Technical characteristics of the scooter TULA T-200

Total information

Type – Heavy road single; Base, mm - 1380; Ground clearance, mm - 120; Overall dimensions, mm: Length – 1930; Width – 515; Height - 1100; Fuel tank capacity – 12.5 – 13.35 liters; Weight, kg: Dry – 160; Operational – 175; Fuel consumption rate on the highway, l/100km – 3.5; Fuel range on the highway, km – 360; Maximum speed, km/h; - 80; Main capacities, l: Gearbox housing – 1.0; Front fork vibration damper – 0.25; Rear suspension – 0.18;

Engine

Type – Single-cylinder two-stroke with return two-channel purging and forced air cooling; Cylinder diameter, mm – 62; Piston stroke, mm – 66; Working volume, cm cubed – 197; Maximum power l. With. - 8; Compression ratio – 6.6; Number of piston sealing rings – 3; Material: cylinder head – aluminum alloy; head gaskets – reinforced asbestos; pistons – aluminum alloy; Piston pin diameter, mm – 15; Valve distribution phases: opening of the intake window - 67.5 degrees b.c.t. closing – 67.5 degrees after t.m.t. opening of the outlet window - 66 degrees BC. closing - 66 degrees after BC. opening of purge windows - 54 degrees BC. closing - 54 degrees after ground mt.

Supply system

Carburetor - one K-28-G; Diffuser diameter, mm – 24; The fuel filter is a mesh filter in the sump.

Transmission

Forward gear – chain; bushing chain operating in an oil bath, 2.35. Chain size, mm – 9.525 by 9.5; Clutch - multi-plate operating in an oil bath; Number of disks: leading – 5; slaves – 5; Number of springs – 5; Gearbox – four-speed; Speed change control – foot control with electric speed change indicator; Gear ratio: at first speed – 3.0; – second – 1.643; — third – 1.233; — fourth – 0.90; Overall gear ratio: At first speed – 15.8; - second - 8.65; — third – 6.5; - fourth - 4.7

Ignition and electrical equipment

Ignition type – battery dynamo; Ignition coil – B-51; Breaker – mounted on the generator stator; Rechargeable battery – 3-SMT-11; Generator – dynastarter DS-1; Voltage, V – 12; Power, W - 90; Glow plug – A11U; Relay-regulator – PP – 45; Signal – S-36; Headlight – FG-50B; Ignition timing is 5.5 degrees plus or minus one degree before T.M.T. Ignition timing adjustment – Automatic, with a centrifugal regulator; Gaps, mm: Between breaker contacts – 0.4 – 0.6; — spark plug electrodes – 0.6 – 0.7;

Chassis

Frame – tubular welded; The front and rear wheel suspension is of the lever type with springs and a hydraulic vibration damper; Brakes - shoe; Wheels – disc collapsible interchangeable (on discs); Tire size, in inches – 4.00 – 10; Air pressure in tires (first number without a passenger), atm: Front wheel – 1 atm, 1.5 atm; Rear wheel – 1.5 atm, 2.0 atm.

Return to contents — ↑

Specifications

The model in question has a six-cylinder diesel engine. The diesel engine is started up by the driver from the cab using an electric starter. The presence of an individual torsion bar suspension and rubber-metal joints ensures the unit runs smoothly. A transmission with an 8-speed gearbox allows the tractor to perform the entire range of work at increased speed.

The driver's cabin has a frame base. Inside for comfortable work there is:

- good noise insulation;

- ventilation and heating system;

- a seat that has armrests and the ability to adjust, taking into account the weight and height of the driver.

The Altrak tractor is also equipped with a towing mechanism, a hydraulic system, a PTO and a rear linkage for attaching additional agricultural equipment, the traction class ranges from 3-5. Compared to the T-4A tractor, the productivity of the T 404 is 40% higher.

Motor scooter Tula T-200

The T-200 scooter is equipped with a single-cylinder two-stroke engine with crank-chamber purging and forced air cooling with a power of 8 liters. With.

The main part is a block-type crankcase, which houses the crank mechanism, gearbox, clutch, motor chain and dynastarter.

Cylinder 2 is cast from fine-grained cast iron, on the outer surface of which cooling fins are located. The cylinder has an inlet, two bypass and exhaust channels.

The inlet channel has a pipe for connecting the K-28G carburetor.

The exhaust channel is connected to an exhaust pipe ending in a muffler.

Cylinder head 1 is cast from aluminum alloy and has fins for heat dissipation. A copper-asbestos gasket is installed between the head and the cylinder.

Piston 3 is aluminum. It has a convex bottom and is connected to a stamped steel connecting rod using piston pin 5. Three sealing rings 4 are installed on the piston.

A bronze bushing is pressed into the upper head of the connecting rod, and a double-row roller bearing is pressed into the lower head. The piston pin is lubricated through six holes drilled in the upper end of the connecting rod.

Crankshaft 7 is not dismountable, composite, consists of two journals pressed onto the crank pin. The shaft rotates on two ball 9 and one roller bearings.

The crankcase is cast from aluminum alloy. Consists of 16 right and 8 left halves. It is closed with lid 14.

The crankcase halves are connected using screws screwed into the left half.

Cooling is carried out by the air flow created by the fan impeller 20.

Lubrication of the rubbing surfaces of the T-200 motor scooter is carried out similarly to the lubrication of the VP-150 motor scooter.

The power system consists of a fuel tank, an air cleaner, a K-28G carburetor, a suction pipeline and fuel lines with a tap.

Carburetor K-28G - with a horizontal throttle valve and air-mechanical fuel braking, consists of two main parts: a float chamber 10 and a horizontally located mixing chamber 2.

Fuel enters the float chamber from the fuel tank through a fitting and a shut-off needle, the conical part of which fits into the socket of the cover 8. A hollow float is fixed to the needle using a pin spring. On the cover of the float chamber there is a float stopper 7.

From the float chamber, gasoline flows through the main jet 22 into the mixing chamber. Where are the throttle valve 24 with the corrector 19 located. And the carburetor idle system.

In the closed position, the spool and the corrector are held by springs 26 and 18. The idle system includes a screw 5 for adjusting the quality of the mixture and a screw 13 for adjusting the amount of the mixture.

The K-28G carburetor has two operational adjustments: for idling and at medium speed.

On the T-200 scooter engine, the air entering the carburetor is cleaned using a contact-oil air cleaner.

With its pipe 3, the air cleaner is mounted on the inlet pipe of the carburetor.

Return to contents — ↑

Electrical equipment of the Tula T-200 scooter

The T-200 scooter is equipped with two 3-SMT-P batteries with a capacity of 11 Ah each. The batteries are connected in series, which made it possible to obtain a total voltage of 12 V. The series connection ensures that the engine starts using a dynastarter.

The DS-1 dynastarter is a direct current electric machine, which, when starting the T-200 scooter, works as an electric motor, and during driving it generates electricity to power lighting devices, ignition system devices and to recharge batteries.

When starting the engine, the dynastarter consumes a current of about 120 A, and when operating in generator mode, its power is 90 W.

Armature 1 of the dynastarter is mounted on the crankshaft and is locked using a key. Stator 3 is attached to the engine crankcase, has six poles formed by a series winding, and six poles formed by a shunt winding.

When starting the T-200 scooter, the poles of the series winding are turned on and active, and when the dynastarter operates as a generator, the poles of the shunt winding are activated.

The dynastarter works in conjunction with the relay-regulator PP-45, which provides: - turning on the dynastarter when operating as a starter; — automatic switching on and off of the dynastarter operating in generator mode from the power supply network of current consumers; - maintaining, regardless of the engine crankshaft speed, the current voltage generated by the dynastarter within certain limits.

The PP-45 relay-regulator consists of a housing in which the starting and reverse current relays and a voltage regulator are mounted.

All relay-regulator devices are closed on top with a lid.

The starting relay is switched on using the ignition key into the current circuit supplied from the battery to the stator poles formed by the series winding, and the dynastarter begins to work as a starter.

To turn off the start relay, just stop pressing the ignition key. The reverse current relay and voltage regulator are similar in their purpose, design and operation to similar devices of other types of relay regulators described above.

The B-51 ignition coil, installed on the T-200 scooter, is used to convert low voltage current (12 V) into high voltage current (14-16 thousand V).

The breaker is connected to the circuit of the primary winding of the ignition coil and ensures the induction of high voltage current in the secondary winding at the right moments.

The opening of the contacts of the breaker 10 and 11 occurs at those moments when the textolite pad 6 of the lever 9 leaves the protrusion of the cam 8, rotating on an axis fixed to the hub of the dynastarter armature.

Fixed contact 11 is located on stand 3, pressed to the base 1 of the breaker with a screw. Movable contact 10 is soldered to the end of lever 9 and connected by wire to the primary winding of the ignition coil.

For normal engine operation, the gap between the breaker contacts must be within 0.25 - 0.35 mm.

The opening of the contacts should begin at the moment when the engine piston is 3 - 4 mm before the c. m.t.

The gap between the contacts is adjusted by rotating the adjusting screw 2.

The T-200 scooter engine has an automatic ignition timing device, fixed with its base 1 to the dynastarter armature and rotates with it.

The weights 6 with their protrusions fit into the grooves of the cam 3 of the breaker. Each weight sits on a separate axis and is pulled by a spring 5 to the cam.

When the engine begins to develop speed, the weights, under the influence of centrifugal force, begin to overcome the force of the springs and move apart. In this case, the short arms of the weights turn the cam against the direction of its rotation, and the opening of the breaker contacts begins earlier.

This provides the necessary time for more complete combustion of the working mixture in the engine cylinders, which is especially necessary at high crankshaft speeds.

When the engine reaches 2500 - 3000 rpm. The weights disperse to their stops, and the machine no longer changes the achieved ignition timing.

The T-200 scooter uses A11U spark plugs with a gap between the electrodes of 0.6 - 0.7 mm.

The FG-50B headlight, installed on a T-200 scooter, consists of an optical element, a diffuser, adjustment and fastening parts. A two-filament lamp with low and high beam filaments is installed in the central socket.

The rear light serves to illuminate the license plate in the dark and to signal the braking of the scooter.

The S-30 sound signal installed on the T-200 scooter is similar in its effect to the S-34 signal on the VP-150 scooter.

Electrical diagram of the Tula T-200 scooter

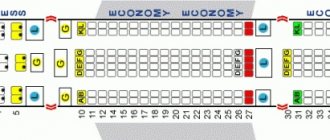

The T-200 scooter has a light indicator of the selected speeds.

When any speed is turned on, the electric switch interlocked with the gear shift mechanism closes the current circuit from one of the indicator lamps.

If the gearbox is in neutral, the green warning light located on the instrument panel lights up.

The central switch with the ignition switch has three positions: - position 0 corresponds to the inclusion of electrical equipment necessary for daytime driving; — in position 1, the parking light is on; — the key installed against position 2 closes the switch slide with the contact for turning on the lighting devices when driving in the dark.

There are two warning lights mounted on the top of the switch base.

The red lamp lights up if the ignition is on and the electrical equipment is powered by the battery.

When the dynastarter begins to produce a current of 12.5 volts, the reverse current relay of the relay-regulator is activated, and the red lamp goes out.

Return to contents — ↑

Advantages and disadvantages of a bulldozer

The following parameters should be noted as advantages:

- machine versatility, applicability for different industries;

- performance in any climatic conditions;

- long service life (up to 10 thousand hours) without major repairs;

- availability of conditions for repairs (spare parts are still produced);

- ease of control and high reliability of equipment;

- relative accessibility (in comparison with foreign analogues).

But we cannot ignore the disadvantages inherent in the T-170 bulldozer. Among them:

- transportation of special equipment is allowed only with removed attachments, which takes time;

- rapid wear of the friction clutch;

- poor sound insulation.

Transportation of bulldozer T-170

Despite the cessation of mass production of the T-170 tractor, it is still popular and in demand for a variety of jobs. This model has an optimal price-quality ratio, which is noted by many users.

Transmission of the Tula T-200 scooter

The multi-plate clutch, operating in oil, is mounted on the input shaft of the gearbox and consists of four steel-reinforced plastic drive discs 3 and 5 steel driven discs 4.

The driving drum 2 has grooves into which the projections of the driving disks fit. The driven disks, with their internal protrusions, fit into the grooves of the driven drum 6. The driving and driven disks are pressed against each other by the force of five springs 13.

The drive drum, through the drive chain, receives rotation from the engine crankshaft, and when the clutch is engaged, rotation through the drive and driven disks transmits rotation to the driven drum and then to the input shaft of the gearbox.

The clutch is released by lever 17, the lower end of which, through rod 14, ball 15 and rod 16, rests on the adjusting screw 9 of the pressure plate. When the clutch is disengaged by turning the lever, the adjusting screw 9 presses the pressure plate 10, the clutch discs are released, and the engine is disconnected from the gearbox.

The gearbox installed on the T-200 scooter has four forward gears. The box is made with constant meshing of gears, with movable gears-carriages and are placed in a common crankcase with the engine.

On the input shaft 6, manufactured integrally with the first gear gear 5, the gears of the second 4 and fourth 2 gears rotate freely. The movable gear 3 is mounted on the splines of the input shaft and can move along its axis.

On the secondary shaft, gear 8 of the first gear, which is in constant engagement with gear 5, and gear 11 of the third gear rotate.

Gear 12 of the fourth gear is pressed onto the output shaft.

The movable gear 9 can move along the splines of the secondary shaft.

At the end of the secondary shaft, a sprocket 15 is mounted on splines, connected by a chain to the sprocket of the rear wheel and being the drive sprocket of the main gear.

The gears are switched by moving the movable gears 3 and 9 of the primary and secondary shafts to the appropriate positions. These movements are carried out using a switching mechanism operating from a double-armed foot lever.

The forward gear is used to transmit rotation from the engine crankshaft to the clutch drive drum gear, which is carried out using a chain placed on the crankshaft sprocket and the drum gear.

The main gear of the T-200 scooter consists of a bushing-roller chain connecting the sprocket 14 of the secondary shaft of the box with the sprocket of the drive wheel.

Return to contents — ↑

Material characteristics

Avialium refers to compounds that consist of a compound of three metals (Al-Mg-Si). This means that it contains aluminum, magnesium and silicon. This metal is very ductile and rolls well. Such characteristics of AD31T make it possible to make decorative parts from it that are not highly durable.

The material has anti-corrosion resistance in aqueous solutions and has proven itself in aggressive atmospheric conditions.

These properties are imparted by the oxide film that forms on the surface of the material. It protects aluminum from dissolution in sulfur, with the exception of halogens.

The alloy is well suited to color anodizing and powder coating. The material can be pressed to produce hollow semi-finished products for facade structures and pipes.

Properties of AD31T alloy

This type of metal has various modifications. Here are some of the modifications: AD31T1 and AD31T5. The weldability of the AD31T1 is quite satisfactory, as is the case with other modifications. The main characteristics of AD31T1 and AD31T5 are high strength and anti-corrosion. The service life of such metals increases to seventy years.

The AD31T variety is used in the construction of complex marine structures, mechanisms, and technological equipment.

It has become widespread due to its qualities:

- Non-toxic.

- Corrosion resistant.

- Lasting.

- Electrically conductive (second place after copper).

- Excellent soundproofing material.

- Beautiful appearance.

This alloy has an imported analogue. Its distinguishing feature from ours is its inflated price, and in terms of quality and composition, our alloy was no different before the amendments were made. However, in 2000, amendments were made to GOST 4784-97. Because of them, the chemical composition of the airline had to change slightly.

Download GOST 4784-97