Interesting Facts. Unusual pistol safeties.

In this article I would like to talk about the most unusual safeties on modern pistols. And I’ll start my story with the Russian pistol.

PSM

PSM - Self-loading Pistol Compact. The safety of this pistol deserves special attention, since the functional implementation is very original! Due to the fact that the safety is located on the back of the slide (near the trigger), the shooter can simultaneously remove the pistol from the safety and cock the hammer with one movement of his thumb!!!

Colt 1911A1

Of course, I can’t forget about the calling card in Colt pistols! In addition to the main safety, Colt pistols, particularly the legendary Colt 1911A1 , have a button on the back of the grip that acts as an automatic safety. It blocks the trigger until the pistol grip is tightly grasped by the hand.

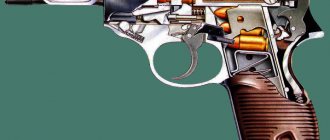

Mauser M2

Not the most famous pistol among fans of this type of weapon. However, it has an unusual design, too safe and inconvenient to use. What is its excessive security?

This pistol features:

1) indicator of the presence of a cartridge in the chamber (on top of the bolt),

2) automatic striker safety, which did not allow the striker to activate the primer before the end of the full stroke of the trigger,

3) automatic magazine safety - even if the cartridge is loaded into the chamber, but the magazine is not inserted, the shot will not fire!!!

4) and the fuse itself, the hero of today’s celebration, located in an extremely original place. In general, look at the photo))))

SigSauer P225

This safety principle is implemented in most SigSauer pistols, but consider its police version, which does not have a separate safety flag, but nevertheless the safety exists! On the left side of the handle there is a safety release lever, its head protrudes behind the trigger guard. When the lever is pressed down, the trigger will be released and the safety cock will be cocked. There is an automatic firing pin safety that locks it until the last moment of pressing the trigger before the shot itself. But this implementation has a disadvantage - the release is very, very heavy - 5.5 and 2 kg, respectively, for self-cocking and normal modes. I note that the lever above the left cheek of the grip is a slide stop used when disassembling the pistol, and not a safety.

Glock 17

Where would we be without it)))) The pistol is equipped with three independently operating automatic fuses. Glock called this system Safe Action. The safety lever, which is equipped with the trigger (tab on the trigger), blocks its movement back and releases it only when the shooter consciously presses it. The automatic firing pin safety makes it impossible for the firing pin to hit the cartridge primer in case of accidental de-cocking of the sear. The trigger rod, with its special protrusion, lifts the safety, which is a cylinder with a groove, and opens the way forward for the striker. The shockproof fuse is a cross-shaped protrusion of the trigger rod that fits into the groove of the bolt-casing. It prevents the combat platoon from breaking off the sear during an external blow

04 June 2013

Labor protection requirements before starting work

2.1. Wear proper working clothing and fasten all buttons.

2.2. Before the beginning:

— check the lighting of the workplace;

- inspect the workplace, put it in order: remove foreign objects, clear the approaches to it, clean them of debris and remnants of building materials, eliminate the presence of moisture and oil on the floor.

2.3. Before starting work, it is necessary to inspect hand tools and fixtures to ensure the absence of:

— chips, gouges, cracks and burrs on the heads of hammers and sledgehammers;

- cracks on the handles of files, screwdrivers, saws, chisels, hammers and sledgehammers;

- cracks, burrs, work hardening and chips on hand-held impact tools intended for riveting, cutting grooves, punching holes in metal, concrete, wood;

— dents, nicks, burrs and scale on the surface of the metal handles of the pliers;

— chips on working surfaces and burrs on the handles of wrenches;

— nicks and burrs on the handle and overhead bars of the vice;

- bending of screwdrivers, drifts, chisels, jaws of wrenches;

- nicks, dents, cracks and burrs on the working and fastening surfaces of replaceable heads and bits.

2.4. Workbenches, racks, tables, cabinets, bedside tables must be durable and securely installed on the floor.

2.5. The vice must be in good working order and provide reliable clamping of the product. On the working surface of the steel replaceable flat bars of the vice jaws, cross notches should be made in increments of 2-3 mm and a depth of 0.5-1 mm. When the vice is closed, the gap between the working surfaces of the steel interchangeable flat bars should not exceed 0.1 mm. There should be no nicks or burrs on the handle of the vice and on the steel replacement flat bars.

It is necessary to ensure that the moving parts of the vice move without jamming or jerking and are securely fixed in the required position. The vice must be equipped with a device that prevents the lead screw from being completely unscrewed.

2.6. Detected violations of labor safety requirements must be eliminated by the employee before starting work; if this is impossible, the employee is obliged to report the deficiencies to the work manager and not begin work until they are eliminated.

Labor protection requirements during work

3.1. When performing work it is necessary:

- place on the workbench only those parts and tools that are necessary to complete this work;

— place the tool in the workplace so that the possibility of it rolling or falling is excluded;

- remove dust, shavings, sawdust and metal scraps with brushes, scrapers, hooks or other devices.

3.2. Prohibited:

- place the tool on the railings of fences or on the unfenced edge of the platform of scaffolding, scaffolding, as well as near open hatches and wells;

- blow off dust and shavings with compressed air using your mouth;

— place the workpieces on your knees;

- place long parts (axles, shafts, etc.) vertically, leaning against walls or equipment.

3.3. When working with wedges or chisels using sledgehammers, wedge holders with a handle of at least 0.7 m in length must be used.

3.4. When using wrenches, it is prohibited:

- the use of shims when there is a gap between the planes of the jaws of wrenches and the heads of bolts or nuts;

- use of additional levers to increase the tightening force.

3.5. A stop must be installed on the inside of the pliers and hand scissors to prevent pinching of the fingers.

3.6. Before working with manual lever scissors, they must be securely fastened to special racks, workbenches, and tables.

3.7. Prohibited:

— the use of auxiliary levers to lengthen the handles of lever scissors;

— operation of lever shears in the presence of defects in any part of the knives, as well as in the case of dull and loosely touching cutting edges of the knives.

3.8. When working with hand tools and impact devices, it is necessary to wear safety glasses (face shield) and personal protective equipment for the worker’s hands from mechanical influences.

3.9. When carrying or transporting a tool, its sharp parts must be protected.

Repeating rifles with manual reloading

Rifle bolt arr. 1891. 1 — stem, 2 — combat larva, 3 — connecting bar, 4 — trigger.

To engage the safety, the trigger must be pulled back as far as it will go and turned counterclockwise.

For a military rifle with manual reloading, the carrying of which with a cartridge in the barrel outside combat conditions is a rare exception, the safety can hardly be considered any significant mechanism: for example, French rifles managed without it, and this even applies to magazine systems, up to the one recently adopted pre-World War II MAS-36. The safety device in the first model of the Lebel rifle was represented by a rotary trigger (a similar system was used in the Mosin rifle). In the 1893 model, the safety was abandoned altogether, since on the march the rifle was still carried with a loaded magazine, but an empty chamber.

In the Mosin rifle mod. 1891/30: the firing pin and a twisted cylindrical mainspring are located in the bolt. The mainspring is compressed when the bolt is unlocked; when locked, the firing pin rests on the sear. It is possible to cock the firing pin manually with the bolt closed; to do this, you need to pull the trigger back (in this case, the trigger is the tip screwed onto the shank of the firing pin). To engage the safety, the trigger must be pulled back as far as it will go and turned counterclockwise.

The Schmidt-Rubin M1889 has a trigger equipped with a ring for easy finger grip when putting the safety on and cocking it into combat mode. To set the trigger to the safety cock, you need to pull the ring back and turn it to the right.

Mauser 98k

The now well-known flag-shaped safety lever on Mauser rifles was developed for the Gewehr 71 rifle using 11 mm cartridges filled with black powder. On Mauser rifles (Mauser 98k), a three-position safety was installed at the end of the bolt on the right:

- 1st position (safety is set to the right) - the hammer is locked, the bolt is locked

- 2nd position (safety in central position) - hammer locked, movable lock

- 3rd position (safety is set to the left - the hammer is unlocked, the bolt is moving - the rifle is ready to fire

The safety only operates when the rifle is loaded; otherwise the fuse will not move.

In the Lee-Enfield rifle, the safety is in the form of a rotating lever, mounted on the left of the receiver.

Occupational safety requirements in emergency situations

4.1. If a tool or equipment malfunction is detected, stop work immediately and report it to your immediate supervisor.

4.2. If a fire or signs of combustion are detected (smoke, burning smell, etc.), you must:

— take measures to extinguish the fire using fire extinguishing means available at the workplace;

- if it is impossible to extinguish the fire on your own, immediately report the fire by calling 101 or 112 (give the address of the facility, the location of the fire, your last name), as well as your immediate supervisor.

4.3. In the event of an accident, provide first aid to the victim, report the incident to the immediate supervisor, if necessary, call an ambulance or take measures to deliver the victim to a medical facility, and, if possible, preserve the situation of the incident.

Fuse designations

- The safety of the Nambu Type 14 pistol is in the “fire” position.

- IMI Micro Uzi. S (safe) - safety, F (fire) - automatic fire.

- HK MP5 (S - Sicher - safety, E - Einzelfeuer - single, F - Feuer - automatic fire)

- MG 34 S - Sicher - safety, E - Einzelfeuer - single, D - automatic fire

- HK MP5K (fire modes are indicated by pictograms)

- PP-2000

- Thompson submachine gun: safe - safety, fire - fire The safety lever is also an indicator of the selected position.

- Vektor R4 “S”—safe—safety, “R”—repetition—single, and “A”—automatic fire.

- FN F2000. Location of the double-sided safety/fire mode selector under the trigger guard. "S" - safety, "1" - single, "A" - automatic fire.

- Skorpion vz. 61: "0" - fuse, "1" - single, "20" - automatic fire)