Forced engine VAZ 2106

The power unit of the VAZ 2106 is outdated, both morally and physically, because such cars have not been produced for a long time. But if desired, you can assemble a rather powerful unit from a six engine. The simplicity of the design and the almost complete absence of electronics in this case is even a big plus for making a forced VAZ 2106 engine with your own hands .

The result, in any case, depends on the efforts of the one who performs this tuning of the VAZ 2106. Here you should not save on time and effort. If you do everything carefully and carefully, you can increase the power of a car engine to 150 horsepower. To get such an engine, its volume should be no more than 1.6 liters, because a larger displacement will give a greater load and the engine will have difficulty gaining speed. As for the tools, we will need the entire set that will be useful during assembly and disassembly; in addition, it is worth preparing an electric drill, cutters and polishing paste. Next comes the modification of the main cylinder block. This is quite labor-intensive, but without this procedure, high-quality forcing cannot be achieved. First, we use a cutter to process the channels of the cylinder block through which fuel flows from the intake manifold. The channels should have a smooth transition and a larger cross-section. Be careful, in the end all channels should be identical in size. We carry out a similar operation with the release, although the cutter here needs a smaller diameter. If possible, it is best to install valves from Mitsubishi Pajero on the VAZ 2106 engine and then independently bring their rods to standard ones. In addition, we modify the valve plates, and then the valves are adjusted according to weight.

Now it's time to work on the camshaft. It is recommended to install a camshaft with a high valve lift. To more accurately adjust the valve timing, it is necessary to use a split gear. We thoroughly bore and polish the intake manifold. Of course, it will not be possible without modifying the carburetor, because after boosting more fuel and air will pass through it, so the element needs to be prepared. Remember that a motor modified in this way must breathe well; we install a zero-resistance air filter. In this case, you cannot do without this element. It is also recommended to completely replace the exhaust. The most preferable option: spider 4-2-1, pipe without resonator, direct-flow system. In the engine itself, you will need to replace the standard VAZ 2106 with racing rods of the same size. We buy forged pistons, each of which has a pair of T-rings. This is not the cheapest option, but conventional alloy wheels will not be enough for a high-speed engine. In addition to the above, we change the bearings and install faster ones that can withstand up to 10,000 rpm. We make the advance angle in the ignition distributor larger; such an operation can increase engine power by 10 horsepower. An equally important point is the entire engine. All parts installed on the motor should be selected from light but durable metal.

Source

Search

New on the site

Our friends

Increasing the displacement of the VAZ engine

As you know, one of the most important parameters in relation to internal combustion engines is the working volume. The engine’s power, throttle response, etc. depend on the volume of the engine.

It is more comfortable to operate a more powerful car, since the reserve of torque and power allows you to not “turn” the engine too much, since acceptable traction appears at lower speeds.

When it comes to increasing working volume, there are two main ways:

- change the diameter of the cylinders;

- increase the piston stroke by replacing the crankshaft;

These methods are actively practiced for tuning AvtoVAZ serial engines, which are found under the hoods of different models. More precisely, we are talking about the very first engine on the “penny” 2101 with a power of 60 hp. or the “eleventh” engine 21011, and the VAZ 2103-06 power unit with a power of 71-75 hp. Also, do not forget about the carburetor 80-horsepower 1.7 liter engine on the Niva model and other modifications of the above-mentioned internal combustion engines.

Let's get back to tuning. To perform modifications, you can use both serial parts and special elements for tuning. In the first case, the total cost of modifications will be noticeably cheaper, since serial parts are easier to find and cheaper to buy.

So, let's look at a specific example. If you have a VAZ 2101 engine, you can bore the cylinders to 79 mm, and then install pistons from the 21011 engine. The working volume will be 1294 cm3. To increase the piston stroke, you need to have a crankshaft from 2103 so that the stroke is 80 mm. Then you will need to purchase shortened connecting rods (by 7mm). As a result, the volume will be 1452 cm3.

It is quite obvious that if you bore the cylinders and at the same time increase the piston stroke, the end result will be a “penny” engine volume, which will be 1569 cm3. Note that similar operations are carried out with other motors on “classic” models.

Please note, regardless of the block, it is not recommended to bore cylinders larger than 3 mm, as the risks of severe thinning of the walls and reduced service life, as well as damage to the cooling system channels, increase significantly.

It is also important to consider that after installing a different crankshaft and increasing the piston stroke, the compression ratio increases, which will require the use of gasoline with a higher octane number. Additional adjustments to the compression ratio may also be necessary. The main thing is to choose the right shortened pistons, connecting rods, etc.

We also add that the simplest and cheapest method can be considered boring for repair pistons. However, even if the block is bored to the last repair size, the volume increases by no more than 30 “cubes”. In other words, you shouldn’t count on a significant increase in power in this case.

FORCING VAZ 2101-06 and M-412 ENGINES (part 3)

Cylinder head design and preparation

The engine cylinder head, together with the cylinder, forms a supra-piston cavity in which all thermal processes of the working cycle take place. The complexity of the cylinder head design is due to the many functions it performs, as well as a number of requirements placed on it: providing a combustion chamber shape that helps improve the combustion process to achieve maximum values of mean effective pressure;

sufficient rigidity and strength;

possibility of placing a camshaft;

smooth transitions and uniform wall thicknesses to increase reliability under mechanical and thermal loads;

ensuring minimal resistance in the intake and exhaust tracts;

ensuring uniform circulation of coolant with more intensive cooling of the hottest walls around the exhaust channel;

possibility of placing inlet and outlet pipes and other auxiliary equipment.

The cylinder head of the M-412 engine is made of aluminum alloy AL-4 with a hardness of at least HB 75. The good thermal conductivity of the aluminum alloy predetermines the possibility of engine boost associated with an increase in the thermal stress of the cylinder head and equipment placed on it. For athletes who have completed the sports category and reached the finish line of several competitions due to the reliability of a standard engine, it is time to think about increasing the dynamics of the car and increasing its maximum speed.

In table Figure 28 shows the calculated values of the compression ratio of the M-412 engine for different milling depths of the cylinder head. (Compression ratio of the standard M-412 engine = 8.8.)

Dependence of the compression ratio of the M-412 engine on the depth of milling of the block head

| Milling depth, mm | 0,5 | 0,8 | 1,0 | 1,2 | 1,4 | 1,6 | 1,8 | 2,0 |

| Compression ratio | 9,25 | 9,64 | 9,83 | 10,09 | 10,48 | 10,81 | 11,62 | 12,85 |

Dependence of the compression ratio of the VAZ-21011 engine on the depth of milling of the block head

| Milling depth, mm | 0,2 | 0,5 | 0,8 | 1,0 | 1,2 | 1,5 | 1,8 | 2,0 | 2,5 | 2,9 |

| Compression ratio | 9,0 | 9,2 | 9,4 | 9,5 | 9,8 | 9,9 | 10,2 | 10,4 | 11,0 | 11,5 |

The VAZ plant produced cylinder heads with three markings cast on the left side above the parting plane. Heads marked 2101-1003015 and 21011-1003015-10 (a unified head currently installed on engines of all models) have the same combustion chamber volume - 32 cm3. The cylinder head marked 21011-1003015 was installed until mid-1976 only on VAZ-21011 engines. This should be taken into account when assembling parts for engine assembly.

Bleeding the brakes of a VAZ 2107 yourself photo and video

Repair of the brake system KamAZ-5320

The brake system of the VAZ 2107, like any other, requires periodic maintenance and repair. And contrary to popular belief, no modification of individual elements or the entire system exempts you from fulfilling this responsibility. In this case, in addition to monitoring the condition of the brake pads and discs, it may be necessary to bleed the system to remove air bubbles from it.

The need to bleed the brake may arise in the following cases:

- Replacing the fluid in the system in accordance with the maintenance regulations;

- System repair;

- Fluid leak;

- Deterioration in brake performance after checking the condition of the brake discs and pads.

Brakes are usually pumped with the participation of two people: one (mechanic) works directly with the brake system, the second (assistant) is located inside the VAZ 2107 car. The tools for work you will need:

- Wrench 8/10 “tube” or socket;

- 8/10 open-end wrench or special, for brake pipes;

- Hose of appropriate diameter;

- Container for waste liquid.

In addition, if your car is equipped with 8-mm wrench fittings, it is strongly recommended to improve this drawback by replacing them with similar ones, but with a 10-wrench hexagon. Before starting work, add fluid to the brake reservoir to the maximum level.

The procedure for bleeding the brake system has a certain sequence - starting with the wheel furthest from the master cylinder:

- Right rear;

- Left rear;

- Right front;

- Left front.

The rear wheels of the VAZ 2107 are bled from the bottom of the car, so it is better to use the inspection hole. To bleed the front brakes, you need to remove the wheel. Otherwise, the bleeding procedure is the same for all wheels. After removing the protective rubber cap, you need to loosen the fitting using an 8/10 spanner. Particular care should be taken, as there is a risk of licking the edges, after which it will be difficult to unscrew the fitting.

Having loosened the fitting, put a hose on it, the other end of which is lowered into the container. After this, the assistant presses the brake pedal 3-5 times (until noticeable pressure appears in the system), after which he continues to hold it in the lower position. The mechanic uses an 8/10 open-end wrench to unscrew the fitting half a turn, as a result of which liquid with air bubbles comes out through the hose into the container, and the pedal “sinks” to the floor. Do not release the pedal until the liquid stops flowing out. The fitting is tightened and the procedure is repeated until when the fitting is released through the hose no more air bubbles come out.

Similar work is performed on the remaining wheels of the car. It is necessary to periodically monitor the fluid level in the tank and top up if necessary. If the volume is not replenished on time and the liquid in the tank runs out, air will enter the system and everything will have to start over.

As you can see, no particular difficulties are expected in bleeding the brakes of a VAZ 2107 car. All stages of the work can be done with your own hands at home.

It should be noted that recently the modification of the standard system has become widespread, consisting in the replacement of standard elements (calipers, discs, pads) with similar imported parts of higher quality and efficiency. However, the modification does not eliminate the need to periodically pump the system, so the described procedure will remain relevant.

How to increase engine power in a VAZ 2106: description, photo, video

The VAZ 2101, 2103-06 or Niva models, well known in the CIS, are usually called “classics”. The power units on these machines are carburetor and today are very outdated, however, given their prevalence, there are many who want to modify these internal combustion engines.

Taking into account the fact that the engines themselves are quite simple and do not have electronic control, such tuning of a VAZ classic engine can be done even by yourself in a garage. The main thing is that you have at hand all the necessary tools for disassembling the internal combustion engine, the necessary spare parts, as well as the availability of knowledge and skills.

The result may be boosting the engine to 110-120 horsepower. There are even examples with a power of about 150 hp. (depending on the quality and depth of modifications). In this article we will look at how to increase the engine power of a VAZ classic.

Carrying out tuning of the VAZ-2106 engine

Over the years, owners sometimes become so accustomed to their vehicle that they are unwilling, under any circumstances, to consider selling it and purchasing a new vehicle.

However, I also don’t really want to silently contemplate how my favorite “horse” gives in to powerful foreign cars, so the only option arises, which involves tuning the VAZ-2106 engine.

The power in the standard VAZ-2106 engine is not enough, so the owners of this vehicle often decide to tune it

Indeed, tuning a VAZ-2106 engine with your own hands is a process that requires certain knowledge, but this condition should not slow down the desire of the car owner, since on the Internet you can find a lot of useful recommendations, based on which even a novice car enthusiast can successfully tune a VAZ carburetor engine. 2106.

Boring an internal combustion engine

Let's consider the first option, forcing. To do this, you need to bore the cylinders.

The standard version of the eight-valve six engine has a volume of 1,600 cubic centimeters, four hundred per cylinder. When boring, you will have to remove a certain layer of metal on the cylinder walls. This can only be done on special machines.

You can remove as much metal as the walls will allow. But do not forget to take into account the peculiarity - in the factory design the walls were designed for a certain mileage, and boring will significantly reduce this figure.

The essence of the forcing method is boring on a special machine and installing a new, enlarged piston. This modification option will make it possible to increase the power by more than a dozen “horses”.

Extreme options: superchargers and turbochargers

However, there is another method of boosting, which is perfectly suitable for an “ancient” engine with a relatively low compression ratio. We are, of course, talking about supercharging, and there are many options - you can apply the classic method of American hot rodding by installing a drive supercharger (the cheapest source is dismantling right-hand drive cars, keywords - SC-12, SC-14), you can choose with a large amount of work turbocharger.

However, at the same time, this method of boosting is also the most difficult to set up: a lean mixture and incorrectly selected ignition timing can “kill” the engine very quickly. At high boost pressures, it will be necessary not only to lower the geometric compression ratio, but also to completely rebuild the engine, replacing the pistons, connecting rods and crankshaft with stronger ones than the standard ones, so such a project will also become the most expensive.

In conclusion, we note that such simple “tuning” options as “zero” filters and direct-flow mufflers are useless without the modifications described in this article.

Also read our material in which we tell you what cramps are.

Description of common actions

Increasing power is a whole set of measures aimed at increasing engine power in VAZ 2106 and 21063 without causing harm to the unit. It must be emphasized that if the complex for “boosting” the VAZ 2106 engine is completed completely, then modernization will inevitably be needed. Let’s look at the measures for ordinary technical tuning.

- Installing a zero resistance air filter. This operation does not increase motor power. Installing this part simplifies the operation of the unit, freeing up some of the energy that was spent on overcoming the resistance of the standard filter.

- The same effect is produced by replacing a conventional muffler with a direct-flow muffler. The only difference is that gas flow resistance is eliminated at the exhaust. Together with the previous operation, installing direct flow gives a tangible increase in motor power. The drawback is the excessive noise of the exhaust system.

- Installing an electric ignition system will ensure smooth operation of the unit, and poor sparking will contribute to higher quality and complete combustion of fuel in the cylinders.

- Polishing the internal surfaces of the intake manifold will also reduce the resistance to the mixture of fuel and air, the unit will begin to “breathe deeply.”

- Replacing the carburetor has its own aspects. If you have a standard DAAZ 2105 or DAAZ 2107 carburetor, then it is better to change it to a Solex from a VAZ 2108 with an engine capacity of 1.5 liters. On older “sixes” there are Weber carburetors with forced opening of the secondary chamber. They are completely repairable and replacing them does not always make sense, because these carburetors are structurally capable of working with an engine with over-powered engines.

Obviously, to get the desired effect from the configurations, your car’s engine must be in good technical condition. By completing all the items on this list, you are guaranteed to experience an increase in engine power.

Specifications

The VAZ 2106 engine has standard technical characteristics that are inextricably linked with all representatives of the “classic” line. If you look from a design point of view, then all VAZ 2101-2107 internal combustion engines on a carburetor basis are similar to each other. Before proceeding directly to the modification, let’s consider what technical characteristics the power unit labeled 2106 has:

| Names | Characteristic |

| brand, model | VAZ 2106 |

| Type | Gasoline with the possibility of installing LPG |

| Injection system | Carburetor |

| Power | 81 hp |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel consumption | 10.5 l/100 km |

| Cylinder diameter | 79 mm |

| Cooling system | Liquid, with forced fan |

What's the result?

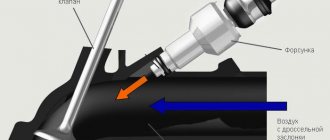

As you can see, engine tuning, including classics, in terms of the scope of work largely affects the BC and cylinder head. However, we should not forget that the carburetor will also need tuning. It is not surprising that a forced engine requires more gasoline and air, that is, the carburetor also needs to be upgraded and tuned.

As for the parts for the internal combustion engine, everything will depend on the specific tasks. If the budget allows, it is best to install special connecting rods, replace cast pistons with forged ones, replacing bearings, etc. is also recommended.

Finally, I would like to add that if all the work is done correctly, then even a significant increase in engine volume does not greatly affect fuel consumption. Moreover, consumption may drop. The fact is that better traction, elasticity and throttle response of the engine after modifications allow you to spin the power unit less in lower gears for acceleration and maintaining the usual driving pace.

The main thing is to correctly configure the carburetor and ignition system, taking into account the changed working volume of the internal combustion engine. As a result, a forced engine increases the operating comfort of the vehicle, and the procedure itself is often cheaper than swapping an engine or, moreover, installing a turbocharger on a carburetor with minimal modifications to an existing power unit.

Possibility of installing a turbocharger on an engine with a carburetor. The main advantages and disadvantages of turbocharging on a carburetor car.

Refinement and modernization of the carburetor. The main disadvantages of the carburetor injection system and how to eliminate them, settings. Intake manifold tuning.

Boosting the engine. Pros and cons of modifying an engine without a turbine. The main methods of boosting: tuning the cylinder head, crankshaft, compression ratio, intake and exhaust.

Selecting a mechanical supercharger or turbocharger. Design, main advantages and disadvantages of solutions, installation on an atmospheric tuning engine.

Features of installing gas equipment on a turbocharged engine. What gas equipment is best installed on engines with a turbine. Tips and tricks.

Tuning the fuel system of atmospheric and turbo engines. Performance and energy consumption of the fuel pump, choice of fuel injectors, pressure regulators.

We boost and increase the power of the VAZ engine 2106

Many adherents of traditional Lada models are trying in every possible way to improve the properties of their beloved cars. One of the main questions that arises is how to increase engine power, how to do this on the VAZ 2106 and on the VAZ 21063, the power of which is lower than the “pure six”?

Related modifications: flywheel and fuel supply systems

A side effect of installing a crankshaft with an increased crank radius and larger diameter pistons is an increase in the moments of inertia of the moving parts of the engine. It becomes noticeably “dumber” as the speed increases, despite the fact that the “classic” engine is not initially sporty.

Since the inertia of the flywheel makes a huge contribution to the total moment of inertia (up to 80-90%) (its diameter is maximum, and the moment of inertia of rotation is proportional to the square of the radius), the most effective way to facilitate engine spin-up is to reduce the flywheel and clutch. In the now classic books of E.G. Singurindi, dedicated to the preparation of production cars for competitions, this issue was considered up to the presentation of specific drawings.

Although when the flywheel is lightened, its mechanical strength suffers, if the metal is cut correctly, this has no practical effect on reliability. After modification, dynamic balancing of the flywheel and crankshaft assembly is required.

Tuning flywheels make it possible to achieve an even greater reduction in the moment of inertia in comparison with machined cast iron ones. However, excessive relief is also a “thing in itself”, since it has a negative effect on the “lower parts” (it is more difficult to start, to drive hard).

The “classic” power system, be it a carburetor or fuel injection on the latest releases, is not very suitable for a tuned engine. Moreover, injection is the most promising: it’s not only about the ability to fine-tune the fuel supply and ignition, which in itself gives the maximum return from the engine, but also about a more advantageous configuration of the intake tract, especially with tuning receivers.

For the carburetor to operate, it is necessary to create a vacuum in its diffuser, that is, even in the most “extreme” tuning options, when an individual carburetor is installed on each cylinder, there is still parasitic resistance in the intake tract, which reduces the filling of the cylinders.

In injection systems, gasoline is supplied to the manifold under pressure, and it becomes possible to reduce resistance as much as possible (bored channels of the cylinder head and manifold, a throttle body of increased diameter, a receiver tuned for a specific engine). Standard ECUs allow easy flashing; programs for editing injection system calibrations and ready-made tuning firmware are also available.

Taking into account the same maximum unification of the Tolyatti conveyor, installing fuel injection on an initially carburetor engine is not a problem: the standard front cover is replaced with a new one, with a boss for the crankshaft position sensor, the old KV pulley is replaced with a new one, with a cut reference ring. The cylinder head is also the easiest to install from the “injection” model (the shapes of the intake channels are different, there are now no extra channels for supplying coolant to the carburetor manifold). Taking into account the fact that we are talking about complex tuning, it is best to immediately take a cylinder head from a Niva with fuel injection.

Power increase

Increasing the power of the VAZ 2106 engine is carried out in several stages. Of course, you can catch up on power characteristics superficially, but if we talk about full-fledged tuning, then it is worth understanding that the power unit is subject to modification entirely. This process takes more than one hour or day, so you should be patient. Why is it worth increasing the power of the engine - of course, with boring.

Boring

The VAZ 2106 power unit is bored on a special boring stand. But first, it’s worth deciding on the spare parts that are installed in the cylinder block. The best recommendation is the 82mm piston group from API.

At the same time, the pistons are 160 grams lighter than standard ones, which reduces the weight of the power unit. So, for these pistons you will need sets of oil scraper rings, also produced by this company.

As for the crankshaft, it is worth understanding that in order to achieve maximum power effect, it should also be replaced. Of course, the part itself costs a lot, so most car enthusiasts who perform tuning on their own leave the old crankshaft.

But, nevertheless, if the motorist decides to go all the way, then you can install a crankshaft, which is offered by the Polish manufacturer DDT. It is worth understanding that it must first be sharpened before the first repair, since the main journals will not fit into the yokes.

Another modification is the replacement of the camshaft and valves. The inlet and outlet valves can be purchased from API, but the seats for them will have to be machined using standard ones. The camshaft can be installed new, natively produced, or a lightweight one from DDT.

Ignition installation

The next stage of improvement is the installation of contactless ignition. Today, it can be easily found in any automobile market at an affordable price. Thus, you will have to replace not only the lock, but also the spark plugs, as well as the ignition coil and high-voltage wires. In this case, the best and most budget-friendly cables are those from Tesla.

Coolant circulation system

The cooling system should also be replaced. At the same time, it changes completely. There are several companies that produce tuning kits for cooling systems for classic VAZ cars. These include such well-known manufacturers as Mastersport, Brembo, AWD, Intenzo and others.

The cooling system tuning kit consists of:

- High power water pump (in some cases can be found with a forced electric activation function).

- Thermostat.

- Set of silicone cooling system pipes.

- Aluminum radiator with increased area.

- Electric fan.

- Coolant system sensor with wiring.

If you install such a kit, the engine will be better cooled even at high speeds, which will protect the engine from overheating.

Carburetor

As a rule, to increase power, an additional carburetor is installed on the VAZ 2106. This is done in order to increase the amount of fuel in the cylinders, but it does not do without additional air injection.

Turbine

Since an additional carburetor was installed on the engine, it will be necessary to restore the balance of air and fuel. This is achieved by installing turbocharging. Of course, the easiest way to install a turbine is from a MTZ tractor, but a lot will have to be changed. Therefore, there are already monoturbines on sale that are designed specifically for installation on classic cars. The average cost of such a ready-made kit is about $500.

Turbo kit

A new model of a mechanical drive supercharger has been launched into the series. With its help, you can increase power by a third, extend the life of the power plant, and reduce gasoline consumption. The delivery element comes with all the spare parts necessary for installation.

Here are all the basic works with which you can perform tuning. Make the most suitable choice for yourself, or use all the recommendations at once. Just decide in advance what you can do yourself and what work you will involve specialists in.

Simple ways to increase the power of the VAZ-2106

If you are only counting on a slight increase in power and want to avoid large financial costs, we can recommend the following ways to achieve your goal:

In addition, you can try to increase the compression to 15 atmospheres by properly cleaning the valves.

All of the above methods make it possible to achieve a rapid increase in power with minimal financial costs. If expenses are not of particular importance, you can go another way.

Crankshaft selection

We won’t touch the nameplate power, since the increase will be symbolic, but it will affect the dynamics. All that remains is to choose a human crankshaft, and this is not an easy task. If you buy a used one, there is a chance that you will run into a shaft with hidden defects - cracks, bending or too much wear. And if the shaft has been restored, then you can end up with poor-quality surfacing of the journals. If you are not sure of the quality of such a crankshaft, it is better to look for a new one. A good quality crankshaft will not shine like chrome.

This is how low-quality shafts made of raw, unhardened steel are prepared for sale. The necks of a good cemented shaft will be matte with a characteristic tint, and it should be packed in oil paper and lubricated with grease. And, of course, with the marking 2103-1005020.

Source