VAZ 21214 engine modifications and their differences

| Motor modification | Availability of power steering | An exhaust manifold | EURO environmental class |

| 21214-41 | welded from stainless steel become | 3 | |

| 21214-34 | _ | cast iron | |

| 21214-33 | |||

| 21214-32* | |||

| 21214-31 | welded from stainless steel become | 4 | |

| 21214-30 | — |

Lada 4×4 2121 Niva (VAZ Niva 2121)

*21214-32 – has fuel pipes with quick connectors, a flywheel for the clutch of 215 mm (200 mm on other models).

The geometry of the cylinder block 21214 and 21213 is the same. There are no liners in the cylinders. Due to the use of an ejector, the configuration of the front engine cover has been changed to accommodate the installation of a crankshaft position sensor. To mount the power steering, a hole is made on the block for installing a bracket; in addition, there is a threaded hole for installing a knock sensor, as well as threaded holes with studs for mounting the ignition module bracket.

The ShPG came from 21213. Crankshaft 21213-1005015 sets the piston stroke to 80mm. The crankshaft pulley is distinguished by the presence of teeth along the outer diameter for the operation of the crankshaft position sensor. The latest internal combustion engine models are equipped with a damping pulley (21214-1005058-10). The presence of a damper made it possible to reduce the load on the crankshaft to prevent cutting of the key, and also make the operation less noisy.

Cylinder head 21214-1003011-30 (36) was modified from the head from 21213. For modification, it was necessary to introduce holes for installing a phase sensor and studs for mounting the intake receiver. To install hydraulic compensators, bosses are cast in the head and have threaded holes in them. With the introduction of hydraulic thermal gap compensators, adjusting bolts were eliminated from the head design.

the second ones have M24x1.5 holes, and the wells have drainage holes (the markings are made in the casting). Interchangeability of heads, as well as hydraulic supports of old and new designs, is not possible. A new oil rail 21214-1007180-30 made of stainless steel is used, supplying oil to the hydraulic compensators. Interchangeability with ramp 21214-1007180 is maintained.

Valve levers 21214-1007116-30, in contrast to the previous 2101-1007116, have a smaller radius (11 mm) of the platform support interacting with the camshaft cam, as well as an additional groove on the side of the hydraulic compensator. Both lever options are interchangeable.

In the timing camshaft drive, instead of a double-row chain, a single-row chain 21214-1006040-03 is used on rollers and bushings. Single-row sprockets for the chain are taken from the 2123 engine. The oil pump sprocket has the number of teeth reduced to 30 to increase the performance of the oil pump and improve the operation of the hydraulic chain tensioner and hydraulic compensators.

The camshaft 21214-1006010 is original with a modified cam profile and can be interchanged with the shaft from 21213.

The exhaust manifold can be made of cast iron or stainless steel. The cast iron manifold is made by casting. The stainless steel manifold version has a welded design. A welded manifold is lighter and heats up quickly, which is good for the operation of the catalyst located in the manifold. In addition, an oxygen sensor is installed in the exhaust manifold.

The intake manifold and fuel rail (2123-1144010-11) were borrowed from the 2123 engine. The injectors of the fuel injection system are SIEMENS VAZ 20734 (yellow), injectors (0280 158 110) were installed on early engines.

Ignition module from engine 2112.

Electronic control is carried out by the BOSCH MP 7.9.7 ECU. or JANUARY 7.2 depending on the year of manufacture and modification of the internal combustion engine.

Weaknesses of the VAZ 21214 engine

Cylinder block. This weak point appears on various models of Nivov engines, including the previously discussed 21213. Due to insufficient quality control, the assembly unit is manufactured with a high percentage of factory defects. In short, the drilling depth of the intake manifold stud holes is not maintained, causing the holes to meet the camshaft stud holes.

In this way, L-shaped through channels are obtained. After installing the studs at the factory, the connections remain sealed for some time and the problem is not identified when the quality control department employees accept engine tests. After the sale of new cars with low mileage, during sharp braking, oil begins to seep through the studs onto the hot intake manifold, so much so that smoke from the oil burning in the manifold pours out from under the hood, and accordingly, there is nothing to breathe in the cabin.

A sketch for the technical specifications for eliminating oil leaks from under the exhaust manifold studs.

- Remove the GC cover;

- Unscrew the two studs securing the bearing housing (see sketch) and remove oil from the threaded holes;

- Thoroughly degrease the holes and stud;

- Apply sealant UG-10 or its analogues to the lower threads of the studs;

- Place the studs in place;

- Tighten the bearing housing nuts;

- Install the cylinder head cover;

- Wait at least 30 minutes for the sealant to set.

- Water pump;

- Engine, manual transmission and transfer case oil seals;

- Generator;

- Starter;

- manual transmission;

- Valve cover gasket;

- Cooling system pipe connections;

- Radiator;

- Thermostat;

- Expansion tank;

- Vacuum brake booster.

Also interesting: Engine jerking at idle: causes of malfunction

The water pump (pump) is characterized by frequent failures on new cars after 2,000 km.

The generator has a high probability of failure. As a rule, it burns out even on new cars that have not reached 4,000-10,000 km.

The starter has a low service life without repair.

The valve cover gasket loses its properties over time and allows oil to leak out.

The connections of the cooling system pipes in the places where the clamps are installed are not reliable and lose their tightness very early, which is fraught with loss of antifreeze.

The radiator is leaking. The problem occurs due to the appearance of cracks in the radiator pipe package, accompanied by loss of coolant. This defect has become widespread.

The thermostat does not provide thermal conditions for the coolant in the engine cooling system. The manifestation of this problem is no exception. The cause of the defect is a failure of the valve mechanism inside the thermostat. To check that the thermostat is working properly, after starting the engine, simply place your palm on the lower (outlet) hose, through which hot antifreeze circulates into the radiator for cooling. If the thermostat is working properly, after some time the hose should become hot; if the hose remains cold, the thermostat must be replaced.

Vacuum brake booster (VUT). Manifested by a stiff brake pedal. The speed may fluctuate when the brake pedal is pressed, as well as hissing. The problem is solved by replacing failed rubber products and replacing clamps in connections.

Troubleshooting - identify and eliminate

Lada Niva 2121 2018

At an average speed of 80–100 km, this car consumes 6.5–7 liters per 100 km. This flow rate was achieved using an injector. An injector is a device that completely replaces the operation of a carburetor. It consists of injectors and a fuel rail, as well as electronic sensors that give a signal for fuel injection

Fuel is injected into the engine using injectors, so it is very important to monitor and clean them on time so as not to interfere with the operation of your car’s engine. It is also worth refueling with high-quality octane fuel

As a result of untimely replacement of fuel and air filters, as well as the use of low-quality fuel, the injector may fail. Don’t rush to a car service center - first, make sure that the reason for the poor performance of the car and the decrease in power lies not in these spare parts, but in something else. One of the main reasons for poor injector performance is incorrect operation of the control unit, the so-called computer. To identify the causes, you need to go through; in some cases, you will need to completely flash the unit.

During poor injector operation, the VAZ 2107 significantly increases fuel consumption, and the corresponding indicator should light up on the instrument panel, indicating the presence of an operating error. Problems in operation are also indicated by a decrease in engine power, and failures are also possible when pressing the gas pedal.

You can do a complete one at a car service center, or, after purchasing the necessary ones, you can do everything yourself.

These procedures will cost you much less, but they require technical skills and care. Before carrying out work, it is necessary to check all electronic sensors. This action can be performed by turning off the chips on them, and a characteristic sound should be heard on the instrument panel and one of the indicators should light up.

Which Niva is better to buy with a carburetor or an injector?

VAZ 2121 (Niva)

You should immediately make a reservation that you will not buy a new Niva, or even a well-preserved one in the carburetor version. If you are completely unlucky and someone has not preserved a rare specimen for you relatively intact. Therefore, the comparison will be quite theoretical for most readers.

However, there is still a choice and for many it is important. Moreover, it has quite a lot of aspects, such as practicality, reliability, territory and conditions of use of the car, its maintenance, and finally, modern design, ecology and comfort. Let's first consider both options separately.

Length is a variable quantity

Another parameter that has been tried many times to change when creating new modifications of the Niva is the length of the car. For those who found the regular Niva too compact, there were several options:

| VAZ-212180 Fora - Niva extended by 300 mm. VAZ-212180 Fora - Niva extended by 300 mm. | VAZ-2129 (popularly known as Kedr) is a Niva extended by half a meter with a three-door body. VAZ-2129 (popularly known as Kedr) is a Niva extended by half a meter with a three-door body. |

| VAZ-2131 is a five-door version extended by 500 mm based on the VAZ-21213, which is still in production. The car has good cross-country ability, it can comfortably accommodate four adult passengers, and the trunk of the car is quite spacious. VAZ-2131 is a five-door version extended by 500 mm based on the VAZ-21213, which is still in production. The car has good cross-country ability, it can comfortably accommodate four adult passengers, and the trunk of the car is quite spacious. |

Diesel Niva (VAZ-21215)

Perhaps many will be surprised now, but diesel engines were actually installed on Nivas. This happened at the end of the second and beginning of the third millennium. This version of the Niva was not designed for the domestic market and was produced exclusively for export. Diesel engines with the index XUD9SD were borrowed from the French auto giant Peugeot. In addition to the engine, the car also received a number of changes to the body. A lot of plastic was added on top of the usual body, and the rear door providing access to the trunk was extended to the level of the bumper to ensure comfortable loading. Due to the lengthening of the door, the rear lights had to be made vertical.

How does Niva permanent all-wheel drive work?

Some Niva owners, when purchasing a car, do not quite correctly interpret the concept of permanent all-wheel drive, believing that by moving the short handle of the transfer case you can turn the front axle on or off.

Niva transfer case shift knobs

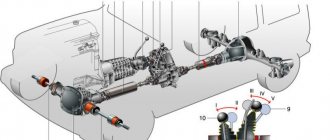

The engine crankshaft transmits torque to the transfer case through the clutch mechanism and gearbox. The very name of the transfer case comes from its functions, i.e. it “distributes” or distributes rotational energy in two directions - to the front and rear axles. Rotation is carried out through cardan shafts, which are connected to the axle gearboxes at a slight angle using a connection with a spider.

Niva driveshaft with crosspieces

Currently, cardan shafts have been developed using a CV joint (constant velocity joint), which ensures smoothness and eliminates vibration.

cardan shaft with CV joint

Torque from the transfer case is transmitted in equal shares to the vehicle's axles. Conventionally, this division can be expressed as a percentage - 50% for the rear gearbox and 50% for the front gearbox. In the front and rear axle gearbox, in addition to the main gear, there is a differential unit that allows the wheels to spin at different angular speeds. The ability of the differential to automatically adjust the speed of rotation of the wheels allows you to avoid skidding, wear on the tire tread, hub bearings, vibrations and vehicle handling when cornering or at different tire pressures. But besides this, the transfer case has an axial differential that regulates the rotation of the front and rear axles.

gearbox Lada Niva

Thus, the transmission of rotation to the wheels with regulation of angular speeds on the Niva car is carried out by differentials installed on the front and rear axle gearboxes, as well as by the axial differential of the transfer case. Thanks to this design, torque is constantly transmitted to all four wheels and the technology of such transmission is called permanent all-wheel drive (in the international designation 4WD).

How does the all-wheel drive of a Niva work?

The system of three differentials provided by the design makes it possible to forcefully lock one of the differentials, namely the center differential installed on the transfer case. The blocking is done by using the short transfer case control handle in the direction opposite to the movement of the vehicle (in other words, from the instrument panel console). The activation of the lock is indicated by a yellow indicator lamp on the instrument panel).

The need to turn on the lock arises when overcoming difficult sections of roads (slippery ground surface, sandy or snow drifts, uneven roads with potholes). When the short handle is engaged, the slipping of one axle in relation to the other is eliminated, which increases its off-road capability.

In a real world situation it might work like this. When the car moves on an uneven surface, one of the wheels (for example, the front) may end up in the “air”, i.e. completely lose traction. If the locking is not turned on, then all the rotational energy (conditionally 100%) will be transferred to this wheel, which has no grip with the road surface, and there is also no friction force. In this case, both the rear axle and the wheel on the front axle, which has traction, will not receive rotational energy. In this case the car will not move. But when the center differential lock is turned on, the rotational energy will be distributed equally to the front and rear axles. A condition will arise for the transmission of rotation of the rear wheels that have traction with the road surface. The front wheel, suspended in air, will also spin, but the rear wheels will also begin to rotate.

It is also possible that both the front and rear wheels are weighted diagonally. In this case, locking the center differential will not affect the wheels that are in engagement with the road surface, since the differentials on the axles will rotate exactly those wheels that have the least resistance. The car will not move until artificially created engagement on any weighted wheel (creating an embankment under the wheel, placing stones, etc.). Experienced drivers, by varying the parking brake, level the operation of the gearbox differential, forcing the wheel that has traction with the road to rotate.

Fuel consumption and temperature

A uniform and smooth driving style helps reduce gasoline consumption. It is not recommended to brake or accelerate the car sharply - the result will be the opposite. Some factors are present only in winter. Thanks to them, the average gasoline consumption on a VAZ 21214 can almost double.

Increased fuel costs are determined by air temperature. The lower the thermometer shows, the higher the gasoline consumption.

This is explained by the fact that the engine, seats, external windows and steering wheel, windshield and rear windows warm up. In addition to this, there are a number of other reasons:

- reduction in tire pressure, which occurs automatically due to low temperature. This entails a narrowing of the tire rubber, resulting in a drop in pressure;

- The condition of the road in winter plays a big role. If there is ice on the road, then when the car starts moving, the wheels are polished and gasoline consumption increases;

- bad weather conditions (snowfall, blizzard) force drivers to reduce their speed, which entails the same high fuel consumption.

Causes of malfunctions

Reasons why repair or replacement of the TPS may be required:

- The contact elements have become acidic. This problem can hardly be called a breakdown, but it refers to malfunctions that can be eliminated. During prolonged use, the sensor contacts may oxidize. This is due to the operation of the TPS under conditions of temperature changes and exposure to moisture. To eliminate the problem, you need to dismantle the controller and clean the contact elements with cotton wool treated with WD-40.

- Erasing the coating based on the initial segment of the slider movement. If the resistive base is removed, the controller will not operate correctly. As the slider moves, the voltage supplied to the control module will increase. But as a result of erasing, this does not happen, since there is no resistance. This leads to problems, and sometimes the control module malfunctions.

- Damage to the tips on the device. If this happens, burrs will form on the lining, which will ultimately lead to failure of the remaining elements. In some cases, the contacts will continue to function, but this will not last long, especially since the wear on the substrate will increase. With such problems, the slider and the resistive layer will refuse to contact, which will lead to the inoperability of the machine’s motor.

- Slider failure. This component of the device wears out over long-term use. As a result, it may deviate from the required trajectory, which will lead to problems.

One of the reasons for the failure of the throttle position controller is shown in the video of the “Everything Yourself” channel.

Niva for travel (VAZ-2121 “Auviga”)

There was also a modification for travelers, which consisted of two independent parts - the front part of the car was a pickup truck made from a short-wheelbase Niva. On top of this pickup, the second part, which actually consisted of a room with windows and a door, was laid and tightened with two fasteners. This part had one wheel axle, absolutely identical to the wheelbase of any other Niva. Since the car was quite large, large mirrors were screwed onto the front fenders for safety. About 2 such models were produced. Due to the collapse of the USSR, production of this Niva ceased.

Right-handed Niva (VAZ-21212)

There was also an export version for countries with left-hand traffic. It was the only Soviet car that was exported to Japan. Before and after this delivery (one small batch was delivered), no Soviet cars were observed on the territory of this country. Most copies of this model were exported to England. Nowadays, it is already difficult to find a “right-hand drive Niva” - unless among connoisseurs of retro cars. The technical characteristics of this model did not differ from the basic version. The same 1.6-liter engine and 4-speed manual transmission were used.

So which is better?

In the general case - an injector. But carburetors also have fans.

First of all, these are conservative people of the older generation. They are instinctively afraid of complex electronics, because they are used to dealing with designs that can be “fixed on the knee.” In the case of an injector, they see incomprehensible hardware, which they have neither the desire nor the opportunity to understand. And it is difficult to convince them that this is usually not necessary. But the almost complete use of injectors in cars existing on the roads nullifies this point of view.

The second category is jeepers. People who drive their cars into such dense places where it is very difficult to get help. Hence the requirements for the reliability of equipment. Or for quick repairs with a limited number of tools. Here, of course, it will be simpler with a carburetor. There is nothing special to break there, and each of them can be washed and blown out.

But most of them now use injection Nivas. Firstly, they are fresher, which means they are more reliable. And secondly, not every failure leads to the death of the car. It’s even easy to list them. The engine will not work if the fuel pump, ignition module, controller or crankshaft sensor fails. All other sensors either have little effect or are bypassed by the computer program. And the ignition can also fail on a carburetor Niva; it is usually electronic there. Critical components are usually carried with them in spare parts stock.

And it’s also worth noting that the jeep movement is gradually becoming more environmentally friendly. In this environment, it is considered indecent to leave trash behind, destroy vegetation, or wash cars in bodies of water. Apparently, the understanding that a carburetor engine poisons the air will also receive a steady increase.

A call from an old friend was unexpected: “Listen, I’m about to buy a long Niva, please advise which is better - carburetor or injection?”

Five-door Niva VAZ-2131 – characteristics

Indeed, five-door VAZ-2131 Nivas are now produced with a 2130 engine - 1.8 liters and a carburetor power system or a more modest 1.7-liter unit 21214 - with distributed fuel injection. In terms of characteristics, the engines are almost identical: the first has 0.6 Nm more torque, the second is more “revving” and more powerful. one horsepower. The carburetor engine, judging by the passport data, gives the car slightly better dynamics. In addition to the “1.7i” nameplate on the rear, the fuel-injected Niva can be identified by two electric fans – they can be seen under the radiator trim. On a carburetor, the only belt-driven fan is located behind the radiator. The prices of both modifications are approximately equal, even despite the expensive neutralizer and lambda probe for the injection version - about $7,500 in the capital. By the way, there is a suspicion that the introduction of Euro II toxicity standards, planned for January 2004, which means the departure of the carburetor power system from the scene, will be postponed.

As soon as I began to explain all this, my friend made it clear that he himself was literate - he had already read all the advertising brochures, instructions and specifications. Numbers are numbers, but how does this difference feel behind the wheel? Or is there no difference? Okay, I say, call me back in a week. Further, as in “The Diamond Arm”: “Are there any similar ones, only blue? No? Will seek". Finally, at the Lada car dealership in Varshavka, we found what we needed: two bright metallic 31 Nivas (plus $300) with the required engines, ready for testing. The next day they were already driving towards the Dmitrovsky training ground.

Niva with carburetor engine

There are actually two of them. If not more, but we will not pay attention to very exotic cases.

Niva VAZ-2121. On the one hand, this is like a generalized brand of car, but this designation has a very specific car, the same one that was presented at the 25th Congress of the CPSU back in 1976, and since 1977 has gone into large production.

The car was equipped with a 1.6-liter carburetor engine from the VAZ-2106 and has now become almost a rarity. Although there are quite decent, preserved or well-restored specimens. The engine is as simple as a stool in a school labor class, it is widely known to everyone (at least to people of the older generation), and nowadays it’s even scary to look under the hood of this car, there is so much free space.

Niva VAZ-21213. Put on the conveyor in 1993, it is actually a restyling of the old 2121 and is equipped with a 1.7-liter engine model 21213. The engine is quite improved compared to the 2106, noticeably more powerful, a carburetor of the Solex family is installed, in contrast to the previously used classic carburetor of the "Solex" type. Weber”, as well as an electronic contactless ignition system. In this form, the Niva lived until the era of the injector, as the fuel injection system is commonly called. It’s not difficult to buy such a car even now, so it’s worth focusing on it if you choose the carburetor option.

Technical characteristics of the carburetor version

Since what year did the injector on the Niva make the previous model become a thing of the past? pros and cons of such a machine compared to the carburetor version

To find out which Niva is better - carburetor or injection, first you need to consider the technical characteristics of both models. So, let's start in order. Initially, the engine for the Niva was taken from the classic Zhiguli. This is the same engine, but with an increased volume of the combustion chamber. The first for a Soviet SUV was the 2121 engine with a displacement of 1580 cubic centimeters. This engine developed a power of 80 horsepower. With it, the car accelerated to hundreds in 21 seconds. At the same time, according to the passport data, the consumption was 13.1 liters, but in reality it was even more.

A few years later, the car began to be equipped with a more modernized engine. The engine received the index 21213. This is a motor with a displacement of 1690 cubic centimeters. The power of the power unit is 83 horsepower. With this internal combustion engine, the car became more playful. Acceleration to hundreds decreased to 18 seconds. Consumption has also decreased. According to the passport data, the 1.6-liter Soviet Niva consumes 11.5 liters of gasoline. But still, the owners claim 13-liter consumption. And in winter, this figure will always be one and a half liters higher (this is mainly due to more frequent and longer engine warm-ups).

Since what year did the fields become injected?

Good afternoon I’m looking at a Niva, the budget is 100-150 rubles, respectively, for this money 2000-2006, the usual 21214 are injection, but there are also Nivas from the 80s in excellent condition, with natural carburetors. I read that the “Soviet” ones have thicker metal and supposedly have a lot of good things :))) but the new ones have all foil, etc. and so on. I would like to ask anyone who owned old and new to speak out, is there such a big difference, is it true that “they used to do it differently”, or on the contrary, fresher is fresher, after all, improvements were gradually introduced almost every year in different units, probably not in vain? Is a carburetor really that scary in the fields? including consumption?

The third option is to save further and take either a 21214M or a Chevy Niva, where the budget already starts from 300 tr. it turns out. For example, we have a Niva 1980 hanging in our advertisements. ideally for 100 tr. Krasnodar region, so the problem of corrosion is not so relevant here.

Comments 13

In our family we had Nivas from 1987, 2000 and Nivas from recent years (grandfather changes them every 3 years). Niva '87 is a beast of a car. 150 km/h at 4 mortar, V-1600. Of course she periodically demanded attention. Both the body and all the mechanics. I also really liked the Niva 2000 (at that time it was 8-9 years old). It broke very rarely. At that time, my father took it in the north (they don’t pour salt on the roads there). I looked through a lot of them. Everyone was painted. I chose the dirtiest one. It stood in a guy's garage and was used for his summer cottage. Mileage 60 t. km. Well, about injection fields. Good devices. More comfortable, BUT on the vase they strangled Nivov engines with EURO requirements. She just became stupid. I don't know what to do with this. It can flash the brains, or it can stop worrying and take the carburetor. I would try to get a 5-6 year old carburetor.

About 2 years ago, my friends took the Niva. One took a new one from the showroom, and the other took a 1-year-old one, but well stuffed with “craftsmen”. In the “stuffed” one they made noise reduction, covered the interior with leather, installed different seats, installed electric windows and little things. Both comrades are as happy with the Niva as boas. The first one exploited and did not invest, except for consumables and maintenance, and the second did not invest anything at all (only gasoline). Of course, they didn't kill them off-road. Mostly around the city and to the dacha. Without fanaticism. The third acquaintance owned an old Niva (88-89, I think). He was also happy as a boa constrictor, but after going hunting he drove him into the hole and always changed something. He complained that spare parts were expensive and their quality was not so good. I went to tune the carburetor several times. Each time I was not very happy with the result. Either it was running out of fuel, then it was stalling, or some other nonsense. In general, an old car is an old one that requires attention and constant “care”. Therefore, I am for the 3rd option. Save up and take Shniva or at least Niva for no more than 1-2 years. They already come with power steering, it’s becoming more and more pleasant to turn the steering wheel. You can take the old one, in some ways it may be better than the new one, but it will take a lot of time. It may not even be so much a financial investment as a temporary one.

| OJSC "Lutsk Automobile Plant" in the third quarter of this year stops assembling carburetor VAZ-21213 cars and switches to producing an injection modification. |

VAZ-2121 Niva

VAZ-2121 “Niva”

Total information

| Assembly: | VAZ, LuAZ, Asia-Auto (Kazakhstan) |

| Class: | Passenger all-terrain vehicle of the second class |

| Other designations: | LADA 4×4 |

| Layout: | front-engine, all-wheel drive (permanent all-wheel drive[1]) |

| 2121 | |

| Manufacturer: | VAZ |

| Brand: | 2121 |

| Type: | petrol OHC |

| Volume: | 1,580 cm3 |

| Maximum power: | 58.8 kW (80 hp), at 5400 rpm |

| Maximum torque: | 116 Nm, at 3400 rpm |

| Configuration: | in-line, four-cylinder |

| Cylinders: | 4 |

| Valves: | 8 |

| Piston stroke: | 80 mm |

| Cylinder diameter: | 79 mm |

| Compression ratio: | 8,5 |

| Supply system: | carburetor |

| 21213 | |

| Manufacturer: | VAZ |

| Brand: | 21213 |

| Type: | petrol OHC |

| Volume: | 1,690 cm3 |

| Maximum power: | 59.5 kW (81 hp), at 5200 rpm |

| Maximum torque: | 125 Nm, at 3000 rpm |

| Configuration: | in-line, four-cylinder |

| Cylinders: | 4 |

| Valves: | 8 |

| Piston stroke: | 80 mm |

| Cylinder diameter: | 82 mm |

| Compression ratio: | 8,5 |

| Supply system: | carburetor |

| 21214 | |

| Manufacturer: | VAZ |

| Brand: | 21214 |

| Type: | petrol OHC |

| Volume: | 1,690 cm3 |

| Maximum power: | 59.5 kW (81 hp), at 5000 rpm |

| Maximum torque: | 127.5 Nm, at 4000 rpm |

| Configuration: | in-line, four-cylinder |

| Cylinders: | 4 |

| Valves: | 8 |

| Piston stroke: | 80 mm |

| Cylinder diameter: | 82 mm |

| Compression ratio: | 8,5 |

| Supply system: | fuel injection |

Mechanical 4 tbsp. (VAZ-2121/21219), 5 tbsp. (21213/ 21214/ 21215/ 21218)

Characteristics

Mass-dimensional

| Weight: | 1150 kg (2121); 1210 kg (21213/21214) |

| Full mass: | 1550 kg (2121); 1610 kg (21213/21214) |

Dynamic

| Acceleration to 100 km/h: | 2121 - 23 s; 21211 - 26 s; 21213 - 19 s; 21215 - 25 s |

| Max. speed: | 2121—132 km/h; 21211 - 125 km/h; 21213 - 137 km/h; 21215 - 120 km/h |

On the market

| Similar models: | AMC Eagle Hath, Dacia 10 hard top, Subaru Leone Hathback, Suzuki Vitara 3-dr |

Other

| Fuel consumption: | 2121 - 10.8-13.4 l/100 km; 21213 - 8.3-11.5 l/100 km, 21215 - 8-9.1 l/100 km |

| Designer: | Semushkin Valery Pavlovich |

VAZ-2121 "Niva"

, currently designated

LADA 4x4

[2] - a Soviet off-road passenger car. The world's first comfortable small-class SUV with a monocoque body and permanent all-wheel drive. Serially produced since April 5, 1977. In the history of the world automotive industry, Niva is considered the founder of “crossovers” - a class of passenger cars that was especially popular at the beginning of the 21st century, as well as the most original and popular car of Soviet and Russian production. There are Niva fan clubs in many countries.

What engine can be installed on a VAZ 2107 instead of the standard one?

Some car enthusiasts who are accustomed to upgrading cars with their own hands decide to replace the installed engine with a more productive one. Like any other car, the “Seven” can be converted and equipped with an engine from another car, but a number of rules must be followed:

- The replacement engine must exactly match the dimensions and weight of the standard device. Otherwise, there may be problems with the operation of the new motor.

- The new engine must be mated to the existing transmission.

- The power of the new power unit cannot be greatly overestimated (no more than 150 hp).

Motors from other VAZ models

Of course, first of all, the owners of the “Seven” turn their attention to the engines of other VAZ models. The best option (a little more powerful and durable) is a carburetor with a VAZ 2114

It fully corresponds to the dimensions of the VAZ 2107 carburetor, but is a more modern and productive device. In addition, you can install the engine from a VAZ 2114 with virtually no modifications - the only problems may arise with the RPD, but they are easily solved.

Engines from foreign cars

The VAZ 2107 can also be equipped with an engine from an imported car. Power units from Fiat and Nissan brands are ideal for replacement. The thing is that the progenitor of VAZ engines were Fiat engines, which also served as the basis for the development of Nissan engines.

Therefore, engines from these foreign cars can be installed on the “Seven” without any alterations or modifications.

Rotary engine

There was a period in the history of AvtoVAZ when some car models (including the Seven) were equipped with rotary piston engines. Initially, such installations were highly productive, but the VAZ 2107 with such engines had many disadvantages:

- high heat losses, due to which fuel consumption was higher than on conventional carburetor VAZ models;

- problems with engine cooling;

- the need for frequent repairs.

Diesel engines

Car enthusiasts, in order to save on fuel, sometimes replace gasoline power units with diesel ones. On a VAZ 2107 you can also carry out this procedure. Again, for replacement it is better to take engines from Fiat and Nissan. Diesel engines are more economical than gasoline engines, but require increased attention from the car enthusiast, as they are very capricious in terms of maintenance.

Mishanya

https://www.semerkainfo.ru/forum/viewtopic.php?t=6061

Thus, the VAZ 2107 carburetor was initially designed for typical loads and a short service life before the need for repair. However, the repair itself is considered a simpler and more accessible procedure than, for example, the overhaul of an injection engine. In addition, the nuances of the “Seven” design give owners a chance to install engines from other car models in order to get the quality of work that is required.

Description of the design [edit | edit code ]

VAZ-2121 (21213/21214) is a small-class all-terrain vehicle (SUV). The body is monocoque, three-door - hatchback type, five-door - station wagon. Transmission with permanent all-wheel drive, four-speed manual gearbox (starting from 21213 - five-speed), two-speed transfer case and locking center differential. The geometric parameters of cross-country ability are good due to the fairly high ground clearance (220 mm), small body overhangs (approach angle 32°, departure angle 37°) and a relatively short 2.2-meter wheelbase. The first VAZ-2121 model was equipped with a VAZ-2121 engine, created on the basis of the VAZ-2106 engine, an in-line four-cylinder carburetor with a volume of 1580 cm³. Power 80 l. With. at 5400 rpm, maximum torque 116 Nm at 3400 rpm. The restyled modification of the VAZ-21213 was equipped with a VAZ-21213 carburetor engine with a displacement increased to 1690 cm³ and a power of 81.9 liters. With. at 5100 rpm and maximum torque of 126.1 Nm at 3000 rpm.

One of the features of the Niva is the use in its design of large-scale units from the VAZ model range. Thus, from the VAZ-2106 model, a 1.6-liter engine with a timing chain drive, a gearbox and a rear axle gearbox were used (on the first Nivas, the axle gearboxes used main gears from the VAZ-2101 with a gear ratio of 4.3). Nevertheless, the Niva immediately demonstrated cross-country ability that was unique for its class.

In October 2021, on the LADA 4×4, VAZ introduced a bearing into the front hubs that does not require periodic adjustment. The car has a modernized steering knuckle, independent mounting of the front axle gearbox and gas-filled shock absorbers [7] [8].

Pros and cons of the injector

Which is better - Niva carburetor or injector? Among the advantages of the carburetor Niva, it should be noted:

- Simple design of the power system. In the event of a breakdown, you can fix the problem yourself.

- Cheap service.

- Unpretentiousness to fuel quality. Many Soviet Nivas can easily “digest” even 76-octane gasoline.

- Lack of many sensors.

It would seem that the answer has been found to the question of which is better - a Niva carburetor or an injector. However, a carburetor engine has more disadvantages. Among them:

- Low reliability. Every season you need to adjust the carburetor and carry out its maintenance.

- Dependence on air temperatures. In winter, the spark plugs could easily be overfilled, making starting impossible until the spark plugs were subsequently unscrewed and dried. Also, in winter, due to condensation, the float often “stuck”. And in the summer the fuel pump often got hot.

- Greater fuel consumption.

- Less productivity. To unlock the potential of the engine, it was necessary to spin it up to high speeds.

No matter how simple and maintainable this power system may be, it requires a lot of attention. Over the course of a year of operation, you will have to rebuild the carburetor several times. A modern car enthusiast is unlikely to be happy with this situation (especially adjusting the carburetor or drying spark plugs in 20-degree frost).

Which is better - Niva carburetor or injector? This question interests many car enthusiasts. Here are the advantages of the injection Niva:

- Stable operation of the internal combustion engine. Thanks to the presence of IAC, owners have forgotten what floating speed is. For carburetor engines this was a real disease.

- Great performance. The fuel-injected Niva responds more quickly to the gas pedal.

- Less fuel consumption. We have already seen this by looking at the technical specifications. With the arrival of the injector, consumption decreased by 20 percent.

- Excellent starting in any weather. The injection engine does not flood the spark plugs, and in the summer the fuel pump does not overheat. The latter is submersible and is cooled by gasoline, as it is located in the tank.

- Reliability. Since there is no carburetor, there is no need to regularly tune it, change jets and clean it. The maximum that the owner of an injection-powered Niva can do is clean the throttle valve, but this procedure is by no means mandatory. It is recommended to do this only if the car selects high idle speeds.

And if the engine refuses to start, the contact may have come loose from the crankshaft position sensor. But fortunately, these problems don't happen that often. And you can diagnose them with a simple multimeter by measuring the resistance or contact voltage of one of the sensors. Thus, breakdowns mainly concern only electronics. The mechanical part does not raise any questions.

"Niva" with an injector

In 2005, innovations affected all VAZ models. This also applies to the answer to the question, since what year did the Niva with an injector appear in all car dealerships in the country?

The car began to be equipped with an engine with the index 21214. Being a gasoline unit with a volume of 1690 cubic centimeters, it could boast the same power and acceleration speed as its previous carburetor brother. But fuel consumption was reduced by 1.5 liters.

Currently with motor 21214-28. The engine meets the Euro-4 standard, with a displacement of 1774 cubic centimeters and a power of 92 horsepower. Acceleration to 100 kilometers per hour occurs in 17 seconds, and consumption is less than 10 liters of fuel.

Let's sum it up

So, which is better - a Niva carburetor or an injector? For off-road use and for the city, the second option is definitely better. An injector is a more reliable and practical system. There are far fewer problems and headaches with it, as evidenced by numerous reviews from owners. The engine starts easier and responds better to the gas pedal. In this case, the consumption is always less. If you don’t know which car to buy – a Niva with a carburetor or an injector, reviews advise considering the second option for purchase. In addition, these “Nivas” are more recent, and they will not require constant repairs and large investments.

Source