PCV valve signs of malfunction

You probably don't realize how important the PCV system—your car's positive crankcase ventilation valve and its associated components—is to the well-being of your engine.

What are crankcase gases - gases that enter the crankcase from the operation of an internal combustion engine (abbreviated as ICE), this also includes vapors from automobile oil and even water vapors, as a rule, the percentage of exhaust gases entering the crankcase does not exceed 5-10 percent of the total emissions of the entire internal combustion engine.

A bad PCV or related component can cause many symptoms. For example, if it becomes clogged or stuck in the closed position, you will notice one of these symptoms.

- Increasing engine internal pressure

- Failure of one or more oil seals or gaskets

- Engine oil leaks

- Moisture and deposits in the engine

- Engine runs rough and may produce black smoke

If the PCV is stuck open or a system hose becomes disconnected or ruptured, causing a vacuum leak, you will notice one or more of these symptoms.

Symptoms of a Stuck PCV

- Engine misfires at idle

- Lean air-fuel mixture

- Presence of engine oil in PCV valve or hose

- Increased oil consumption

- Hard engine start

- Rough, unstable engine operation at idle

Additionally, a stuck PCV valve can cause a check engine light due to increased air flow. And the diagnostic computer may mistakenly show this error due to the mass air flow sensor or oxygen sensor, making it difficult for you to identify the real source of the problem.

Why is the PCV valve important?

Faulty PCVs can cause engine oil contamination, sludge buildup, oil leaks, high fuel consumption, and other engine damage problems, depending on the type of fault.

While some of these problems can be caught before they escalate with simple checks, failure of the PCV valve or related components often results in costly repairs. This is because most car owners do not include the PCV system in their maintenance routines. Even though some car manufacturers suggest replacing this part regularly, car owners still forget to replace it. Additionally, not all manufacturers emphasize the importance of regular system checks.

Later in this article we will discuss how car owners can test their own PCV valves.

But before we get to that, here's this entire article in a nutshell: what the crankcase ventilation valve does, what happens when it fails, and how to test it.

PCV valve function in a nutshell

| How does the crankcase ventilation valve work: | • Uses engine vacuum to draw scavenging gases from the crankcase. |

| • Pushes gases down the intake manifold and back into the combustion chambers where they are re-burned. | |

| Some signs | • One or more seals or gaskets have failed. |

| • The engine runs unevenly. | |

| • The engine may emit black smoke. | |

| • Engine internal pressure increases. | |

| • Moisture and dirt accumulate inside the engine. | |

| How to check it: | • Check rubber parts. |

| • Replace the strainer under the valve. | |

| • Disconnect the hoses and inspect them carefully. | |

| • Remove the valve and shake. If it doesn't rattle, it needs to be replaced. |

Conclusion

This system is very important for the correct operation of the car engine. Its malfunction leads to damage to any sealing seals, rubber bands, and oil leakage. Therefore, it is necessary to monitor its performance. Moreover, “taking care” of her is not very difficult.

I would like to note that the operating principle and design of the crankcase ventilation system of atmospheric MPI engines differs from turbocharged ones. If you are interested, I will write a separate review on this topic. Write about it in the comments, I look forward to your feedback.

Source

Operating principle of the crankcase ventilation valve

First, let's discuss its function so that you can better understand the causes of your symptoms. Understanding this will help you better understand the system when reviewing and testing it.

Up until the late 1950s, car engines released "explosive" gases—unburned fuel—to prevent engine damage. The problem was that these gases were harmful to the environment, which is very bad.

When your car's engine is running, an air-fuel mixture enters each cylinder. Hundreds of powerful explosions occur to release the fuel's energy, producing highly toxic and harmful gases. After each combustion process, the exhaust valve directs these gases into the exhaust system, where the catalytic converter converts them into much less toxic vapors before releasing them into the atmosphere.

However, a small amount of gas in the combustion chambers enters the crankcase (engine block) through a pressure leak between the piston rings and the cylinder wall.

Left on their own, these fumes will destroy your engine. Purge gases contain hydrocarbons (unburned fuel), carbon monoxide (partially burned fuel), particulate matter, water, sulfur and acid. Together, these substances corrode any metal engine component they touch, dilute engine oil, build up harmful residue that accelerates wear, and clog small passages and hoses.

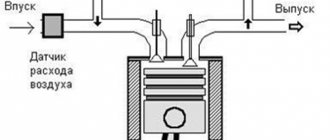

In 1961, the PCV system was introduced to solve this problem. This simple exhaust gas control system uses engine vacuum to pull scavenging gases from the crankcase, pushing them down the intake manifold and back into the combustion chambers, where they are returned.

However, the PCV system will fail if the engine system is poorly maintained.

Engine crankcase ventilation

Crankcase ventilation is designed to remove crankcase gases resulting from the breakthrough of fuel combustion products through the gaps between the liner and piston rings and their interaction with oil vapor.

The gases contain sulfur compounds and water vapor that pollute the oil, which form sulfuric and sulfurous acids, which significantly deteriorate the quality of the oil. Water vapor causes the oil to foam and form an emulsion, which makes it difficult for oil to reach the rubbing surfaces. Gases escaping into the crankcase increase its pressure, which can cause oil leakage through the crankcase seals.

It is also unacceptable for gases to penetrate under the engine hood, and then into the body and cabin of the car, since the harmful substances contained in the gases are dangerous for passengers and the driver. Suction of crankcase gases reduces oil aging, and also, by creating a vacuum in the pan, prevents the possibility of oil leakage through the seals.

There are two types of crankcase ventilation used in automobile engines:

- open – with crankcase gases vented into the environment;

- closed - with gases being sucked into the engine intake system.

Open ventilation (Fig. 1) is carried out under the influence of vacuum that occurs in the exhaust pipe due to the relative movement of air when the car is moving. To prevent oil particles from being carried away along with crankcase gases, a special labyrinth-type breather is used, on the walls of which oil drops settle and flow into the pan.

The disadvantage of an open crankcase ventilation system is its low efficiency, as well as the poisoning of the environment with substances harmful to human health and wildlife.

In closed systems, gases may be vented into the air cleaner before the carburetor or directly into the intake manifold. Gas removal through the air cleaner does not create the required suction intensity at minimum crankshaft speeds and full load. In addition, the passage of crankcase gases through the carburetor causes tarring of its channels, jets and moving parts. Therefore, a system with gas suction directly into the engine intake manifold, in which there is always a vacuum, is more preferable.

The ventilation system shown in Fig. 2, works as follows: under the influence of vacuum in the intake pipe 10, crankcase gases rise upward and through the elbow 9 and hose 5 enter the oil separator housing, closed by a lid 1. Between the lid and the housing there is a rubber membrane 2, pressed by a spring 3 to the housing. Oil particles settling at the bottom of the oil separator housing are drained through tube 6 into the engine crankcase.

Using membrane 2, which is located on one side under atmospheric air pressure, and on the other under the pressure of crankcase gases and springs, excess pressure is maintained in the crankcase.

In Fig. Figure 3 shows a diagram of the crankcase ventilation of a carburetor engine of VAZ cars. Here, crankcase gases are sucked through the oil separator 7 and hose 6 into the exhaust manifold 4 of air filter 3. From the exhaust manifold at idle and at low engine loads (when the vacuum in the air filter is low), crankcase gases flow through hose 2 and spool 1 under the carburetor throttle valves .

In other engine operating modes, crankcase gases enter the carburetor through air filter 3. Oil is released in oil separator 7 and flows through outlet tube 8 into the oil pan. Flame arrestor 5 prevents flame from penetrating into the engine crankcase during possible flare-ups in the carburetor.

Source

The principle of operation of the crankcase ventilation valve - how it works

Checking Your PCV Valve

Unfortunately, many car manufacturers are not strict in maintaining the PCV system. Some suggest servicing the system every 20,000 or 50,000 miles. However, checking the system more frequently helps prevent costly repairs and keep your engine running smoothly.

To begin checking your vehicle's PCV system, first locate the PCV valve and its associated components. Depending on your specific model, you may find the valve on a rubber grommet on the valve cover; on the vent around the intake manifold; or closer to one side of the engine block.

Keep in mind that some newer models don't have PCV at all; instead, you will find a simple vacuum hose running from the valve cover to the air duct. Others may have a simple stopper in place. However, you may want to check the restrictor, hoses, and other components.

If you are unfamiliar with the PCV system in your vehicle or cannot find one, purchase a service manual for your specific vehicle make and model from your local auto parts store. An aftermarket manual costs about $20 and contains instructions for many simple maintenance and repair tasks. If you don't want to buy a copy right now, look for the manual online.

Fortunately, checking the system does not take much time.

- Check PCV system parts. Rubber components such as gaskets, O-rings and hoses swell, become hard and brittle after constant exposure to high temperatures. They start to flow. Replace one or more of these components as necessary.

- Carefully disconnect the valve and all system hoses and inspect them. If you find that the hoses are filled with mucus, clean them with lacquer thinner and replace them.

- Many engine models use a simple, inexpensive valve, and many car owners simply replace it at every service interval. Others include heating elements and are more expensive. Regardless of the type of PCV your engine uses, always buy a quality one as a more accurate calibration for your specific engine model is more likely to be possible.

- On some engines you will find a strainer under the valve. Some car manufacturers recommend replacing the filter every 30,000 miles or so.

- Most PCVs contain a spring-loaded device. Once you remove the valve, shake it by hand. You will hear a rattle. If you don't hear it, it's time to replace the valve.

Some vehicles, including some older Ford Escort models, are equipped with a small, hollow plastic block with no moving parts. If you have this type of valve, simply clean it with lacquer thinner if necessary and reinstall it.

Crankcase gas recirculation system

Where does the escaped gas mixture go? As a rule, through various channels (for example, where the chain runs) they rise up into the valve cover (they can rise up directly from the crankcase through hoses). And here the most interesting part begins, namely the crankcase gas recirculation device; they can be divided from conventionally “old” to progressively “new”.

Old device . Here everything was simply “like a drum”, a special “tube” (hose) came out of the engine crankcase, sometimes there was even just a box on blocks that simply connected to the atmosphere, yes - yes, they simply exited into the atmosphere. At that time, everyone was absolutely “on the side” about the environment; there were no environmental systems in the cars (such as catalysts , etc.). There were special “oil catchers” (sometimes just a labyrinth of small channels, sometimes a metal mesh), which retained the oil mist and returned it in the form of oil back to the engine.

It is worth noting that crankcase gases are contaminated - essentially this is an unburned air-fuel mixture + “waste” that escaped directly from the combustion chamber and mixed with the “oil mist” that is in the crankcase of the internal combustion engine. And all this explosive (very dirty) mixture previously (without any filters) simply went out into the engine compartment, and then into the atmosphere. By the way, both the driver and passengers could also breathe all this, because nothing prevented these gases from passing into the cabin

The first recirculation systems . BUT then people began to think that this was not correct and that this matter needed to be filtered somehow (at least minimally). Therefore, on the first, carburetor ones , for example VAZ 2101 - 2103, crankcase gases rose up the hose and went out to the carburetor air filter. Drivers of that era remember the round air filter, which prevented dust and dirt from entering the carburetor; all this was enclosed in a round metal case and closed with a lid.

Thus, for the first time, crankcase gases did not escape into the atmosphere, but were sucked back into the engine and burned again. This recycling system did not carry any practical or useful meaning for the internal combustion engine; it was made simply for the sake of the environment.

First generation recirculation injection systems . Here the device is slightly different, because the system itself is very different from a carburetor. Here, a special pipe (breather) came out of the valve cover (or from the engine), an oil catcher was installed behind it (usually inside), a hose was connected to it on one side, which, in front of the throttle valve on the other side, crashed into the air supply line (for example, on our VAZ 2110, 2111, 2112, etc.)

Essentially everything is the same, these gases were sucked in along with new air and got inside the engine.

The only problem was that the throttle valve became dirty relatively quickly because this gas mixture carries a little oil mist, so it was advisable to clean it every 50 - 60,000 km.

Modern recycling systems . Now the systems are more advanced, here crankcase gases also rise through special channels, either from the cylinder head or from the engine block itself. And through special valves (for example, a recirculation valve), they enter the intake manifold or air supply channel. However, now the flow almost always comes after the throttle valve

PCV Valve Service

In addition to visually checking the condition of the various PCVs and related components, check the system while the engine is running.

- Vacuum testing

- Start the engine and let it idle for about twenty minutes to warm it up to operating temperature.

- Then open the hood and disconnect the valve from the cover and block the end of the valve with your finger. You will feel the vacuum from the system's suction on your fingertip and notice a brief drop in idle speed of about 40 to 80 rpm.

- If you notice a greater drop in RPM and engine idling, your PCV valve may be stuck open.

- If you can't feel the vacuum at your fingertip, check the hoses for dirt blocking air flow. If necessary, clean the valve and hoses with lacquer thinner and a fine hose brush.

- Alternative tests

- Another way to check the vacuum is to pinch or block the vacuum hose connected to the PCV valve. The idle speed will drop from 40 to 80 rpm and then return to normal. If not, look for a blocked or restricted vacuum hose or valve.

- On some engines, access to the PCV is difficult. On these models, you can remove the engine oil dipstick and cover the hole in the dipstick with a piece of tape. With the engine idling, remove the oil filler cap on the valve cover. Then place a thin piece of cardboard over the hole. Wait about a minute. You will notice that the vacuum is sucking and pressing the paper into the hole. Otherwise, there is a leak in the system or the system is clogged. Check the condition of the hoses, their connections and gaskets.

Should the PCV valve be suppressed or not?

From all of the above, one more conclusion can be drawn. And this conclusion is associated with the damping of this valve.

It's no secret that many car owners, having listened to a lot of advice on the Internet, try to muffle this valve so that it supposedly does not contaminate the throttle valve and intake manifold.

The reason for such “tuning” is, of course, “iron”, but few people think about the consequences. Moreover, the consequences not only for the crankcase ventilation system, but also for the operation of the engine control system as a whole.

It is clear that the crankcase ventilation system will not get any better from such modifications. But the engine management system will also change the operating conditions. In particular, as we understand, this will at least lead to a change in the IAC steps at idle.

A diagnostician, who in the future may be diagnosing such a car, may pay attention to slightly elevated IAC steps and may even want to correct the situation, but he will not be aware that the problem is not a dirty throttle assembly or something else, but that the PCV valve is plugged. Some people don’t even see the connection between these things.

I talked about this case in this video

Therefore, if you do not understand what you are doing and are not aware of all (all!!!) the consequences of such manipulations, then I recommend that you refuse this kind of action.

And, in general, you shouldn’t turn off the PCV valve.

PCV system maintenance

Sometimes, bad valve symptoms are mistakenly reported as coming from a bad sensor. This is why it is important to regularly check the PCV and related components. It takes only a few minutes. If your engine is missing a valve, or you can't get to it without removing one or more components, consult your repair manual for the best way to check your specific system. Also, check your system's maintenance schedule and replace necessary components at regular intervals, even if it appears to be in good condition. Most PCV valves and related components are inexpensive and will save you money on costly repairs if you replace them at the recommended interval.