23.09.2019

| (Votes: 2, Rating: 5) |

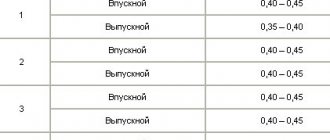

Issues discussed in the material:

- How does engine braking work?

- What are the pros and cons of such braking?

- How to brake with a manual engine

- Is engine braking possible on automatic and variator?

Reducing the speed of the car by pressing the brake pedal cannot always be considered the optimal solution. Experienced drivers use engine braking in some situations. However, to use this method, you must have certain skills. Incorrect actions can lead to accelerated wear of the motor and various breakdowns. In this article we will tell you in what situations it is worth using engine braking on cars with different designs.

How does an engine brake a car?

The design features of internal combustion engines are that for these units it is more natural to operate at idle. When the driver presses the accelerator, the engine speed increases, but as soon as he releases the pedal, the speed drops. If such actions are performed while the car is moving, then as the engine speed drops, the speed of the car also decreases. This process is called engine braking. The method of reducing the speed of a car without using braking systems is an important skill that allows you to prevent wheel locking during braking on a slippery road, as well as to avoid an emergency situation in the event of an unexpected breakdown of system elements.

How does engine braking help reduce vehicle speed? This method is based on the resistance of the power unit to inertial loads aimed at increasing the number of crankshaft revolutions. The process occurs at the moment when the car is driving at speed with the gear engaged, and the supply of the fuel mixture is reduced or stopped altogether.

A drop in the volume of fuel entering the internal combustion engine leads to a decrease in the amount of energy transferred by the engine to the transmission, which in turn begins to transfer the inertia of the rotating wheels to the engine. This leads to a drop in crankshaft speed and the car loses speed.

Let's consider the features of the engine braking process. First of all, it should be noted that in this case it is not always possible to provide a noticeable reduction in the speed of the car. When you press the accelerator, the supply of the fuel mixture increases, which leads to an increase in the number of crankshaft revolutions (the engine “spins up”). When you release the gas pedal, the speed decreases.

If we take a simplified look at the operation of the transmission, we can note that the function of the gearbox is to transmit and distribute torque to the wheels. In other words, the gearbox transfers a certain amount of motor energy, depending on the selected gear.

When driving in lower gears (1st to 3rd), maximum force is transmitted to the wheels, but the car will not be able to reach the highest speed. After engaging higher gears, the car can drive faster, but the acceleration energy will decrease, since the gearbox can no longer transmit maximum force from the engine, as in first gears.

In higher gears, the car accelerates much less, and in most situations the car can only maintain the achieved speed. In 4th, 5th and 6th gears, more significant inertial forces begin to operate, so engine and transmission resistance is minimized.

We recommend

“Why engine valves knock: top 5 reasons” Read more

Thus, good acceleration dynamics can only be ensured when driving in lower gears.

It is at such moments that, by releasing the gas pedal, you can provide significant resistance to inertial movement. If you let off the gas in higher gears, the car’s deceleration will not be so noticeable, since the inertial resistance will be low.

Pros and cons of engine braking

The main benefit of engine braking is that the risk of the vehicle skidding is significantly reduced. When the driver presses the brake pedal, the wheels lock and, consequently, the car loses control. To minimize the risk of a car skidding, automakers equip modern models with active electronic safety systems, but on a slippery road, even ABS cannot guarantee the complete absence of a skid.

Taking into account the information presented above, we can come to the conclusion that engine braking can be considered an anti-accident technique on a slippery road. Drivers often use this method on long descents, mountain roads, and when driving along serpentine roads or during icy conditions. It prevents wheel locking and protects the system from overheating caused by too much braking.

Drivers often use engine braking in situations where it is possible to drive on the highway at full speed, to save fuel, as well as to reduce wear on brake pads and discs. In this regard, it is attractive that in modern injection models of cars with a manual transmission, the supply of the fuel mixture stops when the accelerator is released.

It is also worth remembering that engine braking can come to the rescue if the brake system is faulty. It’s worth considering here that you won’t be able to immediately stop the car using this method, especially when driving downhill, but you can slow down, which will allow you to use the standard braking system with minimal risk and without much damage.

We must recognize the validity of skeptical opinions that engine braking can harm the power unit. What are these judgments based on?

We will begin to consider the adverse consequences of reducing the speed of a car due to the engine with a rather simple and invisible problem caused by the asymmetry of modern internal combustion engines. To reduce the lateral load on the piston while it is at top dead center, the designers moved the piston pin relative to the cylinder axis. In this case, the axes of the crankshaft and cylinders do not coincide. When the engines are braking, the asymmetry begins to work against the internal combustion engine.

There is an increase in lateral loads on the piston (at the same torque value, such loads will be higher than for the working stroke). The asymmetrical design of the crankshaft bearings, connecting rods and piston pin is also designed to take into account the loads of the power stroke and does not take into account those that occur during engine braking.

It is worth noting that the lack of fuel supply leads to the fact that the internal combustion engine valves will operate “dry”, but even with prolonged engine braking, this factor slightly increases the wear of the valves (in addition, they cool down at such moments). For internal combustion engines that undergo a “cold run-in”, such a technique can be considered as forced idling, extended over a longer period. But it should be noted that the valve seats in this case will be subject to greater wear than during normal operation of the power unit.

The vacuum created in the intake manifold, which will be 1.5 - 2 times higher than at idle, can also harm the engine. Strong vacuum increases the load on the crankcase ventilation system and leads to leakage of various seals. In addition, outside air may be leaked.

The greatest troubles can occur when the valve seals are severely worn. Strong vacuum causes oil to flow into the intake manifold from the camshaft. In addition, oil will be drawn into the cylinders through the piston assembly. If the internal combustion engine is equipped with a turbine, then oil will also flow into it, which often causes failure of this unit.

An increased flow of oil into the intake manifold, which is especially typical for worn-out engines, contributes to the formation of carbon deposits on spark plugs and pistons, as well as to catalyst failure and increased harmful emissions through the exhaust system into the environment. Vacuum and pressure surges cannot but affect the condition of the flexible components of the inlet assembly (pipe, valve, etc.).

When the engine brakes, dirt and dust from the intake manifold will enter the cylinders. This factor can cause especially great harm if the catalyst is located close to the collector. In this mode, the working substance of the catalytic system will crumble. During operation under load conditions or when warming up engines with direct injection, there is a large amount of solid soot particles in the intake system. Such particles, along with dust, enter the engine cylinders, which is caused by the overlap of the valve timing (which is why the engine manages to draw in a small amount of air from the intake manifold. If the design of the exhaust system includes an EGR valve, then over time its tightness may deteriorate, which leads to the entry of dirt and dust into the intake manifold and, as mentioned earlier, into the cylinders.Solid particles of dust and dirt in the cylinders lead to scoring on their walls and damage to the valves.

We recommend

“How to properly turn off a car engine: some useful tips” Read more

During engine braking, a sharp change in the number of crankshaft revolutions occurs, which leads to shock loads on engine parts. This effect can be equated to the consequences of careless handling of the gearbox and clutch. But it should be noted that fluctuations in rotational speed in running engines occur constantly, and damper pulleys, idle clutches, etc. are used to protect the transmission.

The most significant disadvantages of the engine braking method include the increasing risks of creating an emergency situation. The car slows down, but the brake lights do not light up like when you press the brake pedal. As a result, the driver of the car driving behind may not react in a timely manner to the braking of your car, which will lead to a collision.

They say that engine braking reduces its life. Is it so?

How does engine braking work?

Why does a car slow down at all if you release the accelerator pedal while driving and in gear?

Aerodynamic losses and losses due to wheel rolling and friction in the transmission have an effect, but the main factor will be engine braking. Many drivers do not quite correctly imagine the essence of the process. Mechanical friction is not at all the main factor braking a car. Unless on diesel engines, where there is no throttle valve and exhaust restrictor, all the deceleration will be due to internal losses of the engine and heat transfer from the compressed air.

Gasoline engines create braking torque primarily through pumping losses. When the throttle is closed, the engine loses a lot of energy in an attempt to pump air through its pistons, creating a vacuum in the intake manifold. But the losses due to air compression and expansion are minimal here. The amount of braking torque depends mainly on engine speed and the degree of vacuum, which is regulated by the throttle valve.

Forced idle

Long gone are the days when the engine’s spark plugs would “throw” at idle due to the supply of a too thin mixture and the drawing of oil into the combustion chambers. Now oil consumption of more than 300-400 grams per 1,000 km is a reason for a major overhaul, and when the engine is braking, fuel is not supplied at all, down to the lowest speeds. Total benefits and savings.

When traction is needed, the engine management system will instantly supply fuel, without any traction failures. And, at first glance, absolutely nothing bad happens to the engine. Engine manufacturers have made sure that this mode of engine operation does not cause any obvious problems.

The engine braking mode with cutting off the fuel supply is called “forced idling”. It is this mode that is used for engine braking on all modern cars.

But still, the skeptics who talk about the traumatic nature of such a regime are also right. And that's why.

Why is engine braking harmful?

Let's start with a simple and subtle problem. The piston group of modern engines is arranged asymmetrically. In order to reduce the lateral load on the piston at TDC, the piston pin is offset relative to the cylinder axis, and the axis of the crankshaft does not coincide with the axis of the cylinders. When braking by the engine, all this asymmetry turns against the motor.

The lateral loads on the piston increase, and with the same torque module they will be even higher than during the working stroke. The asymmetry of the crankshaft plain bearings, connecting rod heads and piston pin is also designed for the power stroke, and not engine braking.

And all together this means that you need to brake with the motor carefully, without creating too much braking torque. Mechanics simply do not tolerate “reverse” loads well.

Articles / Practice Temperature suicide: why modern engines are doomed to overheat Boiling antifreeze in the radiator, steam, temperature arrow in the red zone - we seem to all know the symptoms of engine overheating and its consequences in the form of a warped cylinder head. The reasons are also long ago... 209773 59 43 07/13/2017

Increased wear of engine valves operating without gasoline lubrication during prolonged braking does not have a significant effect, especially since the temperature of the valves at this moment drops. But on engines that undergo the “cold run-in” so beloved by masters, which is essentially nothing more than forced idling, just for a very long time, the valve seats wear out an order of magnitude more intensely than in real operation.

Oddly enough, even a banal vacuum in the intake manifold can harm the engine. In engine braking mode, it is one and a half to two times higher than when idling. Accordingly, leaks through all seals increase, and the load on the crankcase ventilation system increases. Vacuum inside the cylinder block when the ventilation system is operating without a valve can lead to unauthorized air intake from outside.

Worn valve seals especially cause a lot of trouble. With a large vacuum at the inlet, oil in liquid form flows directly from the camshaft into the intake manifold. And the oil separator, which cannot cope with the load, adds some more from the crankcase. Oil is also drawn through the piston group, directly into the cylinders. If there is a turbine, also through it.

Such a “peak” oil supply, especially on an already worn-out engine, leads to carbon deposits on the spark plugs, breakdown of the catalyst and coking of the piston rings. Not to mention the emissions into the environment. And to top it all off, pressure drops affect the life of flexible intake elements - various pipes, valves and similar elements.

Articles / Practice The imperfection of spontaneity: reliability and problems of engines with direct injection “Into the new century - with a new power system!” It seems that European manufacturers began to implement the technology with this motto. What was left for them? Requirements to reduce fuel consumption forced... 59221 0 16 06/02/2016

The entry of dust and dirt from the exhaust manifold into the intake and directly into the cylinders is also due to the engine braking mode. It is especially dangerous when the catalyst is located close to the collector and is actively crumbling. And also when there are a lot of solid soot particles at the exhaust, which is typical for warm-up modes and load modes of engines with direct fuel injection .

All dust and dirt gets into the cylinders due to the fact that the valve timing has an overlap. This means that the engine, at least a little, manages to draw air from the exhaust manifold. If there is an exhaust gas recirculation (EGR) and it is leaking, which happens quite often, dust and dirt enter directly into the intake manifold. Well, any dirt in the cylinders means increased wear and risk of scuffing, as well as damage to the valves.

And the last trouble that threatens the engine in forced idling mode is shock loads due to a sharp change in the crankshaft speed and torque. In other words, simply careless handling of the clutch and gearbox. There are always torsional vibrations in a running engine, but usually they are not dangerous for the engine itself, and the attachments are protected by damper pulleys, freewheels or other means.

But everything changes if you slow down the engine. The supply of torque from the flywheel loads the crankshaft in a completely different way; in this mode it is more vulnerable, and besides, the power take-off to the auxiliary mechanisms and timing gear still occurs at the front end of the crankshaft. But much more unpleasant for the engine are possible sudden loads from the transmission. But the moments acting on the engine can be an order of magnitude higher than the torque of the motor itself. This is how, in most cases, the crankshaft is broken, the timing belt is damaged and it is twisted much higher than the nominal value.

There is no way to protect yourself from gross errors in the operation of the transmission during braking mode. And even the automatic transmission here, alas, is not a panacea - if the gearbox breaks down, shock loads do not spare the engine, although they are unlikely to be so great that they will break it right away.

Nothing can be done

So, we realized that the rumors about the dangers of engine braking are quite justified, especially if you have a car with a mileage of “over 150”. This does not negate the usefulness of engine braking technology in the name of traffic safety. If you don’t want to give up this useful habit, but at the same time you want to slightly extend the life of the engine, then what should you do? I dare to give some advice:

1. Do not use engine braking too much.

Brake in the highest possible gear, and try not to shift to lower gears when braking unless absolutely necessary. In normal city conditions, brake in fourth or fifth gears until the speed drops to the idle zone.

In the mountains, you should not choose a deliberately lower gear, so that it slows down, and pulls, and so as not to switch again. And even on slippery surfaces in cars with ABS at speeds of less than 30 kilometers per hour, you can safely finish braking in neutral.

2. Do not use prolonged engine braking in the urban cycle.

It is better to choose a speed at which you will have a minimum of braking at all. Engine braking is not a panacea for errors in choosing the speed of movement, and in terms of fuel consumption it is far from free. More than 70% of the machine's excess kinetic energy will be wasted.

And it is even more harmful to drive in low gears in the city with speed controlled only by the gas pedal, without using the brakes. This is only suitable if the standard brake system is in poor condition or the clutch or gearbox is inoperable.

Afterword

In the article, the author preferred to use the term “discharge” as an established one for describing processes in internal combustion engines in the technical literature. However, when editing and proofreading, we decided to pay tribute to the formal rules of the Russian language and replaced “ya” with “e”, especially since the essence of the phenomenon here is the same, but here we make a reservation so as not to offend the feelings of those who also consider the author’s spelling to be correct.

Survey

Are you engine braking?

Your voice

Total votes:

Mechanical engine braking

Reducing engine speed on a car with a manual transmission involves performing the following actions:

- Release the accelerator pedal.

- Depress the clutch pedal.

- When the car speed decreases, change to a lower gear.

- After the speed has been reduced as much as possible, engage 1st gear.

It is important to understand how to select a gear when braking with a manual engine. An error in this case can lead to motor damage. The fact that the gear has been selected incorrectly is indicated by too high speed readings on the tachometer and a sharp “nodding” of the car. This not only creates discomfort for the driver, but can also lead to damage to the internal combustion engine.

Incorrect engine braking modes, caused by untimely transition to lower gears, can lead to wheel locking, as a result of which the car may skid. In addition, violating the order of transition to low speeds increases wear on the motor and leads to the risk of damage to its parts.

When driving a car in 5th or 6th gear, you need to switch to 3rd gear to brake the engine, since 4th can provide a very slight reduction in speed. From 3rd or 4th gear you need to switch to 2nd. To make the switching process smoother, we recommend performing a “re-throttle”.

To completely stop the car, you need to use the car’s braking system after reducing the speed to 5-10 km/h.

How effective is engine braking? The answer to this question depends on several factors, the most important of which are experience driving a car, the ability to adequately assess the road situation, and the technical condition of the car.

Important

: using emergency engine braking techniques on a car that is equipped with an ABS system will lead to the loss of precious seconds, since this system copes with such situations much more effectively. But this rule also has its exceptions: if there is ice on the highway, then for safety reasons, to urgently reduce speed, you should choose the engine braking method.

There is an opinion that the engine braking system is more effective for cars equipped with diesel engines. This judgment is based on the fact that the compression ratio in diesel cylinders is almost 1.5 times increased. At the same time, there are no significant differences in the braking speed of gasoline and diesel engines.

When applying engine braking, you do not have to worry about increased fuel consumption. Fuel consumption will not exceed the values that are typical for stopping a car using the brake system. In both cases, the driver does not touch the gas pedal while reducing speed, so the level of fuel supply to the engine cylinders tends to zero. After gaining speed, fuel begins to flow in standard mode. Sometimes, for more economical fuel consumption, drivers use the coasting effect. If there is a long descent ahead of the car or the traffic light turns red, you can switch to neutral gear and roll so that the engine is idling.

We recommend

“Cleaning fuel system injectors: choosing products for gasoline and diesel” More details

When braking the engine, you need to monitor its speed. For gasoline power units, downshifting can be done at 2.5 thousand revolutions. The subsequent downshift is performed already at 1 thousand engine revolutions. It is not recommended to turn the steering wheel while braking, as this may result in loss of vehicle control.

Given the information provided here, we can conclude that it is important to acquire engine braking skills. This technique will be especially useful for owners of cars with a manual transmission.

Why does a car benefit from engine braking in some cases?

Summer heat and driving in dense city traffic negatively affects the service life of many technical components in the car. The power unit and gearbox may overheat, and the cooling system is working at its limit. In such conditions, it is very important to adjust the temperature balance. There are several ways to do this. Let's consider how engine braking can help in this matter and whether it is beneficial when operating a vehicle in hot weather.

As a rule, braking is carried out in second or third gear of a manual transmission. The greatest efficiency is observed when the tachometer needle is in the range of 4000 - 5000 rpm

How to brake with an engine. Motor braking occurs using the internal resistance of the vehicle mechanics. The propeller shaft causes the engine crankshaft to rotate, creating a situation in which mechanical losses reduce the vehicle's speed. The process of engine braking is actually the simplest. If you release the gas pedal on a car with a manual transmission, depress the clutch and shift the lever to second gear, the internal resistance in the transmission and engine will begin to increase. Moreover, the higher the speed, the greater the resistance will be. Because of this, the speed of the car decreases and stabilizes at 30 km/h.

As a rule, braking is carried out in second or third gear of a manual transmission. The greatest efficiency is observed when the tachometer needle is in the range of 4000 - 5000 rpm. Therefore, if you release the gas pedal at a speed of 80 km/h, you can safely engage 3rd gear. If you release the pedal at a speed of 60 km/h, you will need to put the manual transmission in second speed. You should not immediately engage first gear, as this will put an increased load on the engine, which can lead to damage to the timing belt.

Old brake fluid may boil in extreme heat. Gas bubbles form inside, which reduce the forces on the pads and the deceleration intensity decreases.

Brakes overheating . As a rule, engine braking is used when driving down a hill to reduce the load on the pads and calipers. When driving downhill for a long time, the driver is forced to constantly hold the brake pedal, which is why all elements in the system quickly overheat. At low speeds, the force of the incoming air is not enough to cool them. This is why old brake fluid can boil in extreme heat. Gas bubbles form inside, which reduce the forces on the pads, and the intensity of deceleration decreases. Engine braking can reduce this risk. The pads remain idle and the vehicle is slowed down by the load in the engine and transmission.

Fuel economy . If you periodically brake the engine, you can notice a slight fuel economy. During coasting, the electronics block the supply of fuel to the cylinders. The car is rolling, but the ignition does not work at this moment. As a result, while the car is going down the mountain, fuel is not consumed, which means the budget is saved.

The main disadvantage is the heavy load on the timing belt. Therefore, at the beginning of braking there is no need to sharply release the clutch pedal.

Motor cooling . There are enough systems in the car that operate using engine speed. This includes the oil pump. The higher the speed, the higher the oil pressure. During engine braking, the ignition is turned off and the pump creates maximum oil pressure. Circulation improves, which means heat is removed faster. The motor is cooled and lubricated at the same time. This advantage is especially relevant for turbocharged power units.

Coolant circulation . The motor shaft drives the cooling system pump. The faster the engine rotates, the more efficiently fluid will circulate in the cooling system. Therefore, when braking the engine, you can prevent the possibility of local boiling of antifreeze.

The main disadvantage is the heavy load on the timing belt. Therefore, at the beginning of braking there is no need to suddenly release the clutch pedal. In addition, a car that is braking with its engine cannot signal to other road users to slow down, since the brake lights do not work.

Bottom line . Engine braking is a useful technique that is often used when descending a long downhill slope. It has several advantages, but in the wrong hands it can cause a car breakdown or an accident.

Is engine braking possible on automatic?

In the previous section, we figured out that in order to reduce the speed due to the engine in a car with a manual transmission, you need to consistently shift to a lower gear. Now let's look at whether engine braking is possible with an automatic transmission?

Automatic transmissions have a more complex design and shorter service life compared to manual transmissions. The machines consist of planetary and friction mechanisms, an oil pump and other elements. In this case, interaction with the engine is ensured by the torque converter. On a car with an automatic transmission, you can also use engine braking, but it is less effective compared to a manual transmission.

The shape of the torque converter resembles a lifebuoy, inside which two turbines are installed, placed in an oil reservoir. There is no direct mechanical connection between the turbines, but when one of them rotates, the blades begin to direct oil flows in a circle and set the other in motion. This is how torque is transmitted.

When the car picks up speed, the hydraulic coupling is blocked, the shafts begin to rotate synchronously, and torque is transmitted directly. When engine braking occurs, the fluid coupling lock is disabled at a speed of about 50-60 km/h. At this moment, the oil damper begins to work, smoothing out the loads. The hydraulic coupling effectively compensates even for high loads on the automatic transmission, protecting the transmission from damage. The torque converter allows different rotations of the input and output shafts without damaging the entire mechanism. At the same time, load smoothing has a negative impact on the efficiency of speed reduction, so a car with an automatic engine brakes much slower than a car with a manual transmission.

Buyers of cars with an automatic transmission need to carefully study the operating instructions, paying special attention to the operating modes of the transmission. For some types of automatic transmissions, designers do not provide engine braking at all, and in other automatic transmission models this mode is blocked by the electronic control system. There are modifications of automatic transmissions in which the engine braking mode begins to operate without driver intervention. In some automatic transmission models, a manual gear shift function is provided to reduce the speed of the car due to the motor.

As an example, consider one of the possible options for engine braking on a car with an automatic transmission:

- You need to enable overdrive mode, after which the automatic transmission will switch to 3rd speed.

- When the driving speed decreases, you should set the 2nd gear, which will facilitate the braking process.

- The automatic transmission lever must be placed in the “L” position, which corresponds to 1st gear.

While the car is moving, the automatic transmission lever can only be set to the “D-2-L” positions; turning on other speeds can lead to damage to the gearbox (it is strictly forbidden to use the “R” and “P” positions while driving).

In most cases, electronic systems themselves control the operation of the automatic transmission. So, at high speed, the electronics will not allow you to force a switch to 1st gear.

The technology of engine braking in a car with a hydromechanical automatic transmission is reminiscent of driving a manual transmission with the clutch not completely disengaged (the gear is engaged, the engine hums, but the speed is not reduced as effectively). The car, moving downhill, rolls faster and faster, so the driver has to regulate its speed with the brake pedal.

Based on the information above, we can conclude that cars equipped with automatic transmissions can brake with a motor and have electronic systems that protect against breakdowns. In addition, the loads transmitted from the wheels to the automatic transmission are damped by a fluid coupling, and therefore it is impossible to damage the transmission when driving downhill. At the same time, an automatic transmission cannot provide effective engine braking, so you should not be particularly careful with the brake discs and pads.

We recommend

“Diagnostics of a car engine: review of means and methods” More details

If the instructions for a car with an automatic transmission indicate that this modification does not have an engine braking mode, then such a technique should be used only if absolutely necessary, so as not to shorten the service life of an expensive Automatic transmission.

To summarize, we note that engine braking is more effective for a car with a manual transmission, since in this case a rigid clutch of the transmission gears is ensured. When driving a car with an automatic transmission, you should rely more on the braking system.

What does engine braking mean?

When using this braking method, the vehicle's power unit resists the inertial force, which can increase the speed of the car. The motor can slow down a car moving in a certain gear with the minimum possible fuel supply.

If, as a result of pressing the gas pedal, the amount of fuel supplied increases and the engine spins up, then when it is released:

- the fuel entering the cylinders is reduced;

- the speed starts to decrease;

- The engine torque is no longer transmitted to the transmission.

The result is radically opposite - the load from the wheels is transferred through the transmission to the internal combustion engine of the car. As the compression resistance in the internal combustion engine cylinders increases, the speed of the vehicle decreases.

As the car moves, the gearbox automatically transmits the torque received from the car’s engine to the wheels in a dosed manner, in accordance with the set gearbox ratio.

When moving a vehicle with an automatic transmission in low gears (1-3), the maximum permissible amount of energy is transferred to the wheels. At this time, the car will not be able to accelerate to high speeds. Although even if you turn on the high mode, namely 4-6, and increase the speed, the resulting acceleration of a car with an automatic transmission will not be intense enough, the power transmitted to the wheels will decrease compared to the first three gears.

Benefits of Engine Braking

A lot of them. First of all, thus, while losing speed, the engine does not consume fuel. So what makes it come out? It's simple, the pistons are moved by the energy of the rotating wheels. This can be checked by monitoring instantaneous fuel consumption on the on-board computer. When driving in gear without pressing the accelerator, the consumption is zero, and when the neutral (“idle”) gear is engaged, it usually fluctuates between 1-3 l/100 km.

Another benefit of engine braking is the reduction in wear on brake discs and pads, which are often slow brake pads. Of course, when the road situation calls for it, you must use the brake.

Why is engine braking dangerous for a car?

Looking ahead, I will answer - nothing, except that at one moment, when the car’s speed is below 20 km/h, the engine will “stall”.

Apart from this problem, engine braking is not dangerous for the car and its components.

. The fact is that when the driver brakes the internal combustion engine while the gear is engaged, the crankshaft and all engine parts continue to rotate. The engine oil pump rotates together with them, the pressure created by it ensures the supply of oil to the rubbing pairs of the engine, ensuring their lubrication. Therefore, their operation in this mode is no different from engine operation at idle speed or in normal driving mode.

Engine braking and safety

In addition to reducing brake wear and reducing fuel consumption, engine braking also improves driving safety. A car "at rest" simply rolls along sluggishly and is not ready for sudden acceleration if necessary. When braking with the engine, we always have a specific gear selected, and if necessary, you can press the gas and accelerate quickly.

Engine braking – what to look for?

Reduce gears before turning on straight wheels. Depressing the clutch (this applies mainly to driving on snow) when cornering releases the rear of the car and can cause it to slide. Therefore, we must enter the turn in a certain gear. Sudden engagement of the clutch and ineffective deceleration can destabilize the vehicle even on a smooth road (again - more so on snowy/icy surfaces), so the clutch pedal must be operated accurately.

Engine braking with CVT

It is not at all difficult to reduce the engine speed in a car with a CVT. Many modifications of transmissions of this type have a corresponding function (the lever is set to the “L” position). The variator itself reduces the speed of the car, setting a suitable gear after the driver releases the accelerator if the lever is set to position “D”. With such driver actions, so-called dynamic engine braking automatically occurs.

To improve the dynamics of cars with a variable transmission and reduce fuel consumption, many owners of such cars want to disable the engine braking option in software. Experts do not recommend rushing to such a decision. Reducing the speed of movement due to the motor is a quite useful function. Every driver should master this technique, even if he is not a fan of extreme driving. Additional emergency driving skills help you avoid accidents in difficult driving situations.

When to use the engine braking method

The opinion that engine braking can harm a car has a right to exist (especially in the case of cars with more than 150,000 km on the speedometer). Nevertheless, from a safety point of view, mastering this technique will be useful for every driver. Here are a few recommendations that will help you use the engine braking technique in a gentle mode for the power unit.

1. You should not reduce the speed of the car too much using the engine . Apply engine braking in higher gears and try not to engage in lower gears unless absolutely necessary. In city traffic, brake in 4th or 5th gear until the engine speed drops to idle speed. On mountain roads, you should initially select a low gear (so that the engine pulls the car on climbs and reduces speed on descents without unnecessary shifts). Even if the car has an ABS system, on a slippery road at a speed of less than 30 km/h, the process can be safely completed by braking in neutral gear.

2. In city traffic, it is not recommended to use prolonged engine braking . In urban conditions, you should choose a speed limit that will require a minimum amount of braking. Using the motor to reduce speed will not save you from the consequences of mistakes when choosing a speed mode. In this case, about 70% of the vehicle's kinetic energy is wasted. Driving in city mode in low gears, adjusting the speed only with the accelerator pedal, without using the brakes, is harmful to the engine. This technique for driving a car can only be justified if there is a malfunction of the brake system, transmission or clutch.

In what cases should you use engine braking?

- If the car's brakes have completely or partially failed.

- When there is a long descent ahead.

- When driving on mountain roads and serpentines.

- If the road is wet or slippery, engine braking will provide more traction on the road surface.

In icy conditions, you should use the clutch carefully, as if you drop it suddenly, the drive wheels may lock. When performing engine braking, it is also important to pay attention to the length of the braking distance and the rapidity of the reduction in speed.

Which braking method is best to use?

What is the best way to stop a car - using engine braking or the brake system? In normal day-to-day operation of the machine, both methods should be combined. Braking using only the standard system is in many cases dangerous and is considered illiterate from the point of view of the quality of driving. The combined braking method involves reducing speed by pressing the brake pedal without changing gear. This method is the most effective and safe.

The use of engine speed reduction techniques and ABS braking provide different deceleration rates and therefore lead to different results.

An emergency reduction in speed with ABS occurs at the limit of permissible adhesion of the tires to the road surface. This braking mode allows you to stop the car as quickly as possible and reduce the braking distance.

It is quite difficult to carry out sharp engine braking, so with this method the braking distance will be maximum. We will not consider the case of a car stopping due to a drop in inertia forces in neutral gear (car coasting).

Thus, the question “how to brake - with the engine or using the braking system” takes on the following formulation: “what is the best way to stop the car - sharply or smoothly?”

It is impossible to give a definite answer. For example, let's take a situation when a car is moving along a city road, and ahead at a distance of about 0.5 km the traffic light turns red, so the driver decides to slow down. If you press the brakes so that the ABS is activated, the car will stop quickly, but not in the place where it is necessary. When driving at a speed of 60 km/h on a snowy road, the braking distance of a car with winter tires will be approximately 70 meters.

In the example described here, it would be more rational to use the engine braking technique. The driver can simply release the gas, and the car will begin to gradually lose speed as the engine speed decreases. Thus, the car will approach the traffic light at a minimum speed, and at the right place it can be stopped by lightly pressing the brake pedal. If the inertia of the car is not enough to reach the traffic light, then the driver can gradually press the accelerator, and, conversely, if the distance is not enough to stop, you can smoothly press the brake, slightly increasing the braking.

We recommend

“Repairing a Volkswagen Touareg diesel engine: weak points and types of repairs” Read more

Now let’s take a different situation. For example, a pedestrian suddenly runs out onto the road, or when approaching a closed turn at normal speed, the driver sees a car with the hazard lights on. In such cases, you need to understand that engine braking will not allow you to avoid a collision; the only way out is to sharply press the brake. And to the accompaniment of the crackling ABS, hope that the remaining space will be enough to stop.

As we can see, different braking options are used for different driving situations:

- If there is enough room to stop, the engine braking technique should be used;

- if the intensity of engine braking is insufficient, this technique should be combined with the stopping method using the standard braking system;

- if you doubt that the car will have enough space to stop, you should use combined braking from the very beginning (press the brake pedal while the gear is engaged);

- if there is critically little space to stop, you need to brake sharply using ABS (press the clutch and brake all the way).

Stopping a car with ABS allows you to disengage the clutch, since during sharp braking the engine will no longer affect the intensity of the speed reduction, but when the gear is engaged, it may stall. This is why car manufacturers and driving instructors recommend depressing the clutch when braking in an emergency.

What is important to remember?

However, there are also some nuances here that need to be remembered. So, for example, when braking with the engine, your brake lights will not work, because they are tied to the brake pedal. Therefore, other road users may not notice that you are braking, creating a potentially dangerous situation where an accident may occur.

Mechanical engine braking

— release the gas pedal; — depress the clutch; — after reducing the speed, engage second gear; — after further reduction in speed, first gear is switched.

If you move at a significant speed (in fifth or sixth gear), then you need to switch to third, but not fourth (since such a deceleration will be quite weak). These are general recommendations, but it all depends on specific driving conditions and road conditions.

For example, if you quickly shift into second or first gear, sudden braking can lock the wheels and the car may skid. Plus, this creates an increased load on the engine, which can also lead to increased wear and even breakdown of its individual elements. Therefore, it is important to follow a couple of rules here:

Article on the topic

Have your brakes failed? Seven options to stop a car

— Never engage first gear right away. — When switching to a lower gear, do not suddenly release the clutch.

Automatic engine braking

Engine braking with an automatic transmission has its own characteristics and entirely depends on the design of the automatic transmission. Therefore, it is important to first read your car’s operating documentation on this topic.

It is also worth remembering that if the car has ABS, then in most cases in an emergency it is still better to press the brakes rather than waste time on engine braking, which will still not give that deceleration. But in the end, these are precious meters that can prevent an accident, save your car, your health and perhaps even your life.

Is it worth braking with the engine: the opinion of car enthusiasts

- “Continuous use of the brakes is harmful because kinetic energy is converted into heat, which further reduces the efficiency of the motor. It’s better to drive in a quiet mode, smoothly picking up and reducing speed without using the brake pedal, but only using the engine by switching to a lower speed.”

- “How often do you need to brake using the engine to ensure noticeable fuel savings? If, when reducing speed using the braking system, the fuel consumption is about 1.5 liters, then to save this amount of liters you need to brake for a total of 100 km. Does it make sense to force the engine like that?”

- “Engine braking is a dangerous technique. With this method of reducing speed, the “stops” do not light up, so the driver driving behind may not have time to react to this maneuver in a timely manner. My car’s rear bumper was dented.”

- “Pressing the brake pedal on a long descent will lead to overheating of the discs and pads. For me, the question of the dangers of engine braking is not relevant. If you turn on the reduced speed in a timely manner, then this speed reduction option will not affect the motor in any way. It seems to me that the load on the motor when accelerating or braking is the same. If there is any difference, let the experts explain it to me. I find engine braking helpful when going downhill, downhill, etc.

We recommend

“How to drain the coolant correctly and fill it with new one” Read more

- “Experienced drivers (maybe immodestly, but I consider myself like that) use engine braking without thinking about the harm or benefit of such a technique. There's no harm in it. Motors, transmissions, and injectors and ECUs are designed to operate in this mode, not only in emergency situations. The injector cuts off the fuel supply to increase braking efficiency and reduce fuel consumption. When the speed drops to idle, the injectors start working again. The same principle was used in the operation of EPHH on carburetor engines. This type of braking saves fuel and also extends the life of brake pads and discs. Moreover, the process of reducing speed is often safer (especially on ice). The risk of transmission failure is present only if the box has already exhausted its service life.”

- “Once, while braking with the engine, I accidentally switched into 1st gear right after 3rd, and the car went into a skid, almost flying into the oncoming lane. After that, I use this technique extremely carefully.”

- “During sudden braking, unusual situations often arise. The car is capable of changing its trajectory; a car running parallel can skid or approach sharply. Using the engine braking technique, you can quickly correct the situation by pressing the gas pedal.”

- “Engine braking can and should be used. In some not very serious films there are moments when the “hero”, whose brakes have been broken by attackers, tries in vain to stop the car, nervously pressing the brake, and crashes. Even a not very experienced driver in such a situation would have long ago remembered that the engine can also reduce the speed. This technique can even be applied to cars with automatic transmission.”

How to brake with an engine

There are several ways to brake the engine, but most often only a couple of techniques are used. In this case, the techniques depend on the type of gearbox used, namely, CVT, manual transmission and automatic transmission.

On mechanics

The owner of a vehicle with a manual transmission must perform engine braking in a certain sequence:

- Release the accelerator pedal.

- Depress the clutch.

- After reducing the vehicle speed, use the manual transmission lever to shift to a lower gear.

- After further reduction in speed, you need to engage first gear.

If you do not follow the order of shifting to lower gears, the wheels may lock and create an emergency situation on the road. The wear and tear of the vehicle engine also increases.

When moving in 5th-6th gear of a manual transmission, you need to switch directly to 3rd, since switching to 4th will give a very slight deceleration of the car. If you are moving in 3-4 gears, then when braking with the engine you need to switch to 2. To simplify the transition, you should perform a “change of gas”.

How to brake with a manual transmission in a corner?

In fact, you don't need to brake when turning. Speed should be reduced before turning. But if such a need does arise, remember a few rules:

- It is strictly forbidden to suddenly press the brake pedal while turning.

- Do not press the clutch; you must turn while in gear.

With locked wheels, the car can fall off the trajectory. Therefore, you need to brake so that the wheels maintain rotation. The engaged gear gives the car additional stability.

Braking with a manual transmission on a descent

The next feature of driving a car with a manual transmission is braking on a descent. The main rule is not to separate the engine and transmission. That is, do not depress the clutch, do not put the transmission in neutral, only brake with the engine. The brakes should only be used to periodically slow down the vehicle briefly if the speed exceeds the safe one.

The fact is that during prolonged prolonged braking, for example when descending a steep mountain, the brakes can overheat and fail. Therefore, you should only brake downhill using the engine, so as not to subject the brake pads to heavy loads.

How to brake correctly on a slippery road?

The main rule on a slippery road is to prevent the wheels from locking. While the wheels are spinning, the car is controlled; if necessary, you can carefully change the direction of movement and go around an obstacle. With locked wheels, the car will no longer obey the steering wheel, and the trajectory of movement will become unpredictable.

When braking, you must try to keep the wheels on the verge of slipping. This can be done by periodically pressing and releasing the brake pedal. And this is done with the gear engaged. Since a car deprived of torque on the drive wheels can unexpectedly slip into a skid, which will be difficult to cope with without special skills.

Automatically

As for how to brake with an automatic engine, in this case you will need to do the following:

- Turn on overdrive so that the automatic transmission goes into third gear.

- When the car speed drops to 90 km/h, you need to switch the automatic transmission to second gear. After this, the car will begin braking.

- When the speed decreases to 50 km/h, you should switch the automatic transmission to L.

On a variator

In certain CVTs, the developers also provide a special mode that brakes the car using the engine - mode L, and to use it, just switch the lever. As a result, automatic braking of the car begins, while the system independently changes gears; it is enough for the driver to release the gas pedal. However, due to the fact that when turned on, it leads to excessive fuel consumption and a decrease in dynamics, it is often turned off at the software level.