History of the 4a91 engine

The initial development and production of the engine was carried out by MDC Power, the rights to which belong to the automobile manufacturer Daimler. Its headquarters are located in Stuttgart. For such a small-volume engine paired with a manual transmission, acceleration to 100 km/h in 11.4 seconds is considered a very good indicator. The designers worked from scratch to develop the camshaft, pistons, exhaust manifold, air filter, intake manifold, valve stem seals and flywheel. All these elements have an individual design that has not previously been used in Mitsubishi engines. It was first installed on a small Mitsubishi Colt car in 2004, and a little later it began to be equipped with the Mitsubishi Colt Plus, as well as the Mitsubishi Lancer 10 with the index CY2A.

Engine repair 4A91

Material from Mitsubishi Lancer Club FAQ

I’ll say right away that I’m not a professional, but rather a fan of tinkering with technology in my free time, so I ask you to be loyal to the details.

Patient:

Lancer X, purchased in Rolfe in 2008, mileage 108 thousand km. All maintenance according to regulations in Diamante.

Starting from about 80 thousand km, an appetite for oil appeared. In anticipation of a serious burn, my mother went and added oil as needed, and I waited until it got big so I could change the rings.

But then a nuisance happened in the form of refueling with bad gasoline somewhere in the depths of the Ryazan region, and as a result, my mother came home with an engine running on 3 cylinders. It became clear: repairs were inevitable.

Using a video endoscope, it was determined that the cylinder failure was associated with a burnt-out exhaust valve in the 2nd cylinder.

After weighing the pros and cons, I decided to repair it myself.

So, for repair you need:

literature on the 4A91 engine from Colt (“The Third Rome” sucks, everything there is for two-wheelers, a lot of things are not the same as in real life, everything has to be thought out and done by analogy, because everything is schematic, there are no tightening torques). A set of good tools, a set of Torx sockets and a torque wrench are also required. I had these sets:

- oil seals MR 984262

(16 pcs.) - cylinder head gasket MN 195370

- exhaust manifold gasket MN 195556

- intake manifold gaskets MN 149030

(4 pcs.) - sealant

- antifreeze

- oil

- filter

- rings (I didn't change)

- in my case the valve

- and of course, the desire to do all this.

In order (I will indicate the usual operations briefly, since a more or less experienced person will get into the engine, I don’t see the point of indicating about every screw and wiring), we begin to remove all the attachments:

Engine mount and belt attachment:

Air filter housing, fuel hose, all wiring to various sensors, unscrew the brackets from the head:

Drain the antifreeze (there is a special tap in the lower right corner):

We remove the intake manifold together with the throttle valve, while disconnecting the heating pipes with antifreeze:

I removed the fuel rail while the head was standing, but it’s better to remove it later, after washing off the dirt; if there is one, it’s more convenient to pull it off on a fixed head. In my case, I removed the valves, so it was possible to clean the intake. If the valves are normal, then the ramp does not need to be removed; it is enough to thoroughly wash the dirt on the already removed head.

Well, everything is ready to remove the valve cover (note that there are Torx head bolts everywhere.)

We remove the valve cover and see the cleanliness:

Next, we climb down, unscrew the crankshaft pulley (in my case, it was unscrewed with a long wrench from the kit; there are turnkey recesses on the camshafts, they can be used to fix the knee through the timing chain) and remove the pan. There are also Torx bolts, and it is sealed. To unstick it, you need to work hard. In general, we grab the corners with a sharp screwdriver and gradually tear it off. I even bent mine a little, but then I tapped it and straightened it, so it’s not a big deal if it’s bent.

Next, unscrew the oil receiver, and, making sure that nothing is in the way, unscrew the timing chain cover. There are many different bolts, so I advise you to remember which ones are screwed in where:

Please note that the pump sits glued to the lid. If it works, then you don’t have to peel it off, it doesn’t interfere, and it will be more intact. I removed it because I needed to wash off all the carbon deposits. The following picture appears:

Before removing the chain, I had no information about the location of the marks on the pulleys, so I prudently stroked the marks on the pulleys and chain teeth just in case. Like this:

Specifications

The 4a91 engine unit is one of three representatives of the 4a engine line. The volume of its working cylinders is 1499 cubic centimeters. Depending on the vehicle on which the 4a9 is installed, it is capable of developing power from 102 to 109 hp. The approximate lifespan of the engine, which it can cover without major repairs, ranges from 80,000 to 150,000 km, depending on the loads on the engine and the quality of the lubricants and fuel fluids used. Its operation is based on the DOHC system. Engines with this system have two camshafts, 4 cylinders, and 16 valves.

The location of the camshaft is on top of each row of intake and exhaust valves. This engine has no rocker arms, rods or rockers. To significantly reduce loads and better combustion of the fuel-air mixture attributable to the springs, these engines install four lightweight valves per cylinder, instead of two, heavier valves. This also led to the fact that, thanks to two valves with a small diameter at the inlet, 50% more fuel enters the cylinder than through one valve of a larger diameter.

It also contains a system that allows you to change the phases of gas distribution. Engines with this mechanism have higher economic indicators and efficiency compared to other naturally-aspirated engines of the previous generation. The power unit number is located on the surface of the front part of the cylinder block, near the location of the hydraulic power steering pump.

Summary table of technical characteristics of internal combustion engine 4a91

| Power | 102 hp (75 kW) | 105 hp (77 kW) | 109 hp (80 kW) |

| Fuel type | Gasoline | Gasoline | Gasoline |

| AI-92, AI-95 | AI-92, AI-95 | AI-92, AI-95 | |

| Maximum torque/speed | 138 N*m (14 kg*m)/ 4000 rpm | 141 N*m (14kg*m)/ 4000 rpm | 143 N*m (15 kg*m)/ 4000 rpm |

| System that changes the cylinder displacement | Absent | Absent | Absent |

| Fuel consumption | 6 l/100 km | 6.2 l/100 km | 6.3 l/100 km |

| Compression ratio | 10.5 | 10.5 | 10.5 |

| Piston stroke | 83 mm | 83 mm | 83 mm |

Engine block head Lancer 10 1.5 l.

The Mitsubishi Lancer X 1.5 liter cylinder head is made of aluminum alloy. The camshafts directly affect the valves. That is, the cams of the shafts run into the cups, which in turn press on the valve stems. Luckily there are no rocker arms there. But this engine also does not have hydraulic compensators. The valve clearance is adjusted by selecting pusher cups (size 31), which have different bottom thicknesses. The spark plug wells are located in the center of the cylinder head.

Timing drive of the Mitsubishi Lancer 10 1.5 l engine.

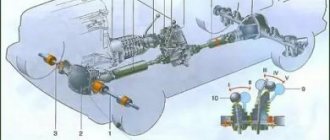

The timing drive is chain driven and usually does not cause problems. All marks for installing a new chain are present. But experienced craftsmen make their own additional marks. Do not forget that there is a phase shifter on one shaft, which operates due to oil pressure, which is regulated by the solenoid valve of the MIVEC system. The service life of the chain is not known for certain, since against the background of stiff valve stem seals, sunken piston wheels and wild oil consumption, this is not a problematic part of the engine at all. Timing drive diagram for Mitsubishi Lancer 10 1.5 below.

Engine characteristics Lancer 10 1.5 l.

- Working volume – 1499 cm3

- Number of cylinders – 4

- Number of valves – 16

- Cylinder diameter – 75 mm

- Piston stroke – 84.8 mm

- Timing drive - chain (DOHC)

- Power hp (kW) – 109 (80) at 6000 rpm. per minute

- Torque – 145 Nm at 4000 rpm. per minute

- Maximum speed – 178 km/h

- Acceleration to the first hundred – 14.3 seconds

- Fuel type – gasoline AI-95

- Fuel consumption in the city – 8.9 liters

- Fuel consumption in the combined cycle – 7 liters

- Fuel consumption on the highway - 6 liters

This engine is rather weak for the Lancer, but for the Mitsubishi Colt the engine is perfect. Before buying a used Mitsubishi Lancer X 1.5, think about how much it will cost you to repair the power unit.

Motor reliability

This unit does not have very good reliability indicators and requires special attention during the entire period of operation. Even cars that have just rolled off the production line are sometimes characterized by increased oil consumption in large quantities. Violation of regulated maintenance is guaranteed to lead to increased wear of the cylinder-piston group and other elements. In the future, this will lead to the following consequences: the appearance of oil in the spark plug wells, the piston rings may become stuck, and the connecting rod bearings and main bearings may rotate, since the engine oil is not distributed correctly due to wear of the cylinder-piston group.

The designers installed a chain in the gas distribution mechanism. This is a good solution because it gives greater reliability to the engine. The removal and installation of the timing chain must be carried out by highly qualified specialists, since incorrect installation of the chain can lead to serious problems, even to the point of requiring expensive engine repairs.

What oil to fill and period of regulated maintenance

As mentioned earlier, replacement of lubricants and filter elements must be carried out strictly within the required time frame. The manufacturer recommends using branded Mitsubishi oil 0W30, 5W30, 5W40, 10W30. The regulated mileage for a vehicle using this oil is 15,000 km. However, if the car is operated under constant dynamic driving, then the lubricant must be replaced twice as often.

However, among owners of Mitsubishi Colt and Lancer X cars, there is an opinion that the original Mitsubishi engine oil is not the best choice for this engine. They claim that the engine life when using world-famous branded lubricants almost doubles the life of the power plant and is about 150,000 km, while the use of the recommended oil will force a major overhaul of the engine already at 80-90 thousand km.

Maintainability and maintenance

In general, the engine is very simple and compact in size. This allows you to carry out repair work even in a garage environment. However, spare parts, their availability and price, if the main elements break down, forces the owner to replace the entire engine with a contract unit. Most often, in monetary terms, this replacement costs the owner less than purchasing a large set of spare parts to be replaced.

After repair work has been carried out on the engine, it is necessary to configure it for correct operation. Engines with a DOHC system have their own distinctive features in valve adjustment. The fuel consumption, as well as engine compression, depend on the correct setting, as a result of which you can notice a deterioration in the dynamic acceleration qualities of the car. Pistons and piston rings are supplied to the Mitsubishi automaker by Teikin and TP - Teikoku Piston.

The ignition system and attachments are reliable elements in the 4a91 engine. It is necessary to replace spark plugs on time, since the power plant is very sensitive to the quality of the spark. The data written in the book on maintenance and repair of engines from the 4a9 series indicates the need to replace spark plugs every 10,000 km, regardless of their condition. Also, the manufacturer of these motors recommends paying attention to the tightening torques of all engine connections, since the internal combustion engine contains many associated elements that operate under high loads.

The drive of the gas distribution mechanism is shown in the figure

1 - Tension shoe; 2 - Exhaust valve gear; 3 - Exhaust valve gear; 4 — Chain damper; 5 - Crankshaft gear; 6 - Timing drive chain; 7 - Chain tensioner; a,b,c,d,e – Timing chain marks

The tenth generation Lancer is a popular car. There is a good article on the topic of car reliability in the Autoreview magazine, in the “Second Hands” section. Anyone interested will find it and read it. About engines, it is mentioned in passing that the 1.5-liter engine (model 4A91) is problematic, prone to ring sticking, and it’s not worth buying such a car second-hand. Well, it’s mentioned and okay, who doesn’t.The people's path to the K-POWER Workshop is not overgrown, the queue for repairs is not decreasing, and now a person well known to us, who occupies not the last place in our local hierarchy, appears on the threshold, with a conversation. And the conversation was about this - he drove a Mitsubishi Lancer 10 , he didn’t know any grief, the car was excellent, he bought a new one in 2011 from a dealer, changed the oil on time, poured only original Mitsubishi 0W30 , the engine didn’t break, and here’s the problem - oil consumption after 100 thousand km mileage began to increase sharply and reached a liter per thousand km. The warranty has expired, the officials offer to come for repairs when the consumption reaches 2 liters per thousand. But adding oil is a bit expensive - a liter has risen in price to 700 rubles. We thought about it and decided to open the engine. The mileage at the time of opening was 116 thousand km , honest and transparent. The initial verdict is that the oil scraper rings are stuck.

As always, the author is interested in delving into a previously unknown engine and gaining new experience. Here the interest is double - the engine is relatively fresh, still relevant, and even made in Japan! There is no doubt that all parts were checked and marked personally by the Emperor, and as always, the driver is to blame for the breakdown, but not the Japanese. Is this so, what engineering solutions were used by the Japanese, the luminaries of engineering progress, and whether the Emperor’s seal was there - all this had to be checked. During the report, the author will inevitably compare design solutions with motors of other brands.

Let's get started. The space under the hood is pleasing to the eye - the engine is compact and extremely easy to service and access. The motor is a chain, there is only an external accessory belt, which is tensioned by a generator. We begin to disassemble the engine.

Things are moving quickly, the harnesses are quickly disconnected and moved to the side, the ease of dismantling the intake manifold is phenomenal, although the lower bolt of the generator fastens against the thermostat housing, this is not significant - access to everything is very simple and convenient. Along the way, let's evaluate the rear suspension - it has a multi-link, the levers are not as strong as Ford's, but also not an Alfa Romeo or Jaima bike. The design layout initially provides for all-wheel drive.

The wiring is of high quality, the connectors are very tight, waterproof and difficult to remove. I was surprised that the four contacts in the electronic throttle block are gold-plated, as are the mating pins on the throttle itself. Remove the valve cover. The engine is a 16-valve valve, a timing chain drive with a bushing-roller chain, a phase shifter clutch is installed on the intake camshaft, proudly referred to by Mitsubishi as MIVEC . This clutch, like the Alpha, turns the intake camshaft with oil pressure, the flow of which is regulated by an electromagnetic valve. The candles are dirty with burnt oil. Let's take a closer look - again there are no hydraulics! Instead, there are solid pushers, like on a Ford. Again, savings and hassle in adjusting the valves, and the cams of the shafts are so narrow!

To our relief, the engine is quite simple in terms of timing marks! The crankshaft pulley is positioned with a pin, there is a mark on the exhaust sprocket, there is also a mark on Miveka (and more than one, but you won’t fool us), there is also a mark on the crankshaft (and again, more than one, but the Japs won’t fool us here either). Before dismantling the timing belt, we set the crankshaft to TDC, take notes on all the marks, put down additional marks - in the future we will not have problems with installation. And you don’t need any special tools, like Ford.

The valve clearances were measured and all data was recorded on a plate. In general, the gaps are in tolerance, only at the intake the two outer intake valves are at the very bottom of the tolerance. The pushers are very thin and there is practically no adjustment margin in case of flat grinding, because the thickness changes on the thin central section, the tubercle, next to which the nominal thickness of the cup is indicated in numbers, but the rest of the bottom is very thin. A search of catalog prices showed that one pusher costs around 500 rubles. For a throttle setup, this is a pretty bleak engine. But there is no gas here and adjustment of the gaps is not required yet, then we begin to disassemble the engine further. The side engine mount is simple rubber, we don’t see any hydraulic cushion. On the one hand - reliable , on the other - cheap. The chain is in perfect condition! The tensioner reaches no more than 15-20% of the stroke, has a pawl ratchet (you don’t have to worry about the chain jumping when the engine is off), and is activated by oil pressure. The timing drive design is one-in-one, like Ford's. But the oil pump is screwed to the front cover from the inside and rotates with the crankshaft. Not a bad decision.

After unscrewing the exhaust manifold (access is also convenient and simple) and the side bracket, the head can be removed by first unscrewing the tightening bolts. Having removed the pan (glued with sealant), we take out the pistons. And here the pleasant impressions about the car, the wiring and the Japanese, the beacons of engineering, begin to disappear. And if you google it, you can find out that the engine has German Mercedes roots. The pistons look like burnt grandma's pies left in the oven a couple of hours too long. Connecting rods and liners are jewelry! The connecting rod is thinner and lighter than Priorov’s, the connecting rod bolts are completely unimaginably miniature. The earbuds are barely noticeable on the table, they are so narrow and thin. The piston pin is pressed into the upper end of the connecting rod, making potential repairs difficult in the future. The rings were simply amazing - if the Priorovsky rings have a thickness of 1.2-1.5-2.5 mm, then the Mitsubishi 1 has 0.7-2.0 mm ! The second ring is like foil, it is so thin and fragile! The oil scraper rings are completely stuck and clogged with coke in the grooves. On the Lancer forum, topics about the oil-guzzling 4A91 and its causes are covered on dozens of pages, but it’s unlikely that anyone would have guessed one of the reasons for the occurrence of rings on this engine. If on Ford this was due to the lack of drilling in the oil scraper ring groove, then on Mitsubishi there are drillings. But the engine does not have piston oil cooling nozzles! In a sixteen valve! Forced!! The light of engineering has gone out, the search for the Emperor’s seal is useless, it was long ago sacrificed to a god named Economy... Here you have burnt pistons-pies, here are the rings that are stuck due to local overheating and lack of lubrication...

The worst thing is with the 4th piston and cylinder. A piston skirt with black scuff marks is a consequence of oil starvation. There is also a vertical tear on the cylinder (it’s hard to see in the photo - the light block illuminated the frame). What we saw vividly reminded us of VAZ 8-valve Samaras, where the same scuff marks were always present on the pistons after several years of use, because There are also no oil nozzles. The remaining cylinders are in good condition, there are risks of honing. Measurement of pistons and cylinders showed a disappointing picture. The wear on the piston skirts was 0.04 mm, which, with the cylinder diameter plus 0.04 mm, turned into a gap of 0.08 mm ! Let me remind you that the wear limit on Zhiguli cars is 0.15 mm! That's Japanese quality... Against this background, you can completely close your eyes to the taper and ellipse of the cylinders at some measly 0.01 mm.

The author no longer expected anything good from the Mitsubishi cylinder head and also stopped searching for the Emperor’s seal. The head is a very ordinary one, albeit of high quality. The valve stems are 5 mm in diameter, there are no oil supply pushers in the wells and they are lubricated by gravity, the shifting of the pushers is visible and as yet imperceptible wear along the well is noticeable, the valves are covered with a coat of soot, and the valve stem seals are completely stiff . After searching and assessing the availability and options of spare parts for this engine, the owner of the car was called to a consultation to decide what to do next with this miracle of Japanese engine building.

After a detailed demonstration and story of all the nuances, consequences and their causes, the client’s face turned crimson red. Nobody expected such a picture. There are no repair pistons for this engine yet; almost all spare parts are original, except for the cylinder head gasket and spark plugs. One piston with a pin costs about 7,000 rubles, a set of rings for 1 piston costs 1,600 rubles, etc. According to the mind, if you do it with a guarantee, then the block needs to be dismantled and lined either with old pistons, or even better - with new ones. The cost of potential repairs was growing by leaps and bounds. The client decided this - “we won’t bother any further, we’ll change the rings and caps, and the car will be sold - the time has come.” But the “time” came at the wrong time, the client took a ride through dealer showrooms and became saddened by the new price tags. A familiar mechanic from the officials made the client happy - “you’ve already driven twice as long, we open them at 50-60 tkm.” The officials don’t have any spare parts, and the prices are outrageous (one valve stem cap costs 220 rubles, and that’s on order, but I ordered a good non-original one for 60 rubles per piece). At the same time, the same mechanic made a reservation that he opened the engine on his Lancer, there was the same scuffing and after replacing the rings, the oil consumption disappeared, and the mileage after repair was already 20 tkm. As a result, the client did not change his decision - “we’ll limit ourselves to replacing rings and caps for now and will drive until the next repair,” and he also changed his mind about selling the car. The client did not agree to the proposal to embed the oil injectors into the block, and it was risky for me - for Mivek, the oil pressure in the system is important, and I did not want to take on the multi-thousand-dollar cost of the block in case of any error.

The author selected and ordered a set of new rings (original), new cylinder head bolts (original), caps (Ajusa) and spark plugs (Denso). The cylinder head gasket is not original from Vitya Reintz. The restless Japs, after two years of production of the 4A91 engine, modernized it and replaced the valve stem seals with the version from the 1.6 liter engine. The difference in the caps is shown in one of the photos (old caps on the left, new ones on the right). The valves were cleaned of carbon deposits (it is strictly forbidden to rub them against the seats) and the head was assembled. The pistons were washed and cleared of carbon deposits, especially the ring grooves. The connecting rod bearings were not changed, and the tightening of the connecting rod bolts must be approached extremely scrupulously - the torque there is very small, and pulling out the threaded body with subsequent destruction of the bolt is very simple. It’s definitely not worth coming here without experience.

Tightening the cylinder head bolts is also akin to shamanism - the bolts are thin, the block is aluminum, but Vitya Reintz's instructions contain a diagram and tightening torques - everything went smoothly. The throttle valve was washed from abundant soot deposits to a shine (it’s strange where the soot came from, because the engine does not have an EGR valve, although space for the channel is provided by both the gasket and the manifold - but even here they made it cheaper), the generator was rebuilt (the client complained about a whistle in the morning) — Japanese bearings have dried out in three years. In general, assembly of the motor was quick - easy access, the motor is relatively simple.

The oil was filled with Elf 5W30, the engine started easily and began to work quietly. The client noted that the engine began to run smoother.

The entire repair of the Mitsubishi Lancer X (4A91, 1.5 l, 109 hp) cost the client 26 thousand rubles. including labor and all spare parts. The car is in plain sight, the client drives a lot, and all statistics will be published in this article in the future. Well, if someday the oil gluttony happens again, we already know what to expect from the engine (we no longer have any illusions about the beacons of engineering from the Land of the Rising Sun and their seal of the Emperor) and what we should prepare for during repairs.

I suggest the reader also watch videos filmed during the repair of the Mitsubishi Lancer X (4A91, 1.5 l, 109 hp) - there you can see nuances not described in the text of the article.

Update July 5, 2015:

Several months have passed, we can sum up some results of the Mitsubishi engine repair. The client, of course, did not sell the car; he drives it every day. Since the repair, it has covered several thousand kilometers, the oil level does not change, and oil consumption has been completely eliminated.

A few weeks after the repair, the car came to replace the graphite ring of the exhaust manifold. This ring is the weak point of Lancers; with its destruction, exhaust noise appears during intense acceleration (the ring begins to cut). The next photo shows an old burnt ring and a new one - I had to order the original one, at a price of about 650 rubles.

Replacing the ring does not present any difficulties, but the nuts and bolts must be coated with copper paste before tightening to avoid further sticking.

Otherwise, the client is completely satisfied with the repairs performed and continues to use the car.

Update from August 15, 2015:

The mileage on the odometer is 126 thousand km. The oil began to leak again, but it was not the rings that were to blame - during an inspection on the lift, they discovered a leak in the front oil seal! He was squeezed out of his seat. The oil seal was replaced with a new one (original) and glued with Loctite to be sure (the fit of the oil seal in the socket is weak), and the oil was changed at the same time (the deadline has come).

At the same time, we checked the spark plugs - the insulators were clean, without traces of oil burnt (at the beginning of the article there is a photo of a spark plug with loose carbon deposits, before replacing the rings). Those. Oil consumption due to the rings has stopped.

Article written: April 12, 2015 Article updated: August 15, 2015 Author of the article, photo-video materials: © Quasar Prohibited without the written permission of the author: reprinting the article in whole or in part, reprinting and use of photo-video materials, as well as their modification and editing for further publication on third-party sites.

Tuning

The problem with upgrading the 4a91 engine is that it is ideally tuned by the factory to meet all the declared indicators of dynamism and efficiency. Any intervention in the integral design of the engine installation will lead to less than ideal engine operation, as well as a possible increase in the consumption of lubricating and fuel fluids. The most common type of tuning of any engine from the 4a9 series is changing the readings and flashing the electronic control unit. It is tuned so that fuel economy and dynamic performance indicators correspond to the declared indicators. If you set it for maximum fuel economy, the dynamic qualities of the car will decrease significantly. The advantage of the ECU installed on these engines is that returning to factory settings is very simple.

The mechanical part is very difficult to tune, since there are practically no stock parts in the engine. The intake system is filled with electronic systems, so after upgrading, a large number of errors may appear. However, some car owners are not afraid of this, and they resort to changing the design of the piston group and modernizing the camshafts. However, when assembling the engine, you need to be very careful and make the tightening torque of the crankshaft and other elements corresponding to the factory parameters. Most automotive experts claim that swapping 4a91 to 4g92 will bring more effect in terms of dynamic performance than tuning a 1.5-liter engine.

Do-it-yourself valve adjustment on Mitsubishi Lancer 10

The most common engine on the Lancer 10 in Russia is the 1.5 liter 4A91 unit. This is an inexpensive to maintain, economical engine with a long service life. The main reasons for its breakdowns are long-term operation at low temperatures and low-quality Russian fuel, which leads to the formation of soot, a drop in compression and disruption of the valve system.

Car manufacturers recommend measuring valve clearances every 100 thousand miles if there are no visible problems. Proper valve adjustment requires the installation of new pushers; each pusher has its own code (in total, 31 types of pushers of varying thicknesses and 0.02 mm pitches are produced for the 4A91 engine), but in some cases you can do without replacement.

Mitsubishi Lancer after 2000 is equipped with several options for new engines of different displacements:

| Engine volume | Power hp | Year of issue | RPM | Type |

| petrol | ||||

| petrol | ||||

| 1.8D | diesel | |||

| petrol | ||||

| petrol | ||||

| 2.0D | diesel | |||

| petrol |

Owner reviews

I bought a 10th generation Lancer at a dealership 7 years ago. Currently the mileage is 146,000 km. My car is quite reliable, perhaps because I use the most expensive lubricants and spark plugs and replace them according to regulations. The engine consumes approximately 1 liter of oil per 10,000 km, which is the acceptable standard by the manufacturer.

I bought a car with a mileage of 80,000 km and have already driven about 30,000 km in a year. A month ago I had to undergo a major overhaul, during which I had to purchase taiho liners, original valve stem seals, spark plug rings, valve lifters and much more. After the overhaul, the car began to drive much faster. There is no oil burn.