Engine mount with hydraulic mounts

The power unit is attached to the body on elastic supports

.

They absorb vibrations so that they are not transmitted to the body and do not become sources of unpleasant noise in the cabin. In addition, the supports protect the engine from sudden shocks when the car moves on uneven roads. The most common and cheapest option is rubber-metal supports. The name speaks for itself: two plates and a rubber spacer between them. Sometimes, for greater rigidity, springs are installed inside the cushions, and buffers are installed to soften impacts. Such rather simple elements do not effectively dampen vibrations over the entire operating range of the engine. Hydraulic mounts

react more flexibly to changes in speed . At minimum speeds, the cushion must be soft to effectively dampen vibrations. As the speed increases when the car moves, the amplitude of vibrations increases - in this case it is necessary for the engine mount to become stiffer. The operating principle of the hydraulic support resembles conventional shock absorbers. The vibrations are dampened by the working fluid flowing from one chamber to another. They are filled with propylene glycol (popularly known as antifreeze). With small movements of the power unit (engine idling), the vibrations are smoothed out by a movable membrane - a soft support dampens engine vibrations transmitted to the body. The crankshaft revolutions and speed increase, and along with them the amplitude of vibrations also increases. The membrane can no longer cope with the increased load, and the throttle device comes into operation. Under pressure, liquid flows through its channels from the upper chamber to the lower one - the rigidity and energy intensity of the support increases.

The operating principle of a modern hydraulic mount with mechanical control:

a) at idle, soft support:

1 – lower (expansion) chamber; 2 – throttling channel; 3 – upper (working) chamber; 4 – movable membrane; 5 – hydraulic support body; 6 – damping fluid channel.

b) in motion, rigid support:

in motion, support is rigid

Hydraulic mounts for each engine model are configured separately. The performance characteristic is set by changing the diameter and length of the channel of the throttling device. There are options for “pillows” with electronic control; they are more complex in design, but respond faster to changes in modes. For example, let's take supports with an electric vacuum drive. The engine control unit receives information from the crankshaft position sensor, takes into account the vehicle speed and supplies power to the solenoid valve of the pipeline running from the intake manifold to the support. The resulting vacuum pulls out the damper membrane and opens a channel through which liquid flows from the upper chamber to the lower one - in this case the cushion is soft. The engine speed has risen, the car has moved off - the electronics close the vacuum channel and connect it to the atmosphere. The vacuum in the support drops, under the influence of atmospheric pressure the membrane rises up and closes the hole between the upper and lower chambers. The only path left for the liquid is through the spiral channels of the throttling device. At the same time, the resistance increases, and accordingly the rigidity of the cushion increases, which allows it to effectively withstand vibrations of greater amplitude - for example, when driving on an uneven road.

Operating principle of an electronically controlled hydraulic mount:

a) at idle, soft support:

1 – damper membrane; 2 – lower (expansion) chamber; 3 – throttling channel; 4 – upper (working) chamber; 5 – hydraulic support body; 6– spiral channel of the throttle device; 7 – fitting for supplying vacuum.

b) in motion, rigid support:

in motion, support is rigid

There is a similar design with electronic control, but without a vacuum line. At minimum speeds, the channel connecting the air cushion cavity with the atmosphere is open. When the power unit oscillates, the working fluid flows freely from the upper chamber into the cavity above the air channel and back. In this case, the membrane easily bends and displaces excess air out. When moving, the solenoid valve closes the channel connecting the air cavity with the atmosphere. The rubber membrane of the air chamber stops bending, and liquid begins to seep from the upper to the lower cavity through the throttling device.

Source

The design and principle of operation of various types of engine mounts

Regardless of the type of support and its design features, the operating principle is the same: shocks (oscillations) are dampened and the power unit is held in place.

However, parts of different categories have their own characteristics:

- Rubber-metal mounts have a simple design: two metal plates connected to each other, between which a cushion made of the rubber stiffness required for a particular car and engine is placed. A more advanced design of these supports additionally contains buffers designed to soften impacts, and a spring that increases the rigidity of the part. Along with rubber elements, many manufacturers also offer a polyurethane analogue, which is more wear-resistant. Supports in this category can be permanent or collapsible. Rubber provides the vibrating engine with relative freedom of movement, and thus dampens vibrations quite well.

Engine mounts based on a polyurethane component are most often used on sports cars, where the cars accelerate to high speeds and require a structure of increased rigidity.

- Hydraulic supports are considered a more progressive mounting option. The operating principle of the hydraulic support resembles conventional shock absorbers. The vibrations are dampened by the working fluid flowing from one chamber to another. The fluid is more dynamic, it responds to engine vibrations faster. The active hydraulic mount also contains a chamber with hydraulic fluid. The difference is that the bottom of this chamber is a membrane that can move based on a signal from the engine control unit, adjusting the characteristics of the unit to the operating mode of the motor.

Dynamic engine mount

There are the following types of hydraulic support control:

- Mechanical - are developed separately for each make and model of vehicle, since the part will be based on either damping at a speed of strong vibrations or good noise insulation at idle;

- Electronic is a more advanced design. Allows you to control the rigidity of the part during movement via electronics. Thus, by increasing or decreasing the rigidity of the support, comfort at speed or at idle will be equally high.

- Dynamic (based on electromagnetic influence) - the operating principle of such units is to use magnetic fluid, i.e. containing magnetizable metal particles. As a result of such an effect, such a liquid changes the viscosity coefficient and, accordingly, the rigidity of the entire structure.

Today, hydraulic supports are the most popular, however, rubber-metal ones are still used. Regardless of what type of airbags are installed in the car, it is not recommended to quickly start moving from a standstill or drive through deep bumps on the roads at high speeds. This can quickly destroy them.

Once a week we send a digest with the most interesting news and useful articles about cars.

Field name*

Email*

( 2 ratings, average: 5.00 out of 5) Loading…

Engine hydraulic mount: how is it designed, how to diagnose it and can it be repaired?

It is a rare modern engine that does not rest on hydraulic cushions under the hood in order to minimally disturb the driver and passengers with its vibrations. What are the benefits of such supports, when did they appear in the automotive industry, how will they evolve and... when will they disappear?

The fact that the oscillating parts of the mechanism need to be vibration-isolated from the stationary ones was clear to the ancient Romans, who already in the first century BC figured out how to hang the “body” of the cart from a chassis with wheels on belts made of thick shock-absorbing leather. In the automotive industry, rubber dampers for installing an engine on a chassis were introduced by Walter Chrysler in the late 1920s, initially for Plymouth models. Vibration isolation was a good competitive advantage, so technology even came up with the marketing name Floating power. In Europe, the pioneer in the introduction of rubber dampers was Citroen, which bought the rights to the technology from Chrysler to implement it in the Traction Avant design.

For many decades, the rubber engine mount remained one of the most conservative parts of any car, and its evolutions were extremely subtle. And these days there are still quite a few cars driving on the roads (UAZs, Volgas, Moskvichs), whose engine support cushions are the simplest monolithic rubber block or disk...

In principle, to prevent engine vibrations from destroying the steel frame of the body and causing chronic seasickness in the driver, these primitive rubber “chocks” are quite sufficient. However, the growing requirements for comfort inside the car gave rise to some of their development - engineers played with the shape of dampers, made sandwiches from rubber of different elasticity, and included steel springs in the structure. This bore fruit - the supports began to work in a wider range of vibrations and loads: at loads of different strength and direction, different elements of the rubber modules were included in the work, providing, when necessary, increased elasticity or, conversely, increased rigidity:

However, in the mid-80s of the twentieth century, European automakers began to introduce rubber-hydraulic engine mounts into their models. Thus, one of the first cars to use hydraulic support was the Mercedes-Benz W124. Unlike purely rubber ones, they damped vibrations in a wider range of frequencies and amplitudes, acting on the principle of a shock absorber - damping vibrations due to the resistance of the liquid forced through calibrated throttling holes.

Engine mount

The main purpose of the engine mount is to compensate for vibration and oscillatory movements transmitted by the operating mechanism to the car body. Without it, a comfortable trip is impossible; the process will be reminiscent of flying in an old “corn truck”.

It should be noted that the engine mount is a special gasket that separates the engine from the body elements. Old Soviet passenger cars were equipped with such a product, made from a single piece of rubber, complemented by fasteners on opposite sides. In addition, manufacturers began producing cars with front-wheel drive only in 1985.

Today, the engine mount is most often a rubber-metal gasket. There are also hydraulic products, but due to their significant cost, they are used only for expensive machines.

Self-diagnosis of suspension

If it is impossible or unwilling to visit a car service center, it is possible to determine the malfunction yourself. An independent check of the condition of the engine mounts is carried out using the following devices:

It is recommended to carry out subsequent manipulations in the following order:

Using a tackle, position yourself under the car and conduct a visual inspection. This inspection method makes it easy to examine engine mounts for signs of malfunction acquired by the engine mounts during operation.

Even an inexperienced car enthusiast can see symptoms of support delamination, cracks and tears in the product, and also independently determine that the gasket has failed as a result of excessive hardening of the rubber. In such cases, it is strongly recommended to urgently replace the engine mount.

To detect possible play at the junction of the engine with the front beam of the car or the body, a visual inspection is not enough. Here you will need to use a pry bar. A similar lever is used to deflect the engine in different directions. The absence of play indicates the serviceability of the supports; repair of the cushions is not required.

You can eliminate this symptom as follows:

In this way they get rid of the backlash.

Replacing engine mounts yourself

In order to keep your car in perfect order, you need to regularly check its technical condition. Since the failure of one part can destroy the entire expensive unit, it is necessary to promptly replace the faulty mechanism.

We offer you detailed instructions on how to change unsuitable engine mounts with your own hands:

Separately, we note that all the proposed manipulations are recommended to be performed in pairs with an assistant. Outside participation will be required to guide the motor lever while installing the support in the required location.

Inspecting and replacing the top cushion is a fairly simple process. The accessibility of manipulations is ensured by the ability to do without a pit. In addition, it is not necessary to lift the car.

What signs indicate a torn engine mount?

The engine support (engine mount) is designed to reduce vibration loads and oscillatory movements of the internal combustion engine in the engine compartment, as well as to minimize the transfer of such loads to the vehicle body. In other words, the engine is attached to the load-bearing elements of the car body not directly, but with the help of special supports, which are also called cushions.

Next, we will talk about what signs indicate that the power unit mount is torn, as well as how to diagnose and check engine mounts.

Signs and causes of engine mounting problems

The main symptoms of faulty engine mountings are as follows:

- strong vibration on the steering wheel when the engine is running;

- knocking in the gearbox installation area when driving over uneven surfaces;

- jerks in the transmission while driving and changing gears at high speed;

- knocking under the hood when overcoming a rough road, as well as at idle and when the load changes while the engine is running;

When these signs appear, it is worth diagnosing the pillows. You can do this yourself.

Engine mount: what it affects and how it works

On various domestic and foreign cars until the 80s, the engine mount was actually a thick rubber that was screwed to the engine and body. This solution was widely used on cars, which at that time were overwhelmingly rear-wheel drive. At the same time, simple supports coped well with their tasks.

However, later the bodies became lighter, the thickness of the steel decreased, the requirements for passive safety changed, etc. As a result, pillows evolved into more complex products made of metal and rubber. Elite car models now have hydraulic engine mounts that can provide maximum comfort compared to other analogues.

As for the internal combustion engine, it is customary to highlight the right airbag, as well as the front and rear. The right engine mount is attached to the front right side member. This support is located on top. The front engine mount is often attached to the front beam, located below. The rear cushion is also located at the bottom and can be attached to the underbody or to the subframe. By the way, on many models the rear support is structurally absent.

If we talk about the design, rubber-metal engine mounts may differ in shape and materials of manufacture, but often they are based on a metal cylinder into which a silent block is pressed.

The main task is to securely, but not rigidly, fix the internal combustion engine, while the cushion simultaneously absorbs vibrations and dampens the resulting vibrations. As a result, vehicle controllability improves, the engine itself is less vibration-loaded, attachments suffer less from vibrations, vibrations are not strongly transmitted to the car body, etc.

Torn engine mount: signs

Like any other part, the power plant support also has a limited service life and eventually fails. On average, airbags on modern cars are designed to last at least 100-120 thousand km, although in practice these elements may need to be replaced both earlier and much later than this period.

Usually the cause of problems is the rubber insert, which simply cracks and breaks under load. Less often, cracks appear in the metal part of the support, the installation sites of fasteners are broken, etc.

One way or another, the following symptoms usually indicate a malfunction of the engine mounts:

To check the engine mounts, it is not necessary to immediately go to a service station and drive the car to a stand. Usually, a fault can be identified and localized on your own, even if you do not have much experience in car repair and maintenance.

The simplest method of initial diagnosis is to rock the engine with your hands in the engine compartment, after which you can localize a torn or cracked support by knocking.

To carry out a more detailed check, you first need to find out in advance where exactly the supports are located on a particular model. Then the elements available for review will need to be pre-inspected. Cracks, breaks and other damage are usually visible and easily visible.

For a full visual assessment of the lower airbags, you need to be prepared for the fact that the car will need to be parked in a garage with an inspection hole, driven onto an overpass, or using a lift.

If a superficial diagnosis shows nothing, then the assistant should be used again. One person uses a pry bar to move the support, while the other watches for tears in the rubber insert at the very moment the support moves. It happens that some cracks are not immediately visible without rocking.

How to check the condition of pillows

Before checking the supports, you need to understand the design features of the vehicle's power plant. There can be two or four pillows. They can be mechanical or hydraulic.

ATTENTION! On expensive cars, hydraulic engine mounts have adjustable stiffness and airbag performance controllers, which, if a unit breaks down, report information to the on-board computer.

Having dealt with the technical features, open the hood and inspect the engine mounts. If cracks are detected on the pillows, they are replaced . It is not always possible to see the presence of a problem from the engine compartment. In this case, use a more complex but informative method:

- the front part of the car is raised and a support plane for the engine is constructed;

- gradually lowering the car, relieve tension from the cushions until the motor stops resting on them;

- After this, use a mount to check for any play in the support (there should not be any) and visually inspect the cushions from all possible sides.

It will be useful: Which H4 low beam bulbs are better?

The absence of gaps in the engine mounts and intact surfaces of the support units indicate the absence of obvious defects. The cause may be hidden or related to other parts of the car. But in 90% of cases, a faulty pillow will have an external sign of failure . When the internal parts of the unit (spokes, membranes) fail, they destroy the rubber surfaces of the supports, forming external defects.

There is also a more dangerous way to determine a malfunction, which does not provide an objective assessment. It is performed by simultaneously pressing two pedals on a car equipped with an automatic transmission (with the gear engaged). Depending on whether the engine remains in its place or jumps sharply, a decision is made about the possible presence of a defect. The danger of this technique is obvious and its use to identify a defect is not recommended.

Having weighed their capabilities, everyone decides whether to diagnose the engine mounts themselves or seek help from specialists.

The presence of extraneous noise when the engine is operating in certain modes requires the identification of the true cause of the malfunction. Operating a vehicle with knocking and excessive vibration can lead to serious damage, the elimination of which will exceed the cost of the supports several times. Fixing a fault at an early stage will cost less and will not affect other components of the car.

Tips and tricks

It is important to understand that the airbags experience the heaviest loads when the car suddenly starts from a standstill, as well as during heavy braking. The service life of the supports is also reduced by driving through potholes when the body and engine sway, especially at high speed.

As for diagnostics and repairs, it is necessary to check and change engine mounts in a timely manner, since increased vibrations not only affect comfort, but also have an extremely negative impact on the engine itself, the body and the equipment. In other words, even if one airbag is torn, it is strongly not recommended to further operate the car with such a malfunction.

Why might the engine vibrate at idle? Causes of malfunction, diagnostics. Tips and recommendations for reducing engine vibration levels.

Car engine mounts: purpose. Types of power unit supports and design differences. Signs of malfunctions of engine support cushions and inspection.

The engine twitches at idle: why does this happen? Engine jerking in idle mode, diagnostics of possible malfunctions, recommendations.

Replacing engine mounts: what are the signs that indicate that the cushions need to be changed? Types of support cushions, how to change engine mounts with your own hands.

Causes of vibration and unstable operation of a diesel engine in idle mode. Possible causes and fault diagnosis.

Ways to check the engine when choosing a used car: diagnostics by appearance, sound of operation, condition of spark plugs, color of exhaust gases, etc.

Features of operation

If excessive engine vibration occurs, check the integrity of the engine mount.

The engine mount is a part subject to wear, as it always works when the engine is running. The greatest challenge for the supports is starting the engine, moving away, and stopping the car. At such moments, the load on the supports is greatest. Wear or failure of this part increases the load on the engine and increases the likelihood of engine failure.

Cracks and tears in the support cushion are visible if a routine inspection is specifically carried out for this purpose, but symptoms such as increased vibration with feedback to the steering wheel when the engine is running or shifting gears with jerks, and if the cushion near the gearbox wears out, it can knock out the speed. Here the obvious facts are clear, you need to buy a set of new supports in order and start replacing.

Having a set of keys at hand, the jack and the inspection hole can, in principle, be changed independently without special skills, although there are cases where the procedure for replacing engine mounts is a very amusing matter.

It is not difficult to monitor the condition of rubber-metal supports: you just need to check the integrity of the rubber gasket and regularly remove dirt and oil from it, and tighten the fastening bolts.

If your vehicle is equipped with hydraulic mounts, you must open the hood and start the engine to test them. Next, you need to drive a couple of centimeters forward and backward. If there is something wrong with the supports, the engine will move out of place when starting and return to place when stopping, which will be accompanied by clearly audible sounds.

Regardless of which support cushions support the engine on your car, the advice is the same for everyone. You should not crash sharply, thereby putting maximum load on the supports, cross potholes and humps at low speeds, so that engine vibrations are minimal, and therefore the vibrations that need to be absorbed by the engine mounts will not be significant.

Subscribe

to our channel in

Index.Zen

Even more useful tips in a convenient format

Source

We independently change the front right hydraulic engine mount on a Ford Focus 2 car

Hello dear readers of my short note.

I would like to share with you and tell you about the front right engine support (mount) on the Ford Focus 2, 2.0 liter engine. Draw small conclusions for yourself and not repeat mistakes. Be more scrupulous in studying the question posed regarding the repair or replacement of a particular part on a car. All's well when all's well ends. These are not my words, but the people's.

Without any embarrassment, read the forums about this car. There are very competent specialists and car owners on the forums. In my case, I always read technical literature, what car repair luminaries write there. I have a Ford Focus 2 and I, like many car owners of these cars, go to the forum known among Ford owners as the Ford Club.

Do you think I listened to the guys who have been using Ford Focus 2 cars for a long time. What are you talking about, we ourselves know everything. Yes, I won’t lie, it’s just that the “toad of stinginess” was choking me. Why change two supports on the car at once.

After all, the front right support (hydraulic support) is working and I have not observed any fluid leaks. I think my old support will last for several thousand kilometers. Yeah, that was not the case. Having replaced the rear support, I left the garage. There was no vibration. Gear shifting became softer.

I drove a hundred kilometers and immediately noticed a vibration on the car. I opened the hood of my iron friend and began to look at the right mount of the car. Yes, I think my original front right engine mount was leaking. This can be seen in the photo below.

Oil leaks are visible from the hydraulic mount. When I pressed the elastic itself, it turned out to be torn. Well, what about the “toad” I thought. Don’t you feel sorry for your time? I would buy two supports at once and install them at once. Now the “chronic miser’s toad” is coming out sideways. Again, drive the car into the garage into a pit and carry out the procedures previously completed with the lower support.

Let's look at what 2 engine mounts the Ford Focus has. In this model, three damper engine mounts are used for stable engine operation without vibration.

In the lower engine mount (mount), as I wrote earlier, these rubber dampers are torn, as in the photo below (1) and (2). Here, as they say, you need to take into account the nature of the ride. Calm driving and aggressive driving. During aggressive (sporty) driving, the engine mounts come out faster.

You want the supports to last longer. The ride should be moderate. But my personal opinion is that everything depends on the quality of these parts. For example, I have had the supports for more than 166,000 km. I think that this is great for this car. according to the service life of these engine mounts.

The front right hydraulic engine mount (mount) of the Ford Focus 2 engine, as sources write, is a modern mechanism (device) that very effectively copes with various engine vibrations.

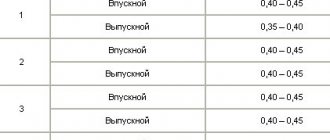

Let's look at how a mechanical hydraulic mount works on an engine:

The principle of operation of the hydraulic support is similar to the operation of conventional shock absorbers. Here, vibrations are damped by the liquid in the shock absorbers by flowing from one cavity to another. The cavities of the hydraulic support are filled with a liquid popularly called antifreeze, but from the technical side this liquid is called propylene glycol. At lower engine speeds, the cushion should be soft and all the liquid should be practically concentrated in the upper cavity of the support (1). All vibrations at idle when the engine is running are smoothed out by a movable membrane as shown in the photo below.

As the engine speed increases, the vibrations, as you understand, increase proportionally and the support for damping vibrations must be solid. The liquid from the upper cavity under the pressure of the engine flows through the cavities into the lower cavity (2). I think we have figured out the operation of the hydraulic support and its operating principle is clear.

We are starting to replace our already worn-out right hydraulic mount on the Ford Focus 2 engine. Front right mounts for 1.8-2.0 liter engines. identical. Original Finis Ford 1862540. So the price for the original varies from 7463 to 8395 rubles. I took the prices from the online store website.

I bought myself a support for 2686 rubles, not the original one. You know, I don’t get such a big salary to pay 8,000 rubles for a support, it seems to me that it’s just too much. The prices are just astronomical. What kind of support did I buy and how to install it, watch a short video

What can happen if faulty supports are not replaced?

What happens if you do not pay attention to possible malfunctions of the engine mounts? At first, when vibration and knocking are unnoticeable, nothing critical will happen. But with the destruction of the engine mounts, the power unit will begin to transmit vibrations to chassis parts and they will begin to fail much faster; this could have happened under the same operating conditions. Also, the engine can hit elements of the engine compartment and lead to damage to various pipes, hoses, wires and other parts. And the condition of the engine itself may suffer due to constant impacts that are not dampened by anything.

How to extend the life of engine mounts

Engine mounts work hardest when the engine vibrates the most. This is primarily starting from a stop, accelerating and braking. Accordingly, a driving mode with a soft start and less sudden acceleration and stopping prolongs the life of the engine mounts.

Of course, these parts last longer on good roads, but this factor is very difficult for us to influence. As well as for launches in sub-zero temperatures, when the rubber hardens and tolerates vibrations less well. But in general, we can say that a careful and quiet ride can extend the life of many parts, including engine mounts.

We begin to remove and install the front hydraulic mount on the Ford Focus 2 2.0 liter engine.

After some time, I dismantled the old front support of a Ford Focus 2 2.0 liter engine. Watch a short video:

As we see, there is nothing complicated in replacing the front right engine mount on a Ford Focus 2. You can do all this yourself and with your own hands. This concludes my short note about the front right engine mount of the Ford Focus 2. Dear reader, if you have any questions about me or to this note. A small request to leave your comments.

Source

"Ford"

Vibrations on the car body at idle and while driving indicate that the engine mounts are out of order or damaged. Signs of malfunction (Ford Focus 2 as well) may be different. Ford Focus cars use two supports. The right one is hydraulic, the left one is the gearbox support. In case of damage, it is recommended to replace both elements.

Naturally, you can replace only the damaged one and the vibrations will go away, but the new support will be subjected to significantly greater loads and will fail much earlier than its intended life. As a replacement, it is worth purchasing original parts. Inexpensive analogues last less than 20 thousand kilometers.