How much does it cost to overhaul a VAZ and foreign car engine?

If you maintain a domestic engine in a timely manner (change engine oil and coolant on time), then its service life is about 200,000 km. At a certain point, it becomes necessary to overhaul the engine. Experts from the magazine “Behind the Rules” determined the price of such an event.

The main signs of the need for major repairs

:

- high oil consumption;

- smoking;

- loss of power;

- low oil pressure.

What operations does engine overhaul include?

:

- Removing the engine.

- Disassembling the engine and washing all its parts.

- Measurement of basic parts (cylinder block, crankshaft, cylinder head). Check for cracks and tightness of the cooling system jacket. Checking the crankshaft and camshafts for bending. Checking valve mechanisms. Checking the condition of the oil pump.

- Boring of cylinders for repair size or liner. In the latter case - installation of sleeves. Grinding of main and connecting rod journals to repair size. Replacement of valve seats and bushings. Machining the plane of the cylinder head.

- Engine assembly with installation of new rubber elements, seals and gaskets.

Price

Such a major overhaul of a VAZ engine along with spare parts in the Moscow region costs no more than 50,000 rubles.

For comparison, overhaul of a naturally aspirated engine of a foreign car

will cost approximately 180,000 rubles if replacement of basic parts (cylinder block, crankshaft and cylinder head) is not required.

Diesel engine overhaul

will cost 220,000–230,000 rubles

Turbo engine overhaul

- this is a plus of 30,000 - 100,000 rubles to the cost of an aspirated engine, i.e. 210,000 - 280,000 rubles.

Have you ever had to overhaul a VAZ engine? How much money did the repair require?

Let us remind you that during the operation of the engine and gearbox, tiny metal particles enter the oil, which appear due to the rubbing of parts against each other. A crankcase drain plug with a neodymium magnet helps collect metal debris and extends the life of the units by allowing them to operate in clean oil.

Source

How to determine the wear of oil seals on a VAZ-2110

An oil leak from under the clutch housing cover can be seen if you drive the car into an inspection hole.

If oil leaks are found on the car engine housing, you should not immediately buy new oil seals and change them.

The oil seal itself is a product made of a combined material. In this case, it is rubber and metal. The purpose of the oil seal is to provide a tight seal between the rotating parts of the car. In another way, the oil seal is called the shaft cuff.

Before changing oil seals, you need to check the following engine parts and systems:

- Check the oil supply system for blockages.

- Oil filter.

- Hoses for their integrity.

- Crankcase ventilation system.

Cuff edges

If all these systems are in working order, and oil leaks on the engine do not disappear, it means that the seals have most likely become unusable. The most characteristic sign that indicates the deterioration of the seals is traces of oil smudges on the edges of the cuff.

Since the crankshaft pulley rotates at high speed, oil gets onto the entire front part of the engine, and the accessory belt also becomes oily. Such a belt will have to be changed, since its contact with oil is unacceptable. In addition, there is another sign indicating wear of the rear oil seal. These are traces of oil on the joints of the clutch housing and cylinder block.

Engine overhaul VAZ 2110 16 valves price

Free check using 54 parameters

1 year warranty on repairs

Every driver dreams of his car driving like new for a long time after purchase. But this is not always possible due to engine problems. What to do if the Lada 2112 engine did not meet your expectations and unwanted damage or extraneous sounds appeared? Try to contact our service department immediately, don’t delay, engine failure requires immediate repair. After all, at an early stage, you can eliminate the malfunction faster.

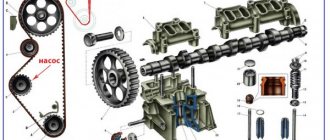

Cylinder block, connecting rods, pistons

The VAZ-2112 engine (16 valves) is equipped with a block cast from high-strength cast iron. At first glance, it seems that it is completely similar to model 21083. But this is not so. The main difference is the 10 mm smaller diameter of the head bolts. Other bosses for injection system sensors and another honing technology.

The connecting rods are made of steel by forging. They are distinguished by their I-section. These same connecting rods can be found on the 2110.

The pistons are steel, hollow, floating. The finger has a diameter of 22 mm. Length – 60.5 mm.

Turnkey stages of Lada 2112 engine repair

- Visual inspection of the engine, as well as its diagnostics using a special computer stand

- Classification of breakdown, its nature and complexity of solution

- Search for the most optimal solutions

- Dismantling and disassembling the power unit

- Repair or replacement of failed elements

- Motor assembly and installation

- Functionality check (multiple levels)

All identified problems must be corrected under appropriate conditions:

| Professional tools | Original spare parts |

| We provide estimates for spare parts and labor | Experts have more than 10 years of experience |

Additional repair services for VAZ 2112:

| Engine diagnostics | Grinding the crankshaft | Adjustment of valves |

| Engine overhaul | Cylinder block boring | Connecting rod repair |

| Removing and installing the engine | Replacing hydraulic compensators | Changing the engine oil |

| Replacing crankshaft seals | Replacing camshafts | Engine flushing |

| Cylinder head repair | Replacing the timing belt | Replacing the engine pump |

| Replacing the engine mount | Replacing the timing chain | Replacing an engine injector |

| Replacing the cylinder head gasket | Repressing pistons | Replacing the engine filter |

| Replacing the valve cover gasket | Block sleeve | Replacing glow plugs |

| Replacing the oil pan gasket | Replacing the oil pump | Engine replacement |

| Replacing the fuel pump | Replacing valve stem seals | Replacing the engine mount |

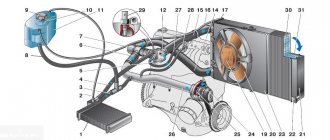

Timing device VAZ 2110 injector 8 valves

Many people are concerned about the question: Do the valves on the VAZ 2110 injection engine bend ? No, it doesn’t bend , the 8-valve injector does not suffer from this defect. But this does not mean that you should not monitor the timing belt. Because loosening and subsequent jumping of the belt by a certain number of teeth will lead to inevitable problems. It is worth paying special attention if engine oil gets on the belt; an oiled belt will not last long. Below is a detailed image of the timing diagram of the 8-valve injection engine “tens”. See the photo below.

When replacing the timing belt on a VAZ-2110, it is necessary to clearly align the marks on the camshaft and crankshaft pulleys; without this, the engine will not operate normally. Another important point is that when the tension roller moves to its original state, the marks shift as the belt tension changes. Therefore, carefully check whether the timing marks are clearly aligned before putting on the cover covering the timing belt.

We repair the following Lada 2112 engine models

1999-2008

- 2112 1.5 i (91 Hp) , Mechanical, 1499 cc, 91 hp

- 2112 1.5 i 16V MT (92 Hp), Mechanical, 1499 cc, 92 HP

- 2112 1.5 i MT (78 Hp), Mechanical, 1500 cc, 78 HP

- 2112 1.5 MT (71 Hp), Mechanical, 1499 cc, 71 hp

- 2112 1.6 i 16V MT (89 Hp), Mechanical, 1597 cc, 89 hp

- 21121 1.6 i MT (80 Hp), Mechanical, 1597 cc, 80 HP

- 21122 1.5 i MT (78 Hp), Mechanical, 1499 cc, 78 HP

- 21124 1.6 i MT (80 Hp), Mechanical, 1597 cc, 80 HP

Engines

Manufacturers offered five power units for the model, depending on the modification:

- A modification of the VAZ 21122 was equipped with a 1.5-liter 8-valve engine 2111;

- The 1.5-liter 16-valve engine 21120 was equipped with a modification of the VAZ 21120;

- The 1.6-liter 8-valve engine 21114 was equipped with a modification of the VAZ 21121;

- The 1.6-liter 8-valve engine 21124 was equipped with a modification of the VAZ 21124;

- 1.8-liter 16-valve engine producing 100 hp. offered for modification of VAZ 21128.

Our mechanics

| Viktor Nikolaevich | Vasily Ivanovich |

| Working with engines since 1979. |

Experienced senior mechanic.

The engine is the heart of the car. If you want to be sure of the quality of repairs, sign up for diagnostics and come to our car service center! Our technicians will advise you on all issues related to the operation of the Lada 2112 engine.

We guarantee high quality services and reasonable prices!

The model of the Volga Automobile Plant VAZ 2110, produced from the second half of the 1990s to the end of the 2000s, gained wide popularity among motorists. The updated design and aerodynamic properties allowed it to quickly win the hearts of its fans.

During the production process, several engine options were installed on the car in order to improve dynamic characteristics. But no matter how good the car is, the time comes when it is necessary to overhaul the engine. The average cost of its implementation in Russia is from 12,000 to 20,000 rubles .

Overhaul of 8 and 16 valve VAZ 2110 engines

The tenth model was created with extensive use of components and assemblies of the previous model - 2108. At the beginning, the car was equipped with a 1.5-liter VAZ-21083 8-valve engine with a carburetor. At the next stage, a more powerful VAZ-2111 engine with the same volume and number of valves, equipped with a direct fuel injection system, was installed.

On the next modification of the VAZ-21124 engine, the cubes were increased, which made it possible to increase the power to 100 hp. and show good performance. Finally, the sixth version of the VAZ 2110 car was equipped with an imported 2-liter, injection, 16-valve Opel X20XEV CTi engine, which allowed the car to accelerate to speeds of over 200 km/h.

Installation of spacers under the rear shock absorbers of a VAZ-2110 car

Often, even a new car, with a fully or sometimes partially loaded trunk, hits the wheel arch liners with its rear wheels. You can get rid of this trouble, and at the same time increase ground clearance, by installing spacers between the lower ends of the rear shock absorbers and the eyes of the rear suspension beam.

We chose spacers that allow the rear of the car to be raised to three different positions.

When lifting the rear of the car, three important parameters change: the position of the rear brake pressure regulator, the direction of the light beams of the headlights and the caster angle of the front wheels.

The first two parameters can be adjusted independently. Castor decreases when the rear is raised, affecting the stability and controllability of the car.

For a vehicle in running order and with a payload of 320 kg (4 people) in the cabin and 40 kg of cargo in the trunk, the wheel alignment angles must be within the following limits:

caster angle

Vehicle wheel alignment angles in running order

(without driver, passengers and cargo)

caster angle

To install the spacers, we hang up the rear of the car.

1. Using a 19mm wrench, unscrew the nut of the shock absorber lower mounting bolt, holding the bolt from turning with a head of the same size

2. ...and remove the bolt.

Similarly, disconnect the lower mount of the second shock absorber.

3. On one side of the spacer, the distance shown in the photo is greater than on the other. With this side we orient the spacer towards the longitudinal axis of the car.

Please note that the spacers are mirror symmetrical and can be installed on both the right and left side of the car.

4. For proper installation of the spacer, it is necessary that the line passing through the centers of the holes for fastening the spacer to the beam and the lower end of the shock absorber is close to vertical and coincides with the longitudinal axis of the shock absorber.

Therefore, when installing the selected spacer on the right side of the car, only one hole can be used to attach the shock absorber.

5. If this option does not suit you, we place this spacer on the left side.

In this case, you can use one of the other two holes to mount the shock absorber.

We install the spacer on the beam eyes.

6. Place a spacer between the beam eyes and insert a bolt.

Place a nut on the bolt and tighten it to a torque of 70–85 Nm (7.0 -8.5 kgf∙m).

In this position of the spacers, the rear of the car can be raised to the maximum or minimum amount.

We chose the bottom hole

7. Insert the bolt into the holes of the spacer and into the shock absorber bushing.

Place a nut on the bolt.

Similarly, install a spacer between the lower end of the other shock absorber and the eyes of the rear suspension beam.

We tighten the nuts securing the lower ends of the shock absorbers to the spacers in the “car on wheels” position with a torque of 70–85 Nm.

To correctly install the pressure regulator, press the rear of the car with a force of 400–500 N.

8. Using a 13mm wrench, loosen the bolt securing the pressure regulator to the regulator drive lever bracket

9. ...and move the bracket with a screwdriver so that the gap between the lever and the lever spring is within 2.0–2.1 mm.

We check the gap with a drill or a piece of wire of the appropriate diameter.

After adjustment we carry out a road test. An observer outside the car should note that the rear wheels lock, which should occur slightly later than the front wheels when braking sharply from a speed of 30–40 km/h.

If the locking is too late, we reduce the gap; if it is early (the locking of the front wheels is ahead of the locking), we increase it, with the obligatory check in the manner indicated above.

To adjust the headlights, we place the equipped car (with a spare tire, tools and a full tank of fuel) on a flat horizontal platform 5 m from the screen - a light wall of a building, garage, etc.

We check and adjust the tire pressure on all wheels to normal, and place an assistant in the driver’s seat or place a 75 kg load.

We mark the screen as shown in the figure (in this case, the intersection points of line 1 with lines A and B should be at the height of the centers of the headlights).

Set the headlight hydraulic adjustment handle to the minimum vehicle load position.

What determines the cost of overhauling a VAZ 2110 engine?

The cost of repair work depends on the following main factors:

- Models of the installed engine.

- The degree of wear of its components and parts.

- Number of spare parts to be replaced.

- Availability of additional work on repair of cylinder head, shafts, cylinders.

- Car mechanic qualifications and workshop equipment.

During the overhaul process, it may be necessary to replace or repair other engine-related components and assemblies, requiring additional financial costs.

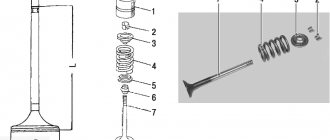

What are cylinder head and valves? How are they connected?

So, valves in a car are an element of the cylinder head (cylinder head). It is this part that is responsible for the processes of fuel combustion in the engine and the removal of exhaust gases (see figure).

Its components include:

The top of the cylinder head also contains other parts, such as camshafts, backing washers, etc. The gas distribution mechanism (GRM) is also located here.

Non-removable parts of the cylinder head include valve seats, which serve to ensure the tightness of the timing belt. Fixed parts also include valve guides.

A typical problem faced by VAZ 2112 car drivers is the need to replace valves. The reasons for the breakdown can be different; they often fail due to overheating of the car engine.

To avoid this, experts recommend that while driving you periodically pay attention to such points as:

The presence of any of these symptoms may indicate a valve malfunction.

Of course, the best solution in such a situation is to contact a service center. However, a difficult financial situation or lack of time often does not allow resorting to the services of professionals. Then you can try to fix the problem yourself.

The main stages of overhauling the VAZ 2110 engine

The process of restoring the performance characteristics of the power plant takes place in several stages:

- Dismantling of the internal combustion engine, complete disassembly, washing of parts.

- Inspection of rubbing surfaces and abutment planes, identification of damage.

- Control of the geometry of the crankshaft and camshafts.

- Determination of replacement parts.

- Processing of crankshaft journals, cylinders, coating.

- Elimination of geometric defects of shafts.

- Refurbishment of cylinder head.

- Complete with new liners, piston rings, gaskets, seals.

- Assembly and return of the engine to the car.

- Replacement of filters, connection of all systems.

- Run-in and final adjustment.

The need for additional work may become clear during the repair process. So sometimes there may be a need to repair the fuel or oil pump, clean the carburetor, and in the case of injection, repair the injection system.

How much does it cost to overhaul a VAZ 2110?

Depending on the type of engine, the estimated cost of removing/installing an 8-valve engine is from 3,000 rubles , and a 16-valve engine is from 4,000 rubles . The approximate cost of cylinder head repair, excluding the cost of parts, is from 3,500 rubles and from 5,500 rubles , respectively. On average, boring a cylinder block will cost from 1,200 rubles. Replacing sleeves will cost from 2500 rubles .

The average cost of a major overhaul of a VAZ 2110 engine equipped with 8 valves will be from 12,000 rubles . Repairing an engine with 16 valves will cost from 19,000 rubles .

Landing VAZ 2110 – photo, description on VAZ-2110.net

Lada 2110 Without springs.

URGENT SALE! I'm selling KiK Torus wheels with Yokohama 165/60 tires.

Photo of VAZ 2110 on landing.

VAZ 2110 planted photo.

ProPosadku Part 2 WITHOUT LANDING – AUTO.NET.

Photo of a VAZ 2110 landing.

VAZ Priora interior photo.

Tightly tinted (Bpan – basin – vaz – auto).

The landing at the moment is as in the photo! after some minor modifications the car lay down.

Recommendations from a Lada 2110 car owner.

Nya pictures – planted VAZ 2110 – Nyashki.

Bogdasha 2110. very happy)already torn panties around Krasnodar)Che is pne.