Engine 2111 (in everyday life the designation 2114 is sometimes found) is an analogue of the famous VAZ engine 21083, which uses an injector instead of a carburetor.

Subsequently, a number of 1.5-liter engines were developed on its basis (2112, 21124, 21126, 21127, 21114, 21116). Combined with a gearbox and clutch, the VAZ 2111 engine is located in the engine compartment of the car on support cushions.

History of the creation of the VAZ 2111

Since the late 80s, AvtoVAZ manufacturers have been considering the project of creating a new luxury station wagon. The already created power units, VAZ 21083 and VAZ 2110, were not suitable for the new project. An engine was needed, stronger and more powerful.

AvtoVAZ engineers were able to obtain more torque and more power by installing an injector instead of a carburetor on the VAZ 21083 engine. The first injection engine was labeled VAZ 21093i.

It was planned to launch a motor with distributed point injection into mass production already in 1992. However, the crisis slowed down the development of AvtoVAZ for several years. The first pilot batch rolled off the assembly line only in 1994. It was still the same de VAZ 21093i, only the cylinder head was taken from the VAZ 2110. Now the engine began to be called the VAZ 2111, just like the station wagon for which it was invented.

Maintenance

Regular maintenance of the VAZ 2111 engine ensures fairly long and trouble-free operation. Like all VAZ power units, the VAZ 2111 engine must be periodically inspected (visual inspection), paying special attention to:

- presence of antifreeze and engine oil leaks;

- integrity of high-voltage wires;

- serviceability of spark plugs;

- condition of the air filter element;

- cracks appear on the generator drive belt.

It is also recommended to regularly check the level of engine oil in the crankcase and antifreeze in the expansion tank of the power unit.

The list of mandatory procedures that must be carried out during scheduled vehicle maintenance includes replacement work (no later than):

- engine oil and oil filter - every 15 thousand km. mileage;

- fuel filter and air filter filter element - every 30 thousand km;

- timing belt and tension roller - every 75 thousand km. mileage;

- generator drive belt - every 30 thousand km. mileage;

- coolant - every 75 thousand km. mileage;

- spark plugs - every 60 thousand km.

Description of the VAZ 2111 power unit

The 2111 engine is a typical representative of tenth generation power units. It has a BC head with one overhead camshaft and eight valves, one intake and one exhaust valve for each cylinder. The timing belt drive has a protective casing. The placement of the cylinders is in-line-transverse, which means that the engine, like all front-wheel drive cars, is placed transverse to the movement of the car. The VAZ 2111 engine is equipped with a five-speed manual transmission.

The car is lubricated using a combination of methods. Some of the more heavily loaded parts of the internal combustion engine receive oil through special channels and highways. Other parts are lubricated using the spray method. The oil gear pump, as on the previous VAZ 21083 model, has a direct drive from the crankshaft.

CO 2111 has small and large coolant circulation circles. When the engine starts, the coolant moves in a small circle, and when the temperature reaches 103C, the thermostat opens. When opened, the coolant will move in a large circle. If the engine temperature continues to rise, the fan will start, it will forcibly cool the engine and prevent it from overheating.

The main difference between the 2111 and its earlier counterparts is the injection power system. Thanks to this innovation, the torque and power of the internal combustion engine increased by almost 10 percent. This engine is an improved model of the VAZ 21083. The cylinder head has undergone major changes. It was adapted for an injection power system, and the air supply system was also changed. The crankshaft has undergone minor changes, the parameters remain the same, and the counterweights have been increased for better balancing. The piston pin seating device has also changed. Previously, the pin was pressed into the connecting rod head and rotated only in the piston bosses. The 2111 used floating landing technology. With this technology, the piston pin moves freely in all parts. And to prevent axial displacement, retaining rings were installed. The result is a dynamic, nimble engine.

Technical data VAZ 2111

A four-stroke, gasoline engine with an in-line arrangement of four cylinders. The motor is located transversely. The material used to make the BC is especially durable cast iron.

- The internal combustion engine power system is distributed point injection.

- Gas distribution system, one shaft for eight valves, top shaft location.

- The piston stroke length is 71 cm, the diameter of each cylinder is 82 centimeters. Compression ratio of VAZ 2111 - 9.8:1

- The exact engine capacity is 1499 cubic centimeters. Engine power at 5400 rpm min., 78 l., bhp.

- Torque 2111 at 3000 rpm, 116 Nm.

- VAZ 2111, when moving from a standstill, accelerates to 100 km per hour in 14 seconds.

Fuel consumption

The fuel used when driving around the city is 8.8 liters per 100 km. On the highway 5.7 liters. The total consumption is 7.3 liters per 100 km, mileage.

Engine oil consumption and volume

The permissible consumption of motor lubricant is 0.05 liters per 1 thousand kilometers. Types of oil used: 15W40, 5W40, 10W40, 5W40. The amount of oil in the quarry is 3.5 liters. When filling a new one, take 3.2 liters.

Engine life

The service life of the power unit, according to manufacturers, is 150 thousand km. The real service life of the VAZ 2111 internal combustion engine with proper operation can reach 250 thousand km.

Characteristics of the motor 2111

Since 1993, the manufacturer AvtoVAZ opened the VAZ-2110 project. A front-wheel drive luxury sedan was being developed, so carburetor modifications of engines 2108, 2110 and their variants did not meet the conditions.

Already at the initial stage, the project was divided into two independent works. A simple conversion of the G8 hatchback into a sedan was called VAZ-21099. The name of the second project remained the same, but work on it was considerably delayed for a number of reasons:

- in 1985, a test sample appeared; the car with the new engine was planned to be launched into series in 1992;

- the crisis confused plans, the management of the manufacturer's plant put the VAZ-2110 on the assembly line only in 1996;

- The first cars had a carburetor internal combustion engine, then a modified 2111 injection type.

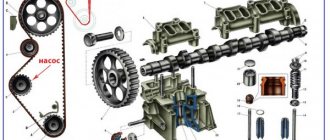

Engine diagram

The designers managed to make maximum use of existing engine elements so that the user of previous generations of VAZ would not be confused about which oil and coolant to use. By default, the technical characteristics of the ICE 2111 are as follows:

| Manufacturer | AvtoVAZ |

| Engine brand | 2111 |

| Years of production | 1997 – 2014 |

| Volume | 1490 cm3 (1.5 l) |

| Power | 56.4 kW (77 hp) |

| Torque | 183 Nm (4400 – 4800 rpm) 186 Nm (4400 – 5200 rpm) |

| Weight | 127.3 kg |

| Compression ratio | 9,8 |

| Nutrition | injector |

| Motor type | in-line |

| Injection | electronic multipoint |

| Number of cylinders | 4 |

| Location of the first cylinder | TVE |

| Number of valves on each cylinder | 2 |

| Cylinder head material | aluminum alloy |

| Intake manifold | short partitions |

| An exhaust manifold | width 1 – 1.4 mm, angle 45° |

| Camshaft | from 2110, provides intake valve stroke of 9.6 mm, exhaust valve stroke of 9.3 mm |

| Cylinder head | cast iron |

| Cylinder diameter | A-class – 82 – 82.01 mm B-class – 82.01 – 82.02 mm C-class – 82.02 – 82.03 mm D-class – 82.03 – 82.04 mm E-class – 82.04 – 82.05 mm |

| Pistons | from 2110 |

| Rings | from 21083 |

| Piston diameter | A-class – 81.94 – 81.95 mm B-class – 81.95 – 81.96 mm C-class – 81.96 – 81.97 mm D-class – 81.97 – 81.98 mm E-class – 81.98 – 81.99 mm |

| Crankshaft | model 2112 |

| Number of main bearings | 5 |

| Piston stroke | 71 mm |

| Fuel | AI-95 |

| Environmental standards | Euro-2/Euro-3 |

| Fuel consumption | highway – 8 l/100 km combined cycle 9.5 l/100 km city – 13 l/100 km |

| Oil consumption | maximum 1 l/1000 km |

| Engine oil for 2112 | 5W-30 and 10W-30 |

| Engine oil volume | 4.5 l |

| Operating temperature | 95° |

| Motor life | declared 200,000 km actual 250,000 km |

| Adjustment of valves | washers in the pusher socket |

| Cooling system | forced, antifreeze |

| Coolant quantity | 7.8 l |

| water pump | from 2108 |

| Spark plugs for 2111 | BPR6ES, A17DVRM |

| Gap between spark plug electrodes | 0.5 – 0.6 mm |

| Timing belt | from 2110, 111 teeth, belt width 19 mm |

| Cylinder operating order | 1-3-4-2 |

| Air filter | Nitto, Knecht, Fram, WIX, Hengst |

| Oil filter | catalog number 90915-10001 replacement 90915-10003, with check valve |

| Flywheel | thickness 27.5 mm, clutch diameter 208 mm |

| Flywheel mounting bolts | M10x1.25 mm, length 26 mm, groove 11 mm |

| Valve stem seals | code 90913-02090 inlet light code 90913-02088 exhaust dark |

| Compression | from 13 bar |

| XX speed | 750 – 800 min-1 |

| Tightening force of threaded connections | spark plug – 18 Nm flywheel – 61 – 87 Nm clutch bolt – 19 – 30 Nm bearing cap – 68 – 84 Nm (main) and 43 – 53 Nm (connecting rod) cylinder head – 4 stages 20 Nm, 69.4 – 85.7 Nm + 90° + 90° |

The official manual contains information about what kind of oil to pour: 5W30/5W40 (winter), 20W30/20W40 (summer) and 10W30/15W40 (all-season). The manufacturer specifies engine lubricants from Rosneft, Mobil and Lukoil; a service station specialist usually recommends Mannol, Zic and Valvoline engine oils.

Layout of components and mechanisms on the engine

The motor, together with the manual transmission and clutch, constitute a power unit installed in the engine compartment of the car. The internal combustion engine is attached to three rubber-metal exhibitions. The right insert is attached to the motor bracket, and the rear and left ones are connected to the gearbox mounts.

The necessary mechanisms and components of the power unit are mounted on the cylinder block:

- On the right side of the engine, when looking in the direction of travel of the car, there are: coolant pump and camshaft drives. They are operated using a toothed rubber belt. Also on the right is the generator drive, it is also driven by a poly V-belt;

- on the left there is: a thermostat, an engine starter, a sensor indicating the coolant temperature;

- in front of the engine are located: wires with high voltage, a hose designed for crankcase ventilation, spark plugs, a knock sensor, a generator, an oil dipstick;

- At the rear of the engine are installed: a sensor for engine lubricant pressure, a receiver, a filter for filtering engine lubricant, both manifolds, fuel injection nozzles, and a fuel rail.

Description

The 2111 engine is a classic VAZ design with an overhead single camshaft (SOHC). On the cylinder block you can additionally:

- install a knock sensor;

- secure the generator bracket;

- place the ignition module.

The timing mechanism (timing) drive uses an elastic toothed belt.

IMPORTANT: if the timing belt breaks, the valves do not bend.

In the process of creating the VAZ 2111 engine, two versions were envisaged, differing in the injection system:

- Pair-parallel injection - VAZ 2111-80 (Euro-II version).

- Phased injection - VAZ 2111-75 (Euro-III version).

On power units equipped with a phased injection system, a camshaft with a pin is installed, which allows the corresponding sensor to monitor the opening and closing of the valves. This pin is located at the end of the camshaft, marked with the index 111.

The motor is controlled by an electronic control unit (ECU). For different versions of power units, different types of ECUs (controllers) are used:

- "January", GM or Bosch. At the same time, MP 7.0 or “January 5” controllers are used with Siemens 6238 injectors;

- "Siemens VAZ 6393" uses controllers "January 7.2" or M 7.9.7.

Design features of the BC ICE VAZ 2111

The 2111 power unit is an improved copy of the VAZ 21083 and VAZ 2110. The new power unit uses the cylinder block from the 2110. It is exactly the same in size as the VAZ 21083. The main difference is that the 2110 block has additional mounting holes for the ignition module , generator bracket, knock sensor. The holes intended for mounting the cylinder head have a thread of 12 by 1.25 millimeters. The distance from the central axis of the crankshaft to the extreme point of the BC surface is 194.8 mm. The diameter of the cylinders has a length of 82 millimeters. The repair dimensions for the cylinders are 82.4 mm and 82.8 mm. Cylinder classes, just like on the VAZ 21083, are indicated by Latin symbols and correspond to the same dimensions. The size difference between classes is 0.01 mm. And the wear of the cylinder wall, which is allowed before a major engine overhaul, is equal to 0.15 millimeters from the length of the diameter.

At the bottom of the BC there are five supports with covers. The inner surface of the supports is processed together with the covers, so the covers are not interchangeable and cannot be swapped. The supports are designed for installing main bearings. The design of the middle support provides special sockets into which thrust half-rings are installed. They prevent the crankshaft from moving relative to its axis. The half rings have different colors, are made of different materials and face opposite directions. The half-ring, made of an alloy of aluminum and steel, is white and faces the crankshaft pulley. The second ring, made of metal-ceramic, is yellow in color and faces the flywheel. Half rings have normal and enlarged sizes. The increase is 0.127 mm. If the axial play of the crankshaft exceeds 0.35 mm, one or two half rings are replaced.

Engine tuning

By default, the engine uses the maximum cylinder diameter, so boring them out even more will not be possible or will be too expensive. The following types of tuning are used:

- FNS filter – zero resistance can “revive” the motor;

- throttle 54 – a valve with a larger diameter must be mounted in conjunction with the Federal Tax Service;

- direct-flow exhaust system - spider circuit 4/2/1 and resonator with banks;

- sports camshaft – gas distribution modes change.

Thus, the ICE 2111 is an order of magnitude superior to carburetor modifications, does not bend valves, is economical in operation, so it was produced for a long time and in large quantities to complete the entire line of front-wheel drive cars produced at that time. Thanks to several repair sizes of the piston and cylinder, you can make major repairs on your own.

Source

Design features of the crankshaft 2111

The VAZ 2111 power unit is equipped with a crankshaft 2112-1005015. The size of the crank and the piston stroke size of 71 millimeters coincide with the dimensions of the crank and the piston stroke of the VAZ 21083. The differences are in the increased counterweights. This allows you to reduce detonation, vibration and increase the dynamics of the power unit.

These eight counterweights are cast together with the crankshaft from highly durable cast iron. To supply engine lubricant to the connecting rod journals from the main ones, special channels are used, the outlet holes of which are closed with plugs. Channels and plugs take part in cleaning motor lubricant. When the crankshaft rotates, a centrifugal force is created, throwing small particles that were not retained by the filter towards the plugs. Therefore, when overhauling the engine, the plugs must be removed and the channels cleaned of dirt and deposits. Old plugs must be disposed of and new plugs installed in their place.

In front of the crankshaft, using a segment key, a pulley is installed that drives the camshaft. A pulley that drives the generator is attached to it by means of a pin. It is also a damper on which there is a gear ring that helps determine the TDC by the sensor.

At the rear of the crankshaft, a cast-iron flywheel with a steel ring gear pressed onto it, necessary for starting the engine with a starter, is attached to six bolts secured through a large common washer.

Description of the engine structure, the procedure for repairing the power unit of the Lada 2110 car, the stages of assembly and disassembly of parts of the Lada 2112 cylinder head, adjusting the engine valves with your own hands VAZ 2111, VAZ 2112, VAZ 2110. Maintenance of the engine of the Lada 2112 car. Instructions for repairing the cooling system, exhaust exhaust gases, power supply of the Lada 2111. Features of the 8 and 16 valve engines of the Lada 2110. Operation of the main components and assemblies of the engine

Gasoline, four-stroke, four-cylinder, in-line, transverse, sixteen-valve, with two camshafts. The operating order of the cylinders is: 1-3-4-2, counting from the crankshaft pulley. The power supply system is phased distributed injection. Engine control – controller (Bosch, “January” or GM). Most engines are equipped with an exhaust gas converter. The engine, gearbox and clutch form a power unit mounted in the engine compartment on four elastic rubber-metal supports. The right and left supports are the same as on the VAZ 2110 and 2111 engines. The front and rear supports are the same, which are rods. One end of the rod is attached to the bracket on the engine, the other - to the bracket on the body. On the right side of the engine (along the direction of the car) are located: the drives of the VAZ 2112 camshafts and the coolant pump (by a toothed belt) and the generator (by a V-ribbed belt). On the left are: thermostat, coolant temperature sensors, oil pressure sensor, starter (on the clutch housing). Front: intake manifold, fuel rail with injectors, knock sensor, oil dipstick, crankcase ventilation hose, alternator (bottom right), timing sensor (top right). Rear: exhaust manifold, oil filter, crankshaft position sensor (lower right). On top (under the plastic cover) there is a receiver, spark plugs (in guide pipes sealed with rubber rings) and high-voltage wires. The cylinder block is cast from cast iron and has the index “21083” - like the engines 2110 and 2111, however they are not interchangeable: the holes for the cylinder head screws have a thread M10x1.25 (as opposed to M12x1.25 for engine blocks 2110 and 2111) and smaller depth. Another difference is associated with the more intense thermal regime of the 2112 engine compared to the 2110 and 2111 engines. To cool the pistons during engine operation, their bottoms are washed from below with oil through special nozzles pressed into the second, third, fourth and fifth main bearing supports. The cylinders are bored directly into the block. The nominal diameter of 82 mm can be increased by 0.4 or 0.8 mm during repairs. The class of the cylinder is marked on the bottom plane of the block in Latin letters in accordance with the diameter of the cylinder in mm: A - 82.00-82.01, B - 82.01-82.02, C - 82.02-82.03, D - 82 .03-82.04, E – 82.04-82.05. The maximum permissible cylinder wear is 0.15 mm per diameter. At the bottom of the cylinder block there are five main bearing supports with removable caps, which are attached to the block with special bolts. The covers are not interchangeable (the holes for the bearings are machined together with the covers) and are marked for identification with marks on the outer surface (see the figure in the section Disassembling and assembling the engine). The middle support has slots for thrust half-rings that prevent axial movement of the crankshaft. A steel-aluminum half-ring is placed in front (on the crankshaft pulley side), and a metal-ceramic half-ring is placed in the back. Rings are manufactured with a nominal thickness and an increased thickness of 0.127 mm. If the axial clearance of the crankshaft exceeds 0.35 mm, one or both half rings are changed (nominal clearance is 0.06-0.26 mm). The main and connecting rod bearing shells are thin-walled steel-aluminum. The upper main bearings of the first, second, fourth and fifth bearings, installed in the cylinder block, are equipped with a groove on the inner surface. The lower main bearings, the upper bearing of the third bearing and the connecting rod bearings do not have grooves. Repair liners are produced for crankshaft journals, reduced by 0.25, 0.50, 0.75 and 1.00 mm. The crankshaft is made of high-strength cast iron. It has five main and four crankpins and is equipped with eight counterweights cast integrally with the shaft. The crankshaft of the 2112 engine differs from the crankshaft of the 2110 and 2111 engines in the form of counterweights and increased strength. Therefore, it is not allowed to install a crankshaft from engines 2110 and 2111 into engine 2112. To supply oil from the main journals to the connecting rods, channels are drilled in the crankshaft, the outlet holes of which are closed with pressed-in plugs. At the front end of the crankshaft, a camshaft drive gear pulley is mounted on a segment key; a generator drive pulley, which is also a torsional vibration damper of the crankshaft, is attached to it. On the toothed rim of the pulley, two teeth out of 60 are missing - the cavities are used to operate the crankshaft position sensor. A flywheel (index 2110), cast from cast iron, with a pressed-on steel ring gear, which is used to start the engine with a starter, is attached to the rear end of the crankshaft with six self-locking bolts through a common washer. The cone-shaped hole near the flywheel crown should be opposite the connecting rod journal of the fourth cylinder (this is necessary to determine TDC after assembling the VAZ 2112 engine). The connecting rods are steel, I-section, processed together with the covers. On the covers, as well as on the connecting rods, the cylinder number is stamped (it should be on one side of the connecting rod and the cover). The connecting rods, based on the diameter of the steel-bronze bushing pressed into the upper head, are divided into three classes with a pitch of 0.004 mm. The class number is stamped on the connecting rod cover. Connecting rods are also divided into weight classes - they are marked with paint or a letter on the connecting rod cap. The piston pin is steel, tubular cross-section, floating type (freely rotates in the upper head of the connecting rod and in the piston bosses). It is secured from falling out by two retaining spring rings, which are located in the grooves of the piston bosses. There are three classes of fingers according to the outer diameter (every 0.004 mm): 1 - with blue, 2 - green, 3 - red (smallest diameter) marks. The piston is made of aluminum alloy. The piston skirt is conical in longitudinal section and oval in cross section. In the upper part of the piston there are three grooves machined for piston rings. The groove of the oil scraper ring has drillings extending into the bosses, through which the oil collected by the ring from the cylinder walls is supplied to the piston pin. The hole for the piston pin is shifted from the center plane of the piston by 1 mm. When installing the piston, you must follow the arrow stamped on the bottom (it should be directed towards the crankshaft pulley). The pistons of the 2112 engine have a flat bottom, with four recesses for the valves (the pistons of the 2110 and 2111 engines have an oval recess on the bottom). Pistons according to their outer diameter (measured in a plane perpendicular to the piston pin, at a distance of 51.5 mm from the piston bottom), like cylinders, are divided into five classes (markings are on the bottom). Piston diameter (for nominal size, mm): A – 81.965-81.975; B – 81.975-81.985; C – 81.985-81.995; D – 81.995-82.005; E – 82.005-82.015. Pistons of classes A, C and E (nominal and repair sizes) are available for sale: the calculated gap between them is 0.025-0.045 mm, and the maximum permissible gap during wear is 0.15 mm. It is not recommended to install a new piston into a worn cylinder without boring it: the groove under the upper piston ring in the new piston may be slightly higher than in the old one, and the ring may break on the “step” formed in the upper part of the cylinder when it wears out. For VAZ 2112 pistons of repair sizes, a triangle (+ 0.4 mm) or a square (+ 0.8 mm) is knocked out on the bottom. Based on the diameter of the hole for the piston pin, pistons are divided into three classes: 1 – 21.978-21.982; 2 – 21.982-21.986; 3 – 21,986-21,990. The piston class is also stamped on its bottom. The piston and pin must be of the same class. The pistons of one engine are selected by weight (the spread should not exceed 5 g) - this is done to reduce the imbalance of the crank mechanism. The top two piston rings are compression rings that prevent gases from breaking through into the engine crankcase. They also help remove heat from the piston to the cylinder. The lower ring is an oil scraper ring. The cylinder head – common to all four cylinders – is made of aluminum alloy. It is centered on the block with two bushings and secured with ten screws. A non-shrinkable metal-reinforced gasket is installed between the block and the head (their surfaces must be dry) (its reuse is not allowed). The order and tightening torque of the block head screws are indicated in the appendix. At the top of the cylinder head there are camshaft supports - five on each side of the head. The holes in the supports, made detachable, are machined together with the bearing housing. The housing must be replaced as an assembly with the cylinder head. Loctite No. 574 sealant is applied to the surfaces of the cylinder heads mating with the bearing housing. The procedure and torque for tightening the bearing housing nuts are indicated in the appendix. The camshafts are cast, cast iron, five-bearing, each has eight cams (a pair of adjacent cams simultaneously opens two valves in the cylinder). The camshafts are driven by a toothed belt from the crankshaft. Due to the increased loads on the timing belt, its width in the 2112 engine, compared to 2110 and 2111, is increased from 19.0 to 25.4 mm (accordingly, the width of the toothed pulleys and rollers is increased). There is a support roller under the intake camshaft pulley, and a tension roller under the exhaust camshaft. To operate the phase sensor, a disk is welded to the toothed pulley of the intake camshaft. There are alignment marks on the drive gears: if the mark on the crankshaft pulley coincides with the mark on the oil pump housing (the mark on the flywheel is opposite the middle scale mark on the clutch housing), then the marks on the camshaft pulleys must coincide with the marks on the rear cover of the camshaft drive . The seats (made of cermet) and valve guides (brass) are pressed into the cylinder head. The holes in the bushings are machined after pressing. The inner diameter of the bushings has been reduced, compared to engines 2110 and 2111, from 8 to 7 mm. The set of spare parts also includes repair bushings with an outer diameter of 12.279-12.290 mm (increased by 0.2 mm compared to the nominal one). On the inner surface of the bushings for lubrication there are grooves similar to threads: for the intake valve bushings - for the entire length, for the exhaust valves - up to half the length of the hole. Oil deflector caps made of oil-resistant rubber are placed on top of the bushings. The valves are made of steel, the outlet valve has a head made of heat-resistant steel with a welded bevel. The area of the intake valve disc is larger than that of the exhaust valve. They are smaller in size than the valves of engines 2110 and 2111. The valves are located in two rows, V-shaped. They are driven by camshaft cams through hydraulic tappets. The cam axis is shifted relative to the hydraulic pusher axis by 1 mm. Due to this, when the engine is running, the pusher body rotates around its axis, which contributes to its more uniform wear. Hydraulic pushers select the gap between the cam and the pusher body when the VAZ 2112 engine is running, which reduces the noise of the gas distribution mechanism and also eliminates its maintenance (adjustment of the gap is not required). For hydraulic tappets to operate, a constant supply of oil under pressure is required. To do this, there is a channel in the cylinder head with a check ball valve (it prevents oil from draining from the channels after stopping the engine), as well as channels on the lower plane of the bearing housing (they also supply oil to the camshaft journals). Hydraulic pushers are very sensitive to the quality of the oil and its purity. If there are mechanical impurities in the oil, rapid failure of the plunger pair of the hydraulic tappet is possible, which is accompanied by increased noise in the gas distribution mechanism and intense wear of the camshaft cams of the Lada 2112. A faulty hydraulic tappet cannot be repaired; it should be replaced. The valve closes under the action of a single spring. Its lower end rests on the washer, and its upper end rests on a plate held by two crackers. The folded crackers on the outside have the shape of a truncated cone, and on the inner surface there are three thrust collars that fit into the grooves on the valve stem. VAZ 2112 engine lubrication is combined. Main and connecting rod bearings, support-camshaft journal pairs, and hydraulic tappets are lubricated under pressure. By splashing, oil is supplied to the cylinder walls (further to the piston rings and pins), to the piston crowns, to the camshaft cam-pushrod pair and to the valve stems. The remaining components are lubricated by gravity. The VAZ 2112 oil pump - with internal gears and a pressure reducing valve - is installed on the front wall of the cylinder block. The drive gear is mounted on two flats at the front end of the crankshaft. The maximum diameter of the socket for the driven (large) gear when worn should not exceed 75.10 mm, the minimum width of the segment on the body separating the drive and driven gears is 3.40 mm. The axial clearance for the drive gear should not exceed 0.12 mm, for the driven gear - 0.15 mm. The oil receiver is bolted to the second main bearing cover and the pump housing. The oil filter is full-flow, non-separable, equipped with bypass and anti-drainage valves. The crankcase ventilation system is closed, forced, by suction of gases through an oil separator located in the cylinder head cover. * * * The VAZ 2112 power supply, cooling, exhaust and engine control systems are described in the relevant sections. Engine disassembly operations, which are the same for all three models, are given as an example of one of the engines without indicating its model. For operations that differ between engines, the engine model is indicated in the job title.

VAZ 2112 engine 1 – oil pan 2 – front crankshaft oil seal 3 – crankshaft 4 – crankshaft toothed pulley 5 – oil pump 6 – generator drive pulley 7 – toothed belt 8 – front timing cover 9 – coolant pump toothed pulley 10 – tension roller 11 – camshaft pulley 12 – rear timing gear cover 13 – camshaft oil seal 14 – exhaust camshaft 15 – hydraulic tappet 16 – valve spring 17 – valve guide 18 – exhaust valve 19 – receiver 20 – bearing cap camshaft 21 - guide pipe 22 - cylinder head cover 23 - plastic cover 24 - spark plug 25 - intake camshaft 26 - intake valve 27 - cylinder head 28 - coupling 29 - fuel rail 30 - crankcase ventilation hose 31 - injector 32 – intake manifold 33 – flywheel 34 – crankshaft rear oil seal holder 35 – crankshaft rear oil seal 36 – cylinder block 37 – oil dipstick 38 – piston 39 – connecting rod 40 – connecting rod cap 41 – crankshaft main bearing cap

Cross section of a VAZ 2112 engine 1 – oil pan drain plug 2 – oil pan 3 – oil filter 4 – coolant pump 5 – exhaust manifold 6 – exhaust valve 7 – valve spring 8 – exhaust camshaft 9 – receiver 10 – cylinder head cover cylinders 11 – intake camshaft 12 – hydraulic tappet 13 – fuel rail 14 – injector 15 – intake manifold 16 – valve guide 17 – intake valve 18 – cylinder head 19 – piston 20 – compression rings 21 – oil scraper ring 22 – piston pin 23 – connecting rod 24 – cylinder block 25 – connecting rod cap 26 – crankshaft 27 – oil pump receiver

ShPG design features

The 2111 power unit uses a model 2110 piston. In size and design, it is similar to the VAZ 2110 piston. The only difference is in the grooves for the retaining rings installed in the piston bosses. Retaining rings are needed to limit the axial displacement of the finger having a floating fit. Retaining rings are used with VAZ 21213.

The piston pins differ from the 2108 model. The outer diameter of the VAZ 2111 pins is the same as on the 08 model, equal to 22 millimeters. The length of the pin is reduced by 0.5 mm, and is 60.5 mm, this is necessary for installing retaining rings. For reliability, the walls of the finger have been enlarged and the diameter inside the finger has been reduced, now it is 13.5 mm, instead of the previous 15 millimeters.

The connecting rod 2111 differs from the connecting rod of model 08. The length of the connecting rod is the same 121 mm, but the profile is different, the lower head has a more massive and powerful shape. The connecting rod material has improved mechanical properties.

Tuning

According to the conclusion of specialists professionally involved in tuning power units, increasing the power of engines of the VAZ 2111 family is possible in several ways:

- Increasing engine power by installing a compressor

One of the most effective ways to increase the power characteristics of the 2111 power unit is to install a compressor that can provide a pressure of 0.5 bar. In this case, it is necessary to replace the installed camshaft with a Nuzhdin 10.42 or Nuzhdin 10.63 shaft and, by correctly setting the ECU, achieve an increase in power to 120 hp. With.

- You can increase the power of the power unit without using a compressor

To do this, you need to dismantle the existing camshaft and install instead an OKB Dinamika 108 or Nuzhdin 10.93 shaft with a split gear. After adjusting the phases, the engine power will increase to 85 hp. With. If you then install a receiver, replace the existing throttle valve with a larger one (diameter 54 mm), and install a “4-2-1 spider” instead of the exhaust manifold, you can achieve an increase in power to 95 hp. With. At the same time, the acceleration dynamics of the car will improve slightly.

By modifying the cylinder head and intake manifold by milling, as well as installing lightweight valves, we obtain a power of more than 100 hp. With.

- Another way to increase the power of the 2111 engine is to replace the 8-valve cylinder head with a 16-valve cylinder head with a receiver, an enlarged throttle valve (54 mm) and the organization of an exhaust gas exhaust system on a pipe with a diameter of 51 mm. This makes it possible to obtain power in the range of 105...110 hp. With.

Cylinder head design features

The BC 2111 head differs from the 083 model. It has the ability to install nozzles. The bolts for attaching the head to the BC are long. The camshaft is installed from 2110. Its dimensions are the same as the camshaft dimensions of the 08 model. But the shape of the cams has been changed, and the valve lifting distance has also changed. The changes are not significant, less than 1 mm, however, they have significantly improved the technical performance of the power unit. The timing drive is used with the VAZ 2108 and matches it in all respects.

Design of the VAZ 2111 lubrication system

Combined lubrication of the VAZ 2111 power unit. More loaded components and mechanisms are lubricated with oil, which is supplied to them under high pressure. Basically these are all the rubbing parts of the crankshaft and camshaft. Other, less loaded parts are splash lubricated. The pusher, camshaft cam, and valve stems are also lubricated by splashing. The remaining components receive lubrication by gravity.

The gear pump for supplying motor lubricant has internal gears. To prevent excess pressure, a pressure relief valve is provided in the design. The pump is directly driven by the crankshaft.

Typical faults of the VAZ 2111

This engine, like all previously created engines of the Volzhsky Automobile Plant, has a number of specific disadvantages:

Floating speed at idle speed of internal combustion engine

This problem is typical for all previously known VAZ engines. But before, problems with the carburetor were the cause, now there is no carburetor, but the problem remains. There may be several reasons for this:

- first of all, you need to check the regulator that controls the idle speed of the engine;

- the fault may be caused by the sensor that regulates the opening and closing of the throttle valve;

- Also, the engine speed will be unstable if the sensor that controls the air flow is malfunctioning.

The power unit often trips

On a VAZ 2111 engine, a valve may burn out. This malfunction began to occur frequently after increasing the diameter of the valves on the gas distribution mechanism with 8 valves. Measuring the compression in each cylinder of the internal combustion engine will help eliminate this malfunction. If everything is fine with compression, then the cause of the tripping is in the ignition unit.

Engine temperature

A known malfunction of the VAZ 2111 engine, when the power plant cannot reach normal operating temperature. Everything is simple here, the thermostat is stuck in the open position. This can happen even with a new temperature regulating unit; the quality of domestic thermostats leaves much to be desired.

Engine knock

A knocking sound in the engine is primarily a sign of unadjusted valve clearances. If, after adjusting the valves, the knocking does not stop, the news is bad, since the knocking is most likely the connecting rod or main bearings of the crankshaft. This cannot be done without complex and costly repairs.

Stalls while driving

The engine stalls while driving and does not start, this happens if problems occur with the TPS, mass air flow sensor and if the sensor indicating the position of the crankshaft is out of working order.

Oil leak

The VAZ 2111 still has the problem of leaking working fluids from its prototype VAZ 21083. Here, gaskets that leak must be replaced. Particular attention should be paid to coolant leaks from under the cylinder head. With such a malfunction, the coolant can penetrate into the engine lubricant, which can lead to serious problems.

In conclusion, a positive conclusion can be drawn. Despite a number of the above-mentioned shortcomings, the VAZ 2111 1.5 liter is a simple, reliable engine with high repairability. This power unit meets Euro 2 requirements and the requirements of its time.