How does an air lock form in the cooling system?

This problem occurs more often after updating the antifreeze or partially topping it up. Unqualified replacement, which does not use special equipment that drives antifreeze through the circuit under high pressure, carries certain risks. And the stationary installation eliminates the occurrence of congestion, as it automatically squeezes them out by running and circulating.

The presence of an air lock in the system may indicate worn rubber elements, on which small cracks appear during operation. It penetrates through small bubbles that accumulate at bends and in narrow areas of the cooling circuit.

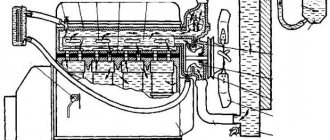

Auto cooling system diagram

In general, it is customary to distinguish between 6 main causes of airing.

- Depressurization of hoses and tubes, as well as connections and fittings. A common occurrence in winter (January, February), when clamps change their physical shape (shrink) due to severe frosts. For this reason, the pressure in the system drops, air passes through weak spots and cracks. And this directly affects the operation of the power unit. Loose joints are a common, known cause of traffic jams.

- Air valve problem. Again, the “culprit” is low pressure, which is why the breather no longer holds.

- Incorrect replacement or addition of antifreeze. For example, if you fill the antifreeze carelessly, too quickly, then the air will not have time to escape in its entire volume, which causes a blockage in the cooling system. This is exactly what happens to inexperienced drivers who change the coolant themselves.

- Poor quality materials. In modern cars, antifreeze leakage is also caused by rapid wear of rubber pipes and connections. The quality of products purchased in the public domain is clearly poor. And original spare parts are very expensive.

- Damage (holes) of the radiator or heater. This usually happens over time when the elements become clogged and rust, which inevitably leads to the formation of a plug. All parts of the heat removal line must be regularly inspected for damage.

- Defect of the head cuff. Antifreeze can easily penetrate the oil, settle in the crankcase and cause a blockage. In addition, gases can penetrate inside, and this will lead to the appearance of an emulsion and serious problems with the engine. In this case, black smoke will come out of the muffler, which will indicate the exhaust of the engine or coolant.

Two more common reasons when it is necessary to remove air from the cooling system are breakdowns in the pump (wear of the cuff) and sticking of the reservoir breather.

You need to understand that the heat removal unit from the internal combustion engine is made in the form of a structure with numerous bends.

Here, due to the nature of the liquid circulation process, a plug may form over time. When it completely clogs one of the channels, problems with engine cooling begin and the channels have to be ventilated.

How to solve problems with air in the cooling system

You can solve such problems the old fashioned way. The car starts, the car owner opens the hood and begins to vigorously press with his hands on the elastic pipes through which the antifreeze moves. This allows you to create increased pressure in the system, the plug will be driven through the pipes, and, ultimately, such an air bubble will end up in the expansion tank, and the entire system will be completely filled with antifreeze.

Often, to de-air the system in this way, it is necessary to actively press the pipes for 15-20 minutes. This work is not easy; turning off the engine and starting it again often helps. As you press on the pipes, numerous air bubbles will come out from the expansion tank with antifreeze, and subsequently the system is de-aired, the engine begins to cool properly, its temperature drops to optimal values, and then no problems arise with the operation of the car.

In certain cases, when the plug is located in hard-to-reach places, and it is not possible to ventilate the system in this old-fashioned way, then it is necessary to completely drain all antifreeze, including from the engine crankcase. After that, coolant is refilled, which, as the pressure in the system increases, will expel the plug from such hard-to-reach places, and subsequently, by pressing the pipes, the system will be de-aerated.

It is also possible to eliminate such air locks from the cooling system under service conditions using special equipment that increases the pressure in the system, the air begins to move through the pipes on its own, and then exits through the expansion tank.

Let's sum it up

Determining the presence of air pockets in the cooling system is not difficult. The car owner will need to monitor the temperature of the antifreeze and monitor the air from the stove, which must correspond to the temperature of the coolant. You should also inspect all pipes for leaks and cracks, from which air can get inside the entire system. You can eliminate the traffic jams in the old-fashioned way, by actively pressing on the antifreeze pipes, and by draining the coolant, or you even have to take the car to a service center, where, using special equipment, they will expel the air from the pipes, completely restoring the operation of the car’s engine.

Signs of airing

Common symptoms when the system becomes airy:

- the needle on the instrument scale rises sharply - it reaches the red zone;

- the stove does not heat in winter even with a well-warmed engine;

- the check indicator is on, the engine status light is on;

- antifreeze leaks from cracked hoses and pipes;

- the muffler smokes a lot - the exhaust is white and thick;

- The engine warms up slowly after starting.

White smoke from the muffler is a clear sign of airiness in the system.

The last symptom may also indicate an internal malfunction of the thermostat, but you will still need to remove air from the system. In general, the thermostat is invariably connected to the heat removal unit. When it malfunctions, airing is not uncommon. The functionality of the element is checked as follows. First, the engine starts, then after 10 minutes the radiator tubes are felt. The lower pipe must be cold (it warms up only after the engine reaches 80-90 degrees Celsius), and the upper pipe must be warm (then cold).

Another element directly related to the cooling system is the stove. If it blows cold air with a well-warmed-up engine, this is more likely to indicate air congestion.

Thus, an air lock in the cooling system prevents the coolant from moving normally through the lines. Due to this disruption of circulation, various problems arise. Therefore, it is necessary to regularly check the amount of antifreeze in the tank and carefully inspect certain areas of the system. First of all, pipes and other cooling lines. They should not have cracks or other defects. Excess air must be vented (removed).

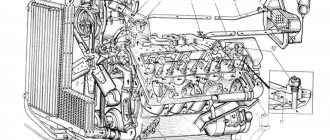

Cooling system pipes and hoses

Air has entered the engine cooling system: the main signs of airing

For a better understanding, let's start with the general operating principles. While the engine is cold, the liquid circulates only through the cooling jacket (special channels in the cylinder block and cylinder head), without entering the radiator. Circulation is provided by a water pump.

After the coolant temperature reaches a certain value, the thermostat is activated, which opens a large circle (the liquid passes through the radiator). If cooling the coolant when driving in a large circle is not enough, then the engine cooling fan (air cooling) is automatically switched on.

Please note that these malfunctions can occur for various reasons, that is, the engine begins to overheat not only due to air locks, but this possibility should also not be excluded.

As with any closed fluid system, air pockets can cause the system to stop operating normally. In this case, the risk of engine overheating also increases significantly, and the stove stops working normally.

One way or another, the air lock does not allow coolant to circulate normally through the channels of the cooling system. As a result of impaired circulation, certain problems arise. As part of diagnosing the engine cooling system, you should check the coolant level in the expansion tank, and also carefully inspect individual areas of the system.

We also note that air can enter through subtle cracks in the rubber pipes, but there may not be intense leaks through these cracks. Usually such cracks are not immediately visible, but a detailed inspection or injection of air into the system under pressure for testing can reveal problem areas. Also, during the check, you should pay attention to the pump, check the operation of the thermostat and cooling fan.

If everything is normal, then there is a high probability that the stove is not working and the motor is overheating precisely because of air locks. In this case, it is necessary to take measures and “drive” such a plug from the cooling system.

Why is aeration dangerous?

Obviously, engine overheating is extremely dangerous. Jamming of the power plant and unplanned stopping of the machine is what this can lead to. Therefore, it is important to clear the blockage in the cooling system immediately to avoid making the problem worse.

A knocking engine can only be restored by a major overhaul. Due to overheating, the rings stick, the CPG lifts, and jams (breaks the pistons). In a word, the entire engine filling becomes unusable.

Under such conditions, the block head, which has a complex casting shape, is necessarily deformed. It bends, the gaskets break, and the oil penetrates the cylinders.

Airing, along with an increase in temperature (500 degrees and above), causes an increase in pressure. Therefore, gaskets, oil seals (seals), and partitions between all motor systems also fail.

How to remove air from the cooling system?

To solve the congestion problem, you can do one of the methods listed below. Specifically, everything will depend on the car model, the reasons for the traffic jam, the age of the car, etc.

For example, it is more difficult to correct the situation with current cars, where the heat removal system is made using a closed structure. This forces you to forcefully remove the plug, and not bleed it out by idling the engine.

Before direct repairs, carefully prepare the workplace, remove interfering elements, and provide free access. It is advisable to carry out the operation in a spacious garage, placing the vehicle in a pit.

Road (pumping)

The fastest and easiest way to remove a traffic jam. But that's where the advantages end. It’s rarely possible to clear a blockage using this method, but it’s worth a try:

- stand in the car as level as possible;

- block the rear wheels with the parking brake;

- raise the front end on a jack - just raise it half a meter;

- unscrew the plug;

- start the engine;

- turn the cabin filter to optimal;

- start pouring antifreeze in a thin stream up to the Max mark;

- increase the engine speed to 3 thousand rpm and wait for the engine to warm up;

- squeeze the lower pipe of the heat removal system with your hand, laid to the radiator, so that the air is completely released (be sure to protect your hands).

Lower radiator hose

This must be done until the plug is completely removed from the tank. In this case, all pipes must be warm, and the stove must warm the interior with hot air when turned on. Then lower the car, remove the jack, add the required amount of coolant according to the level.

The method involves pumping antifreeze, which is done by pressing with your hand on one of the pipes laid to the radiator. You must open the reservoir cap and start the engine. As a rule, ten minutes is enough to bleed the air.

If airing in the cooling system occurs after replacing the antifreeze, then it is better to place the car on a flat surface. Then start the engine and let it “growl” for about 5 minutes at idle. Along the way, it is necessary to add the new composition in portions so that the volume of liquid in the tank does not decrease. Be sure to monitor changes in the temperature of the coolant - the needle on the scale should not rise to the limit.

Normal purging

This is also a simple way to remove a plug, but it is much more effective than pumping. Requires care and caution, since the work is carried out on a hot engine. Below are detailed steps.

- If there is a low level of antifreeze in the tank, then add a new portion to the required mark.

- Warm up the power unit to 60 degrees.

- Remove the uppermost cooling pipe (in injection engines this is the throttle heating element) and place it in a wide container. As for older cars equipped with a carburetor, this point is the intake manifold or the lower zone of the carburetor.

- Blow into the neck of the tank, opening the lid. The free end of the pipe should be placed in a wide container. When pure antifreeze comes out, stop the procedure (there should be no air bubbles). Place the tube onto the fitting and secure with a clamp.

Throttle heating unit and required hose

System purging

The lid of the container must be unscrewed carefully, slowly, allowing the air pressure to bleed. Any sudden and careless movement will cause the hot liquid to burn your hands. In any case, wear protective gloves. If the car has a special thermostatic cap, it is better to blow through the radiator neck. In this case, the tank cap must still be unscrewed.

Radiator neck

Compressor purging

A more professional option, which is often carried out at car services. In this case, you will have to connect a compressor to the expansion tank. It is advisable to cover the neck with a clean rag, and then tighten the rubber tube and blow in air. The antifreeze will begin to flow out with air bubbles, and as soon as it becomes clean, the forced blowing should be stopped.

A powerful compressor at home can be replaced with a conventional hand (foot) pump for bleeding wheels. The main thing is to ensure pressure in the expansion tank.

It is also important to prevent the antifreeze from completely draining (the liquid in the reservoir should not fall below the permissible level).

Complete replacement

This method involves a complete replacement of the fluid. The system is completely emptied, antifreeze is filled in according to all the rules. The method allows you to ventilate the cooling system in any case (if there are no more serious violations). The only drawback is that it is inconvenient to carry out in road conditions.

Below are details on how this is done:

- Drain the antifreeze into a wide container. It is better to prepare two dishes at once. Place one under the cylinder block drain plug, and the other under the main radiator. You also need to open the cockpit of the cabin heater.

- Flush the cooling system with a special product (this can be omitted if the antifreeze is poured with the same brand and color as the old one). The flushing liquid is poured into the expansion tank in the volume of drained antifreeze. After this, the engine starts for 10 minutes, turns off, and the liquid is drained. The procedure can be repeated if the drained slurry is very dirty and contains many impurities. Finally, it is advisable to rinse the system with additional clean water.

- Replace all caps and tighten the tap. The main thing is to fix them well and firmly.

- Remove the clamp, then remove the hose from the throttle heater or carburetor (older cars).

- Pour new antifreeze into the expansion tank in a thin stream. For this purpose, use a funnel inserted into the neck.

- Check the antifreeze drain through the hose. When liquid starts flowing without bubbles, stop the procedure.

- Immediately put the tube back in place. Secure with a clamp.

At the final stage, check the performance of the engine. It must be heated to the maximum permissible temperature so that the thermostat opens and the electric fan turns on. Then check the antifreeze level.

If it drops, then slowly add the required amount. This must be done according to the instructions, otherwise air will re-enter the system.

Popular brands:

Hyundai Santa Fe, Kia Rio, Mercedes-Benz E-Class

Some useful tips for working:

- You need to blow carefully and carefully. It is important that the toxic liquid does not enter the oral cavity. Eye and respiratory protection should also be provided.

- The machine must be placed on a flat, horizontal platform. Why - in order to correctly assess the fluid level.

- It is important to pour new antifreeze in a thin stream, always using a watering can to prevent liquid spillage. High pressure can cause congestion.

- It is prohibited to open the reservoir lid while the engine is running!

Important point. Since the coolant contains substances harmful to the human body and animals, waste is prohibited from being dumped into the ground near wells, reservoirs and pumps, as well as other sources of technical and, of course, drinking water.

Reasons why air appears in the cooling system

Air appears in the system due to malfunctions, actions or inactions on the part of the driver. The following reasons are identified:

- The tightness of the system is broken. This could be a loose clamp, fitting, or cracks in the hoses.

- Work has been carried out to replace or top up the coolant. This is, as a rule, the most common reason for air getting in, because not everyone knows that it should be poured in a thin stream. If you pour in a thick stream, a funnel is formed that swirls the air.

- The air valve is out of working order. This valve is located in the coolant reservoir cap. During natural heating or by installing and starting an autonomous engine preheater, the volume of liquid increases, the pressure in the tank increases and excess air must be discharged through the valve in the lid. This is also a common reason. This is the first place to look for the reasons for airing in the cooling channels. This cover costs 100 rubles for modern VAZ cars. Whoever changes it, when he has already double-checked all the reasons, even after replacing the cylinder head, it turned out that the reason was precisely the non-working cover.

- Problems with the pump (pump). The seals and fibers in the pump may be faulty, causing air leaks.

- There is a leak through a bolt in the cooling radiator (not available on all models). If there is a leak of antifreeze, antifreeze or water, the lost volume is filled with air.

- Burnt cylinder head gasket. If the engine has already been overheated, then there is a possibility that the cylinder head gasket has burned out. When it burns, coolant is released either into the crankcase or into the exhaust system. Seething and boiling begins when the volume of coolant (coolant) has decreased and the entire void is filled with air. In this case, repairs and replacement of the head gasket will be required; for this you need to know what types of cylinder head gaskets there are.

If coolant gets into the engine crankcase, it is easy to check with the oil level dipstick; the level will be higher than expected. If water is used as coolant, the engine oil will turn white. Sometimes air gets into the brake system, in which case the system also needs to bleed air. And for this you need to know the diagram, which wheel to start with and what exactly to do to bleed brakes with ABS and how to bleed brakes without ABS. If the entire fuel fluid has leaked or you want to replace it, then such work also has its own nuances. In particular, you need to know which brake fluids can be mixed and how much brake fluid is needed for replacement.

Prevention of system airing and engine overheating

It is enough to follow simple recommendations to forget about air congestion forever. Carry out technical inspections of your car regularly and fill them with high-quality fluids. Be sure to change the old antifreeze, preferably with a liquid of the color that was before.

Fix leaks in a timely manner, otherwise it will be more difficult to bleed the air later. You should not drive with a half-working system, repeatedly adding antifreeze. There is no need to fill the tank to the maximum yet, as sooner or later the cap will be squeezed out due to strong pressure, and air may get into the system.

And most importantly, do not fill the system with ordinary tap water. Our grandfathers did this, but these were old carburetor cars. Today's cars are equipped with a powerful injection engine. It is accordingly equipped with a more modernized heat removal system - a fairly sealed structure, from where simple water will begin to quickly evaporate. If you use it, then only distillate mixed with acid.

It is important to maintain the system regularly. The radiator, tank, and pipes should be washed from time to time, otherwise the decay products will do their dirty work over time. For example, it will not be possible to avoid corrosion and scale formation.

As for the antifreeze itself, its service life is no more than 2-3 years. The quality of the composition and the manufacturer, the condition of the engine, and the operating conditions of the vehicle are of great importance here. The use of harmful sealants, severe overheating of the power plant, and exhaust gases entering the crankcase can quickly render a fresh coolant unusable.

In short, the heat removal system needs the same regular maintenance as the engine. If this is done in a timely manner, you can always keep the system clean from rust, scale and dirt.