Solex carburetor idle system does not work

The idle system (IAC) of the Solex carburetor 2108, 21081, 21083 is a kind of carburetor within a carburetor.

It has specially selected fuel and air jets, air, fuel and emulsion channels, its own nozzle under the throttle valve (outlet) and adjusting screws for the “quantity” and “quality” of the fuel mixture. Supplying a certain dose of gasoline and air to the engine allows the CXX to ensure the operation of a warm car engine with a minimum rotation speed of 750-800 rpm (the so-called idle speed) with the throttle valves of both chambers closed and the air damper fully open. However, no other Solex carburetor system works.

The idle system of the Solex 2108, 21081, 21083 carburetor is capricious and requires special attention to ensure performance. The slightest deviation in its operation is the cause of the malfunction: “the idle system of the Solex carburetor does not work.” We will try to determine what signs of this malfunction exist (in order to diagnose it ourselves), and also consider the reasons for its occurrence, plus, along the way, we will analyze popular methods for restoring the functionality of the Solex CXH.

Signs of a malfunction: “the idle system of the Solex carburetor 2108, 21081, 21083 does not work”

— Car engine idle disappeared

The idle speed has either disappeared completely (the engine is only running on choke), or the engine is jerking and trying to stall - “troit”. The carburetor does not respond to attempts to adjust the XX adjusting screws, or responds, but weakly, or not at all as desired.

— There are popping noises in the muffler or in the engine air filter housing (carburetor)

Violation of mixture formation in the carburetor idle system leads to a depletion of the fuel mixture (pops in the carburetor), or to over-richness (pops in the muffler).

— Black carbon deposits on spark plugs

Violation of the proportion of gasoline and air in the fuel mixture due to a malfunction of the idle system most often leads to a strong enrichment of the fuel mixture at idle and, as a consequence, its poor combustion and the appearance of black soot deposits on the electrodes of the spark plugs.

Causes of the malfunction: “the idle system of the Solex carburetor 2108, 21081, 21083 does not work”

— The idle system is clogged

The air and fuel jets CXX, the outlet, and channels can become clogged. Clogging may be the cause of a sudden failure of the system to work (at first everything worked fine, and then it failed). There can be several reasons for clogged jets. For example, deposits and debris in gasoline, oil from the air filter housing (if it is thrown there due to an engine malfunction), soot from the intake manifold.

Diagram of the idle system of the Solex carburetor 2108, 21081, 21083

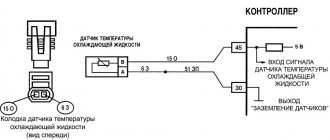

— The carburetor solenoid valve (EMV) is faulty

Sudden failure of the EMC is a common occurrence on Solex carburetors. The EHR itself or the associated EHR system may fail. In this case, its needle will completely or partially block the opening of the CXX fuel nozzle and the system will not work.

— The adjustment has gone wrong (screw position)

After repairing the carburetor or installing another carburetor, the adjustment of the engine idle speed with the adjusting screws (quantity and quality) is lost.

— The position of the air and throttle valves of the carburetor is broken

As a result of damage to the damper drive or its incorrect adjustment, the position of the throttle and air damper required for idling is violated. And this affects the preparation of the fuel mixture in the combustion chamber, the presence or absence of vacuum in the carburetor to ensure its operation.

Solex carburetor air damper drive parts

— “Suction” of foreign air into the carburetor

Excessive depletion of the fuel mixture at idle due to the “sucking in” of excess air will lead to the failure of the CXC to operate. Places for air “suction” on the Solex 2108, 21081, 21083 carburetor: rubber o-ring on the fuel mixture “quality” screw, gaskets under the carburetor, o-ring on the solenoid valve.

Places of “suction” of foreign air into the Solex carburetor

What to do if the Solex idle system does not work?

If the idle speed suddenly disappears, then most likely the CCV is clogged or the solenoid valve fails. The easiest way in such a situation is to use carburetor cleaner. Unscrew the EMC, remove the air filter cover, start the engine on choke and spray cleaner into the hole under the EMC. Give it some gas, then pop some more. And so on several times.

Details about cleaning the Solex CXX: “Cleaning the idle system of the Solex carburetor.” If there is no cleaner, we swap the wire tips on the spark plugs and try to start the engine. “Shots” into the carburetor will clean the CXX. You should not overuse this procedure, as you can damage the carburetor.

The serviceability of the solenoid valve and the EPH system can be checked using these instructions.

If the idle speed system stops working after repairing the carburetor, replacing its parts, or replacing the carburetor itself with another, you will have to deal with the idle speed adjustment using adjusting screws. Read more: “Adjusting the idle speed of a car engine with a Solex carburetor 2108, 21081, 21083.”

Or, you need to check the position of the carburetor throttle and air dampers and adjust their drive if necessary. See “Adjusting the air damper drive of the Solex carburetor” and “Adjusting the throttle drive of the 1st chamber of the Solex carburetor.”

If there is a suspicion of foreign air “suction” into the carburetor, we check and eliminate the “suction”. Read more: “Suction of foreign air into the carburetor.”

Notes and additions

The cause of the malfunction “Solex carburetor idle system does not work” may be problems with the car’s engine ignition system. For example, faulty spark plugs, “broken” armored wires, incorrect ignition timing, or a faulty distributor will lead to “triple” of the engine at idle.

In addition, signs of malfunction of the car engine itself in some cases coincide with signs of failure of the CXX carburetor. For example, a valve has burned out, the valves have not been adjusted, the head gasket is broken, the marks in the timing drive are displaced.

All these circumstances should be taken into account when independently diagnosing a malfunction. Details: “The idle speed is not adjusted (reasons not related to the carburetor).”

What are the reasons for the drop in turnover?

Many car enthusiasts do not pay attention to the condition of their cars, much less the engine. Often, the consequences can be expressed in malfunctions, which will develop into major repairs, which will cost a considerable amount of money . It is for these reasons that if a malfunction occurs with the engine, it is necessary to return it to normal functionality.

So, let's look at the main reasons that lead to low idle speed:

- The adjustment of the “quantity” and “quality” screws is broken

A common cause of low idle speed on Ozone carburetors. Often, tightening the fuel adjustment screws is enough to restore normal speed.

- Fuel level is incorrectly adjusted

In addition to a drop in engine speed at idle, this leads to a drop in power. The engine may stall or start after much suffering. Long-term operation on lean fuel can lead to engine failure.

- Foreign air enters the carburetor

The “suction” of excess air can interfere with engine operation. Another option is that the air filter is dirty and not enough air is getting in.

Engines designed to consume high-quality fuel may malfunction or fail if they are “fed” with lower quality fuel, for example, 92 instead of 95. Moreover, the engine may encounter a lot of new problems that will have to be solved, so it is better to use good gasoline.

- On-board computer malfunctions

It also happens that the on-board computer begins to show inaccurate data. If everything seems to be fine with the engine, but the electronics persistently indicate that there is a problem, you can try to connect a working BC and check it on it.

- It's time to change the spark plugs

Determining the cause of the malfunction

The following steps will help you determine the reason why the idle speed has dropped.

- If there are no additional signs of a drop in speed (for example, vibration), you can check the engine on another on-board computer.

- Check sensors.

- Inspect the spark plugs.

- Make sure the fuel and idle levels are adjusted correctly

- Make sure that excess air is not “sucked” into the carburetor.

- Inspect the air filter for contamination.

Adjusting the idle speed of the Solex carburetor

If you are the owner of a carburetor car, over time you will inevitably encounter uneven idling. The car may even stall or “float” - naturally, the question arises of how, without special instruments, you can adjust the idle speed on the carburetor. In this material we will try to answer this question.

What do we have in stock? Solex carburetor, flathead screwdriver and tachometer. It's enough. We need a screwdriver to “penetrate” the opening that you see in the photo (indicated by the red arrow). There is a screw that regulates the quality of the mixture supply - it is responsible for the amount of fuel supplied at idle. The photo below is a view from the right wing.

Step one - we need to set the ignition. Yes, that’s right - first we adjust the ignition, and then we adjust the quality of the air-fuel mixture (FA) to suit it.

So, our ignition is well set, nothing rattles in the engine under load, and the car doesn’t drive badly at all - not like a scooter with 50cc uphill.

To make the indicators more accurate, warm up the engine to 90 degrees and look at the tachometer. It is difficult to do this on the dashboard, since up to 1000 rpm it is not at all clear what this device is showing. It’s good if you have a europanel. And if not? Buy a strobe with a built-in tachometer or count fractions of a millimeter on the dashboard...

Let's move on to adjustments. Let's take a pre-prepared screwdriver and try to insert it into the place indicated by the red arrow in the image. You need to try and get into the groove of the screw, which is located in that place. Make a mark on the screwdriver to make it easier to count the turns of the screw.

The next step is to tighten the screw clockwise until it stops. The engine should stall. If this is the case, everything is fine - the screw is working properly and regulates the fuel assembly. Now unscrew the screw two turns counterclockwise and try to start the engine. If it doesn’t start, unscrew the screw one more turn.

Gradually unscrew the screw so that the idle speed does not begin to increase. Sooner or later, they will stabilize. Then one or two more turns, and the idle speed will be constant. Then, if you make another revolution, the idle will drop - its rpm will begin to decrease.

Basic functions and purpose of the speed sensor

To control the speed of movement, a special device is installed on the dashboard - a speedometer. But it only displays the information received, and the speed sensor is responsible for collecting data. If it fails, it will create many dangerous situations on the road, since it will become difficult to control the speed limit in the city and on the highway.

But besides this, thanks to the integration of the electronic control unit into the system, the speed sensor allows you to perform the following functions:

- fuel consumption control

- displaying information on the instrument panel

- in cars with an automatic transmission it is included in the complex responsible for engine control

In case of failure, you are allowed to continue the journey, but this will become difficult.

Each car has a speedometer in its design, which displays the speed of movement of the vehicle. But the speedometer is only a display of useful information; the main function of indicating the speed of movement is performed by the sensor. If it malfunctions, further travel becomes a pain, especially on city highways, where it is necessary to maintain the speed of movement.

Therefore, the main function of the device is to read information about the movement of the vehicle. Indirect functions of the device include:

- possibility of rational fuel consumption;

- regulation of traffic according to road markings and signs;

- makes it possible to regulate speed in order to avoid fines.

There are two types of speed sensors:

- Mechanical or optoelectronic. It works by transmitting the number of revolutions of the box shaft using a cable.

- Electronic or cableless. Actually, that’s what we’ll be talking about.

A speedometer is installed in the design of almost every car. But the speedometer is only a general display that displays information. The main function of indicating speed is performed by the sensor itself. If the device is faulty, further movements become very difficult, if possible at all. The part needs to be replaced as quickly as possible.

The main purpose of the device is to read information related to moving around the city. There are other, so-called indirect functions:

- Adjust speed to avoid fines.

- Simplified traffic following road markings and signs.

- Rational fuel consumption. It is also important for cars produced in 2007.

Without this part, driving a car is possible, but it becomes much more difficult.

A speedometer is installed on the Niva's instrument panel, which is necessary to display the current speed of the car. In the event of a malfunction, driving becomes difficult as most roads have speed limits that must be followed. In addition, a malfunction of the speedometer can affect the calculation of other data by the on-board computer. Based on the DS data, the required fuel consumption is determined and gasoline savings are ensured while idling.

Therefore, it is necessary to carry out diagnostics as soon as possible and identify the cause of the breakdown.

Signs of failure in the fuel system

The presence of possible malfunctions in the operation of the vehicle’s power system can be judged by the characteristic signs of the vehicle’s behavior on the road:

- Failure - while pressing the gas pedal, the car continues to move at the same speed (or deceleration) for a short period of time (from 1 to 30 seconds), and only after a while begins to pick up speed;

- A jerk is reminiscent of a failure, but it is more short-lived;

- Rocking - periodic failures;

- Twitching is several jerks that follow each other;

- Sluggish acceleration is a reduced rate of increase in vehicle speed.

In addition, you can judge the presence of malfunctions in the engine power supply system by the following signs:

- Increased fuel consumption;

- The engine does not start;

- Idle speed is reduced or increased;

- Difficulty in starting a hot/cold engine;

- Difficult operation of the car engine in cold mode.

Shift in gas distribution phases, wear on the camshaft cams, incorrect adjustment of heat clearances, reduced or uneven compression in the cylinders, as well as burnt valves significantly reduce the vehicle’s power, cause vibration and increase fuel consumption.

The carburetor and its malfunctions also play an important role. Let's look at the most common carburetor malfunctions using Solex as an example. How to properly clean, check and adjust the carburetor, using the VAZ 2109 as an example, is described in the article. So.

If the cylinder-piston group is worn out, then crankcase gases, oil vapors and tarry substances can enter the carburetor area, clog the filter element of the filter, and also settle on the jets and other elements of the carburetor, thereby disrupting the operation of the engine.

Lost idle speed on injection engine, reasons

A list of the main, most common reasons for the appearance of unstable idle speed or their complete disappearance on injection engines (2111) of VAZ 21083, 21093, 21099 cars.

All malfunctions are grouped by engine systems: ignition system, power system, control system (ECM), engine engine. Most of them are easily determined using diagnostic equipment, but faults can be found without it.

Before identifying a malfunction, it is necessary to carry out a visual inspection of the engine compartment (elements of the ignition system, sensors, tubes, hoses), check the tightness of the contacts in the connecting blocks, the tips of high-voltage wires in the ignition coil and spark plugs.

Typical carburetor malfunctions

If the engine does not start or stalls immediately after starting.

This may be due to the fact that there is no fuel in the float chamber or the composition of the mixture is disturbed (for example, the mixture is too rich or vice versa).

The engine idles erratically or stalls regularly.

If other carburetor systems are functioning properly, malfunctions are possible due to the following factors:

- Clogged channels or idle jets;

- Malfunction of the solenoid valve;

- Malfunctions in the operation of EPHH elements and the control unit;

- Malfunctions and deformation of the rubber sealing ring - a “quality” screw.

Since the transition system of the first chamber interacts with the cold running system, at incomplete speeds, failure, and sometimes even a complete stop of the engine, is possible during the smooth start of the car. By flushing or blowing out the channels, the blockage can be eliminated, but it will be necessary to partially disassemble it. It is also necessary to replace faulty parts.

Difficulty starting the engine and fuel consumption

Difficulty starting a cold engine

may be caused by incorrect adjustment of the trigger mechanism. Partially closing the air damper can cause the mixture to become leaner, which in turn will cause a lack of sparks in the cylinders, and opening it incorrectly after starting the engine enriches the mixture quite richly, so the engine “chokes.”

Difficulty starting the car when the engine is warm

may be caused by a rich mixture entering the cylinders due to the high level of fuel in the float chamber. The reason for this may be a maladjustment of the fuel chamber or the fuel valve is not sealed well enough.

Excessive fuel consumption.

This “defect” is the most difficult to eliminate, since it can be caused by various reasons. Initially, you should make sure that there is no increased resistance to the movement of the vehicle, which is facilitated by braking of pads on drums or discs, violation of wheel mounting angles, deterioration of aerodynamic data when transporting large cargo on the roof or loading the car. Driving style also plays a significant role.

1, 4, 13, 17, 20 — screws securing the carburetor cover to the body; 2 - small diffuser (spray) of the main dosing system of the second chamber; 3 — econostat sprayer; 5 — air jet of the transition system of the second chamber; 6, 7 — econostat channel plugs; 8, 21 — balancing holes of the float chamber; 9 — air damper axis; 10, 15 — air damper mounting screws; 11 — small diffuser (spray) of the second chamber; 12 — air damper; 14 — channel of the main air jet of the second chamber; 16 — channel of the main air jet of the first chamber; 18, 19 — plugs for idle channels; 22 — accelerator pump nozzle

Solex 21083 carburetor: malfunctions and repairs

Like any other vehicle component, the fuel system will require repair under certain circumstances. Malfunctions of the Solex 21083 carburetor, as a rule, occur due to incorrect settings of the fuel system, low-quality fuel, operating conditions, etc.

Let's consider the main causes of malfunction of the Solex 21083 carburetor and how they can be determined.

- Failure - when you press the gas pedal, the car continues to drive at the same speed for some time, or begins to accelerate with deceleration;

- Jerk – a short pause before acceleration;

- Twitching - several jerks at the same time that follow one after another;

- Rocking - the next few failures one after another;

- Sluggish acceleration – the car starts to accelerate slowly.

In the Solex 21083 carburetor, malfunctions can occur when parts are worn out, when oil vapors from the piston group, as well as crankcase gases, begin to enter the cavity above the carburetor, which leads to clogging of the filter element, then all this settles on the jets and other elements of the carburetor, which makes them difficult work.

Idle Air Control Malfunction - Check Engine Signal

Control systems in cars with an injector record deviations in the operation of the fuel regulator. Below are some possible IAC failure codes with decoding:

- P1509 (control circuit overload);

- P1513 (short to ground);

- P1514 (open circuit or other problems at 12 V).

If you receive information about a problem, check the wiring - perhaps the problem lies there. Test codes are received through a special connector using a scanner. You can decipher the obtained values yourself using special tables (search online). If you can't quickly check the system, a thorough cleaning will help delay replacement for some time.

You can determine the serviceability yourself, but this will require skills and an oscilloscope.

Malfunctions in the accelerator pump of the Solex 21083 carburetor

If there is fuel leaking from the pump cover, then in this case there is probably a leaking diaphragm in the accelerator pump that needs to be replaced.

The accelerator pump nozzle may become clogged; this can be checked by simply pressing the gas pedal with the engine not running; if at the moment of pressing, an even stream of fuel without air bubbles does not appear from under the distributor, then the reason is obvious.

Typically this may be due to:

- lack of fuel in the carburetor float chamber;

- the sprayer is clogged in the accelerator pump;

- malfunction of the check valve in the accelerator pump nozzle (the system should be purged).

The absence of fuel in the float chamber is determined by checking the presence of a mixture at the inlet of the Solex 21083 carburetor. Next, if fuel is supplied, it is necessary to check the shut-off needle and strainer in the carburetor, after which we check the fuel pump, etc.

In this case, disassembling and assembling the Solex 21083 carburetor must be performed carefully and in the correct order. Otherwise, during the assembly process, you can disrupt the correct installation of the Solex 21083 carburetor jets, filter, dampers, etc. Which will subsequently lead to unstable operation of the carburetor or its breakdown.

A lean mixture is determined for the following reasons:

If there is no fuel in the float chamber and the fuel pump is working properly, you can check the flow capacity of the carburetor, and directly the hose supplying fuel to the carburetor.

Next, check the mesh filter and the serviceability of the fuel valve needle. It is unlikely that the needle can be jammed in the closed position; this is only possible if there is no pull-out bracket that connects the float to the valve needle, or the needle is severely worn.

The clogged mesh filter is washed with solvent or acetone, and first remove it from the carburetor body, blow the filter with compressed air and install it in place. The faulty fuel valve assembly must be replaced with a new one.

Carburetor repair kit Solex 21083

It is best to have a spare repair kit for the Solex 21083 carburetor so that in case of a malfunction it is at hand. It will be useful not only during carburetor repair, but also in the process of tuning the Solex 21083 carburetor, if there is such a need and desire.

Further, a violation of the supply of the mixture composition can be determined by the position of the air damper. Possible jamming of its drive rod, lever, axle, malfunctions associated with the starting device or incorrect adjustment.

A lean mixture can be caused both during operation and when starting the engine, by a low fuel level directly in the float chamber. There may also be air leaks in the exhaust manifold where it connects to the carburetor.

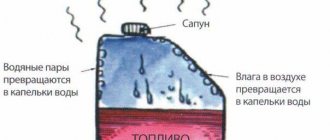

In winter, at subzero air temperatures, there is a possibility of water freezing directly in the fuel line and carburetor channels, clogging with ice plugs, or freezing in the area of the mixing chamber diffusers. As a result, there will be a stop or drop in engine power.

Unstable speed or lack of idle

If the Solex 21083 carburetor systems are working properly, the channels or idle jets may become clogged. Damaged rubber seals of quantity and quality screw rings, loose valve solenoid: these are all possible causes of unstable car operation.

If there is an EPH system (electronic idle control system), then malfunctions are also possible due to incomplete tightening of the fuel nozzle holder, breakdown of the solenoid valve or control unit, as well as damage to the economizer diaphragm.

Since the transitional idle system is combined with the first chamber system, if the idle speed is unstable, the engine is likely to stop or fail when the car begins to move smoothly. Clogged channels are blown out and washed after partially disassembling this carburetor.

All faulty parts are replaced with new ones. The Solex 21083 carburetor repair kit, the price of which remains acceptable for car owners, allows you to avoid trying to install already worn gaskets, springs, etc. Thus, you will protect yourself from premature breakdowns and malfunctions.

Reduced or increased speed, unstable engine operation in idle mode

These reasons may be caused by incorrect adjustment of the fuel level, idle speed, or excess air leakage. This may be affected by wear and improper adjustment of the dampers, both in the first and second chambers of the carburetor.

Impossible or difficult starting of a cold engine: most likely the starting device has been adjusted incorrectly, and the diaphragm in the starting device may also be worn out.

Difficulty starting a warm engine

The most common cause is an increased fuel level or an over-rich mixture. This may be caused by a leaky fuel valve or improper adjustment of the float mechanism. Usually this can happen if done incorrectly with your own hands.

That is why it is worth seeking help from qualified specialists who will correctly and accurately carry out all work on repairing and adjusting the Solex 21083 carburetor, because it is the professionals who know a lot about carburetors of various modifications, such as Solex 21083 1107010 and others.

You can also view a detailed description and video about repairing the Solex 21083 carburetor, where the entire process of assembling, disassembling and repairing the carburetor is clearly presented.

Engine stalls when cold

Car engine power calculator

5 ways to calculate car engine power. Calculator for determining the power of internal combustion engines online

The problem when the engine stalls when cold can occur both in cold and warm seasons. The main reasons why a cold engine starts and stalls are a malfunction of the fuel pump, clogged fuel filter (sometimes the mesh on the pump), dirty idle air valve, use of low-quality fuel, dirty throttle valve or fuel injectors, and others.

The first thing to do when the car stalls on a cold start is to connect an electronic scanner, and use it to look at the parameters of the electronic sensors, and also read the existing errors in the electronic control unit. For older cars, diagnostics should begin with the fuel system.

| Car engine type | Main cause of failure | Faulty node | Troubleshooting methods |

| Gasoline injection | The engine is not getting enough fuel. | Gasoline pump and its filter mesh |

|

| Poor quality fuel |

| ||

| Faulty injectors |

| ||

| Fuel pump relay |

| ||

| Increased engine air consumption | Leak in the air line |

| |

| Unstable engine operation | Problems with sensors | Check the operation of the following sensors and replace them if necessary:

| |

| Idle speed control | Check the IAC; if it fails, replace the unit with a new one. | ||

| Thick motor oil |

| ||

| Spark plug | Check the condition and operation of the spark plugs. If they fail, replace them with new ones. | ||

| Problems with the exhaust system | Catalyst |

| |

| Presence of moisture in the muffler |

| ||

| Exhaust gas circulation |

| ||

| Diesel engine | Low fuel pressure in the system | Fuel pressure regulator and return drain |

|

| Clogged fuel filter |

| ||

| High pressure fuel pump |

| ||

| Air leak in the fuel line | Fuel system elements |

| |

| Changed compression ratio | Pistons |

| |

| Carburetor engine | Idle speed setting is off | Adjustment mechanism | Check the idle speed adjustment mechanism, usually an adjusting bolt. |

| Carburetor | Set up the carburetor and inspect its chambers | ||

| Vacuum in the fuel system | Fuel system | Check for vacuum in the carburetor, intake manifold, and vacuum hoses. |

Idle speed VAZ 2109 carburetor

Recently I encountered the following problem: Lada cars with a carburetor power system stopped idling. The car starts on choke and runs. Everything is fine, you can drive, but as soon as you remove the choke and take your foot off the gas pedal, the engine stalls. Of course, the car is running, but it is very difficult, especially at traffic lights when driving around the city, when you constantly need to either accelerate or slow down and drive without idling. When the car warms up to operating temperature, it may not stall at idle, but shake terribly at idle, the engine speed being about 500-600 rpm. We urgently need to restore the car's normal idle operation, let's look at how. There are many articles on the Internet explaining the reason why the idle speed does not work on nine. 90% of such articles only consider manipulation of the idle air solenoid valve. Indeed, problems with the valve are very often the cause of idle loss, but there are other reasons. I’m sharing my experience because I myself spent many hours searching for normal material, but I only came across hundreds of articles that dealt with EPHH in one go. So, let's go in order: your VAZ 2109 has lost idle speed, with the gas pedal pressed the car works, as soon as you release it it stalls. The reason for this phenomenon is as follows. The carburetor has a special idle system: an idle fuel passage with a jet, an idle air passage and a solenoid valve. When the car is idling, the combustible mixture enters the engine through the idle passage. The throttle valve is closed, and therefore the vacuum in the engine is huge and it sucks the combustible mixture into the engine through the idle channel. The fuel and air nozzles have special holes of a certain diameter, which are selected for stable engine operation at idle. Why does the idle speed disappear? It's simple: either fuel does not flow through the idle fuel channel, or there is an air leak somewhere in the system and the fuel/air ratio in the combustible mixture is maintained incorrectly. The idle speed solenoid valve (hereinafter referred to as ESV) is responsible for the fuel supply. If the valve is not working, fuel will not flow into the space behind the carburetor throttle plate at idle.

What are the signs of malfunction or “death” of the DXH?

The idle air regulator, being a fairly simple device, does not have any diagnostic systems, so neither the car’s on-board computer nor the check engine will be able to report its malfunction. But if subsequent problems are encountered, this may mean that the idle speed sensor needs to be replaced, repaired or cleaned:

- the engine refuses to idle and stalls;

- idle speed is not constant (floating);

- there is no increased speed when starting a cold engine;

- When the transmission is switched off, the engine stalls.

These reasons can also be caused by a malfunction of the TPS (throttle position sensor). The only thing is that the car’s on-board computer will let you know about a TPS malfunction.

Idle speed sensor location.

Engines of the VAZ 2114 family are equipped with an idle speed sensor located on a special seat directly on the throttle assembly. Cleaning the IAC is impossible without removing the sensor. The process of dismantling this engine element is quite simple. This is explained by the fact that the sensor is attached to the pipe with two mounting screws under the cross. Depending on the engine model, it may be located either in a freely accessible area or require removal of the entire throttle assembly. How to dismantle the IAC? As mentioned above, cleaning the idle air control valve is impossible without first dismantling it. In order to carry out dismantling work for the regulator, the car must be put on the parking (hand) brake and the negative terminal from the battery must be removed. After this, you need to disconnect all the wires from the sensor and clean its seat from dirt so that it does not get inside the throttle assembly

Next, unscrew two screws using a “ratchet” or a screwdriver and you’re done, the sensor is removed. The process of cleaning the idle speed sensor on a VAZ 2114. As soon as any problems appear in the operation of the engine (they were given above), you need to turn your attention to the idle speed sensor; it may need to be cleaned. And here many people ask the question: how to clean the idle air valve? The cleaning process is actually quite simple and does not take much time and requires only a carburetor cleaning mixture or the widely used WD-40. So, how to clean the idle air control on a VAZ 2114: 1

The very first thing you need to do is disconnect all the wires that go to the sensor (you can also clean the contacts at the same time). 2. Using a Phillips screwdriver, unscrew the two screws on the sensor. (If the mounting screws are missing, this is a clear sign that the regulator is mounted on varnish. To clean such an IAC, the entire throttle assembly must be dismantled.) 3. We take out the IAC and assess its condition. In this case, you should pay attention to the condition of the valve. The presence of oil and black dirt on it is a clear sign that the entire throttle body needs to be cleaned. 4. Take a cleaning fluid (WD-40 or carburetor cleaner) and spray a generous amount onto the cone needle and spring to clean them. Next, the sensor is dried and installed in place. Before returning the sensor to its place, you should also check the length of the protruding rod. It should not be more than 23 mm. How to clean the idle speed sensor on a VAZ 2114 with a 1.6 liter engine with 8 valves: On a VAZ 2114 equipped with a 1.6 liter engine, the process of removing the idle speed sensor is different in the first step. You must first disconnect the throttle assembly from the receiver. To do this, you need to slightly unscrew the two fastening nuts so that it is possible to disconnect the throttle assembly from the end part of the receiver by at least 1 cm. In this case, the throttle assembly does not need to be completely removed. Next, the whole process is exactly the same as described above. How to clean the idle speed regulator on a VAZ 2114 with a 1.6i engine: In order to remove the idle speed sensor on such an engine, complete dismantling of the throttle valve is required. This is explained by the fact that the IAC is placed in such a way that one screw is easily accessible, but the second is not (it is impossible to insert a screwdriver to unscrew it). Otherwise, the cleaning process is similar with the other two engines. After the sensor has been cleaned and installed in its place and no changes have occurred in the operation of the engine, this may mean that the idle speed sensor has failed and will need to be replaced or repaired. The reasons for the failure of the DXX can be either wear of the cone needle guides, or a break in any wire inside the sensor, etc.

Published: June 23, 2015