Renault Captur is a new product on the Russian market. It is a full-fledged crossover primarily for city roads. Where are models assembled for the Russian market? Not as far as it might seem! Assembly began in Russia at the end of March 2021. But, despite the short period of stay on the market, today Renault Captur can easily compete with its recognized favorites.

Renault Captur

The main advantage of this model was the price. This is what first attracts buyers. The reason for this price was the opportunity to produce models at a plant in Russia. The assembly shop is located in Moscow.

General information about Renault Captur

In March 2021, a plant opened in Moscow, where they began to assemble the French model for the local market. This company is called Avtoframos. Rodina Kaptur and the Russian automaker collaborated and created this project back in 1998, but at that time, we were talking about other models, and not about Renault Kaptur. Then all the production space was taken from AZLK, which had already completely ceased to exist due to ruin. And now this is the place where great cars are made.

It is unknown how much money was spent to improve the plant and adjust it for the production of Renault Captur and other modern European models. However, it is a well-known fact that the modernization process took several years of continuous work, due to the regular replenishment of the Renault model range. Outdated conveyors and production equipment were completely replaced.

Avtoframos plant

This enterprise began with the assembly of other models - Logan and Megan. They are also known all over the world, but in Russia they are popular only in the western part of the country. The opening of the assembly line where Renault Captur began to be assembled took place only in 2021. By the way, in this regard, it was again necessary to modernize the existing equipment. Avtoframos could not have done anything else - Renault Captur is a car completely different from other models of the manufacturer.

The latest equipment, assembly machines of the latest model, conveyor lines of a new format - all this was purchased for the plant in Moscow, and with the help of this the assembly of the increasingly popular Captur began. A new round of assembly also required additional labor, because Avtoframos’ existing staff was not enough.

Is Kaptur stronger than Duster?

The crossover body of the new model is designed in such a way that all doors are recessed into niches when closed (see photo). Duster is characterized by a different scheme: the door simply covers part of the side of the body. And the more complex the relief, the stronger the part. Everyone knows this.

Sidewall welded body Kaptur

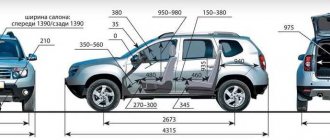

All dimensions of the Captur crossover are smaller than those of the Duster. At the same time, the metal used to make different machines is the same; it is galvanized. This means we have another argument in favor of the strength of the compact body. We wrote in detail about the differences between Captur and Duster in the material: how Renault Captur differs from Duster.

On the assembly line where Renault Captur is assembled, it is not customary to change the thickness of the metal depending on the model. Some people think that the metal is too thin for full-size crossovers. But it is suitable for more compact bodies. Moreover, it’s perfect.

Differences between domestic assembly

The options for domestic and European assembly have significant differences:

- Body. In Europe, the Captur is created on the basis of the modular Clio platform, a model from the same manufacturer. In Russia, assembly is carried out on a traditional GA module, more familiar to French crossovers. It is the one that is more suitable for Russian roads. More adapted and improved.

- Diesel. The fact is that the original Kaptur is a small-displacement diesel engine without all-wheel drive. Such models are not popular on the domestic market - Russian and French marketers have found this out, and therefore a more familiar version of the car is produced at the Moscow plant.

- Equipment. Even though the modernization process lasted several years, it is still inferior to the assembly of a car based on the Renault Clio modular platform. However, this fact was decisive when they planned the release of Captur in Russia.

The car is assembled at a Moscow plant in two shifts. It is handled by approximately 3,000 staff members. Another 1,500 people are involved in the remaining production process.

Assembly at the Avtoframos plant

Also, the full production cycle is used and five immutable rules apply:

- Quick sort

- Strict adherence to production standards

- Order

- Clean workplace

- Employee development and personal skills improvement

Second generation

| Renault Logan II | |

| Total information | |

| Manufacturer | Dacia |

| Years of production | - present tense |

| Other designations | Renault Symbol, Dacia Logan |

| Design | |

| Platform | Dacia M0 |

| Engine | |

| 0.9 L l3 1.2 L l4 1.6 L l4 1.5 L diesel l4 | |

| Transmission | |

| 5-st. Manual transmission | |

| Body modifications | |

| Body type | 4-door sedan (5-seater) |

| Length | 4346 mm |

| Width | 1733 mm |

| Height | 1517 mm |

| Station wagon | |

| Manufacturer | Dacia, Renault |

| Body type | 5-door station wagon (5-seater) |

| Length | 4492 mm |

| Width | 1733 mm |

| Height | 1550 mm |

New Renault Captur 2021

In 2012, at the Paris Motor Show, Dacia presented the second generation Logan. In Turkey, the car is sold under the name Renault Symbol.

The new Logan has greatly changed the external and internal parts. The front suspension of the second generation Logan is MacPherson with a shock absorber strut and spring, two silent blocks in the lever and a ball joint. The rear suspension is a torsion beam with separately mounted springs and double-acting telescopic gas-filled shock absorbers. Logan also has a large trunk with a volume of 510 liters, and you can also fold the rear seats to increase it.

Logan MCV

Logan MCV

Logan MCV was presented in 2013 at the Geneva Motor Show. From a technical point of view, the station wagon is completely identical to the sedan. The trunk volume is 573 liters, but can be increased to 1518 liters. Sales of the MCV version began in the second half of 2013.

The MCV model is not sold in Russia.

Restyling

In the fall of 2021, the updated Renault Logan and Sandero of the second generation were presented at the Paris Motor Show. The sedan received modified headlights, a radiator grille, and both bumpers. There are new lights at the rear. There is only a steering wheel in the interior. There are new engines under the hood.

In Russia

In March 2014, sales of the 2nd generation Renault Logan started in Russia; assembly is carried out at the AvtoVAZ plant.

On the Russian market, Logan is offered with one of three versions of the 1.6-liter engine: 82, 102 and 113 hp. Engines with power of 82 and 113 hp. equipped with a manual 5-speed gearbox, 102 hp engine. — 4-speed automatic transmission. With an 82 hp K7M engine, the acceleration time from 0 to 100 km/h is 13.9 seconds, and the top speed is 163 km/h. With the K4M engine (102 hp), the acceleration time from 0-100 km/h is 11.7 seconds and the top speed is 171 km/h. Since June 2021, the H4M engine (113 hp) has become available, acceleration from zero to 100 km/h takes 10.7 seconds, and the top speed is 177 km/h.

In 2021, sales of the Renault Logan Stepway sedan with increased ground clearance, as well as the Logan Stepway City version equipped with a CVT, began in Russia.

In other countries

In 2013, sales of the sedan began in South America. There it was presented at the Buenos Aires Motor Show.

In 2014, sales started in Egypt.

Sales started in Colombia in 2015. There Logan is produced at the Renault SOFASA plant.

Renault Symbol III

- Turkish version of Logan. Symbol was presented at the 2012 Istanbul Motor Show. Produced in Bursa, Türkiye. Sales of Symbol started in 2013, simultaneously with Tunisia and Algeria.

Ratings

The car received the Car of the Year award in 2013. In the 2021 ranking of the reliability of used cars by the German Association for Technical Supervision (VdTUV), Dacia Logan took the lowest positions in all age categories.

Safety

EuroNCAP tested the Dacia Logan MCV in 2014.

| Euro NCAP | |||

| overall rating | |||

| 57% | 75% | 55% | 38% |

| adult passenger | child | a pedestrian | active safety |

| Model tested: Dacia Logan MCV 1.5 diesel Base, LHD (2014) |

The main features of the enterprise where Renault Captur is assembled

Modernization took place at the expense of French investors, who initiated the idea of producing Renault Captur in Russia. The innovations included:

- Three new robotic systems responsible for floor welding

- Replacement of 30% of welding equipment

- The emergence of new technological control points

- Increasing paint shop productivity through modernization

- Upgrading the qualifications of all staff

Returning to the issue of the power unit, it is worth noting that the 1.6-liter engine is produced at, but the 2-liter engine is supplied from Spanish manufacturing plants.

During production, quality checks occur. It primarily concerns welding seams and body tightness. This check takes place as follows: two cars are selected at random from each batch and sent to the control point.

Absolute leader

Production of Renault Captur began in March 2021 in Moscow. The company that took on the role of manufacturer of this SUV bears the proud name “Avtoframos”. When and how did such a company appear?

According to official information, Avtoframos, the brainchild of a joint alliance between the Russian manufacturer and France, arose back in 1998, when there was no talk of such a model as the Renault Captur.

All the sites were borrowed by AZLK, which by that time had already gone bankrupt and ceased to exist.

Obviously, for modern cars of the European level, outdated conveyor lines and equipment were not enough. It is difficult to say how much money was needed for Avtoframos to become a full-fledged automobile enterprise, but it is absolutely known that the re-equipment continued for several years, without stopping even for a month, due to the constant replenishment of the concern’s model range.

Gradually, the Russian company began producing domestic versions of Logan, Megan, Scenic and many other world-famous models. In 2021, the exact date for the launch of the Renault Kaptur assembly line was announced, and therefore the equipment once again had to be modernized. This is not surprising, because Renault Captur is a completely new model, and it is unreasonable, and not particularly advisable, to base it on the technology for other products of the concern.

As a result, new equipment was brought in to begin production of the Captur, including new conveyor lines and assembly machines. In this regard, Avtoframos had to replenish its staff and announce a recruitment drive; for Renault Captur the old staff would clearly not be enough.

Features of welding during domestic assembly

It is also worth noting that during domestic assembly even the welding of the seams is different. The process, like that of the French manufacturer, is organized at the highest level. And this despite the fact that the principle of flexible production is used, that is, the conveyor can be reconfigured at any time to assemble another model.

Car assembly at the Avtoframos plant

Car enthusiasts claim that the Russian-assembled Renault Captur is much stronger than the original version. And the secret lies precisely in the difference in welding. In Russia, the body for a car of this model is made of two large parts, qualitatively welded together. Optimal part geometry also adds strength.

Features of Russian production

Wherever the 2021 Renault Captur for Russia is assembled, they have a high-quality body, an efficient engine and an attractive design. has been operating in the automotive industry for many years, JSC Renault Russia did not miss the achievements of its old owners and continued its successful path. The production is famous for being a respectable factory where the following rules apply:

- Regardless of where the assembly takes place and at what stage, manufacturing standards must apply.

- The workshops of the car plant are kept clean and orderly.

- Each employee receives a package of necessary knowledge and skills.

- Employees regularly undergo advanced training or improve their skills.

Every motorist understands that it does not matter where the country of manufacture is located, the main thing is that the vehicle complies with established norms and standards. Avtoframos assembles Renault Captur under the strict guidance of the French concern.

In addition to the basic rules, the plant uses innovative technologies. Before production began, the plant where Renault Captur is assembled was modernized. Important changes include:

- Robotic systems for welding work were installed at the car plant;

- Old equipment was replaced;

- Improved manufacturability;

- The paint shop has been modernized;

And most importantly, before starting production of the Captur, the Renault concern trained personnel and issued the appropriate certificates. The two-liter engines of this Renault model are produced in Spain. But the standard ones on . CJSC Renault Russia, where several French cars are produced, has changed significantly after Andrei Pankov became its general director.

Features of welding of the Russian crossover

Due to the fact that the welding shop has undergone modernization and 1/3 of the equipment has been replaced, the Russian assembly of Renault Captur is no different at this stage of production. In accordance with the rules, each batch is checked for the quality of the tightness of the car body and welding seams. The model for Russia is superior in terms of strength to the European version of the Captur - thanks to the type of body assembly, the domestic one is made of two parts, which means it is stronger.

Painting and assembly

After welding work, where innovative body assembly technologies are used, the car undergoes the necessary inspections according to the standards, after which it is treated with galvanizing and priming. Next, the body and components are painted in a special workshop where modernized equipment is used and qualified personnel work. After finishing the painting work, the car is sent to the final vehicle assembly workshop.

Some motorists believe that Renault Captur from a Russian manufacturer does not have the proper quality and purchase European analogues. But according to test drives, the domestic model is in no way inferior to its counterpart from Europe, and even surpasses it in terms of durability and paint quality.

or “Avtoframos”, this is an indicator of which direction other manufacturers should move. The general director of the plant, Andrey Pankov, was able to change the old concept of the company and create efficient production. The plant has a set of rules that specifies the daily routine, the number of shifts, the duration of lunch and other aspects of the life of the staff. This made it possible to create a productive plant that produces up to 188 thousand cars. In addition to the Kaptur, the car plant produces Duster and Terrano.

Conclusion

In the domestic market, Renault Captur occupies one of the leading positions. Moreover, preference is given to domestic assembly. It's all about the strength of the body and the no worse quality of the car, as well as adaptability to drivers.

Every year Avtoframos produces almost 188 thousand units of Renault Captur. This figure regularly grows due to the growing popularity of the crossover. It is also worth noting that regular test drives prove the quality of domestic assembly.

Read further:

Where is Renault Arcana assembled?

Renault Captur: colors

Tuning Renault Captur

Renault Captur Extreme

Renault Captur: configurations

Where is Renault Captur produced for Russia?

One of the most popular crossovers on the domestic market is the Renault Captur. The car of the French company is famous for its quality and excellent performance. However, very often you can hear dissatisfaction addressed to Russian-assembled Capturs.

Photo: Renault Captur

In today's article we will talk about Renault Captur, which is produced in Russia.

The compact crossover is assembled at the Moscow automobile plant, which has been operating since 1998, and is known to all car enthusiasts under the name “Avtoframos”.

It is worth noting that at this enterprise, in addition to Captur, Nissan Terrano and its French brother Renault Duster are also made for Russia.