fluid thins less when the engine warms up and becomes thicker in severe frost.

Substances characterized by low viscosity are found in almost all low-quality liquids. Because of this, the product burns out faster and evaporates on the internal walls of the engine. This contributes to accelerated lubricant consumption and a decrease in the temperature properties of the product.

Determination of viscosity by marking

The flash, boil and freezing point ranges are usually indicated on the engine fluid label. Also on the lubricant container there is detailed information regarding viscosity parameters in accordance with the SAE standard. This value is marked with numerical as well as letter designations, for example, 0W-30 or 10W-40. The letter W indicates winter performance. The numbers located on the sides indicate the operating parameters of the fluid for summer and winter. In the specified range, the manufacturer guarantees uninterrupted operation of the power unit.

Alexey Kambulov tested motor oils with heating, the results are shown in the video below.

Operating temperature range

The viscosity of the product depends not only on the composition of the substance, but also on the temperature over a wide operating range. This indicator is directly dependent on the temperature in the engine, as well as the air. In order for all components of the internal combustion engine to work smoothly, it is necessary to ensure the high-quality functioning of processes within normal limits.

When producing vehicles, the development company's engineers always calculate the viscosity parameters of the liquid. On average, the operating properties of the oil temperature vary in the region of -30 - +180 degrees, but much also depends on the design features of the engine engine and the environment.

Engine oil operating temperature

The lubricant, depending on its characteristics, can be used in the temperature range from - 50 to + 170 degrees. The operating temperature of the oil in a warm engine and the preservation of its viscosity-technical parameters depend on the temperature regime of the engine. Normal engine temperature ranges from + 80 to + 90 degrees. With such heating, the starting unit has maximum efficiency. Oil lubricant warms up 10-15 degrees more than coolant. Therefore, the operating temperature of engine oil in a warm engine ranges from + 90 to + 105 degrees. It is not recommended to exceed the upper value. This threatens the lubricant with loss of characteristics and rapid wear of rubbing parts.

How to decipher the terms “operating oil temperature” and “positive” deviations from this indicator?

The motor unit operates under special conditions. During its operation, increased pressure and high temperature appear in the working area. Both of these factors have a destructive effect on parts. To eliminate negative consequences, to protect parts that are especially susceptible to influence, lubricant is poured into the system. In fact, motor oil is a consumable material that helps maintain a comfortable environment in the system.

The average temperature in the internal combustion engine reaches 90-105 degrees Celsius

Any deviation from this norm, no matter upward or downward, entails significant interruptions in engine operation. It is important to know one nuance here

If low temperatures do not affect power and engine starting, then with “positive” surges, things are more unpleasant.

The flash point of the oil is indicated on the label. This is necessary because each substance has its own boiling threshold. The better the additives used, the higher the temperature level.

Changes in engine oil temperature

Engine parts are designed to expand when heated and return to their original state as the engine cools. The operation of the power unit depends on the temperature of the oil in a running engine. Excessively low or high heating of the oil in a running engine has negative consequences.

The low temperature of the lubricant can be considered + 80 degrees. With this indicator, the efficiency of the power plant decreases and its service life decreases. The parts of the power unit will have a slight expansion, which will lead to the formation of gaps between them and a decrease in compression. When the starter is slightly warmed up, moisture can condense and form acids in the lubricant, which will affect the wear of components and assemblies. Low degrees can cause the lubricant to thicken and freeze. This will affect its passage through the filter, creating a vacuum in the lubrication system and difficulties in the operation of the power plant.

High heat is even more dangerous than low heat. Heating the oil fluid above + 105 degrees leads to its viscosity sharply decreasing and fluidity increasing. Under load, the gap between the parts almost disappears, the parts of the crank mechanism come into contact with each other.

Why is high engine temperature dangerous?

Severe overheating of the motor will cause the unit to boil; this is much more dangerous than the lubricant hardening. With regular use of a car engine under these conditions, the viscosity parameters of the substance drop, as a result of which the internal combustion engine components cannot be properly lubricated. It should be taken into account that when overheated, motor fluid permanently loses the properties and performance characteristics specified by the manufacturer. At 125 degrees, the lubricant begins to evaporate, which helps reduce the volume of oil in the engine and leads to the need to add it regularly. Oil starvation will cause failure of the unit.

In his video, user Mikhail Autoinstructor talked about the causes of overheating, as well as ways to solve this problem.

Causes of excessive heating of engine oil

The operating temperature of Lukoil oil or any other product may change due to prolonged use of the fluid. Over time, the lubricant begins to age as a result of chemical reactions and oxidative processes that occur inside the internal combustion engine. This leads to the appearance of carbon deposits, varnishes, and sludge deposits in the unit. These processes occur faster during self-ignition or when the lubricant operates at elevated temperatures.

Soot is a solid substance resulting from the oxidation of a hydrocarbon. Such deposits may consist of lead, metal and other mechanical elements. The appearance of carbon deposits will lead to engine detonation and tripping, glow ignition, etc. As for varnishes, such deposits are oxidized films that create a sticky coating on rubbing working surfaces. As a result of exposure of the lubricant to high temperatures, boiling of varnishes, which contain oxygen, carbon, ash and hydrogen, can occur.

The presence of a varnish coating impairs the heat transfer of the cylinders and pistons of the internal combustion engine, which leads to rapid overheating of the structural elements of the engine. The piston rings and grooves suffer the most from the effects of varnish; due to coking, these components can become stuck. Coke is formed in the engine due to the chemical reaction of carbon deposits with varnish. Precipitation in the form of sludge is a mixture of oxidation products with emulsion deposits. Their formation contributes to a decrease in the quality of the fluid and disruption of the mode of use of the vehicle as a whole.

The main reason for heating the oil is its low quality, if you do not take into account mechanical problems with the internal combustion engine.

Motor oil neutralization numbers

Below is a list of abbreviations:

- TBN. Indicates the total alkaline parameter of the liquid. Using this indicator, you can determine the amount of acid that is required to neutralize the alkaline elements contained in one gram of the product. The parameter is measured in mg KOH. The TBN value determines the number of weak and strong alkaline elements that make up the base of the liquid.

- TAN. Total Base Number. This value determines the amount of potassium hydroxide that will be required to neutralize the free acids present in one gram of liquid. The operating parameter expresses the number of acidic elements contained in the lubricant.

- SBN. Alkaline index for identifying strong acids. This value determines the volume of acid that is needed to neutralize the strong alkaline components present in one gram of lubricant. As a rule, we are talking about unlimited alkalis, but in practice this happens quite rarely.

- SAN. A parameter for strong acids that determines the volume of alkaline elements required to neutralize them.

Viscosity-temperature characteristics

According to interstate standard 17479.1-85, oils are divided according to viscosity, purpose and performance indicators. Based on viscosity, lubricants are divided into winter and summer classes. The class has a numerical designation; the letter “z” is added to the winter class.

According to their intended purpose, oil fluids are divided into groups that determine the operating mode of power units, with appropriate markings:

- Unforced gasoline and diesel engines. Marked with the letter "A".

- Low-powered gasoline and diesel engines. Marked with the letter “B1” - gasoline, “B2” - diesel.

- Medium-boosted gasoline and diesel engines. Marked with the letter “B1” - gasoline, “B2” - diesel.

- Highly accelerated gasoline and diesel engines operating in various conditions. Marked with the letter “G1, D1” - gasoline, “G2, D2” - diesel, “E1, E2”

The oil marking consists of numbers and letters. For example, the marking M-4з/6В1 means: M – oil, 4 – viscosity class, the letter “z” – winter, 6 – viscosity class in summer, B1 – medium-boosted gasoline power unit. The characteristics are the same as SAE 10w/20 oil.

The viscosity-temperature characteristics of oils according to interstate standard 17479.1-85 and the ratio with SAE are presented in the table:

| Viscosity grade in CIS countries | Highest viscosity at -18C | Viscosity parameters at +100С | SAE classification | |

| minimum | maximum | |||

| 3z | 1200 | 3.8 | 5w | |

| 4z | 2500 | 4.1 | 10w | |

| 5z | 6100 | 5.6 | 15w | |

| 6z | 10500 | 20w | ||

| 6 | 7.0 | 20 | ||

| 8 | 7.0 | 9.5 | 20 | |

| 10 | 9.5 | 11.5 | 30 | |

| 12 | 11.5 | 13.0 | 30 | |

| 14 | 13.0 | 15.0 | 40 | |

| 16 | 15.0 | 18.0 | 40 | |

| 20 | 18.0 | 23.0 | 50 | |

| 3z/8 | 1200 | 7.0 | 9.5 | 5w/20 |

| 4z/6 | 2500 | 5.5 | 7.0 | 10w/20 |

| 4z/8 | 7.0 | 9.5 | ||

| 4z/10 | 9.5 | 11.5 | 10w/30 | |

| 5z/10 | 6100 | |||

| 5z/12 | 11.5 | 13.0 | ||

| 5z/14 | 13.0 | 15.0 | 15w/40 | |

| 6z/10 | 10500 | 9.5 | 11.5 | 20w/30 |

| 6z/14 | 13.0 | 15.0 | ||

| 6z/16 | 15.0 | 18.0 | ||

...then in the cold

Now let's consider the other extreme - underheating of the motor, that is, its operation at temperatures below 90 degrees. Nothing bad will happen to the oil itself - no matter what base it is made on - at a low temperature. After all, the engine developer and oil manufacturer initially assume that there are cold start and warm-up modes for the internal combustion engine, which take quite a long time. However, the lower the oil temperature in relation to the nominal 90-95 degrees, the greater the loss due to internal friction between its layers and the higher the fuel consumption. Moreover, the process of mixture formation and combustion of fuel in the combustion chamber is not optimal, which means that an oxidizing agent - unburned diesel fuel - will enter the oil with crankcase gases. How much the service life of the oil will be reduced can only be determined by testing it in the laboratory, since the rate of oxidation of the additive package is affected by the amount of sulfur contained in the fuel. If a carrier fills a car with diesel fuel of Euro-4 environmental class, then I consider 75 degrees Celsius to be the critical temperature below which accelerated oxidation of the oil will be observed.

Source