The Mitsubishi Lancer 9 has several engine models in its line of power plants. Thanks to this, the buyer has the opportunity to choose between maximum dynamism and efficiency.

Power units differ in design. They do not have significant drawbacks and shortcomings, so they do not cause any special problems to the car owner during operation.

Lack of on-board computer in the nine

The Mitsubishi Lancer 9 is equipped from the factory with one of three sixteen-valve gasoline injection power plants:

- 4G13, 1.3 liter, single camshaft, SOHC design;

- 4G18, the volume of which is 1.6 liters, the camshaft is SOHC;

- 4G63, which is a 0-liter power plant with two DOHC camshafts.

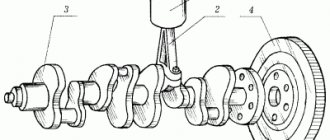

The cylinder block of all Mitsubishi Lancer engines has a similar design. The only difference is the volume of the working chambers. The power plants have a vertical in-line arrangement of four cylinders. The main block is manufactured using a single casting method from high-strength cast iron. The crankcase contains five crankshaft supports made in the form of partitions. The cylinder blocks have special bosses necessary to accommodate power plant components and attachments.

There are slight differences between SOHC and DOHC engine cylinder blocks. It lies in the fact that engines with two camshafts have a pair of balancing balancing shafts. To place them in the cylinder block of DOHC engines, there are special seats for bearings.

There is also a difference between SOHC and DOHC engines in the methods for limiting the axial movement of the crankshaft. In the first case, flanges are used on the middle main journal, and in the second, fixation is made using two half-rings located in the seat of the middle main bearing.

The flywheel is only present on vehicles with a manual gearbox. It is the same for engines with one and two camshafts. In the case of an automatic transmission, a torque converter drive disk is installed instead of the flywheel.

The pistons of the 4G13, 4G18, 4G63 engines are made of an aluminum-based alloy. They have grooves for the oil scraper and two compression rings. There is a technological hole in the upper head of the connecting rod that allows oil to splash onto the bottom of the piston, cooling it. This increases the resource of the power plant. The connecting rod itself is made of steel. It has an I-section.

The crankcase ventilation system in Mitsubishi Lancer 9 engines is a closed type. In all operating modes of the power plant, a vacuum is formed in the crankcase. This reduces the risk of leaks through seals and seals.

Cylinder block

The engine is mounted in the Mitsubishi Lancer 9 on four supports. To reduce the amount of vibration transmitted to the body during operation of the power plant, special rubber cushions are used.

Comparison of SOHC and DOHC engine cylinder heads

The main difference between the cylinder heads of SOHC and DOHC engines is the number of camshafts. At the same time, the number of valves per cylinder for power plants is the same and equals 4.

SOHC powertrain cylinder head

The camshaft of the 4G13 and 4G18 engines has five bearings. It actuates the valves using rocker arms. To compensate for the thermal gap, hydraulic pushers are used. The exhaust valve rocker arms are double.

The 4G63 engine has two camshafts. One of them controls the intake valves, and the other controls the exhaust valves. Each camshaft has six bearings.

The design of DOHC engines involves acting on the valves using push levers. The hydraulic tappets are screwed into the cylinder head. In addition to compensating for the thermal gap, they additionally serve as supports for the levers.

DOHC engine cylinder head

Despite the differences, the cylinder heads of SOHC and DOHC power units have some common features. They are cast from aluminum alloy. The intake and exhaust valves are located on opposite sides of the cylinder head. The hydraulic compensators of the 4G13, 4G18, 4G63 motors are connected by channels to the lubrication system of the power unit.

The main causes of breakage: how to avoid it

Engine UMZ-417. timing mechanism

One of the frequently asked questions regarding the timing belt is why it breaks. This includes:

- wear and tear directly due to long-term use or poor quality of the product;

- the pump or rollers are jammed;

- a breakdown occurred and the camshaft “caught” a wedge;

- The crankshaft is jammed.

The best way to solve a problem is not to create a problem for yourself, so we recommend that you familiarize yourself with the basic rules that will help you avoid such a breakdown:

- The belt must be replaced on time (every 40-50 thousand kilometers);

- regularly check the seals for leaks;

- if you are replacing timing components, use only high-quality parts;

- check the belt tension. Its slippage can also cause damage to valves and cylinders;

- check the integrity of the water pump and rollers.

These tips will help you avoid the problems described above.

Main technical characteristics

The main technical characteristics of the power plants used on the Mitsubishi Lancer 9 are shown in the table below.

| Engine model | 4G13 (SOHC) | 4G18 (SOHC) | 4G63 (DOHC) |

| Power plant volume, cubic cm | 1299 | 1584 | 1997 |

| Maximum engine power, hp at rpm | 82/5000 | 98/6000 | 135/5750 |

| Piston stroke, mm | 82 | 87.3 | 88 |

| Cylinder diameter, mm | 71 | 76 | 85 |

| Compression | 9.5 -10 | 9.5 | 10.5 |

| Recommended fuel for refueling | 92-95 | 95 | |

| Recommended engine oil lubricant | 5W-20 5W-30 10W-40 With high mileage: 10W-60 15W-50 | 10W-50 With high mileage: 5W-40 5W-50 | 0W-40 5W-30 With high mileage: 10W-30 10W-40 |

| Lubricant filling volume | 3.3 liters | 3.5 liters | 4 liters |

| Recommended engine oil change interval (in this case, the lubricant should be changed at least once every two years, regardless of mileage) | every 5-10 thousand km | every 5-10 thousand km | every 7-10 thousand km |

The fuel consumption of the Mitsubishi Lancer 9 in various configurations is shown in the table below.

The maximum speed and acceleration of up to 100 kilometers per hour depend not only on the power of the power plant, but also on which gearbox the Mitsubishi Lancer 9 is equipped with. These technical characteristics can be found in more detail in the diagrams below.

Maximum speed

Acceleration time to 100 kilometers per hour

Motor reliability

This unit does not have very good reliability indicators and requires special attention during the entire period of operation.

Even cars that have just rolled off the production line are sometimes characterized by increased oil consumption in large quantities. Violation of regulated maintenance is guaranteed to lead to increased wear of the cylinder-piston group and other elements. In the future, this will lead to the following consequences: the appearance of oil in the spark plug wells, the piston rings may become stuck, and the connecting rod bearings and main bearings may rotate, since the engine oil is not distributed correctly due to wear of the cylinder-piston group. The designers installed a chain in the gas distribution mechanism. This is a good solution because it gives greater reliability to the engine. The removal and installation of the timing chain must be carried out by highly qualified specialists, since incorrect installation of the chain can lead to serious problems, even to the point of requiring expensive engine repairs.

Engine life

The power plants that are installed on the Mitsubishi Lancer 9 do not have significant design flaws. This allows the owner to drive the car long distances without major repairs.

The smallest 4G13 engine is capable of covering 250-300 thousand km. It is not particularly sensitive to fuel quality. Many car owners note that even with worn-out power units, you can drive for a long time without major repairs, accepting up to a liter of oil per 1000 km.

The 4G18 power unit is designed on the basis of the 4G13. It is also capable of providing 250-300 thousand km before overhaul. Due to greater thermal loads, compared to a 1.3-liter engine, the 1.6-liter engine is more sensitive to oil quality.

The service life of the 4G63 engine largely depends on operating conditions. A sporty driving style can damage the engine within 120-150 thousand km. An incorrectly reflashed control unit can reduce the life of the power unit to 60-80 thousand km. In case of measured driving and careful treatment of the car, the 4G63 engine will require repair only when the mileage exceeds 450-500 thousand km.

Peculiarities

It's essentially a regular compact, but a little different than the others. It was never offered as a hatchback, which was one of the reasons for the lack of interest in Europe.

Mitsubishi Lancer has a fairly long wheelbase - 2600 mm. Like modern Golf cars, Lancer 9 is quite spacious inside. Even rear seat passengers can't complain about the lack of space. The 430-litre trunk won't disappoint either.

Lancer, apart from the independent rear suspension, does not stand out from its competitors in anything special. When creating it, fairly simple design solutions were used. Even the independent rear suspension is simple compared to similar designs. It’s better to forget about advanced multimedia systems right away.

The front panel is so primitive that it seems that the stylists were devoid of imagination. But for those who value simplicity, you won't find a better dashboard in this segment.

Due to the small number of switches, it seems that the car is very poorly equipped. Mitsubishi offered only the bare minimum: two airbags, electrically operated windows and mirrors, and air conditioning. There was also ABS. However, in the sports version you will be fascinated by the steering wheel, aluminum inserts, real sports indicators from the Evo version, leather upholstery and very comfortable seats with developed lateral support.

The biggest advantage of this car is its obedience on the road. There is an opinion among drivers that the Lancer behaves so well that the ESP system is a waste of money. Few people know that in independent tests, the Japanese sedan proved to be no worse than the reference Ford Focus. Unfortunately, it cannot compare with the Focus in terms of comfort. Although a lot depends on the version and configuration. The most interesting is the Sport version with a slightly lowered suspension and 16-inch low-profile tires. This car is relatively stiff, but it drives excellently.

Typical problems of power units

The most common problem with a 1.3-liter engine is floating idle speed. This is due to the design features of the throttle valve. Also, many owners complain that the engine stalls when the mileage exceeds 120-150 thousand km. One of the main problems of the 4G13 is the timing drive. If the belt breaks, the piston bends the valve.

Engine Mitsubishi Lancer X 2.4 liters

Car owners have complaints about the 1.6-liter internal combustion engine due to increased oil consumption. This is due to the early occurrence of the piston rings. You can get rid of the problem by decarbonizing or overhauling the power unit.

The distinctive feature of the 4G63 in the form of two balancing shafts often causes problems for drivers. Despite this, the engine is very reliable.

Transmission

Sometimes troubles also occur within the transmission. So, in a manual transmission paired with 1.6 and 1.3 engines, owners are faced with premature wear of the primary or secondary shaft bearings, and sometimes the differential bearings.

The clutch lasts a long time even in difficult conditions (more than 150-200 thousand km), and a good set will cost about 4-5 thousand rubles.

But a machine gun is quite difficult to kill.

The feasibility of repair and replacement with a contract motor

During the operation of a Mitsubishi Lancer 9 car, the car owner may encounter a situation where most of the parts and components of the power plant have exhausted their service life. In this case, the owner has several options:

- Superficial cosmetic repairs. Suitable for pre-sale preparation, or in case of infrequent use of the car. The piston rings are decarbonized, parts and components that interfere with the performance of the power unit are changed. The cost of superficial troubleshooting ranges from 3 to 15 thousand rubles.

- Major renovation. Recommended if the car owner is the first owner. For major repairs, you will need to remove the motor. The cost of restoring an internal combustion engine is about 30 thousand rubles.

- Replacement with a contract power unit. It’s better to take it from foreign car wreckers. A contract engine costs about 40-60 thousand rubles.

- Engine swap. The engine model changes if the previous power unit did not suit the owner according to some characteristics. The cost of the event ranges from 20 to 150 thousand rubles.

Other problems and malfunctions

Lancer “loves” corrosion, but not excessively. Mitsubishi, like many Japanese manufacturers of the time, applied a very thin layer of poor quality varnish to the car. Therefore, numerous scratches, chips and corrosion of bare metal are quite an expected picture. However, few Lancers are painted in an expensive and rich color, and therefore cosmetic repairs will be inexpensive. More often the problems concern the rear wheel arches.

The materials used for interior decoration may seem unattractive and of low quality. But this is just an illusion. The resistance of interior parts to wear is high. The salon doesn't bother you with squeaks either.

In winter, the rear door locks often freeze. In the future, the lock actuators may fail. A new motor-actuator can be found for 300 rubles

After 150,000 km, the heater fan sometimes starts working only in the 4th speed position. The heater resistor fails (5,000 rubles). One of the reasons is the motor jamming due to contamination and lack of lubrication.

Soon you may also need to replace the steering column cable (from 1,500 rubles).

Tips for choosing a Mitsubishi Lancer 9 with various power plants

For sports driving enthusiasts, it is recommended to choose a Mitsubishi Lancer 9 with a 4G63 engine. In this case, it is necessary to inspect the car as carefully as possible before purchasing. Cars with a 2.0-liter power plant are most often in an excessively worn condition.

For those who like to save money, the Mitsubishi Lancer 9 with a 1.3 liter engine is most suitable. It handles confidently in traffic. Getting on the highway won't be a problem either.

If you want to own a sports car, you should also consider the Lancer 9 with a 1.6-liter power unit. It is often sold in better technical condition compared to cars with 4G63. Moreover, most parts are interchangeable with 4G13. This simplifies the process of repairing the power plant.

Symptoms for replacement

It is recommended to periodically check the belt for visible damage.

Replacement must be done every 90,000 mileage or as wear occurs. This is what the regulations say, we recommend not to tighten it, and to “renew the belt” at 60,000 km.

Characteristic signs for replacing the alternator belt are:

- a knock or whistle coming from under the hood;

- drive grinding or creaking;

- the battery charge light came on on the dashboard;

- the engine cannot be started.

Unpleasant sounds

Extraneous sounds may indicate wear on the rollers. The photo shows a new tension pulley and an old one after a mileage of 70,000 km.

- The belt can make unpleasant sounds when oil or coolant gets on it or the shaft. The squealing occurs due to its slipping along the shaft. To solve the problem, the belt must be removed and wiped with a clean rag soaked in gasoline.

- Loosening the belt also leads to a whistling noise; to eliminate the cause, it must be tightened.

- Whistling sounds can be created when the belt misses the pulley line; even slight misalignment will cause rapid wear. The pulleys need to be aligned correctly.

- A belt that is too tight also produces unpleasant sounds because it does not allow the pulleys to rotate normally. This situation often occurs at sub-zero temperatures, when the belt freezes and becomes hard. When the engine warms up, the squeal disappears.

- Creaks and whistles appear when the bearing on the shaft wears out; after replacing it, the sounds disappear.

Frequent breakdowns occur due to the long service life of spare parts, violation of car care rules and the choice of low-quality parts.

Production

In the early spring of 2000, Mitsubishi Motors released the Mitsubishi Lancer, which received the name Cedia in Japan - “diamond of the century.” In the rest of the world it became known as Lancer 9. It had a number of differences from its Japanese counterpart, namely:

- different body geometry in the front and rear;

- budget trim;

- mechanical transmission.

Installation

- Make sure the alignment marks are aligned or and .

- Install the balance shaft drive belt.

- Make sure the belt is tight between the sprockets.

- Turn the tensioner pulley clockwise toward the belt until it stops.

- Tighten the bolt. Tightening torque: 16-22 Nm.

- Press the belt with your thumb. The belt should bend by 5-7 mm.

- If not: Repeat the tensioning procedure.

- Install the parts in the reverse order of removal.

- Remove grease from the crankshaft sprocket and speed sensor rotor.

- Remove grease from the crankshaft shank.

- Lightly oil the threads and mating surface of the crankshaft bolt.

- Tighten the crankshaft bolt. Tightening torque: 167 Nm.

- Use special tools No. MB991367 and MB991385.

- Install the timing belt as described above.

Replacement procedure

Replacing the timing belt of a Mitsubishi Lancer 9 is not an easy procedure, requiring partial disassembly of the engine and certain conditions. In this case, it is necessary to have a garage, specialized tools and a classified selection of replacement parts.

Therefore, it is safer to turn to specialists, to a service station, where everything is adapted for this. However, you can change the timing drive on Lancer 9 yourself; you just need to have basic skills in servicing and repairing the car.

Algorithm of actions

- Jack up the car on the right side, then remove the front wheel and fender liner.

- Strengthen the machine for stability by placing additional support under it.

- First, you need to remove the power steering drive from the engine.

- Remove the generator and pump drive.

- Remove the crankshaft pulley, first unscrew the bolt.

Remove the top protective cover

Place marks on the camshaft and crankshafts

Carefully remove the tension roller spring using pliers and then remove it. Unscrew the fasteners from the power steering pump and the engine mount. Remove the suspension base. Replace timing drive

Put on the new belt so that the surface opposite the roller is taut.

Reassemble the engine for Lancer 9 in the reverse order.

Alignment marks

When disassembling and assembling the engine for Lancer 9, special attention should be paid to the crank mechanism (CVM) and timing components, since they are interconnected. Before disconnecting these mechanisms, you must first set marks on the corresponding shafts of these devices

To set the marks, turn the crankshaft.

For SOHC engine

The camshaft mark must be aligned with the mark on the cylinder head.

SOHC locating mark

The crankshaft mark must be aligned with the mark on the cylinder block on both engine types. To see this mark, you need to remove the generator drive pulley and power steering pump.

Crankshaft mark for all engine types

For DOHC engine

It is necessary that the two camshaft marks align with the slots on the rear timing cover. The crankshaft mark must be installed in the same way as the SOHC engine mark.

DOHC timing marks

Additional verification method

There is another way to make sure that the piston of the first cylinder is at TDC.

To do this you need:

- Remove the spark plug in the first cylinder.

- Set the piston to TDC. To do this, install the plug in the cylinder hole with a slight tension, then engage 5th gear and put the wheel in place. Smoothly turn it clockwise. As soon as the plug flies out, the compression process has begun and the piston is in the upper position.

- Place a mark on the crankshaft pulley.

- After this, set the camshaft to the mark.

Before removing the tension roller, it is recommended to secure the above-mentioned shafts together. To do this, you can tie the gears together with wire or tighten them with clamps and attach them to the pulley mounting bolt.

When assembling the engine for Lancer 9, special attention should be paid to the marks; therefore, it would be more correct to first install the tension roller and belt and only then turn the tensioner. If you pay close attention to this procedure, the Lancer 9 timing marks should coincide with the protruding marks on the motor housing

To make sure of this, you need to reinstall the piston of the first cylinder to TDC, and then check the alignment of the marks. To do this, you need to put the wheel on the hub and, turning it, make two revolutions of the crankshaft. The marks must match.

Timing belt tension

When assembling the Mitsubishi Lancer 9 engine, before installing the upper timing cover, you need to tension the drive.

To do this you need:

- Rotate the crankshaft one or two turns clockwise and set the piston of the first cylinder to TDC.

- Remove the cover from the service hole.

- Make sure that the tension roller is loosened so that it tensions the belt under the action of a spring.

- Check the gap between the timing drive and the cover. The nominal value should be 31–34 mm.

- Tighten the roller mounting bolt.

- Install the service hole cover.

- Install the upper timing cover.

After replacing the drive and tensioning the belt, start the car and check engine operation.

What spare parts are worth purchasing?

Before you begin scheduled repairs, you need to prepare original consumables:

- Timing drive. The original belt for Mitsubishi Lancer 9 should have the article number MD342154. There is also a replacement for this timing drive under serial number 1145A051, Gates 5535XS, Contitech CT1008. They are not supplied from the manufacturer's factory, but according to their characteristics they are well suited as an analogue.

- Power steering drive MD375935 (Gates 5PK1063 – analogue).

- Alternator belt MN183019 (Gates 5PK903 - analogue).

- Belt tension roller MD356509 (NTN JPU57-008A-4 analogue).

- Camshaft seals – 2 pcs.

- Crankshaft oil seals – 2 pcs.

- Water pump.

It should be noted here that experts recommend replacing the tension roller and pump on Lancer 9 after 150–170 thousand kilometers, it all depends on their wear. If after removing the belt there is no play in the bearings of these parts, then they can not be removed during scheduled repairs after 90 thousand km. Also, seals can only be changed during the second scheduled repair.

The timing belt must be changed every 90,000 km. It is also recommended to replace the timing belt if during inspection the following are found:

Traces of oil on any surface of the belt. Be sure to replace such a belt, as oil quickly destroys rubber. The reason for oil ingress is usually a violation of the tightness of the crankshaft and camshaft oil seals. Traces of wear on the toothed surface. Cracks, folds, depressions or bulges on the outer surface of the belt. Fracture or delamination on the end surfaces of the belt.

To replace the timing belt you will need: 10, 12, 19 sockets. A 12 wrench and pliers.

Timing belt catalog numbers:

Mitsubishi MD342154 – timing belt, originalMitsubishi 1145A051 – timing belt, originalGates 5535XS – timing belt, analogueContitech CT1008 – timing belt, analogue (used by rally drivers on Evo, not inferior to the original and in many ways superior in strength)SUN A343YU100 – timing belt, analogue ( SUN - official packer of the original Japanese plant UNITTA owned by Gates) Catalog numbers of the tensioner roller:

Mitsubishi MD356509 – timing belt tensioner pulley, original NTN JPU57-008A-4 – timing belt tensioner pulley, analogue (NTN is original from the factory). If you order this video, NEP57008A6 still arrives. Both articles appear on the label, both old and new. NTN NEP57008A6 - timing belt tensioner pulley, analogue (NTN is the original from the factory) Mitsubishi does not produce either a belt or a pulley. Therefore, there is no point in buying an original belt with a roller under the Mitsubishi label; the box will still contain original replacements: SUN A343YU100 and NTN JPU57-008A-4.

If this is your second timing belt replacement, you can replace:

Replacement of the camshaft oil sealReplacement of the crankshaft oil sealReplacement of the pump (water pump)Catalog numbers of alternator and power steering belts:

Mitsubishi MD375935 – power steering belt, originalGates 5PK1063 – power steering belt, analogueMITSUBOSHI 5PK1065 – power steering belt, analogueMitsubishi MN183019 – Alternator belt, originalGates 5PK903 – serpentine alternator belt, analogueMITSUBOSHI 5PK905 – serpentine alternator belt , analogue Let's start replacing the timing belt on the Mitsubishi Lancer IX 1.6 (4G18 ).

1. You can do without a hole; to do this, just jack up the car and remove the right front wheel, not forgetting to place boards under the side member:

2. Loosen the bolts on the generator and power steering compressor, then remove the belts. If you are not going to change the belts of the attachment, then it is advisable to remember in which direction the belts rotated, so that later you can prevent the belt from rotating in the opposite direction

Of course, this may be overcautious, but it's better to do it this way

3. It is necessary to unscrew the fastenings of the protective casing and remove the pistons:

4. After that, we got a view of the crankshaft pulley. Unscrewing it can sometimes be a big problem:

5. Unscrew the bolt that secures the pulley to the crankshaft. In the book from the third Rome they advise taking the old alternator belt, clamping it with pliers and unscrewing it! But that most likely won’t work...

>

Mitsubishi Lancer 9 engines

The Mitsubishi Lancer 9 has several engine models in its line of power plants. Thanks to this, the buyer has the opportunity to choose between maximum dynamism and efficiency.

Power units differ in design. They do not have significant drawbacks and shortcomings, so they do not cause any special problems to the car owner during operation.

The Mitsubishi Lancer 9 is equipped from the factory with one of three sixteen-valve gasoline injection power plants:

The cylinder block of all Mitsubishi Lancer engines has a similar design. The only difference is the volume of the working chambers. The power plants have a vertical in-line arrangement of four cylinders. The main block is manufactured using a single casting method from high-strength cast iron. The crankcase contains five crankshaft supports made in the form of partitions. The cylinder blocks have special bosses necessary to accommodate power plant components and attachments.

There are slight differences between SOHC and DOHC engine cylinder blocks. It lies in the fact that engines with two camshafts have a pair of balancing balancing shafts. To place them in the cylinder block of DOHC engines, there are special seats for bearings.

There is also a difference between SOHC and DOHC engines in the methods for limiting the axial movement of the crankshaft. In the first case, flanges are used on the middle main journal, and in the second, fixation is made using two half-rings located in the seat of the middle main bearing.

The flywheel is only present on vehicles with a manual gearbox. It is the same for engines with one and two camshafts. In the case of an automatic transmission, a torque converter drive disk is installed instead of the flywheel.

The pistons of the 4G13, 4G18, 4G63 engines are made of an aluminum-based alloy. They have grooves for the oil scraper and two compression rings. There is a technological hole in the upper head of the connecting rod that allows oil to splash onto the bottom of the piston, cooling it. This increases the resource of the power plant. The connecting rod itself is made of steel. It has an I-section.

The crankcase ventilation system in Mitsubishi Lancer 9 engines is a closed type. In all operating modes of the power plant, a vacuum is formed in the crankcase. This reduces the risk of leaks through seals and seals.

The engine is mounted in the Mitsubishi Lancer 9 on four supports. To reduce the amount of vibration transmitted to the body during operation of the power plant, special rubber cushions are used.

Used Mitsubishi Lancer IX: engines with appetite and an automatic transmission that does not break down

In the first part of our review, we already found out that if you are not afraid of a cramped, boring interior, then the Lancer IX with a high degree of probability can become for you that very Japanese “eternal car”: it has problems with the body, chassis, brakes and steering minimum. Well, what about engines and gearboxes?

Transmission

And the vast majority of cars are equipped with a manual transmission, although the automatic transmission here is excellent, and its service life is probably even longer than that of a manual transmission. The transmission of front-wheel drive cars is generally very reliable. Only CV joints are at risk: their covers tend to wear out, you need to be careful.

Pictured: Mitsubishi Airtrek '2001–05

The differential needs to be monitored, and the oil should be changed more often - for example, every 40-50 thousand kilometers, which is generally not typical for a manual transmission. I am glad that this operation is inexpensive.

Manual transmissions from “European” two-liter cars of the F5M42-2-R7B6 and F5M42-2-R7B4 series often begin to make noise after 50-70 thousand mileage. The chances that the housing is damaged are also higher than in the case of manual transmissions with “small” engines. There are few contract units, but there is a way out: instead of the completely “dead” F5M42-2-R7B6 and F5M42-2-R7B4, you can safely install boxes from 2.4 and 1.8 liter engines. With some modifications, stronger manual transmissions of the W5M31-1 or even KM220 series or the slightly more expensive and new W5M42 will fit here.

Replacing the box can be avoided if you do not delay replacing the bearings, after which the box will last another 40-50 thousand miles. Unfortunately, precise assembly and inspection of all seating surfaces are important here. Rare craftsmen can achieve factory quality (and therefore durability) .

Please note that when buying a car, you can easily get a copy with a box that is already noisy, into which additives have been poured to reduce noise. In this case, you will have to repair or change the manual transmission. Any suspicions about noise should be immediately interpreted in favor of major repairs.

In the photo: Mitsubishi Lancer '2005–2010

Failures of speed sensors are mainly associated with age and contamination of the box with wear products. The most serious problems are usually related to contamination of the valve body, loss of pressure or oil leaks.

The automatic transmission is considered one of the most successful in its class. It is so successful that the A4CF1/2 box on Solaris differs from it in nuances, being a further development of the design, and it is still installed with 1.4 liter engines.

If you change the oil in the automatic transmission every 40-50 thousand, do not abuse racing and replace the gas turbine linings on time, then the gearbox will not require serious repairs. After 200-250 thousand kilometers, most likely, you will only need to replace several solenoids and a filter. That is, you can do without additional investments, although at this age it is recommended to update the rubber seals.

If you take an American or Japanese car with a 1.5 l, 1.6 l or 1.8 l engine, then you will not have a classic “automatic”, but a CVT produced by Mitsubishi / Hyundai F1C1 series. The design is very similar to the best selling Jatco RE0F06A and JF 011 E and is in fact one of its ancestors. Unfortunately, this does not speak of outstanding merits, but of an abundance of children's problems. In particular, this box works very poorly at low temperatures and even when cold. The oil in this variator should be changed every year, and yet the wear of the belt and cones by the mileage of 120-150 thousand is often already critical.

Motors

Mitsubishi engines are considered one of the most thoughtful and successful. Especially the old episodes. And the two-liter 4 G 63 is deservedly considered one of the best engines for tuning, and at the same time very reliable and successful in the naturally aspirated version.

But the bulk of the engines still belong to a different series. In many ways similar in design, but different - to the 4G1 or Orion family. 1.3 l engines – 4 G 13 series, 1.6 l engines – 4 G 18. A rarer one and a half liter modification belongs to the 4 G 15 series.

The Lancer IX was equipped with the latest modifications of the 4 G 18, so it was only available in the version with four valves per cylinder and one camshaft. 4 G 15 “pleases” with great variety: there is GDI on Japanese cars, and four valves per cylinder (three valves are also found, but rarely). There are even modifications with two camshafts.

The 4 G 13 engine is strictly a 12-valve engine with one camshaft.

All engines are distinguished by a cast-iron cylinder block, a timing belt and a fairly convenient design.

With all the advantages of these engines, one cannot fail to note the low service life of the piston group of 1.6 liter engines, their sensitivity to operating temperature and the poor design of the engine throttle valve. In addition, 1.6 l and 1.5 l engines have very weak ignition modules with individual coils.

The poor design of the main radiator makes it prone to loss of seal and contamination. I note that non-original inexpensive radiators often work even better than the original ones.

The material of the cylinder block is also far from “premium”, and if the rings are stuck, then, most likely, the wear of the piston group is already significant, and boring cannot be done without.

The rings of the 1.6 L and 1.5 L engines are stuck due to poor oil drainage on the pistons. The holes become coked, the circulation of coolant becomes insufficient, which leads to overheating. Actually, all diseases here most often arise due to an increase in engine volume: the performance of the cooling system is designed mainly for 1.2 liter and 1.3 liter engines, and a block of a larger volume is barely enough.

In the photo: Mitsubishi Lancer '2003–2005

And as soon as the radiators become a little dirty, an appetite for oil appears. Now let’s add to this the unsuccessful design of the pistons, and here it is – oil consumption and piston wear after hundreds of thousands of kilometers and at least slight overheating. Pistons are inexpensive, but the very fact that overhaul is required after 100-120 thousand kilometers of typical operation can scare off many.

In principle, using regular decarbonization, oils with low viscosity and good washing properties, oil appetite can be stabilized for quite a long time. There are examples of engines with mileage over 300 thousand and an original piston group. True, there are also many nuances of operating conditions to achieve such a result. With frequent trips through city traffic jams, such “survivability” is almost impossible to achieve. The only thing that can be recommended is the use of a “cold” thermostat and regular cleaning of the radiator. Well, oils with a viscosity of SAE 30, of course.

EGR needs to be periodically cleaned or turned off out of harm's way: it largely contributes to accelerated wear of the piston group and ring sticking on 1.6 liter engines.

The catalyst on these engines also does not tolerate operation well in Russia. After the same 100-150 thousand kilometers, the back pressure increases, and sometimes crumbs fly into the intake. This is largely due to possible ignition problems during this run: the spark plug tips are filled with oil due to the poor design of the cylinder head cover gaskets and poor crankcase ventilation. Vapors from crankcase gases, in turn, lead to corrosion of spark plug tips. It's good that they are collapsible and can be repaired.

Finally, they note the low service life of the engine mounts, because of which, after 150 thousand kilometers, vibrations and jerks become frequent occurrences.

If you look carefully, up to 100-120 thousand everything is usually very good, but then large expenses are expected with varying degrees of probability. Separately, the work is not too expensive, even replacing the timing belt, and spare parts, including original ones, do not cost a fortune. But for many, it all ends with the installation of a contract engine, fortunately there are enough of them. And all because you can install a much more successful engine.

The two-liter 4 G 63 in the naturally aspirated version is similar in layout to small-volume engines, but belongs to a different family, the larger 4G6 or Sirius. It also includes the rarely encountered 1.8 liter 4 G 67 series and 2.4 liter 4 G 69 series engines.

Unlike “small” motors, there are balancer shafts, and they are driven by a separate belt. They are also one of the weak points of this line of engines. On 2.0 L and 1.8 L engines, it is recommended to disable the balancer drive and remove the belt. Otherwise, if it breaks, it falls under the timing belt and... everything is clear here. In such a situation, the valves bend on all Mitsubishi engines.

Balancer shafts on older engines are prone to jamming. Otherwise, everything is noticeably better than that of smaller engines: the piston engine is more reliable, there are no problems with overheating. But there are thousands of options for tuning the cooling system, because engines with a power of over a thousand horsepower are assembled on the basis of the 4 G 63/4 G 69/4 G 64. True, sometimes with the replacement of the unit itself: the standard one is not enough even with a return of half this figure.

In the photo: Mitsubishi Lancer Wagon '2003–2005

The supercharged engine option has a similar resource only if the car is driven by a very calm person. Usually 4 G 63T is used harshly, and there is no point in talking about an outstanding resource. But even in such conditions it is extremely reliable, even in a forced form.

The difficulties with the throttle, ignition coils, crankcase ventilation system and engine mounts are the same as with the 1.6 4 G 18 engine.

A few words about the design and functions

This belt is a closed rubber ring mounted on several pulleys. On one side, the surface of the belt is equipped with teeth, thanks to which the torque is actually transmitted.

The main function of this element is to synchronize the operation of the crankshaft and camshaft. The belt is not subject to corrosion, and it operates almost silently (unlike a chain drive). But rubber can stretch and tear. This will lead to dire consequences. To avoid this, you need to tighten the Mitsubishi Lancer alternator belt in time.