The cold season is perhaps the most difficult period for motorists. And it’s not just that road conditions are worsening due to ice and snow; subzero temperatures bring much more trouble, as they cause increased wear and tear on all engine components and assemblies.

To successfully complete the season, you need to prepare your vehicle in advance so that the adaptation of the engine to starting in a cold climate is as painless as possible. Proper preparation includes a whole range of work, such as: selection of special seasonal oil (for the engine and transmission), hydraulic power steering fluid, antifreeze, checking the condition of the battery, etc.

Cold engine start

Winter is a real testing time for motorists.

The first problem that drivers have to face is ice and the need to switch to winter tires. We have already talked a lot on Vodi.su about the rules of driving in winter and how to prepare your car for winter. They also mentioned how to start a car in temperatures below zero. Now let's look at the topic - why a cold start is dangerous.

Engine operating temperature is 70-80 degrees. Even in summer you have to warm up the engine in the morning. In winter, it is much more difficult to warm it up if it is minus 30 outside.

In the cold, the following metamorphoses occur with the power unit:

This leads to the following consequences.

Low battery

First of all, a stronger battery charge is required to spin the starter and crankshaft flywheel. Batteries are also a sore subject in winter. Not only does the laws of physics dictate that the charge level drops to 70-80%, but it also requires a much larger load to start the engine. This is due to the fact that the oil loses its fluidity and becomes thick, which makes it much more difficult to turn the crankshaft.

That is why it is necessary to check the density of the electrolyte and recharge the battery before the onset of cold weather. However, it will still discharge on its own at temperatures below zero.

Engine wear

Secondly, wear of pistons, cylinders, crankshaft journals, main and connecting rod bearings increases. This is because the oil becomes too thick and does not provide lubrication to the engine. It turns out that until the engine temperature rises to a certain temperature, friction occurs dry.

It’s not for nothing that they say that a cold engine start is equivalent to a mileage of 150-250 kilometers. And the stronger the cold, the greater the wear of engine parts.

At the same time, engine compression drops due to increased clearances between the cylinder walls and pistons, and between the valves and guides; accordingly, more oil and fuel are required to ensure starting. When the engine warms up to operating temperature, this parameter will return to normal. However, a seized engine is a common problem in winter.

Spark plugs, ignition mechanism

The battery provides charge not only for the starter, but also for the ignition mechanism. If you haven’t bought good spark plugs for your car in advance - or even better, 2 sets, then there may be a problem with the spark. You can also read how to understand the labeling of candles on our website Vodi.su.

Worn spark plugs produce a very weak spark, which will hardly ignite the fuel-air mixture. Also, due to a drop in compression and increased fuel consumption, the amount of decomposition products increases - all of this settles on the spark plugs, the oil filter clogs faster, and a greater load is placed on almost all engine systems. That is, in addition to new spark plugs, you also need to install new filters - air, oil, fuel. It's never superfluous.

Rubber parts

Rubber technical products (RTI) - oil seals, cuffs, sealing rings - retain their properties at temperatures down to minus 25 degrees.

A sharp change in temperature during startup does not have the best effect on them - cracks appear, especially in the tubes, causing technical fluids to leak out.

For example, in severe frost, it is not recommended to park the car for a long time with the wheels turned out. If you turn the steering wheel sharply, the power steering hose may rupture, which will lead to a fountain of expensive Dexron II or III hydraulic fluid.

conclusions

You can still find a lot of negative consequences that lead to a cold engine start. However, if your car is in excellent technical condition, then all this is not as scary as it seems. Please also note that the engine life is most often designed for 250-300 thousand kilometers. Moreover, this applies to both diesel and gasoline engines.

If you want the engine to last as long as possible, avoid an aggressive driving style in winter, do not apply a heavy load immediately after the start, but gradually increase the crankshaft speed.

Source

Tips for car owners

How to start the engine correctly in cold weather? If you have a gasoline car, you should not immediately start the internal combustion engine after turning on the ignition. You need to wait until the electric pump pumps fuel into the ramp. This will take no more than three seconds. But these are the seconds that can save you when starting the car in cold weather. So, turn on the ignition and wait until the pump pumps in the liquid. This can be determined by the sound. When operating, the pump will make a characteristic hum in the rear of the car. When it is silent, you can start.

A useful step would be to warm up the battery. This can be done without removing it from the car. It is necessary for the battery to receive a load - this will help activate the electrolyte inside. To do this, turn on the high beams for ten seconds. However, remember that when starting, all electrical appliances must be turned off. The slightest load on the battery will significantly worsen the operation of the starter. If the vehicle is equipped with a manual transmission, it is recommended to depress the clutch pedal when starting.

What will this give us? The oil in the manual transmission is very thick (viscosity 75w90), so when the flywheel rotates, the starter will partially work to rotate the gearbox parts. To reduce the load on the battery, which will provide us with starting current, we press the clutch pedal to the floor. This will reduce the risk of an unsuccessful start of the internal combustion engine.

It happens that during a cold start on a gasoline engine, the spark plugs flood. As a result, it is very difficult to start the engine. Of course, a better solution is to dry them in a dismantled state. But you can dry the candles without twisting them. How? To do this, when rotating the starter, you need to press the gas pedal all the way. This operation will increase the purging of the combustion chamber from excess fuel and will allow you to successfully start the engine.

Preparation and algorithm of actions

If there is an urgent need to leave the garage or start the engine of a car parked outside at low temperatures or high humidity, then you need to act according to a specific plan.

You need to adhere to the following algorithm:

On engines with forced fuel injection, you can also bleed the system several times by first turning the ignition key to the second position. In this case, along with other systems, the fuel pump is turned on for a short time. After it stops working, turn off the ignition. After 20-30 seconds, repeat this operation.

In the case of diesel engines, it is necessary to heat the fuel using hot water and glow plugs.

It should be remembered that you cannot turn the starter for too long. Otherwise, there is a risk of draining the battery. Startup attempts should be limited to 15 seconds. After this you need to take a break for half a minute.

How long to turn the starter and how much to press on the gas?

So, we start the engine ourselves - the key is to start! But winter startup is usually not as confident and fast as in summer - sometimes it takes several attempts. If this is your case, do not crank the engine for more than 10 seconds at a time and be sure to pause for a minute between attempts to allow the starter to cool.

On many cars, the engine control unit enriches the mixture after an unsuccessful start attempt in order to accurately start the engine the second time (the first attempt is made with an eye to the environment and minimizing emissions). Therefore, in severe frost, it is better to immediately tune in to starting in two approaches: a short (2-3 seconds) first cranking with the starter, a pause and starting on the second attempt.

Do I need to press on the gas when starting the engine? Some are categorically against it, because this is the best way to fill the candles with fuel and not go anywhere. Others say that you need to apply gas so that the engine does not stall. Both are right, the only question is the moment of launch. While the engine is being rotated by the starter, you should not touch the accelerator pedal - do not interfere with the control unit doing its job, accurately dosing the fuel. But when flashes begin in the cylinders and the engine is almost starting, pressing the gas can help it reach a stable speed and not stall. Of course, to feel this moment correctly, you need experience.

Some important tips from experienced motorists

Even before the onset of constant cold weather, it is important to prepare the car for the winter period of operation. It is recommended to change tires, engine oil, antifreeze, and windshield washer fluid.

At low temperatures, you should check the level of all technical fluids before each trip. If necessary, the problem must be corrected immediately.

Easy starting of a car engine at subzero temperatures largely depends on the condition of the battery and spark plugs.

It should be remembered that:

Therefore, when carrying out this procedure, it is important to follow the following rules:

When using a car, it is important to fully adhere to the rules of its operation, undergoing maintenance on time, changing technical fluids, worn parts, and consumables. The main thing is not to “force” the engine by subjecting it to excessive loads during startup at low temperatures.

Source

Oil

An important characteristic that determines the ease of winter starting is oil viscosity. If the car's annual mileage is more than 20 thousand, experts recommend changing it according to the season. There are several types of motor oil:

All of them are marked with a two-digit viscosity value according to SAE. It is believed that the best oil is what the manufacturer recommends using. But winters are different, so sometimes you can deviate from the manufacturer’s recommendations. Winter oils are marked with the letter W.

If the average air temperature in a given season is from 10 to 25 degrees below zero, you should focus on products with a viscosity from 0W to 10W. You can choose both synthetics and semi-synthetics. Oils with such viscosity will ensure easier engine starting in cold weather. If the winter is warmer, you can use products with a viscosity of 15W. But remember that the lower this number, the less thick the oil. Accordingly, on old engines it can simply escape through worn oil seals, gaskets, or into the combustion chamber through rings. Therefore, there is no need to significantly reduce this indicator.

Voltage sag

With the arrival of cold weather, the degree of self-discharge of the battery increases. A decrease in electrolyte density, sulfitation of plates and a short circuit between banks lead to a decrease in voltage in the on-board network. The progression of non-negotiable processes is a consequence of the exhaustion of the battery life or non-compliance with recommendations for operation and maintenance.

The starter is one of the most powerful consumers in a passenger car. At the time of startup, the current consumption can reach 400-450 A.

As the starting speed decreases, fuel combustion worsens, making a cold engine difficult to start. Drawdown also leads to a deterioration in the quality of the spark discharge on the spark plugs.

Battery voltage

If the car has been standing outside for a long time or the air temperature has dropped below -20 degrees, before starting the diesel engine in cold weather it is worth checking the voltage in the battery. In cold weather, the density of the battery electrolyte may drop. The battery capacity itself decreases. As a result, it is very difficult to start the engine in cold weather. After turning the ignition key, the starter will spin the flywheel lazily. And on the second or third attempt it will refuse to work altogether.

To avoid draining the battery, you should check its voltage before starting. For a successful start, this parameter must be at least 13 Volts. If the indicator is less, it is worth charging the battery.

Features of starting a diesel engine

Unlike a gasoline internal combustion engine, where the mixture is ignited by a spark, the fuel in a diesel engine is ignited by contact with heated air. To raise the temperature in the combustion chamber, the air must be compressed many times. That is why the actual compression of an average gasoline engine is 10-12 Atm, while in a diesel internal combustion engine this figure can reach 20-25 Atm. High demands on the preparation of the air-fuel mixture result in a large load on the starter.

Therefore, in a diesel engine, the requirements for the condition of the battery, the serviceability of the starter and the supply voltage in the circuit are much higher than for their gasoline counterparts.

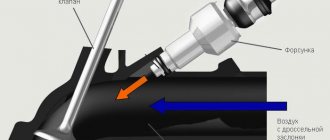

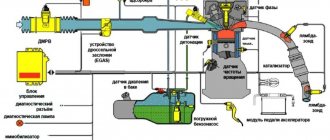

The common rail injection system control unit blocks the control impulse for opening the fuel injectors if sufficient pressure does not develop in the fuel rail when the starter is cranked.

The insidiousness of such a control algorithm is that it can be difficult to determine by ear the missing 50-70 rpm and the associated lack of pressure in the ramp. It may seem that the starter rotates the engine quite vigorously, and therefore there are no complaints about the battery and the starter. To understand why a diesel car has difficulty starting when cold, we recommend using diagnostic equipment to monitor the following parameters at the time of start-up:

Fuel pump malfunction

Another reason why a car has trouble starting when cold is a faulty fuel pump.

In order to check whether the fuel pump is working, you need to turn on the ignition, and you will hear a buzzing sound from the gas tank, it will last for several seconds. As soon as the fuel supply stops, the required amount will be pumped in and pressure will be created in the fuel rail. The pump will then automatically turn off.

If you do not hear a buzzing sound and the car does not start, then you need to check the serviceability of the fuel pump.

Glow plugs

To facilitate cold starting, diesel engines are equipped with glow plugs.

Heaters not only preheat the air in the combustion chamber before starting, but also ensure complete combustion of fuel in the first minutes after start. When the temperature drops below +5°C, spark plugs play a key role in the successful starting of the engine. Old pre-chamber internal combustion engines of the Diesel cycle are especially sensitive to the serviceability of heaters. The breakdown of even 1-2 spark plugs will result in the car having difficulty starting after being idle. Methods for checking glow plugs:

The disadvantage of the glow plug testing methods described above is that you cannot see the heating pattern of the heater. A working spark plug should glow from tip to base. Often the heater is called by a multimeter, but when voltage is applied it only heats up closer to the base. Therefore, the best way to check glow plugs is to test from the power source in a removed state. This way you can be sure to confirm/refute that the car does not start in cold weather due to the glow plugs.

After making sure that the heaters are working properly, check the presence of supply voltage from the glow plug control unit and relay.

Video: Poor starting of a cold engine

What's the result?

As you can see, some of the consequences of a cold start can only be avoided by quite serious cash injections (installation of autonomous engine pre-heaters, oil sump heaters, etc.) in combination with storing the car in a warm garage.

However, if the technical condition of the car is good or the car is new, you should not be afraid of a cold start. The service life of many modern engines is, on average, about 300-350 thousand km. (both petrol and diesel internal combustion engines).

The above may well be enough to ensure that the damage after a cold start is minimal, and the engine reaches operating temperatures as painlessly as possible during operation.

How important is compression and a working starter?

In severe frost, proper operation of the preheating system and good starting speed will not be enough if compression has dropped in several cylinders. Large losses during compression of the mixture do not allow the air to be heated to the ignition temperature of diesel fuel. This is why the car has trouble starting when it cools down. Long cranking of the starter helps compensate for heat losses.

If everything is in order with the compression on the car, similar symptoms of difficult starting are observed in the case of a worn starter. Wear on the commutator lamellas and wear of the brush assembly are the most common reasons for a decrease in starter power and, as a consequence, the number of starting revolutions.

The carburetor engine does not start when cold.

As you know, a carburetor is a mechanical fuel injection system into an engine. It is very primitive, and unlike the injector, it does not have such a large number of sensors that simplify the use of the car.

As a rule, the carburetor has a choke, which opens an additional chamber for air supply, thereby increasing the speed. If the choke is not working properly, then it is very difficult to start the car when it is cold, since the standard speed of a cold engine is not enough for its normal operation when it is not warmed up.

Engine is bad: 5 possible reasons

Sometimes the source of the problem lies in a clogged air filter or oxidation of the battery contacts. Replacing consumables or components does not always solve the problem - you should start with a comprehensive diagnosis.

If the problem of difficult starting affects a car on which there is a gas installation, the tightness of the hoses may have been damaged due to damage to the sealing elements due to high temperature. The leakage of the working environment could have occurred for another reason. Gas is not something to joke about - you need to consult a specialist.

The diesel engine did not start in cold weather. What to do

There is one significant problem with such engines. Diesel thickens at temperatures of -5 and below. In view of this, purchasing anti-gel would be a useful acquisition.

This is a special additive that dilutes diesel fuel. It is added to the tank in small proportions. In winter, the fuel thickens, turning into paraffin. Because of this, fuel is not able to penetrate through the thin pores of the filter. But there are situations when the fuel thickens in the injection pump itself. In this case, you need to carefully pour boiling water over its body. Try not to flood the generator and starter. From now on, try to buy winter fuel at gas stations or use an additive in the tank in advance.

The whole truth about cold starts

Almost all drivers, if they don’t know for sure, then guess that starting the engine without preheating is harmful. That’s right: haste in this matter leads to rapid wear of rotating and rubbing components - pistons, cylinders, liners, crankshaft journals. The thickened oil does not immediately enter the mechanisms; the latter are left without lubrication and are forced to work “dry”. But it turns out it's not all bad news.

Solving diesel starting problems

There are a lot of problems that make it impossible to start a diesel engine. Let's consider the main ones, and also find methods for solving them.

Misplaced fuel injection timing. With late injection, starting a diesel engine in cold weather is almost impossible. In addition, it is often quite difficult to determine that this is the case. This will require diagnostics.

Another current reason is battery current leakage. If in summer this circumstance may not be so noticeable, since the starter does not consume as much energy to start, then in winter this issue requires an immediate solution. Most often the problem is in the winding (something has shorted somewhere). All this is revealed by a basic visual inspection. It is advisable to check the alternator belt for wear and tighten it if necessary. After this, most likely, you can immediately start the engine in cold weather without any problems.

Starting the engine “cold” can be difficult due to:

There is one more point - environmental. Fuel at low temperatures ignites less easily, so a “cold” engine requires a richer fuel mixture. This significantly increases the amount of harmful substances released into the atmosphere. By warming up your car for 10-15 minutes, you can make your own contribution to environmental protection.

There are actually many more reasons why the engine refuses to start. Sometimes replacing or cleaning the spark plugs, installing a new air, fuel or oil filter, or updating the O-rings helps. And sometimes you can get by with tidying up the throttle valve or other elements of the intake tract. Often it is not possible to independently determine the source of the problem, and is it worth it if a good service station can do it faster and better?

Source

Why doesn't diesel start when cold?

Diesel fuel may freeze at low temperatures. Therefore, this type of fuel has varieties for each season. In the summer, summer diesel fuel is poured, in winter, winter diesel fuel is filled, and in regions where it is very cold, “Arctic” diesel fuel is filled.

It happens that the wrong fuel was filled by mistake. The air temperature dropped below zero and it froze. Of course, the pump is unable to pump frozen diesel fuel, so the engine does not start.

Sometimes, at low-quality gas stations, water can get into the diesel fuel. After refueling with such fuel, it settles at the bottom of the tank, and can also freeze in the fuel channels or in the filter.

Engine is bad (carburetor, injector, diesel)

Difficulties starting the engine “cold” arise in different situations. Firstly, leaving the car in the cold for a long time. This could be one night or several weekends. Secondly, the cooling of the internal combustion engine after it has warmed up to operating temperatures, stopped and attempted to restart after some time.

Difficulty starting gasoline and diesel engines has similar causes, but manifests itself in different ways. This applies to engines with carburetor and injection fuel supply systems that have design differences.

In this article we will talk about common problems that lead to additional difficulties when trying to start the engine “cold”, we will give recommendations for owners of cars with power plants running on gasoline and heavy fuel.

Identifying and eliminating engine starting problems

Why is my car hard to start when cold? In most cases, problems can be identified and fixed without much difficulty. Thus, a sign of clogged fuel filters will be difficulty starting the engine (it may stall at idle), a decrease in power, and also the car jerking during inclines.

It is worth noting that such “symptoms” can also be the result of other faults, such as wiring problems or faulty spark plugs. In this case, it is necessary to urgently replace the filters. If this is not done in time, the motor may fail.

Fuel supply can be checked by unscrewing the spark plugs. If they are filled with gasoline, or, on the contrary, are completely dry, then it is necessary to check the sensors or adjust the carburetor.

Another problem, a sign of which may be that the engine does not start when cold, is clogged injectors. In this case, the car loses dynamics when accelerating sharply, twitches and reacts poorly to pressing the gas pedal. In addition, muffled high-frequency noises may be heard coming from the cylinder block.

If the injectors are indeed coated with deposits, they need to be cleaned. You can do this yourself. There are several main ways to restore this part:

- The first cleaning method is rather preventive. It consists of adding special additives to the fuel that help get rid of deposits on the injector. However, many motorists try to use this method as little as possible: it is believed that additives can further worsen engine performance.

- Some experts recommend periodically turning the engine up to high speeds. After several kilometers at a speed of 100-110 km/h, engine performance should improve somewhat.

- If the injectors are seriously dirty, you will have to clean them manually. To do this, you need to disassemble the injector. After this, the parts are washed with high-quality fuel without impurities or kerosene and blown with compressed air.

- There are two more ways to clean injectors. They guarantee almost 100% results, but to implement them you need to use professional equipment and have certain skills. Therefore, it is better to contact a service center here. In the first case, the parts are exposed to ultrasound, which destroys all plaque. In the second, a special liquid and a device are used that is connected to the fuel receiver. After the engine has been idling for some time, the injector will be cleaned.

Important! You should not take action without making sure that a specific node is indeed the cause of the poor startup. This is especially true for complex work, the incorrect execution of which can lead to even more serious damage. If in doubt, it is better to turn to professionals.

Preparatory activities

To simplify your task in finding the cause of the malfunction, check the following:

1. Presence of exhaust gases.

There should be light smoke coming from the exhaust system when the starter rotates. It indicates that fuel is entering the cylinders.

2. Battery charge level.

A completely discharged battery is one of the most common reasons why a car engine will not start. Therefore, we check the battery charge level.

3. Serviceability of the starter (the engine should spin without failure).

If the starter does not spin the crankshaft, then a dead battery is to blame. If not, then the problem lies elsewhere. For example, the contact between the ground and the starter housing has oxidized.

Compression

Owners of old used cars should especially monitor this parameter. On gasoline engines, the compression ratio must be at least ten atmospheres. On diesel engines - from twenty and above. If the compression is lower, the engine will be difficult to start. And if in summer it starts on the third or fourth attempt, then in winter the battery may not have enough strength for such a long start. The measurement is made using a compression meter. It is installed in place of the removed spark plugs. After installation, you need to crank the crankshaft 2-3 times with the starter. And so on for each cylinder. The indicators should not differ by more than one atmosphere. If the compression is weak, such a motor needs to be repaired. Otherwise, the car will not start in cold weather.

But it often happens that the engine does not start with a working battery and normal compression. In winter, the driver has no room for error. Therefore, you need to know how to start the engine in cold weather on the first try. We will talk about this below.

The main causes of problems during cold engine starts

Low quality fuel

The likelihood of refueling a car with low-quality fuel at certified gas stations in large cities is very low. It is much easier to encounter counterfeit products at little-known gas stations on the highways or when purchasing fuel second-hand. Such fuel does not pass quality control and contains a large amount of impurities that contaminate filters and fuel pipe channels. As a result, the pressure in the system decreases and the car does not start.

The use of low octane gasoline is determined by the following criteria:

In diesel engines, a problem may arise due to the fuel selected “out of season.” An owner who uses diesel fuel for the summer during the winter period of operation of the vehicle will encounter difficulties. The main reason is the discrepancy between the physical and chemical properties of the fuel and the operating conditions.

Summer diesel fuel at subzero temperatures turns into a viscous and thick mass that clogs both the fuel line and the filter. Its chemical composition is not suitable for working in such conditions. In this situation, preheating the fuel system and installing a new filter instead of the dirty old one will help.

Poor condition of spark plugs

Remove the spark plugs after an unsuccessful attempt to start the engine. The presence of strong smudges, as a rule, indicates a malfunction with the ignition system and a violation of the tightness of the injectors.

First you need to inspect the external condition of the candles. Check their integrity. You should look at the high voltage wires. There should be no defects.

A dry spark plug indicates that fuel is not getting into the cylinder.

Problems with the fuel pump

Malfunctions in the operation of the pump lead to the inability to pump the required level of pressure. The main reason for this unpleasant phenomenon is a clogged filter. If the filter element is dirty, the required pressure is not created in the ramp. Accordingly, the car will not start. The internal combustion engine receives a lean fuel mixture, which also does not ignite due to the too low temperature in the cylinders.

To find a fault, we check the pressure in the rail and directly in the pump. Engines with fuel injection may also have coked injectors.

To check the fuel pump, turn on the ignition. If everything is in order, you will hear a characteristic buzzing sound from the side of the fuel tank. It lasts a couple of seconds. After the fuel supply stops, the required pressure will build up in the fuel rail. The pumping equipment should automatically turn off.

Presence of air leaks

The air supply system must be sealed. To check its supply, look at the condition of the line. There should be no cracks, breaks or bends that lead to leaks or impede the passage of air. Traces of gasoline leaks are evidence of leaking fuel lines.

Error when choosing engine oil

It is allowed by inexperienced car owners. Incorrectly selected motor oil viscosity grade leads to problems when starting the internal combustion engine. Liquids that are too thick freeze at subzero temperatures. As a result, difficulties arise with its passage through the oil channels.

Features of national engine starting in winter

Let's start. Let's start with the axioms. Necessary and sufficient conditions.

Statistics collected by Ast.

There were 200 cars that were not certified in the cold.

60% of cars are blocked by an alarm (the Chinese relay freezes).

20% of the cars had more than one malfunction (often, for example, there are 5 reasons at the same time).

Let's start

If, after all, the candles are flooded...

A little about “winter” calibrations.

Now a little about calibrations. CTPro owners have already memorized the obvious “winter” calibrations of internal combustion engines. НUMMER-74 (Old Nefor) unearthed an implicit but important calibration - “Injection phase at start-up”. On all VAZ calibrations without exception, the parameter is 162 deg. However, to ensure a reliable start, it seems more correct to supply fuel at the moment when the intake valves are completely closed, in order to avoid flooding the spark plugs. Gasoline will evaporate for some time in the receiver and on the valve plates, and the concentration of gasoline vapors will improve. To do this, you need to set this parameter (Variables-Phase-Injection phase at start) for 8 V – 216 ( 222 ); 16 V – 252 (258). Experimental confirmation required.

And here are the exact injection phase parameters:

2111: Inlet valve. Opening: 0 deg. to TDC. Inlet valve. Closing: 36 deg. after BDC. Exhaust valve. Opening: 30 degrees. to BDC. Exhaust valve. Closing: 2 deg. after TDC.

2112: Inlet valve. Opening: 29 degrees. to TDC. Inlet valve. Closing: 73 degrees. after BDC. Exhaust valve. Opening: 71 degrees. to BDC. Exhaust valve. Closing: 31 degrees. after TDC.

A list of theory- and practice-tested cold start recommendations

The path from the nozzle to the combustion chamber on an injection engine is several tens of times shorter than in a carburetor version. The injector sprays fuel directly onto the plate of the intake valve that has opened into the combustion chamber. Of great importance is how much vapor phase of the fuel enters at this moment. This is entirely determined by the volatility of the fuel. The conditions for ignition can vary so greatly due to differences in fractional composition that they are difficult to control and regulate. If for the carburetor version this is not very significant due to the fact that the fuel flows through the intake pipe for quite a long time and eventually evaporates to a sufficient concentration, then for the injection version everything is much worse: the fuel, supplied directly to the valve plate, does not have time to evaporate and pours the candles. HUMMER's proposal is based on this - to give the fuel more time to evaporate. Having reached the valve at the moment of its closing, the fuel begins to evaporate and on the next intake stroke it is sucked into the cylinder, which has already evaporated to a greater extent.

.

The secret to easy starting of a cold engine lies in two components: a working car and the correct actions of the motorist.

In this article we will look at how to properly start a carburetor engine on choke. The above shows how not to do it :).

First, a little theory. The main component of the “suction” is the air damper. It is located in the first chamber of the carburetor and is controlled by a cable from inside the car. Its function is to control the flow of air passing through the carburetor. If you close this damper (by pulling the cable handle in the cabin) and start the engine, a vacuum will be created in the first chamber of the carburetor. Due to this vacuum, additional gasoline will begin to be sucked into the carburetor chamber - hence the name “Suction” was born. The fact is that a cold engine needs a fuel mixture rich in gasoline to start. After all, if the engine is cold, gasoline will not evaporate well, which means the content of gasoline vapor in the air will be minimal and the mixture will not ignite. To avoid this, engineers came up with a “suction” (“cold start device” or “cold start system”) - a forced enrichment of the fuel mixture, which compensates for the insufficient evaporation of fuel at low ambient temperatures and, accordingly, a cold engine.

That's all for the theory. Let's move on to action!

Starting a cold engine at sub-zero temperatures: instructions

The following procedure assumes that the car and carburetor are in good technical condition.

- Pull out the handle of the “choke” cable until it stops.

- We press the gas pedal twice and don’t touch it again!

- Depress the clutch pedal.

- Turn the key and turn the engine with the starter.

If everything is in order, the engine should start. If the carburetor starting device is faulty or not adjusted, problems with starting the engine are possible:

Possible difficulties

The engine starts and immediately stalls

In this case, the procedure will be as follows:

- Pull out the handle of the “choke” cable until it stops.

- Press the gas pedal three times and on the last press leave the gas pedal pressed 1/3 of the way.

- Depress the clutch pedal.

- Turn the key and turn the engine with the starter.

- If the engine stalls again, repeat steps from step 2 to step 4. However, with each repeated cycle we add 2 gas pedal presses to step 2. That is, the number of gas pedal presses should be as follows: 3, 5, 7 , 9, 11, 13, 15. When 15 gas pedal presses are reached, further increasing the number of presses is inappropriate.

The engine starts, but starts to stall and the speed drops

We fix it as follows:

- With the engine running, press the “choke” handle into the panel a few millimeters.

Engine won't start

- Pull out the handle of the “choke” cable until it stops.

- We remove the handle of the “choke” cable a few millimeters inside the panel.

- Press the gas pedal three times and on the last press leave the gas pedal pressed 1/3 of the way.

- Depress the clutch pedal.

- Turn the key and turn the engine with the starter.

- If the engine does not “grab”, remove the “choke” handle a few more millimeters and repeat steps from step 3 to step 5.

- If the engine starts and stalls, we repeat the steps from step 2 to step 4. However, with each repeated cycle we add 2 gas pedal presses to step 2. That is, the number of gas pedal presses should be: 3, 5, 7, 9, 11, 13, 15. When 15 gas pedal presses are reached, further increasing the number of presses is inappropriate.

Instructions for adjusting the starting device on Solex

is

here

.

If the recommendations described above did not help, then your car probably has technical problems not related to the carburetor starting device. These may include:

- The needle valve is leaking or the fuel level in the carburetor float chamber is not adjusted.

- Problems with fuel supply.

- Strong air leak.

- Ignition system malfunction. Including: poor or no spark, faulty spark plugs, faulty high voltage wires.

- Engine malfunction: low compression, timing mechanism is out of order.

Cold engine start: harm to the internal combustion engine

As you know, even a serviceable engine can have difficulty starting in extreme cold. The fact is that engine and transmission oil thickens, the battery consumes more charge, gasoline evaporates worse, and the diesel fuel in a diesel engine becomes viscous and is difficult to pump through the power system. As a result, it is more difficult for the starter to turn the crankshaft, and the fuel also ignites worse in the cylinders.

If we ignore the starting difficulties themselves, the danger of a cold engine start is that the cold metal “compresses” somewhat, as a result of which the gaps between the mating parts become enlarged. In this case, compression naturally becomes lower.

Since the engine oil becomes less fluid and pumps worse, at the moment of starting “cold” it turns out that the engine experiences oil starvation for the first seconds. One way or another, increased engine wear cannot be avoided. As a rule, we are talking about wear of the CPG (pistons and cylinder walls), crankshaft journals, main and connecting rod bearings, etc.

Simply put, the oil becomes viscous and until a certain warming up is not supplied to the loaded vapors in the required quantity and under the required pressure. The result is that parts experience high loads and suffer from dry friction.

But that's not all. As mentioned above, the compression of a cold engine is reduced, which requires more fuel to start it. At the same time, through the increased gaps between the piston rings and the cylinder wall, fuel in a cold internal combustion engine enters the crankcase pan, further deteriorating the properties of the lubricant. This problem is especially relevant if the engine has to be turned for a long time to start.

In practice, this means that if gasoline or diesel fuel gets into the engine oil, and in large quantities, such a lubricant diluted with fuel is not able to provide reliable protection of the engine from wear after the engine reaches operating temperatures. The result can be not only a reduction in service life, but also engine breakdown, jamming, etc.

The problem of oil leakage in winter should also be highlighted. With the onset of cold weather, rubber gaskets, seals, and seals suffer. As a rule, rubber remains elastic and retains its properties down to -25 degrees Celsius. If the temperatures are lower, the seals “harden” and the engine oil begins to leak.

Also, any seals and gaskets suffer from temperature changes, since a cold internal combustion engine begins to heat up quickly after starting, and heating occurs unevenly. It is not surprising that cracks appear in rubber products, which then lead to leakage of oil and other technical fluids.

Suffice it to recall a simple illustrative example: after a long period of parking with the wheels turned out in the winter, on cars with power steering, you can observe a leak in the steering rack. The reason is the loss of elasticity of the cuffs and oil seals of the steering mechanism, which, after starting the engine and starting the power steering pump, simply do not hold the operating pressure. A similar situation occurs with oil seals in the engine.

“Cold” and “hot” start: nuances of proper engine operation

Problems with starting arise not only for cars that have seen the world: owners of cars that have covered only a few thousand kilometers can also encounter difficulties with “hot” or “cold” starting of the engine. What is the cause of technical malfunctions in the first and second cases?

Problems with starting arise not only for cars that have seen the world: owners of cars that have covered only a few thousand kilometers can also encounter difficulties with “hot” or “cold” starting of the engine. What is the cause of technical malfunctions in the first and second cases?