In the early 90s, a sad situation developed throughout the country, which, in turn, led to a lack of standardized funding in various economically potential sectors. In accordance with this, the N. Kamov Design Bureau begins the development of a new civil helicopter, the B-60, under the Ka-62 category. In 1990, this project was headed by the leading designer V.A. Furman. and deputy head of the department for technical projects Gubarev B.A.

The Ka-62 was built on the Ka-60 model, the fuselage interior of which was made in passenger and cargo versions. A transport-type cabin with a volume of up to 6 m2 accommodates about ten passengers in economy class and six in VIP class. The helicopter is also capable of transporting cargo weighing 450 kg in a mechanized manner. The model of this helicopter was demonstrated for the first time at an international aviation show on the territory of VDNKh.

The Ka-62's cockpit featured innovative shock-absorbing seats and an instrument panel, which was based on a liquid crystal display for the first time in the Russian helicopter industry. It was created by a team of authors from NIIAO, not without the participation of B. Gubarev and V. Krygin.

For almost the entire period of the 90s, OKB employees actively demonstrated the new helicopter at all air shows in order to find buyers. In parallel, negotiations are underway with European firms and companies about the possible joint deployment of helicopter production. The Ka-62 is the first aircraft from Kamov OJSC of the helicopter type, designed using a single-rotor design, and the tail rotor is located in the vertical tail. First of all, the main tilt of the helicopter was made for cruising speed, reducing fuel consumption and increasing weight efficiency.

Thanks to cooperation with TsAGI, theoretical and experimental research carried out jointly, it was possible to reduce aerodynamic drag. It also became possible to use updated profiles, and improved blade configurations resolved the problem of increasing propulsive and relative efficiency. OKB and TsAGI together were able to achieve maximum aerodynamic equivalent quality.

The tail rotor is multi-blade. The airframe and propeller blades are 60% made of composite polymer materials. The glider is distinguished by perfect contours, a three-line landing gear with a tail support and an impressive transport and passenger cabin. The power plant is represented by modular design engines (new generation), developed at the Rybinsk Engine Design Bureau. Unlike the basic military model, the civilian Ka-62 has higher cruising speed, transport performance, fuel efficiency and wide door openings in the transport cabin on both sides.

Thanks to the spacious fuselage, the helicopter can be used for civil transport in comfort and for transporting cargo, which can be placed internally and externally on a sling. High speed allows the helicopter to be used when emergency medical care is needed or in emergency rescue situations. The Ka-62 can be used as a patrol helicopter or ice reconnaissance vehicle.

Since the OKB employees initially planned to promote the helicopter to other countries, its design was carried out taking into account international requirements for safe flights. In the event of an accident with the power plant, landing is possible with one engine. If a rough landing is made, the energy-absorbing design of the seats and landing gear will ensure safety for the pilot and crew. The tail rotor of the keel is additionally protected. Among other things, the helicopter is equipped with fire and anti-icing systems.

An additional advantage of the helicopter is that it can be equipped both for flights in normal conditions in favorable weather, and with a special complex for flights in difficult and night flight conditions. If necessary, the engines and ionics in the helicopter can be foreign.

At the HeliRussia-2012 aircraft exhibition, a model of the Ka-62 with an updated helicopter design was presented. The appearance and layout have been preserved, but the chassis and power plant have changed completely. The Russian RD-600 turboshaft engine was replaced with the French TurbomecaArdiden 3G. The transmission and gearbox will be supplied from Austria. Production of the new helicopter is planned to begin at two and OJSC KumAPP. The first will be responsible for assembling the entire structure, and the second will be responsible for the creation and development of the steering and main rotors. The prototypes are managed by the Arsenevsky Helicopter Manufacturing Plant.

After tests carried out in 2013, it was decided to carry out a number of improvements. Certification will be carried out no earlier than 2020. The military model Ka-62 made its first test flight in March 2014. In July, the first three integrated flight and navigation systems KBO-62 were delivered for OP-1 and OP-2. The first delivery of helicopters for export is planned at the beginning of 2016.

Design of the Ka-62

The helicopter is single-rotor, with two gas turbine engines and a three-pair landing gear. It is distinguished by the massive use of CM (50% of the mass of the entire structure). The helicopter fuselage is characterized by an excellent aerodynamic profile. Metal frame with longitudinal beams and frames. The skin consists of laminated panels made of CM and carbon fiber. In turn, the fuselage includes four sections: the cockpit, the cargo-passenger compartment, and the tail boom with vertical and horizontal tails. For the crew, the cabin was specially conveniently glazed and a power lantern set from KM was installed. The doors open outwards. The pilot's seat is located on the right side of the cockpit to eliminate the possibility of duplication of controls.

The dimensions of the cargo-passenger cabin are 3.3 x 1.75 x 1.3 m with large doors. The tail boom has an ellipsoidal cross-section, thanks to which an uncontrolled stabilizer is installed. Its span is 3 meters. The beam has a vertical tail with a profile channel for the propeller. A keel with an asymmetrical profile is mounted above it.

The three-wheel landing gear is retractable, and there is a self-orienting tail support with twin wheels. Retracts into the tail boom. The supports operate like a lever with nitrogen-oil shock absorbers, which are retracted to the side and front of the fuselage. In some modifications it is possible to install balloons.

The main propeller is four-bladed, the blades are fastened elastically. The bushing body is made of fiberglass. It is detachable, and the bushing itself consists of self-lubricating bearings of vertical hinges, torsion bars made of steel plates and elastic elements made of fiberglass. The one-piece composite blades form a rectangle with a swept tip. The double-circuit spar is presented in the form of a profile toe, along which lies a rubber coating (anti-icing system). Blade chord – 0.53 m.

The power plant includes two RD-600 gas turbine engines (take-off power - 955 kW, cruising power - 735 kW). An emergency power mode has also been thought out. The engines are located in a common fairing, the air intakes are located above the fairing. They are also equipped with an anti-icing air system. A digital electronic system is responsible for the regulation and complete redundancy of engine channels. A four-stage compressor, an annular combustion chamber and a drive turbine are integrated by a generator module. The free and driven turbines are two-stage. The launch is carried out using the AI-9 auxiliary installation.

The fuel system capacity is 1100 liters, distributed over four soft tanks. They are located at the bottom of the cabin with the booster pumps connected. The transmission consists of a two-stage main gearbox and a single-stage tail gearbox. The hydraulic steering drive of the control system, together with rigid rods, is combined into a common unit and includes loading mechanisms. The hydraulic system includes two autonomous subsystems. The first is responsible for feeding the steering drives, and the second regulates the wheel cleaning system.

Notes

- ↑ Andrey Fomin.

(unavailable link). Magazine "Take Off" (May 17, 2012). Retrieved October 15, 2020. - ↑

- ↑ Gubarev B.

A.

Aviation Explorer

. AVIA.RU (July 13, 2014). Retrieved September 29, 2020. - ↑, Multipurpose helicopter Ka-60 “Kasatka”, p. 48-49.

- ↑. Helicopter Industry Association. Retrieved October 8, 2019.

- A. Mazepov.

“Night Shark” and “Alligator” // Ka-50, Ka-52, Ka-50N: Army combat helicopters / A. Mazepov; A. Mikheev, V. Zenkin, A. Zhirnov, A. Fomin. — 2nd ed., add. - M.: Favorite book, 1997. - P. 112-113. — 128, p. — (POLYGON: Aviation series). — ISBN 5-7656-0005-0. - ↑. Publishing house "Helicopter". Retrieved January 29, 2013.

- ↑

- . Kommersant (June 24, 2010). Retrieved January 29, 2013.

Description

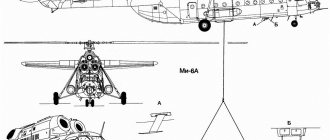

Unlike other Kamov machines, the Ka-62 has an aerodynamic design with one four-bladed main rotor and a twelve-bladed tail rotor placed in an annular channel on the tail of the helicopter. Placing the tail rotor in this way significantly increases the efficiency of its use and increases the efficiency of the power plant.

ka-62 - diagram

The integrated circuit of the fuselage with contours that reduce drag also saves fuel, and composite materials, which make up 60% of the body, play a big role in this, which significantly improves the weight characteristics of the helicopter.

A recently signed contract with the French company Turbomeca allows the Ka-62 to be equipped with highly efficient Ardiden 3G engines with FADEC digital equipment, which reduces pilots’ almost all workload of monitoring engine operation. In addition to FADEC, the crew is helped to monitor the air situation by GPS and GLONASS systems (compatible with the European Galileo), which are part of the on-board navigation system.

The fuselage structure is divided into the following compartments: the pilot's cabin, the passenger and cargo compartment, the tail section and the tail boom. The glass cockpit is protected by organic bird-resistant triplex and has two workstations, and the commander can be placed either in the left or right seat; the avionics layout allows control from any place.

The cargo-passenger compartment can accommodate up to 14 seats; passengers board and disembark through wide side doors on both sides, which slide towards the tail unit. The total load of the Ka-62 is 2.7 tons of cargo, which can be placed inside the cargo-passenger cabin, as well as on an external sling.

passenger compartment

Optimal payload capacity and a spacious passenger cabin make it possible to use the helicopter for aerial surveillance and search purposes, successfully conduct rescue operations, use the machine as an “air crane”, etc.

The small carrying capacity of the Ka-62 was not chosen by chance; studies showed that the Mi-8 could take 4 tons of cargo, and 80% carried out transportation with a load of no more than 2.1 tons, and this had a negative impact on the economic operation of the helicopter.

The vehicle was equipped with a modern chassis; the development of such a unit was carried out on the principle of combined units, which greatly facilitates their further maintenance. The Ka-62 chassis allows it to withstand landing at high vertical speed and provides the ability to fly from the ship's deck.

History of creation

In 1984, the Kamov Design Bureau began developing a medium multi-purpose helicopter for the armed forces, which was supposed to replace the outdated Mi-4. The design of the new vehicle continued until 1990; it received the name Ka-60 “Kasatka”. Problems with financing that began during this period seriously hampered the progress of work. In order to attract private investment, the OKB decided to create a civilian version of the vehicle based on developments on the Ka-60.

The new car was initially designed using the latest advances in aircraft manufacturing. For the new vehicle, new generation RD-600 engines were developed, with technical characteristics at the level of the best gas turbine engines of that time. The designers paid a lot of attention to the convenience and safety of passengers and crew. The Ka-62 helicopter was conceived in passenger and cargo versions, and in the future it was planned to develop a rescue and medical modification of the helicopter.

The model of the helicopter was first demonstrated to the general public during the MAKS-95 aviation salon.

After this, work on the creation of the Ka-62 practically ceased for many years. New dates for the start of operation and serial production of the helicopter have been announced many times. In 2012, an updated version of the Ka-62 was presented to the public. The new helicopter was equipped with French Turbomeca Ardiden 3G engines and a transmission from the Austrian company Zoerkler.

Thanks to their modular design and advanced digital control system, Ardiden 3G engines were distinguished by excellent performance (primarily low fuel consumption), reliability and ease of maintenance. It is expected that the new power plant will significantly increase the helicopter's speed (both maximum and cruising), as well as the vehicle's ceiling.

The Ka-62 also received new landing gear and an extended cargo-passenger cabin.

The helicopters are planned to be assembled at Progress AAK, and components for them will be manufactured at the aircraft plant in Kumertau (KumAPP OJSC).

The Ka-62 helicopter can be operated in a wide range of climatic and geographical conditions, at temperatures from –50°С to +45°С and can fly in icing conditions and in bad weather. The machine is intended to be operated from unpaved sites, airfields and oil platforms. The possibility of storing the machine without a hangar is allowed.

It is planned that the Ka-62 can be used for transporting cargo, passengers (including VIPs), servicing oil and gas drilling platforms, evacuating the sick and wounded, and aerial surveillance.

Operators for 2020.

In total, the Russian Air Force has 72 Ka-52 Alligator units in service. Among them:

- • 8 pcs. – Torzhok (used for flight tests and pilot training);

- • 20 pcs. – Chernigovka (575th air base);

- • 16 pcs. – Korenovsk (393rd air base);

- • 16 pcs. – Ostrov (15th air base);

- • 12 pcs. – Khabarovsk (573rd air base).

In the 80s, OKB im. Kamova N.I. put forward the idea of creating a helicopter equipped with the latest radar devices that would allow it to conduct effective reconnaissance and control the actions of helicopter groups on the battlefield. It was planned to create such a machine on the basis of the B-60 helicopter (later Ka-60). After the collapse of the USSR, work on the project was suspended. In the mid-90s, it was decided to resume the development of this complex based on the Ka-50. The new helicopter was designated Ka-52.

In 1996, the first prototype of the Ka-52 Alligator appeared. Flight tests began in June 1997. It differed from the Ka-50 in the structure of the front part of the fuselage (the canopy of the new two-seater cockpit received a more streamlined outline). Several complexes were used as surveillance and sighting systems. The Samshit-E GOES in a spherical body was placed in the upper part of the fuselage. This complex consists of a thermal imager, a daytime television system, a laser rangefinder-target designator and a laser spot direction finder. The Rotor OPS was initially installed in the nose cone. Subsequently, they decided to replace it with the Arbalet radar complex, which includes systems for detecting ground and air targets. The helicopter's armament is similar to the Ka-50.

New equipment and a two-seat cabin led to an increase in the weight of the vehicle, which negatively affected flight characteristics. The developers plan to solve this problem by installing a new VK-2500 engine (2500 hp).

In modern armed conflicts, a helicopter is required that could quickly detect and attack a target without risking falling into the range of enemy air defense systems. Nowadays, military affairs is inextricably linked with the development and implementation of high technologies. The Ka-52 project is an attempt to create modern weapons that could compete with foreign analogues.

In 2011, the Russian Ministry of Defense signed a long-term contract for the supply of 140 helicopters. It is also planned to place them on Mistral-class helicopter carriers. In this regard, in August 2012, the development of a naval modification of the Ka-52K began.

Mistral-class helicopter carrier

Ka-52 helicopter. Gallery.

Perspective

The Ka-62 was developed at the production facilities of Kamov OJSC, the design bureau and holding company Russian Helicopters. This is the first civil helicopter in the manufacturer’s line, made using a single-rotor design. The tail rotor is enclosed in an annular channel having a vertical tail.

Over 3 billion rubles were spent on the development of the machine over more than 20 years. The amount is quite decent, so the market value of the helicopter will not be low either: presumably about $10 million. It is known that the release of the new product will be largely focused on the international market.

Arsenyevskaya Aviation will be responsible for serial production of the KA-62 model. The military version is expected a year after the launch of full production. Due to its high technology and widespread use of innovative solutions, the KA-62 helicopter will be certified only in 2020. In the meantime, further tests and tests await this model, which will improve the quality and reliability of the aircraft, eliminating possible risks and creating a truly legendary and unique helicopter in the entire global aircraft industry.

Accidents and disasters

03/12/2012. While performing a scheduled training flight, a Ka-52 helicopter (tail number 99) crashed. The crash site is Torzhoksky district, Tver region. The remains of the helicopter were found 10 km from the airfield, near the village of Bolshaya Kiselevka. As a result of the fall, the navigator died on the spot, the pilot was unconscious and received many injuries. A few hours after hospitalization, he also died.

10/29/2013 – a Ka-52 test helicopter caught fire on the territory of the complex where flight tests were carried out in the city of Zhulebino. The helicopter burned down completely. The crew of two pilots managed to be hospitalized. On this Ka-52, scheduled test work was carried out to check the helicopter systems developed by Kamov OJSC. As the investigation showed, the cause of the accident was a failure of the top rotor rod.

Outstanding Features

The Ka-62 is a deep modernization of the Ka-60 Kasatka medium military transport helicopter. The development of this machine started at the Kamov Design Bureau in 1983, a prototype was created, but mass production of the Killer Whale was never launched due to financial problems after the collapse of the USSR.

In the 1990s, domestic specialists began creating a civilian version under the code Ka-62. The main problem in improving the car was the lack of suitable domestically produced engines and transmissions.

Also on topic

A demonstration flight of the Su-35S took place on the eve of the EEF

A demonstration flight of Su-35S fighters and other aircraft took place on the eve of the Eastern Economic Forum in Vladivostok,…

As a result, the engineers abandoned attempts to modify the Saturn RD-600V turboshaft engine (KB Rybinsk Motors) and opted for the French Ardiden 3G power plant of the Safran Helicopter corporation with a capacity of 1545 to 1940 horsepower. It was also decided to install on the Ka-62 gearboxes and transmissions of the main and tail rotors developed by the Austrian Zoerkler Gears GmbH & Co.

In 2012, a mock-up of the Ka-62 was presented at the international exhibition HeliRussia. Pilot production was launched at PJSC Arsenyevskaya Aviation named after N.I. Sazykina". The machine performed its first hover in April 2020, and a full flight in May 2017.

The Ka-62 is made according to the traditional single-rotor design. However, the engineers placed the tail rotor in the tail structure (the blades are enclosed in a special ring-shaped fairing). This technical solution is aimed at increasing the safety and reliability of the helicopter.

Progress specialists managed to achieve outstanding performance. The take-off weight of the Ka-62 is 6.5 tons, the payload capacity is up to 2.5 tons, the flight duration (with full fuel tanks) is up to 4 hours, the practical range is 750 km or 1135 km (with additional fuel tanks).

The successor of the Killer Whale is capable of reaching speeds of up to 310 km/h and can be operated at temperatures ranging from –50°C to +45°C. The crew size is one or two pilots. Experts estimate the passenger capacity of the Ka-62 at 15 people.

- Sample Ka-62 at the Eastern Economic Forum

- RIA News

Purpose

Military aviation and the national economy were in great need of transporting integral cargo with a total weight of over 20 tons using the vertical type of takeoff and landing. In theory, the Mi-12 was supposed to be such a device. The purpose of the helicopter was taken into account in transporting cruise and ballistic missiles, self-propelled artillery units (such as Su-100), PT-76 and T-54 tanks, and armored personnel carriers. In total, this universal helicopter could transport up to 80 types of various equipment and weapons.

During the Cold War, air defense systems were built at strategic points in the USSR. And there was an urgent need to create a heavy lifting aircraft and helicopter that could transport solid heavy missiles in a short time. The B-12 was developed in tandem with the An-22 aircraft. The plane’s mission was to transport military equipment to the airfield, and the B-12 to the nearest position. Therefore, the dimensions of the cargo compartment of these two aircraft were designed to be the same.

Tests of the B-12 were quite successful. There were 122 flights and 77 hoverings, which demonstrated the high efficiency of all helicopter systems.

Rotorcraft transformer

When creating the Ka-26, the predecessor of the Ka-226T, Nikolai Ilyich Kamov’s team was tasked with developing a multifunctional helicopter. Its main area of application was to be agriculture, where the helicopter is especially convenient due to the frequent absence of airfields and difficult terrain. At the same time, the device must be multi-purpose so as not to be idle between seasons. The Ka-26 operated on the principle of a “flying chassis”: various suspensions could be placed behind the cockpit - a passenger unit, tanks, a winch or other equipment.

The same idea was preserved in the Ka-226T. The helicopter is built according to a modular design, which involves the use of various replaceable modules. Several people can replace the module within about two hours.

In the transport version, the Ka-226T can carry a ton of cargo inside the fuselage or on an external sling. To transport oversized cargo, a cargo platform is installed instead of a transport cabin.

The passenger module is equipped with two emergency exits and allows you to comfortably transport up to 7 people. It is also planned to release a corporate passenger version.

For physicians, the Kamov Design Bureau has developed two versions of the module: evacuation and resuscitation. The first can carry two victims on a stretcher and is equipped with all the necessary medical equipment, including oxygen cylinders. Folding seats are provided for staff. The intensive care version accommodates one victim and two doctors who can provide assistance during the flight.

The police modification helps law enforcement officers conduct air patrols, detect and pursue criminals, and regulate the road transport system. This version can accommodate up to 6 people on board.

Separately, it is worth noting the wide capabilities of the Ka-226T in the work of search and rescue services.

Thanks to its unique characteristics, the helicopter can perform a stable hover, which is very important for the safe lifting of victims on board. The small dimensions of the Ka-226T and its excellent maneuverability and controllability make it indispensable for rescue operations in mountainous areas.

The ship-based version of the Ka-226T has the ability to fold the rotor blades, and its systems and components are adapted for use in a hostile marine environment.